Latest news

-

What is Die Casting? Die Casting Overview

January 23, 2024 -

Guide for Vacuum Casting Process

January 16, 2024 -

Comprehensive Guide about Rapid Prototyping and Low Volum Manufacturing

January 09, 2024 -

Congratulations! Noble Passed The Certification Of "Shenzhen Specialized, Special And New Small And Medium Enterprises"

October 11, 2023

What is Die Casting? Die Casting Overview

Die Casting is a quick, precise, and repeatable metal production technique for items big and small, from engine blocks to door handles. Die-cast components include superior surface quality, and various non-ferrous metals can be used. Die casting is usually utilized for high-volume production because of its high start-up costs. In this case, the manufacturing scale makes up for the higher costs of machinery and tooling. The following offers special die-casting options to NOBLE's clientele.This article examines metal die casting in detail, outlining its definition, kinds, appropriate materials, surface polish, applications, and how to select the best die casting service.

What is Die Casting?

Die casting is a manufacturing technique that yields highly accurate and precise metal products in terms of dimensions. It is similar to the injection moulding method used in the production of plastics. It entails pumping molten metal—typically an alloy of non-ferrous metals like magnesium, zinc, or aluminum—under intense pressure into a mold, which is a reusable steel mold. Under pressures ranging from 0.7 to 700 MPa, molten metal is pushed into a mold and solidifies into a metal casting. Molds are made to shape finished products into the desired shape. Die casting uses a mold of two halves, the "cap mold" and the "ejector mold," which are clamped together. The mold is coated with a release agent before injection. Molten metal is forced into the mold cavity using a hydraulic or mechanical press. After the metal cools, the two halves separate, and the solidified part (casting) is ejected. Castings retain the shape and surface finish of the mold with high precision and require minimal post-processing. Die casting produces complex parts with excellent surface finishes and is used for car casings, electrical components, and toys. This process could be combined with sheet metal stamping, forging, and other casting techniques.

How Die Casting Works?

Die casting is a manufacturing technique that creates very precise and detailed metal pieces. It entails pumping molten metal—usually magnesium, zinc, or aluminum—under intense pressure into a die, or mould cavity. The molten metal is expelled as a finished item after rapidly solidifying inside the die and taking on the shape of the mould. Here are steps:

●Mold Preparation

The preparation of the die, which is divided into the cover die and the ejector die, is the first step in the procedure. Usually constructed of hardened steel, these dies are intended to give the finished product the correct shape.

●Mold Clamping

The two halves of the die are clamped together to form a closed mold cavity that can withstand the high pressure during injection.

●Prototype Development

Engineers perform a number of procedures to retain the component's shape once a sheet metal design model has been created. These processes include welding, cutting, bending, punching, and stamping. Surface treatments also contribute to the produced prototype's improved looks. It's crucial to complete these tasks sequentially. The integrity and quality of the finished product may be compromised if the process is rushed or if a stage is skipped.

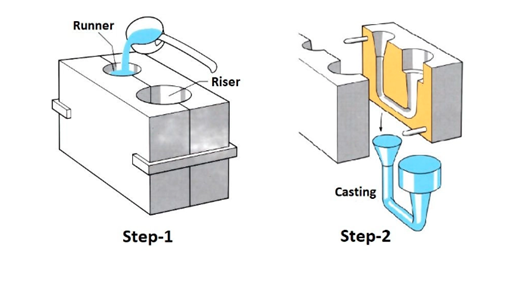

●Injection

After the preparation stage, the molten metal is poured from a furnace into the die through a downward sprue. This can be done manually or using an automated ladle, but it utilizes gravity to move the metal. No additional forces or pressures are applied. The liquid metal is inserted into the die from a vertical position, and it flows down into the cast due to the natural pull of gravity. By avoiding high pressures, turbulence is reduced, and this helps prevent porosity. It also leads to the production of smoother components and parts.

●Cooling and Solidification

The molten metal quickly cools and solidifies as it comes into contact with the cooler die surfaces once it has filled the mold cavity. The solidification process is sped up, and heat dissipation is facilitated by cooling channels inside the die.

●Ejection

Once the cast has gone through the casting process in a gravity die casting machine, a sufficient amount of time is given for it to cool down. After this, the die halves are unclamped and opened, and the cast parts are carefully removed. They can be taken out by hand or, in some situations, ejector pins are used to push the cast safely out of the machine.

