Sheet Metal Cutting

Our Custom Sheet Metal Cutting Services

Provide perfect sheet metal cutting solutions for complex geometric parts at competitive prices. With many years of rich sheet metal cutting experience, we provide customers with unparalleled high-precision sheet metal cutting parts. Get a quote in minutes and parts in days.

- ISO 9001 & ISO13485 Certified Factory

- Advanced equipment & competitive price

- 10+ Years of Sheet Metal Cutting

- Sheet Metal Cutting Parts As Fast As 3 Days

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Sheet Metal Cutting Processes

NOBLE’s sheet metal cutting services can cut almost any material using laser and waterjet capabilities. NOBLE provides a one-stop solution for any project, providing instant quotes, a variety of materials, and a variety of sheet metal cutting process options.

Laser cutting is a thermal cutting process that uses high-power laser to cut metals. Noble provides high-quality laser cut parts in days.

- Quote Within 24 hours

- High Speed and Quality

- Quick Turn Cutting Services

- Competitive Price 30% Cost Save

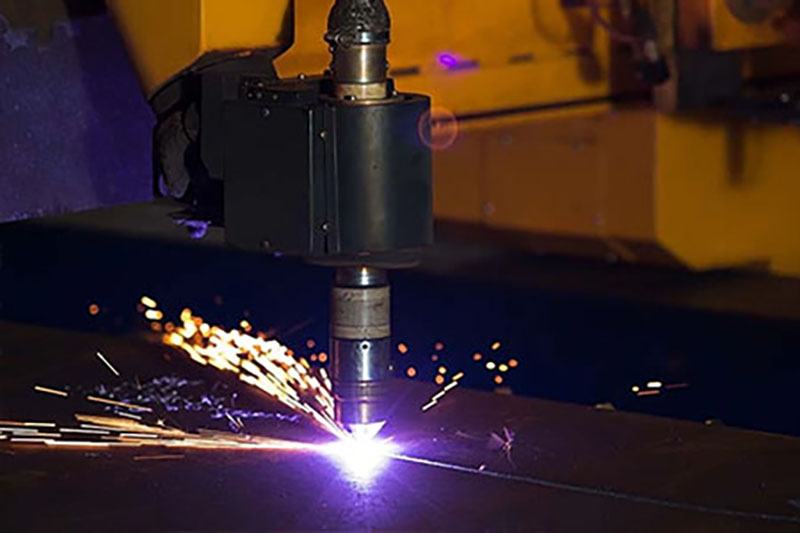

CNC plasma cutting is suitable for cutting thicker sheet metals. Choose our plasma cutting for prototyping and production part fabrication.

- 1-to-1 Quote Analysis

- 100% Part Inspection

- High Precision & Efficiency

- Various Materials Available

It is especially useful for cutting very thick metals, including steel. Our waterjet cutting service is a cost-effective way for on-demand rication.

