What is Vacuum Casting

The liquid material is put into a mould during the casting process and left to harden. By drawing air out of the mould using a vacuum, vacuum casting ensures that the final product takes on the correct shape. Rubber and plastic components are frequently cast via vacuum casting. Because it is quicker and less expensive than other techniques like injection moulding, it is frequently employed for prototype projects or small-scale production. High accuracy and repeatability are further advantages, which make it perfect for applications requiring exact dimensions. Additionally, compared to injection moulding, it enables the casting of more intricate designs. Nevertheless, materials that are heat- or pressure-sensitive cannot be cast with it.

The principle of vacuum casting

Vacuum casting is a physical modeling technique that combines vacuum technology with sand mold casting. In this process, the cavity surface and back of the sand mold are sealed with plastic film. A vacuum pump is used to generate negative pressure, which tightens the molding sand due to the pressure difference between the inside and outside of the sand mold. After placing the sand core, the mold sand is collapsed to obtain the casting. The next step involves closing the mold, casting, waiting for the casting to solidify, and then releasing the negative pressure or stopping the air extraction. Application of vacuum casting in molds.

How does vacuum casting work

Vacuum casting is a manufacturing process used to create high-quality, detailed plastic or elastomer parts. It is often employed in rapid prototyping and small-scale production applications. It is similar to conventional injection moldingHere’s an overview of how vacuum casting works:

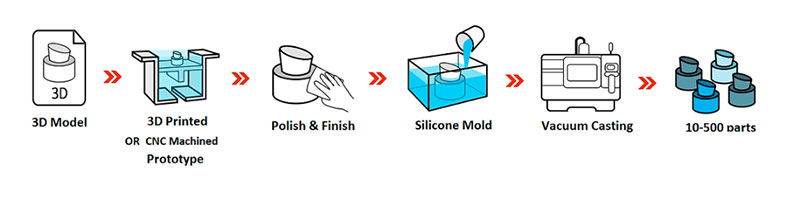

Create a 3D Model

The first step in most modern production procedures is to create a 3D model of the intended form. Objects that are intended for vacuum casting should be created using injection moulding techniques to achieve the best results. This can be done using any design software such as AutoCAD, Solidworks, or CATIA.

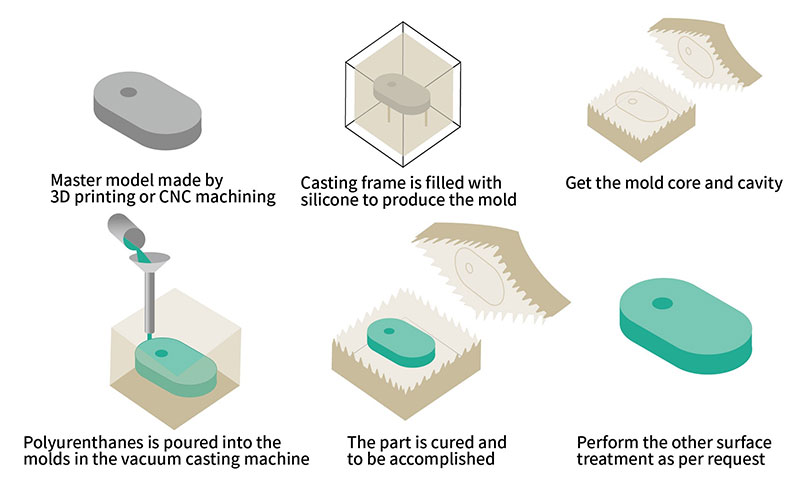

Master Pattern

The 3D model is created, and then it is transformed into a high-quality master model. This master model is typically a prototype that is either 3D printed or machined and is made from a specific material, such as wax or resin. The master pattern represents the final part that is going to be reproduced.