●Trimming and Finishing

After a part is ejected from a die, there may be an excess material along the parting line known as flash. To remove this flash, the part goes through a trimming process which can be performed either manually or with automated equipment. Additional finishing processes like machining, polishing, or surface treatments may be applied to achieve the desired final product.

Advantages and Disadvantages of Die Casting

Advantages of Die Casting

1.Low Cost

Die-cast components deliver consistent quality in big quantities and are comparatively less expensive. Processes that are partially or entirely automated result in lower labour expenses.

2.High Efficiency

The molten metal quickly cools and solidifies as it comes into touch with the cooler die surfaces once it has filled the mould cavity. The solidification process is sped up and heat dissipation is facilitated by cooling channels inside the die.

3.Complex Shapes and Thin Walls

Die casting can produce parts with complex shapes and part sizes ranging from 25g to 25 kg. These parts may be difficult or costly to implement using other manufacturing methods. It can also produce thin-walled parts with thicknesses as thin as 0.38 mm, reducing weight while maintaining strength.

4. Dimensional Accuracy and Consistency

Excellent dimensional accuracy and reproducibility are offered by die casting. Tight tolerances and consistent part dimensions are ensured by the well-built die molds. Die casting is therefore appropriate for uses requiring constant and exact parts.

5.Good Surface Finish

Die casting produces parts with smooth surfaces, fine details, and surface finishes of -0.8–3.2 um Ra. The mold can be designed to produce the desired surface texture, thereby reducing the need for additional surface finishing operations.

6.Material Versatility

Many materials can be used in die casting, such as brass, zinc, magnesium, and aluminum. Each material has unique qualities, such as resistance to corrosion, light weight, or high strength, making it possible to choose a material based on the demands of a certain application.

Disdvantages of Die Casting

1.High Initial Tooling Costs

Die casting calls for the creation of intricate, precisely built moulds, which can be costly to create and produce. Tooling expenses can be a major obstacle, particularly in the case of prototype or small-scale production.

2. Limited Size and Weight Range

Generally, die casting is appropriate for small to medium-sized components. The size and capacity constraints of die casting machines may necessitate the use of other manufacturing techniques for large and heavy components.

3. Porosity and Shrinkage

Die casting's quick cooling and solidification of the liquid metal might cause the item to develop porosity or shrinkage flaws. The castings' mechanical qualities and structural integrity may be jeopardised by these flaws. To reduce these problems, proper design considerations and process management are required.

4. Design Limitations

Die casting's inherent characteristics need specific design constraints. For instance, to encourage homogeneous filling and solidification, pieces should have uniform wall thicknesses. Undercuts and intricate interior elements could also need for further design thought or post-casting procedures.

Die casting remains a widely used manufacturing process due to its numerous advantages. Manufacturers carefully consider the specific requirements of their products to determine if die casting is the appropriate choice for their production needs.

Applications of Die Casting Process

Engine parts and electronics housings can both be made utilizing the strong, adaptable die casting method. Die casting's broad build area, variety of material choices, and capacity to produce intricate, reproducible, thin-walled parts are some of its many advantages.

●Die Casting in the Automotive Industry

Because aluminum die casting can create lightweight parts like gearbox cases, engine brackets, and hydraulic cylinders, it is widely used in the automotive sector. Magnesium die casting is useful for panels and seat frames, whereas zinc die casting is appropriate for fuel, brake, and power steering components

●Die Casting in the Aerospace Industry

Die casting is essential to the aerospace sector because it produces intricate, lightweight parts of superior quality. Aerospace manufacturers choose this production technique because of its cost-effectiveness and capacity to satisfy the industry's strict standards.

●Die Casting in the Medical Industry

Die casting is important in aerospace and medical industries. It produces lightweight, high-quality parts that meet strict industry standards. The technique is favored for producing vital components.

●Die Casting in the Energy Industry

Die casting is important to the energy sector because it makes it possible to produce accurate, long-lasting, and high-quality parts for heat exchangers, fuel cells, electrical components, renewable energy systems, and energy storage systems, among other applications. The process is a beneficial manufacturing method in the energy sector because it may match industry demands for performance, efficiency, and cost-effectiveness.

How to Manufacture Die Casting Parts?