- Direct Delivery to You

- No Minimum Order Quantity

- Competitive & Affordable Price

- Support Various Complex Patterns

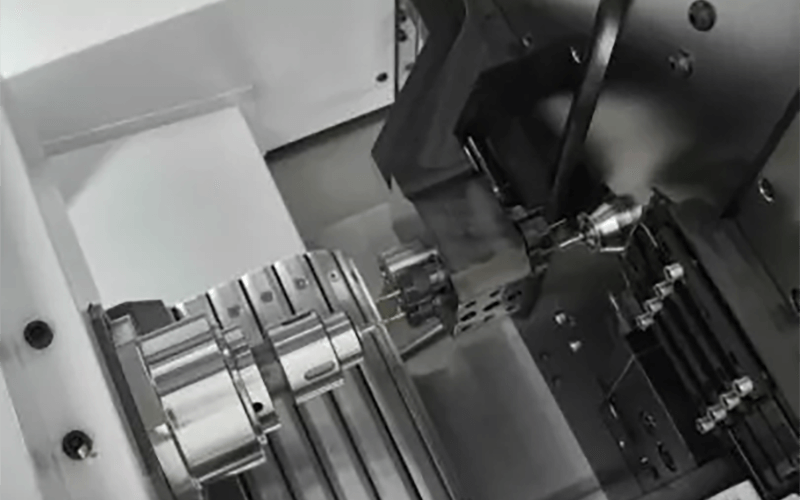

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

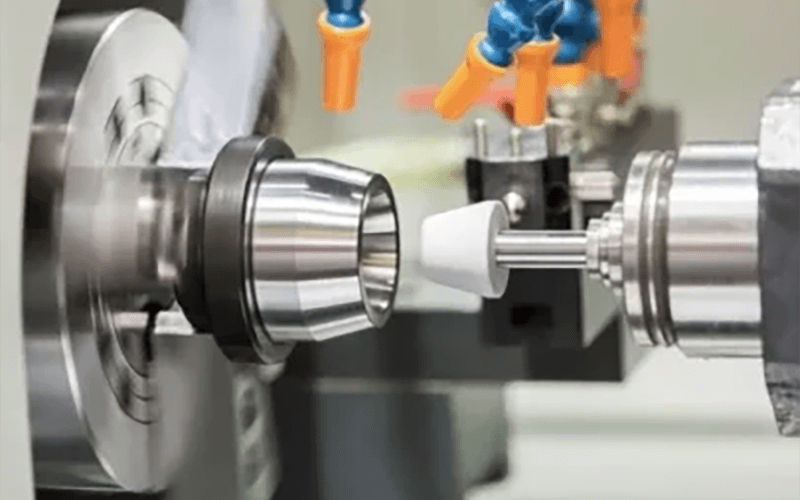

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Sheet Metal Cutting Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.State-of-the-art Equipment

- 10+ Years of Sheet Metal Manufacturing

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Sheet Metal Cutting Services

NOBLE utilizes advanced sheet metal cutting technology to manufacture high-precision sheet metal parts of unparalleled quality. As an ISO 9001-certified sheet metal cutting manufacturer, we possess the necessary machinery, expertise, and stringent quality inspection processes to meet industry standards for flawless prototypes and production parts.

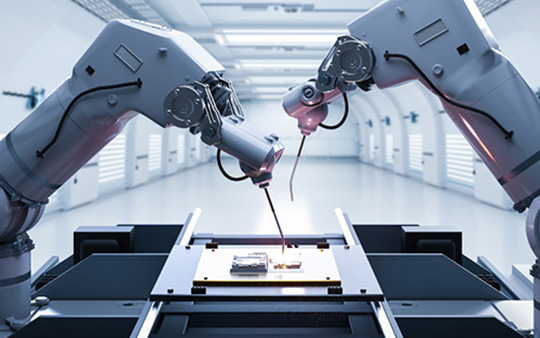

Powerful Factories and Facilities

We have established many of our own factories in China to ensure that your sheet metal cutting is efficient and your delivery time is short. Additionally, our sheet metal cutting capabilities utilize the latest automation facilities to support your various custom sheet metal cutting projects, regardless of their design complexity.

Competitive Pricing

Provide you with high-precision customized sheet metal bending services at competitive prices, from prototype design to sheet metal Fabrication, tailor-made metal bending solutions for you to ensure you get excellent metal bending parts. Our talented team can provide value-added solutions that exceed your budget.

Assured High Quality

NOBLE is certified with ISO13485-2016 and ISO 9001:2015, and every component undergoes a thorough inspection, which guarantees that each part is of top-notch quality and meets your specific standards.

Customization Services

NOBLE provides customized sheet metal parts cutting services according to the specific needs of each customer, from prototype design to manufacturing production, providing customers with high-precision, stable-performance sheet metal cutting parts at competitive prices.

24/7 Engineering Support

No matter where you are, you have access to our 24/7 engineering support year-round. Our experienced engineers can provide the most appropriate sheet metal cutting solution for your part design, material selection, surface finishing options, and even delivery time.

Fast Lead Time

Our strong supply chain and domestic factories with state-of-the-art machinery allow for faster product development and quicker delivery of your sheet metal cutting parts.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Sheet Metal Cutting Standards

To ensure part maneuverability and precision of fabricated prototypes and parts, our custom sheet metal cutting services standards are as following:

| Dimension Detail | Tolerance |

| Edge to Edge, Single Surface | +/- 0.010″ |

| Edge to Hole, Single Surface | +/- 0.010″ |

| Hole to Hole, Single Surface | +/- 0.010″ |

| Hole Diameter, Single Surface | +/- 0.010″ |

| Bend to Edge / Hole, Single Surface | +/- 0.010″ |

| Edge to Feature, Multiple Surface | +/- 0.030″ |

| Over Formed Part, Multiple Surface | +/- 0.030″ |

| Bend Angle | +/- 1 deg |

Materials for Custom Sheet Metal Cutting

NOBLE’s sheet metal cutting service can handle a vast range of premium materials with utmost precision. We work with metals like copper, steel, and aluminum, as well as other materials.