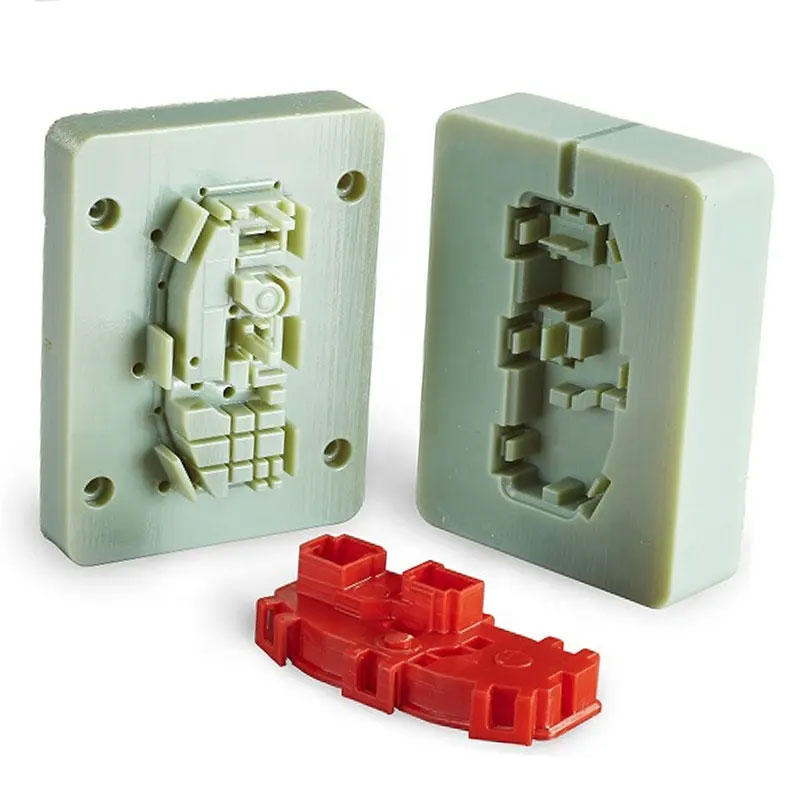

Make the Silicone Mould

Once the master model is created, a silicone mold is cast. The master model, along with the core, inserts, and sprues, is suspended in the casting box. Then, liquid silicone is poured around it, filling in all the details. The formed part is placed in a vacuum casting box and cured for 8–16 hours in a preheated oven at 40°C, depending on the size of the silicone mold. After the silicone has dried and set, the box and riser are removed. Finally, the mold is carefully cut open with a knife to expose the female cavity of the component.

Mixing

Before combining, polyurethane resins used in casting are usually heated to around 40°C. The machine works by precisely combining a two-component casting resin with any chosen colourant, then pouring the mixture into a bowl. After that, the pouring gates are fastened to the mixing and pouring vessel, and the mould is put back in position. Vacuum casting resins and colour pigments are well combined and vacuum-deaerated for 50–60 seconds during the auto-pouring process. Subsequently, a vacuum is generated within the mould, and the resin is introduced. The vacuum technique allows gravity to do all the work of filling the mould by removing the air pockets inside the tool that would otherwise act as a barrier to flow.

Demolding

The mould is opened, and the newly created plastic part is removed once the resin has completely set. Usually, the mould can be used again for several casting cycles.

How to make a mold for a vacuum casting?

The liquid material is put into a mould during the casting process and left to harden. By drawing air out of the mould using a vacuum, vacuum casting ensures that the final product takes on the correct shape. Rubber and plastic components are frequently cast via vacuum casting. Because it is quicker and less expensive than other techniques like injection moulding, it is frequently employed for prototype projects or small-scale production. High accuracy and repeatability are further advantages, which make it perfect for applications requiring exact dimensions. Additionally, compared to injection moulding, it enables the casting of more intricate designs. Nevertheless, materials that are heat- or pressure-sensitive cannot be cast with it.

Key Components of Vacuum Casting

Silicone Molds: Renowned for their flexibility and durability, silicone molds are designed to capture fine details, making them ideal for precise casting applications.

Polyurethane Resins: These resins are available in various formulations, allowing manufacturers to replicate the properties of different materials, such as plastics, rubbers, or metals.

Vacuum Chamber: The vacuum chamber removes air from the mold, which helps to eliminate imperfections and air bubbles, resulting in high-quality, defect-free parts.

Advantages of vacuum casting

Cheaper initial setup cost

Compared to CNC machining and other Rapid Prototyping techniques, vacuum casting is far less expensive. This is since creating a mould only takes a few hours and may be used repeatedly. Costly equipment and supplies are needed for CNC machining.

High precision

Parts with intricate shapes and extreme precision can be created. Using the SLA technique, the mould master model may be created, utilizing additive manufacturing’s flexibility and superior surface quality.