Types of die casting process

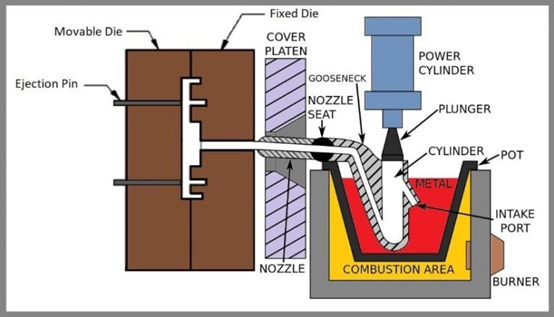

The Hot-Chamber Die Casting Process (Hot Casting)

The hot die or gooseneck casting method are other names for the hot chamber technique. This procedure is utilised for low melting point metals that won't chemically damage the dipped plunger assembly. The plunger and chamber of the injection mechanism are dipped in the molten metal bath of a metal furnace (see image below). The plunger retracts with the dies closed, opening the chamber port and letting the molten metal enter the chamber. Subsequently, the plunger shuts off the port and forces the molten metal through the nozzle and gooseneck into the die cavity. The molten metal is contained under pressure inside the die cavity until it solidifies. The increased pressure in the hot chamber process results in a substantially higher production rate than in the cold chamber technique.Hot chamber casting works effectively with alloys and metals that have lower melting points, including tin and zinc.

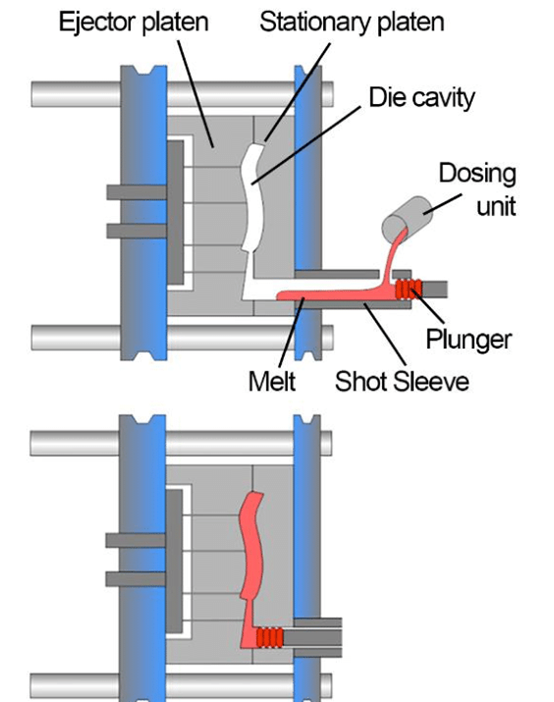

The Cold-Chamber Die Casting Process

The cold chamber die casting process is quite similar to the hot chamber die casting process. In this process, the molten metal is poured into the injection sleeve or chamber part of the injection cylinder before being pushed into the mold. Since the sleeve is not heated, this process is called the cold chamber process. The metal furnace is self-contained, which eliminates any corrosion problems. The cold chamber process starts when the molten material is transferred from the furnace to the injection chamber through the pouring hole. A hydraulic ram seals the cold chamber port and pushes the metal under pressure into the mold cavity. The pressure range lies between 30Mpa and 150 MPa. This process is designed to focus on minimizing machine corrosion rather than production efficiency. Molten metal is scooped into the injection system automatically or manually, which eliminates the need to immerse the injection mechanism in a bath of molten metal. For applications where hot chamber die casting immersion designs are too corrosive, the cold chamber process is a good alternative. This process is suitable for casting metals with high melting temperatures, such as aluminum and aluminum alloys.

The Pressure Die Casting Process

Pressure die casting is a fast, dependable, and reasonably priced manufacturing method for producing large quantities of net-shaped, tightly toleranced metal components. In essence, molten metal alloy is injected under high pressure into a steel mould (or tool) during the pressure die casting process. This solidifies quickly, forming a net-shaped component in a matter of milliseconds to a few seconds. After that, it is automatically extracted.