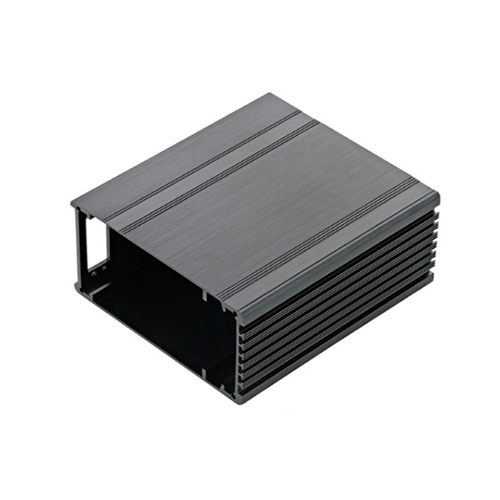

Aluminum

Sheet metal machining often involves the use of aluminum due to its versatility, excellent thermal conductivity, and low resistivity. This material is cost-effective, highly productive, and generates less waste, making it an ideal choice for many applications. Additionally, aluminum is highly reusable, adding to its appeal in the metalworking industry.Subtypes: 2024, 5052, 5083, 6061, 6063, 6082, 7075.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

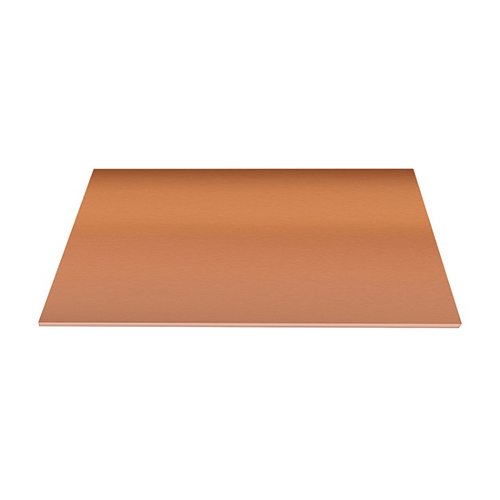

Copper

Due to its strong malleability and ductility, copper is a widely utilized sheet metal fabrication material in numerous sectors. And it is also a good choice for sheet metal manufacturing because of its superior electrical conductivity and heat conduction qualities.Subtypes: C101, C110, C103, C27400, C28000. C36000.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Steel

For industrial applications, steel has a number of advantages, such as rigidity, durability, heat resistance, and corrosion resistance. Steel metal is the best material to use when creating intricate designs and elements that need to be extremely precise. Moreover, steel is inexpensive to deal with and could achieve a superior polishing surface. Subtypes: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140,A36,ST37.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

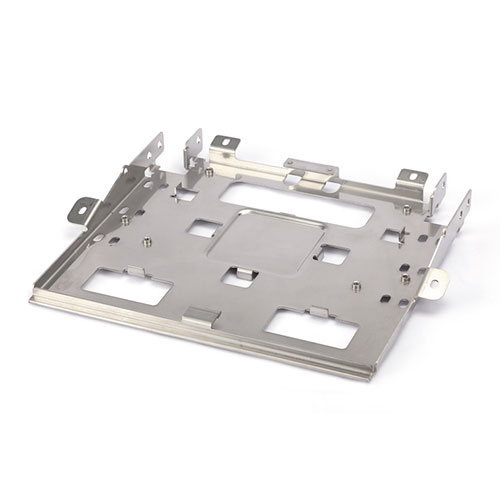

Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for Sheet Metal Cutting

Outstanding surface finishing choices can enhance the surfaces of your bending components and final products. In order to improve the product’s aesthetic appeal and other qualities, a variety of surface finishing could be offered for you from NOBLE.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