Shorter lead time

It is also an industry that makes moulds. A mould trial stage is not necessary for vacuum casting. With new moulds, vacuum forming has a shorter lead time—typically 10-12 days. Reduced mould startup expenses. It is possible to create larger plastic parts using this technology.

Flexibility

3D printing offers a great deal of design flexibility since it can create almost any geometry. Vacuum casting can be used to produce parts that are impossible to make using other methods.

Thin-Wall Casting

Technical requirements are higher for thin-walled castings, but they are lighter and use less material. This is required in certain unique circumstances. For optimal impact, products including functional housings must have thin wall thicknesses. Conduction between thin-walled components is essential to products with intricate interior systems. One of the main reasons for high failure rates in traditional production is the difficulty of casting thin-walled castings. The produced part’s structure may be thick and have thin walls when subjected to continual vacuum pressure.

Comparison with other manufacturing processes

Vacuum casting is appropriate for production in small to medium quantities. It is a method that falls in between plastic injection moulding (big series) and 3D printing (single piece production and small series). In comparison to 3D printing, the procedure is less flexible and faster because it requires a mould. The part’s producible complexity is smaller than with additive manufacturing since it needs to have less undercut to be able to be removed from the mould (a process known as demolding). Conversely, additive manufacturing is limited in this regard, while vacuum casting has an excellent surface quality that, when paired with a greater variety of materials and high strength values, is truly remarkable.

1. Is vacuum casting cheaper than 3D printing?

The two methods vary depending on several factors. The main determinants of cost are the size of the operation and the complexity of the design.

Quantity and Scale

The cost of the original design and moulding will increase if injection moulding is used. On the other hand, 3D printing requires less capital. However, batch manufacturing can easily offset the initial investment cost if your project is really large and requires more than 2,000 pieces. When a large volume is needed, injection moulding is more cost-effective and faster. Even after deducting the initial mould cost, 3D printing is still far more expensive per unit when producing huge numbers of a part or product. Vacuum casting or 3D printing can be more economical if you’re wanting to manufacture small to medium-sized products or need bridge manufacturing services. Although the price per unit might seem higher than injection molding, the final cost will be lower in small production runs because there isn’t a large upfront investment in the mold. If you only need one or two items, then you’re better off sticking with 3D printing.

Complexity of the Design

3D printing is the best option if your design is intricate or if you want to update and modify it while it’s being produced. Moulds used for injections cannot be easily changed. Any modification necessitates starting over with a fresh mould. Whenever you have to start over, the cost of the project increases. As a result, 3D printing is more cost-effective during the product development or prototyping stage when it’s necessary to make multiple revisions to your design or when the project is complicated.

2. Is vacuum casting cheaper than injection molding?

Vacuum casting and injection molding are two different manufacturing processes, and cost comparisons between vacuum casting and injection molding depend greatly on specific project requirements. In general, injection molding is more cost-effective for high-volume production, while vacuum casting can offer advantages for small to medium-sized production runs or when flexibility and customization are important.

Tooling cost

Injection molding involves the manufacturing of costly molds that are typically made of steel or aluminum. This leads to a higher initial mold cost. The molds are designed to withstand high temperatures and pressure. Conversely, vacuum casting makes use of less expensive molds made of silicone rubber or polyurethane. This process is more affordable, particularly for smaller production volumes.

Production quantity

As production quantities increase, injection molding becomes more cost-effective. The higher initial tooling cost can be spread over more parts, resulting in lower unit costs. Vacuum casting is better suited for smaller production volumes or when part demand changes

Design Complexity

Injection moulding is capable of producing extremely intricate pieces with minute details and precise dimensions. It is a good option for producing parts in large quantities with reliable quality. Although it might not be as precise or intricate as other casting processes, vacuum casting can nonetheless generate detailed parts.

What is the alternative to vacuum casting?

Similar to vacuum forming, pressure forming is a widely used method in the production of plastic thermoforming. An oven is used to secure and heat a thermoplastic sheet in both procedures. The technique used to apply pressure or vacuum to the heated plastic sheet to shape it into the required item is different, though.