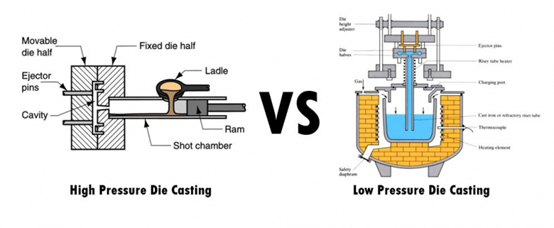

1)High Pressure Die Casting

High-pressure die casting (HPDC) is a highly efficient manufacturing process that can produce a wide range of product shapes. In this process, a metal mold is filled with liquid metal at high pressure and speed. The basic apparatus consists of two vertical pressure plates that hold the mold halves in place when the worktop is positioned on top of them. One of the pressure plates is stationary, while the other is movable, aiding in the opening and closing of the mold. To fill the mold cavity, a predetermined amount of metal is added to the shot sleeve, which is then actuated hydraulically using a piston. Once the metal has solidified, the casting is removed from the mold.

2.)Low Pressure Die Casting

The ideal application for low-pressure die casting is on symmetric aluminium components with an axis of rotation. Wheels for vehicles, for instance, are frequently made using low-pressure die casting. This kind of operation uses a riser tube to link the mould, which is positioned vertically above the bath of molten metal. The metal is drawn upward and into the mould when the chamber reaches pressure, which is typically between 20 and 100 kPa. High casting yields are achieved by removing feeders from this kind of low pressure aluminium casting process.

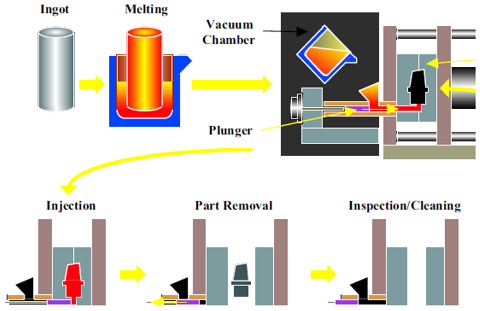

The Vacuum Die Casting Process

The vacuum die casting and cold chamber techniques are most closely linked. Before the molten metal enters the mould cavity, trapped air and gases are removed by a vacuum source. This is a relatively new die-casting technique that reduces porosity, boosts strength, and makes post-casting heat treatments easier to apply. This kind of casting has several benefits, including enhanced mechanical qualities, enhanced surface smoothness, increased dimensional stability, shortened cycle times, and a decrease in flaws brought on by trapped gases. It's possible to heat-treat parts.

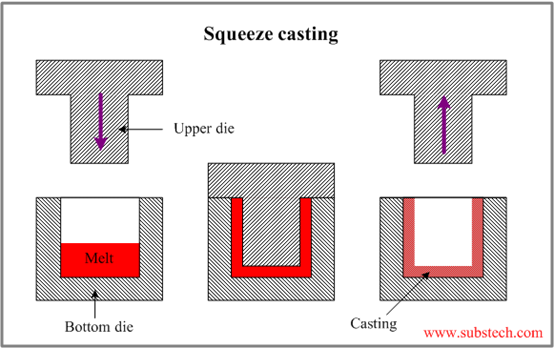

The Squeeze Die Casting Process

Low-flow metals and alloys can be cast, and squeeze casting was developed as a practical method. Known additionally as liquid metal forging.This procedure forces molten metal into a depression in the moulded product by filling an open mould with the metal and then squeezing it tight. Squeeze casting yields an incredibly dense result and works well with later heat treatment. This process is also applied to the creation of reinforced metal matrix composites, where the fiber-reinforced structure is infiltrated by molten aluminium.

The Gravity Die Casting Process

A manufacturing technique called gravity die casting is used to create premium metal parts with intricate forms and generally smooth surfaces. This particular casting technique is a subset of die casting operations as a whole. Two important features set gravity die casting apart from other casting techniques: (1) the casting metal is introduced into the mould only by gravity; and (2) a reusable (or "permanent") metal mould is employed. Usually, cast iron or steel are used to make it.

Common Die Casting Service

●Aluminum die casting Service

One of the primary metals used in die casting is aluminium, and alloys of aluminium are employed in cold-chamber die casting. These alloys usually consist of magnesium, copper, and silicon. Die casting alloys made of aluminium are a suitable option for intricate, finely detailed pieces since they are lightweight and provide good dimensional stability. Good temperature resistance, electrical and thermal conductivity, and resistance to corrosion are some of the other benefits of aluminium casting.