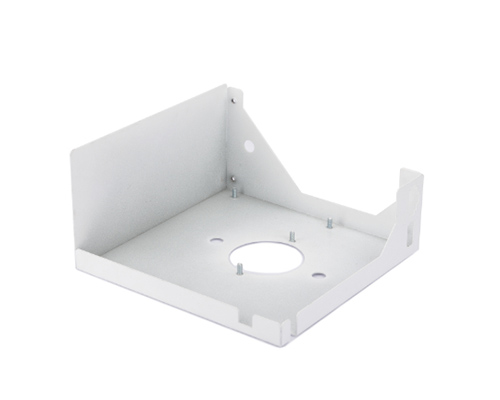

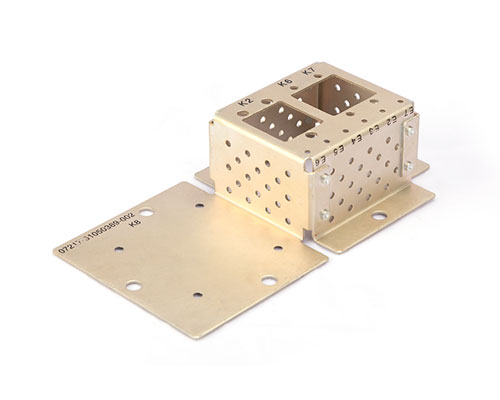

Custom Sheet Metal Cutting Parts Display

Please browse through our extensive gallery showcasing sheet metal cutting parts created by our esteemed customers.

See What Our Customers Say About Us

NOBLE has been engaged in Sheet metal fabrication services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Michael Thompson

Project Manager

I was impressed with the level of expertise and craftsmanship displaved by NOBLE’s sheet metal cuting service.They helped transform my design concept into reality with flawless execution. The cuts were smooth, and the edgeswere perfectly finished. The team provided valuable suggestions and guidance throughout the process, resulting ina final product that surpassed my expectations.

Our Sheet Metal Cutting for Various Applications

Sheet metal cutting is a cost-efficient manufacturing technique used in various industries. NOBLE’s services have aided businesses in creating metal products such as auto parts and medical components.

Oil & Gas

The precise and reliable nature of sheet metal cutting makes it a valuable technique in the oil and gas industry for fabricating components and structures that meet stringent requirements for strength, durability, and safety.

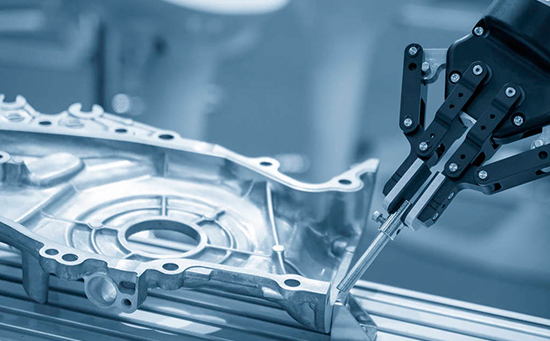

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Metal sheets can be cut in various ways in the automotive industry to produce a variety of robust vehicle parts. Such as fenders, hoods, roofs, and side panels are other vehicle-cutting components.

Aerospace

Precision and close tolerances are necessary for aerospace components. Some lightweight, space-ready component parts like bespoke interface panels, airfoils, and sensor enclosures could be machined by using custom metal cutting services.

Medical Devices

The process of metal cutting is readily available and offers a reliable way to produce long-lasting medical components that meet high standards of accuracy and quality. It can be utilized in the creation of scalpels, surgical instruments, and other essential medical equipment.

Robotics

Sheet metal cutting services are indispensable for precise, strong, and customizable robotics applications. They can create bespoke components that seamlessly integrate with the robot's design and function.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Sheet Metal Cutting of FAQs

Sheet metal cutting is a manufacturing process that involves the separation of flat metal sheets into desired shapes and sizes. It is typically achieved through various methods, including shearing, laser cutting, plasma cutting, and waterjet cutting. Shearing involves using a sharp blade to cut through the sheet metal along a straight line. Laser cutting employs a high-powered laser beam to melt or vaporize the material along a specific path. Plasma cutting utilizes a jet of ionized gas to melt and blow away the metal, while waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through the metal.

Metal cutting by heat involves using hot, high-powered light for processes like plasma and laser cutting to remove excess material.

There are two cutting machines available for cutting metal, namely CNC laser cutters and waterjet cutters. These cutting machines employ different cutting techniques, and as a result, possess distinct cutting advantages.

Its Laser Cutting: This is ideal when you need to cut curves and long cut lines. It’s also the fastest cutting method.

Some Metals like sodium and potassium are very hard and cannot be cut knife easily.

Cutting and machining are two separate processes, each with its own unique characteristics. Cutting involves cutting an object into pieces and removing excess metal or material from a specific workpiece. Machining, however, involves mounting cutting tools in a way that allows the user to manipulate them to achieve a specific task.

Plasma cutting is generally more efficient and faster than other processes. However, for workpiece thicknesses greater than 0.25 in, laser machines make faster cuts. For thicknesses below 2 in, plasma cutting is faster than flame cutting.