Our vacuum casting tolerances

NOBLE offers a range of vacuum casting tolerances to meet your complex custom requirements. Depending on the master model and part geometry, we can achieve dimensional tolerances between 0.2 – 0.4 mm. Below are the technical specifications for our custom vacuum casting services.

| Type | Information |

| Accuracy | Highest precision to reach +0.05 mm |

| Max Part Size | +/-0.025 mm

+/-0.001 inch |

| Minimum wall thickness | 1.5mm~2.5mm |

| Quantities | 20-25 copies per mold |

| Color & Finishing | Color and texture can be customized |

| Typical Lead Time | Up to 20 parts in 15 days or less |

Materials for Vacuum Casting

|

ABS | ABS is a thermoplastic polymer, is widely used due to its exceptional resistance to impact, temperature, and chemicals. It also offers a sleek surface finish and is easy to produce and handle. |

|

POM | POM, also known as acetal or Delrin, is a type of engineering thermoplastic that boasts exceptional dimensional stability, stiffness, temperature resistance, and impact resistance. |

|

PP(Polypropylene) | Polypropylene (PP) is a material that is typically white and translucent and is resistant to corrosion while also possessing good toughness. Its most notable characteristic is its versatility, as it is suitable for use in a variety of processing methods and applications. |

|

PE(Polyethylene) | Polyethylene is odorless, non-toxic, feels like wax, has excellent low-temperature resistance (minimum operating temperature can reach -100~-70°C), has good chemical stability, and can withstand most acid and alkali erosion (not resistant to oxidation) nature acid) |

|

PC(Polycarbonate) | Polycarbonate (PC) is an amorphous thermoplastic known for its exceptional transparency and impact resistance. It also possesses strong electrical insulating properties and moderate chemical resistance. |

|

PMMA(Polymethylmethacrylate) | Polymethylmethacrylate, also known as Acrylic. Acrylic is a highly versatile material known for its exceptional transparency, chemical stability, and resistance to heat, cold, and corrosion. |

|

PEEK | PEEK boasts exceptional mechanical strength, self-lubrication, impact resistance, and flame retardancy. It is also highly resistant to acid, alkali, and other chemical corrosion, hydrolysis, wear, fatigue, stripping, and radiation. |

|

Nylon | Nylon has impressive mechanical properties such as heat and wear resistance, chemical resistance, and self-lubrication. Polyamide fiber also possesses flame retardancy, a low coefficient of friction, and is easy to manufacture. |

|

PS (Polystyrene) | Polystyrene (PS) is a polymer made from the monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum. At room temperature, PS is normally a solid thermoplastic but can be melted at higher temperatures for molding or extrusion, and then resolidified. High-impact strength, low-cost resin with a wide range of options. |

|

Elastomer | Elastomers are polymers with viscosity and elasticity and therefore are known as viscoelasticity. The molecules of elastomers held together by weak intermolecular forces generally exhibit low Young’s modulus and high yield strength or high failure strain. Examples are Natural rubber, Silicone, Polyurethanes, and Polybutadiene, Polyurethane plastic resin. |

Surface Finishes for Vacuum Casting

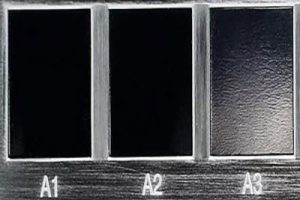

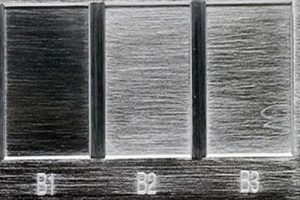

NOBLE can build unique surface layers for your vacuum casting parts using a wide range of surface finishes. These finishes assist you in meeting the aesthetic, toughness, and chemical resistance needs of your products. We can provide the following surface finishes based on your material selection and part application:

|

Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. |

|

Semi-glossy | B-grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B-grade finishing have a matte surface texture. |

|

Matte | C-grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C-grade finishing have a matte surface texture. |

|

Textured | D-grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

Our complete vacuum casting process

Vacuum Casting for Flexible and Economic

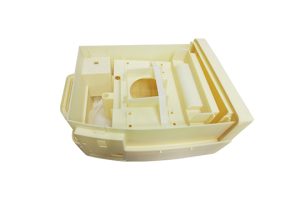

Vacuum casting, also called urethane casting, is a state-of-the-art process that uses silicone molds and a 3D printed master pattern to create stiff, high-quality, short-run parts. The thermoplastic polyurethane is hardened inside silicon or epoxy molds, giving the final products the same shapes as the original master models; the dimensions of the parts ultimately depend on the master model, part geometry, and material choice. Our vacuum casting services provide a comprehensive solution for producing high-quality prototypes and low-volume production parts.