Common die casting aluminum alloys include:

360 360.0 | A360 A360.0 | 380 380.0 | A380 A380.0 | 383 383.0 | |

Density | 2.63 g/cm3 | 2.63 g/cm3 | 2.74 g/cm3 | 2.71 g/cm3 | 2.74 g/cm3 |

Melting Range | 557-596.C | 557-596.C | 540-595.C | 540-595.C | 516-582.C |

Electrical Conductivity | 30 %IACS | 29 %IACS | 27 %IACS | 23 %IACS | 23 %IACS |

Thermal Conductivity | 113 W/(m' K) | 113 W/(m' K) | 96.2 W/(m' K) | 96.2 W/(m' K) | 96.2 W/(m' K) |

Ultimate Tensile Strenghth | 300 MPa | 320 MRa | 320 MRa | 320 MRa | 310 MRa |

Yield Strength | 170 MPa | 170 MPa | 170 MPa | 170 MPa | 170 MPa |

Hardness | 75 BHN | 75 BHN | 75 BHN | 75 BHN | 75 BHN |

Fatigue Strength | 140 MPa | 140 MPa | 140 MPa | 140 MPa | 140 MPa |

Shear Strength | 190 MPa | 190 MPa | 190 MPa | 190 MPa | 190 MPa |

Elongation | 2.5% | 2.5% | 2.5% | 2.5% | 2.5% |

●Zinc die casting Service

Zinc alloys are an important type of metal used for die casting. Zinc casting is a great option for plating and has additional benefits such as impact strength and ductility, making it the most convenient die casting alternative for manufacturers. It can be cast using a hot-chamber die casting machine, and due to its castability, there is less die wear. Zinc is usually combined with copper, magnesium, and aluminum since it is heavier than magnesium and aluminum.

Common die casting Zinc alloys include:

Alloy Grade | Zamak 2 | Zamak 3 | Zamak 5 | Zamak 7 | ZA-8 |

Density (g/cm³) | 6.7 | 6.6 | 6.7 | 6.8 | 6.9 |

Melting Point (℃) | 383-386 | 381-387 | 379-386 | 380-386 | 381-387 |

Thermal Conductivity (W/m`K) | 109 | 116 | 113 | 113 | 116 |

Coefficient of Thermal Expansion (10^-6/K) | 26.5 | 27.5 | 26.9 | 26.5 | 26.5 |

Electrical Conductivity (% IACS) | 27 | 27 | 27 | 27 | 26 |

Main Chemical Composition | 3.5-4.3% Al | 3.5-4.3% Al | 3.5-4.3% Al | 3.5-4.3% Al | 3.5-4.3% Al |

Tensile Strength (MPa) | 295 | 255 | 310 | 345 | 380 |

Yield Strength (MPa) | 240 | 215 | 230 | 275 | 320 |

Elongation (%) | 2 | 3 | 6 | 3 | 1 |

Hardness (HB) | 82 | 70 | 90 | 95 | 100 |

Main Differences | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains more Mg and Cu, suitable for complex-shaped parts | Contains Mg, Cu, Ni, and Fe, with higher strength and hardness |

Main Casting Applications | Automotive, furniture, appliances, mechanical parts | Electrical, hand tools, toys | Machinery, architectural, automotive | Automotive, electrical, hardware | Industrial, automotive, electrical |

Considerations When Choosing Die-Casting Alloys

Die-casting alloy selection will be determined by the end product's application and function. The performance, cost, and manufacturing process are all directly impacted by the alloy choice, which makes it imperative. When selecting die-casting alloys, keep the following important criteria in mind:

1.Mechanical Properties

The performance, cost, and manufacturing process are all directly impacted by the alloy choice, which makes it imperative. When selecting die-casting alloys, keep the following important criteria in mind:

2.Corrosion Resistance

Think about the working conditions and exposure to things like chemicals, wetness, and temperature changes. Certain metals, like zinc and aluminium, withstand corrosion well, whereas other alloys can need extra protective coatings.

3. Thermal Conductivity

Assess whether the component needs to maintain a certain temperature or efficiently dissipate heat. Because of their high thermal conductivity, alloys like copper can be useful in applications where effective heat transfer is required.

4. Machinability

If post-machining procedures are required, take the alloy's machinability into account. While some alloys can be machined more easily than others, some can call for more sophisticated equipment or methods.

5. Cost: Evaluate

The alloy's total cost, taking into account the cost of materials, the effectiveness of the production process, and any additional finishing or treatment needs. The cost of each alloy varies, and some may need more sophisticated processing methods, which raises the part's total cost.