Vacuum Casting from Prototyping to Production

Vacuum casting is a versatile process that seamlessly transitions from prototyping to low-volume production, offering numerous benefits throughout each stage.

- Prototyping

Vacuum casting is a low-cost manufacturing process that is more accessible and cost-effective than other methods for creating prototypes. Using a variety of materials and design variations, you can create high-quality prototypes. Then, simply test your designs and prepare them for functional testing - Market Testing

Vacuum-cast parts can be used for market testing and initial market penetration. This allows you to gauge customer response, conduct field tests, and validate market demand before investing in large-scale manufacturing. - On-Demand Production

Vacuum casting accommodates customization and small-batch production needs. As the molds can be easily modified, it allows for the on-demand production of tailored parts to meet specific customer requirements or niche market demands. - Fast Delivery

We can not only provide faster engineering technical support but are also equipped with a strong supply chain system and advanced Vacuum Casting equipment so that you can obtain unparalleled Vacuum Casting parts with stable performance and shorten your product development cycle.

Application of vacuum casting

Similar to vacuum forming, pressure forming is a widely used method in the production of plastic thermoforming. An oven is used to secure and heat a thermoplastic sheet in both procedures. The technique used to apply pressure or vacuum to the heated plastic sheet to shape it into the required item is different, though.

Vacuum Casting in the Automotive Industry

- Air Intake Systems: Vacuum casting is a production method that is utilized in the manufacturing of air intake systems in automobiles. These systems need components with precise shapes to enhance airflow and performance. Vacuum casting enables the production of complex intake manifolds, air ducts, and throttle bodies with smooth internal surfaces, ensuring efficient airflow.

- Interior components: Door handles, knobs, instrument panels and other interior components can be made using vacuum casting.

- Lighting components: Lenses for headlights, taillights, and other lighting components can be produced with great precision using vacuum casting.

- Exterior components: Automotive manufacturers can create exterior components like grilles, badges, and emblems using vacuum casting.

Vacuum Casting in the Aerospace Industry

In the aerospace sector, vacuum casting is an essential process because it makes it possible to create delicate, lightweight, and robust components. It is used in the fabrication of composite constructions, engine parts, interior design elements, drones, unmanned aerial vehicles, and satellite components, in addition to prototyping. In aerospace applications, vacuum casting helps to improve overall safety, fuel efficiency, and aircraft performance.

- Prototyping: One common technique for rapidly prototyping aeronautical components is vacuum casting. It enables the creation of functioning prototypes with surface quality and material characteristics that closely resemble the finished products. This allows engineers to test and completely assess the parts’ functioning, fit, and performance before moving forward with full-scale production.

- Composite Structures: Vacuum casting is a commonly employed method for creating composite structures. Composite materials, such as carbon fiber-reinforced polymers (CFRP), are used to build these structures because of their exceptional fatigue resistance and high strength-to-weight ratios. The ideal alignment and consolidation of fibers are ensured by the exact placement of reinforcement elements made possible by vacuum casting. This process’s lightweight, robust, and long-lasting parts are frequently utilized in fuselages, aeroplane wings, and other vital structures.

- Interior parts: Interior panels, seat constructions, and overhead compartments are a few examples of these parts. The ability to create lightweight, scalable parts with superior surface polish and dimensional accuracy is one of vacuum casting’s greatest benefits. Additionally, this method allows for the option of adding features to the pieces, including acoustic insulation or integrated electronics.

- UVA and Drone Parts: Parts for these aircraft must frequently be aerodynamic and lightweight. Optimising flight performance and cargo capacity is made possible by the ease with which complicated forms and thin-walled structures may be produced by vacuum casting.

Vacuum Casting in Medical Devices

Customized, well-made, and functional surgical instruments, implants, medical gadgets, diagnostic tools, and rehabilitation aids can all be produced thanks to vacuum casting. The use of vacuum casting techniques has improved surgical methods, patient care, and medical education.