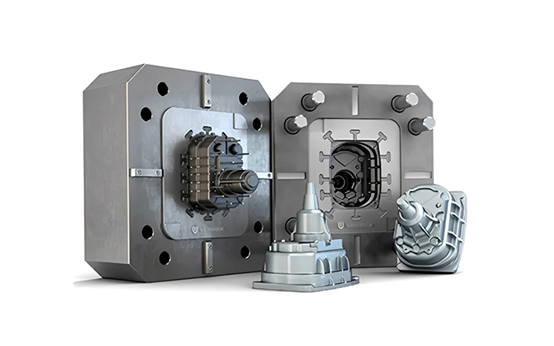

How to Make a Die Casting Mold

The cover side, which is fixed on a plate, and the ejection side, which is mounted on a moveable plate, make up a die casting mould. To create more intricate pieces, such those with holes and threads, certain moulds contain extra components like slides and cores. In order to make numerous components per cycle, a die casting mould may have multiple cavities, depending on the size of the object being manufactured. These moulds are either multi-cavity moulds, which have many identical cavities, or cell moulds, which contain a mixture of different cavities to manufacture different pieces. Die-casting moulds need to be very strong and heat resistant in addition to having good ductility and wear resistance. Because of this, their construction allows them to withstand hundreds of casting cycles every hour and up to two million cycles during their lifetime. They are built of high-performance hardened tool steel, which is frequently heat-treated. Die casting moulds have to be able to work even with extremely strong clamping forces. Using casting-specific design and simulation tools in conjunction with computer-aided design (CAD) is the first step in the manufacturing process of die-cast moulds. Die casting moulds need gates, runners, and gates just like injection moulds do in order to let molten material into the mould cavity. It is also necessary to include ejection and locking pins in order to secure the mould and make ejection easier. Tight tolerances and intricate shapes can be produced through digital mould design.. CNC machining is widely used to manufacture die-casting molds. Typically, die-casting mold manufacturing begins with rough machining of the mold shape, then heat treatment of the metal mold, and finally a round of finishing. Prototype-level molds can also be manufactured using rapid tooling, using CNC machining or other processes such as Selective Laser Sintering (SLS).

Die Casting Materials

Metals with low fusing temperatures, such as aluminum, zinc, magnesium, lead, and copper, are commonly used in die casting. Some ferrous and uncommon metals, however, can also be used. Some common materials as following:

Aluminum

Aluminum die castingoffers numerous advantages, including lightweight construction, high strength-to-weight ratio, excellent machinability, thermal conductivity, corrosion resistance, design flexibility, cost efficiency, and recyclability. These properties make aluminum a popular choice for various applications and contribute to its widespread use in die casting processes.

Magnesium

Magnesium's lightweight nature, high strength-to-weight ratio, excellent machinability, heat dissipation properties, dimensional stability, EMI/RF shielding capabilities, and recyclability make it a valuable material for die casting. Its unique combination of properties opens up opportunities for lightweight and high-performance components in industries such as automotive, aerospace, electronics, and consumer goods.

Copper

Traditional die casting processes usually avoid using copper due to its high melting point and challenging properties. However, a specific variant called copper alloy die casting is designed for casting copper-based alloys. This specialized technique produces high-quality copper-based components that offer excellent corrosion resistance and strength. Despite not being commonly used, copper alloy die casting is tailored to the unique properties and requirements of copper-based alloys, making them suitable for a range of industries and applications.

Zinc die castingoffers several advantages, including excellent castability, high strength, corrosion resistance, design flexibility, high production efficiency, and recyclability. These properties make zinc a popular choice for a wide range of applications, particularly those that require complex shapes, precision, and cost-effective production. including automotive, electronics, telecommunications, consumer goods, and more. Common examples of zinc die cast components include automotive parts, electrical connectors, door handles, hinges, faucets, and various household appliances.

Die Casting Finishing Options

NOBLE can help improve the surface qualities of your products by offering a diverse range of surface finishes. Surface finishes on your customized parts aim to improve their appearance, surface hardness, and roughness, chemical and corrosion resistance, and so on. They also aid in the concealment of any visible tool marks from areas cut with live tooling. Here are some of your best options.

| PIC | Name | Description | Materials | Color | Texture |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Strategy for Selecting a Die Casting Manufacturer

When selecting a die casting manufacturer, it is essential to consider several factors to ensure a successful partnership and high-quality production. Here is a strategy to guide you in selecting the right die casting manufacturer:

1.Define your requirements

Clearly define your project requirements, including the desired part specifications, quantities, quality standards, surface tretment and delivery timeline. This will help you communicate effectively with potential manufacturers and evaluate their capabilities.

2.Experience and Expertise

Seek out producers who have a lot of die casting experience and a solid track record of producing high-quality goods. Examine their experience working with the particular metals and materials that are pertinent to your project. Think about the sectors they have worked in and the intricate pieces they have manufactured with success.

3.Manufacturing Capabilities

Evaluate the manufacturer's production capabilities, including the size and capacity of their die casting machines, available tooling options, and secondary operations like machining, finishing, and assembly. Ensure that their equipment and facilities can meet your project requirements and volume demands.

4. Quality Control Measures

Inquire about the manufacturer's quality control processes and certifications. Look for manufacturers that have implemented robust quality management systems, such as ISO certifications. Ask about their inspection methods, testing procedures, and adherence to industry standards.

5.Design and Engineering Support

Consider whether the manufacturer offers design and engineering support. Skilled manufacturers can provide valuable input during the design phase, helping optimize part manufacturability, cost-effectiveness, and performance. Their expertise can also aid in material selection and process optimization.

6.Communication and Collaboration

Assess the manufacturer's communication channels and responsiveness. Effective communication is vital for a successful partnership. Ensure that they are responsive to inquiries, provide regular progress updates, and are willing to collaborate closely with you throughout the project.

Why Choose NOBLE for Die Cating Service

NOBLE uses advanced technology and has a team of skilled professionals who are dedicated to putting our customers first. Our die casting services are precise, efficient, cost-effective, and produce high-quality results. By choosing our die casting services, you can elevate your business to new levels of success.

●Economical Price & High Quality

We offer the same quality at the lowest price. We strictly control the quality of machining and the finish treatment to ensure that you receive exactly what you designed.

●.Robust Manufacturing Capabilities

NOBLE pride ourselves on our exceptional manufacturing capabilities that offer a wide range of materials and surface finishes. Whether it's a small or large production run, we provide a comprehensive one-stop solution for all project requirements. Our manufacturing capacity is unparalleled, ensuring that each die casting part is of the highest quality, meets all dimensional requirements, and performs exceptionally.

●Strict Quality Control

As an ISO 9001 & ISO13485 Certified Factory, NOBLE is dedicated to providing precise die casting services. Our engineering team conducts strict quality inspections at various stages of the manufacturing process, including pre-production, in-production, first article inspection, and before delivery to guarantee the production of the highest quality.

●Fast Lead Time

With domestic certified factories and a strong supply chain system, but also with domestic workshops and state-of-the-art machinery, we can speed up product development cycles and get ready for your aluminum alloy die casting parts as soon as possible.

●High Precision Die Casting Parts

We strictly implement the quality management system to ensure that the product quality is consistent and in line with expectations. A thorough inspection also ensures that the precision-machined parts you receive are free of any unnecessary defects.

●24/7 Engineering Support

Wherever you are in the world, you can rely on our 24/7 engineering support, year round. Our experienced engineers can provide the most suitable solution for your part custom design, wide material selection, impeccable finishing options and even delivery time.

Related News

- A Comprehensive Guide to CNC Machining: Understanding the Basics and Applications2023-05-15

- What is Precision CNC Machining?Gide for Begineers.2023-07-18

- What Is Sheet Metal Fabrication? A Guide To Sheet Metal Fabrication Processes: Material&Finishing2023-08-29

- Noble Won The Title Of "Innovative Small And Medium Enterprises"2023-11-06

- NOBLE Obtained Three Important Certificates Including Medical Device Production License2023-01-13

- NOBLE Participated in the COSMOPROF ASIA HONGKONG Showcasing Product Features And Scientific Research Concepts2023-11-22

- A Beginner's Guide to Injection Molding:Definition & Types & Advantages2023-12-28

- Congratulations! Noble Passed The Certification Of "Shenzhen Specialized, Special And New Small And Medium Enterprises"2023-10-11

- Comprehensive Guide about Rapid Prototyping and Low Volum Manufacturing2024-01-09

- Guide for Vacuum Casting Process2024-01-16