- Prosthetics and Orthotics: Custom parts that closely resemble the anatomy of the patient can be made thanks to vacuum casting. Vacuum casting makes it possible to produce complexly designed prosthetic and orthotic devices, such as sockets, braces, and supports, that are lightweight, strong, and comfortable.

- Surgical Instruments and Tools: Producing surgical tools with intricate shapes, ergonomic designs, and high precision is possible using vacuum casting, which produces complex handles, grips, and other tools with excellent surface finish, dimensional accuracy, and functionality.

- Implants and Medical Components: Implants, such as joint replacements (e.g., hip or knee implants) or dental prosthetics, can be manufactured using vacuum casting techniques. The process facilitates the production of implants with tailored mechanical properties, biocompatibility, and surface finishes.

- Diagnostic Equipment: Vacuum casting produces precisely shaped and durable components for medical testing equipment such as casings, enclosures, and specialized chambers for imaging devices and diagnostic analyzers.

- Rehabilitation and Assistive Devices: Examples include custom-fit splints, braces, and supports. Vacuum casting allows for the creation of devices that are comfortable, lightweight, and provide the necessary support and functionality for patients undergoing rehabilitation.

Vacuum Casting in the Robotic Industry

It is advisable to introduce a prototype robot made with vacuum-cast urethane into the market to reduce risks and stabilize company expenses. This will allow your company to explore the potential of creating a new generation of robots that can perform a wider range of tasks beyond the monotonous and repetitive ones.

- Robot Grippers and End Effectors: Vacuum casting is employed in the production of robot grippers and end effectors. Grippers are used to manipulate objects and perform tasks in robotics. Vacuum casting allows for the creation of gripper components with precise shapes, complex internal channels, and customizable features such as soft or compliant surfaces for delicate object handling.

- Enclosures and Casing: Vacuum casting is a process that is commonly used to manufacture casings and enclosures for robots. These casings protect the robot’s internal electronics, sensors, and actuators. Custom-designed casings can be created using the vacuum casting process, which can include specific features like integrated cable routing, mounting points, and access panels.

- Robot Structures and Frames: Frames for robots and other structural parts are made by vacuum casting. These parts give the robotic system its structure and assistance. Vacuum casting makes it possible to create structures with intricate geometries that are strong, lightweight, and able to bear the loads and strains that robots encounter while in operation.

Future Trends in Vacuum Casting

High-Performance Resins: The ongoing development of high-performance resins is crucial in enhancing the overall properties of manufactured parts, resulting in improved strength, durability, and functionality.

Eco-Friendly Options: The shift towards sustainable and biodegradable materials in manufacturing processes aligns with global efforts to reduce environmental impact while still maintaining high product standards.

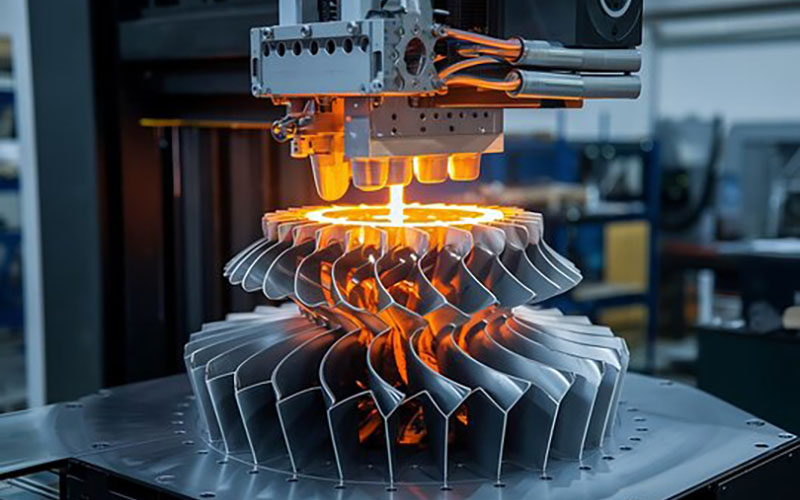

Automated Casting: The integration of robotics into the casting process significantly improves efficiency, reduces manual intervention, and enhances overall productivity.

AI and Machine Learning: The use of AI and machine learning allows for predictive analysis, enabling manufacturers to optimize processes, reduce errors, and enhance the quality of the final product.

Combining Techniques: By combining vacuum casting with 3D printing and CNC machining, manufacturers can produce more complex and geometrically challenging parts that are often difficult to achieve with

Rapid Prototyping: The integration of these advanced techniques enables faster prototyping with high precision, allowing for quicker iterations and refined product designs.

Why Choose NOBLE for Vacuum Casting Service?

NOBLE is a Sino-British joint venture awarded by the government as a”National High-tech Enterprise”. We are a comprehensive enterprise with the ability to conduct independent R&D, production, and sales.

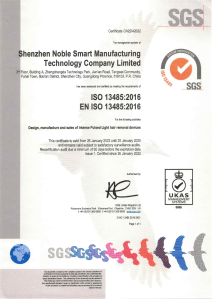

We have certificates ISO9001-2015 and ISO13485-2016, and a Class II medical device production license. Our products have obtained many important certificates, such as a Class II medical device registration certificate and an FDA510K certificate.

Vacuum casting is an excellent method for creating prototypes, pre-production parts, and final parts in low volumes. It removes the need for investing in steel tooling, and the lead time for the first parts is relatively short, usually about 10 days, depending on the size and shape of the part. By integrating cutting-edge technology with the knowledge of our qualified personnel, NOBLE prioritizes client happiness. Our vacuum casting process is precise, efficient, and cost-effective, yielding exceptional results. Choosing our vacuum casting will help your business reach new heights of success.

- Competitive Pricing:

We realize how important it is to stay within your project’s budget. Our price system is competitive and geared to fit the demands of businesses of all sizes, regardless of resource constraints. Our team is available to review your budget and offer value-added solutions that will benefit your company. - Professional vacuum casting expert:

Get reliable custom vacuum casting services from skilled and experienced engineers. With more than ten years of experience in vacuum casting, we can assist customers in optimizing designs, selecting appropriate processes, reducing costs, and achieving rapid mass production. - Complex geometry support

We use high-quality elastomer materials to ensure the manufacture of vacuum-cast plastic parts with complex structures at competitive prices. Experienced engineers provide 7 to 24-hour project support to ensure your prototypes and low-volume components closely resemble the intended end product. - On-Time Production:

We have a large production capacity and a team of skilled engineers and salespeople who prioritize open communication and just-in-time production for your order. This ensures that we can provide the fastest possible delivery time to meet any urgent needs you may have. - Unrivaled Lead Times:

We combine rich Vacuum Casting project experience and advanced equipment to provide high-quality Vacuum Casting services with faster delivery times. - Flexible Color Options:

We carefully mix a variety of pigments to achieve the desired effect on your finished product. You can choose from our extensive list of color options.

Vacuum Casting FAQs

1. Is vacuum casting expensive?

The price depends on the complexity of the part, mold Materials, quantity, etc. It’s important to note that while vacuum casting can be more expensive than other methods for small production runs, it offers advantages such as a high-quality surface finish, fine details, and rapid prototyping capabilities. Therefore, the cost must be evaluated in light of the specific requirements and benefits of the project.

2. Is vacuum casting accurate?

The accuracy of vacuum casting can still be influenced by factors such as mold design, material selection, and process control. Proper attention to these factors can help ensure the highest level of accuracy in the final cast parts..

3. Is vacuum casting permanent?

Vacuum casting is a process that involves creating molds and casting parts from those molds. The molds used in vacuum casting are usually made of silicone rubber, which allows for multiple casting cycles. However, it’s important to note that vacuum casting is a temporary process, as the molds will eventually wear out over time.

4. What is the minimum thickness for vacuum casting?

Although it is challenging to pinpoint a precise minimum thickness without taking particular materials and design elements into account, a reasonable rule of thumb is to aim for a minimum wall thickness of roughly 0.5–1 mm. To find out the precise restrictions and suggestions for your unique project, it’s imperative to speak with the vacuum casting service provider or material manufacturer.

5. How much vacuum is needed for vacuum forming?

In vacuum forming, the vacuum level required can vary depending on factors such as the material being formed, the complexity of the part, and the desired level of detail. Typically, a vacuum pressure of 10-25 inches of mercury (inHg) or 340-850 mbar (millibars) is commonly used in vacuum forming processes.