Overmolding Services

Our Overmolding Services

Our overmolding services help custom quality parts from prototypes to on-demand production with competitive prices and fast turnaround.

- Advanced Equipment & Cost-Effective Price

- ISO 9001 & ISO13485 Certified Factory

- 10+ Years Experience in Overmolding

- Delivery Time As Fast As 3 Days

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful CNC Machining Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

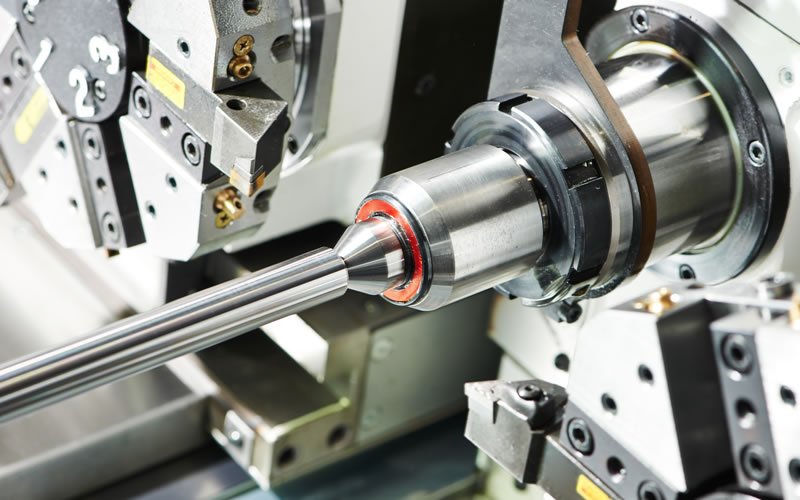

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

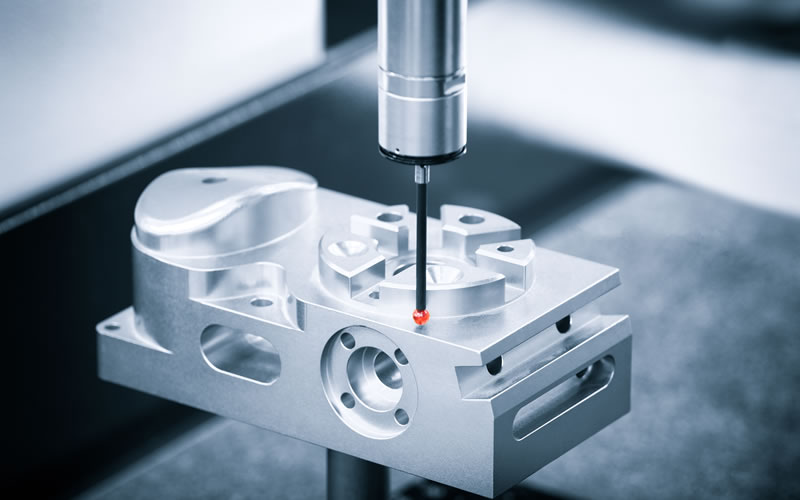

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

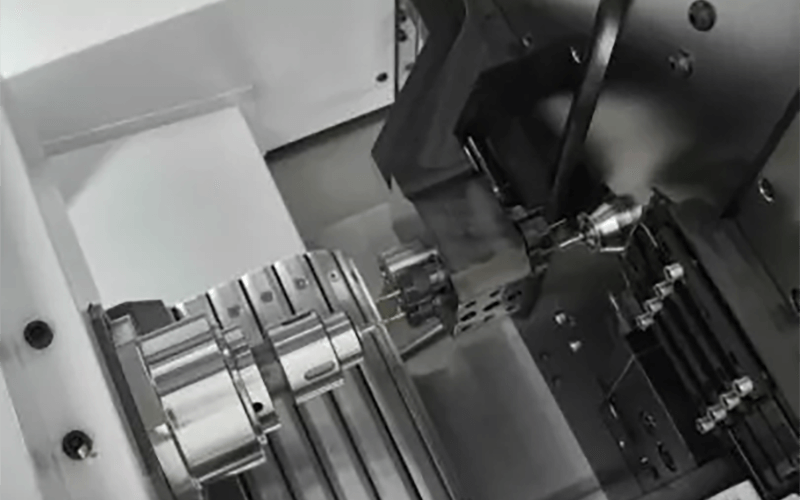

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

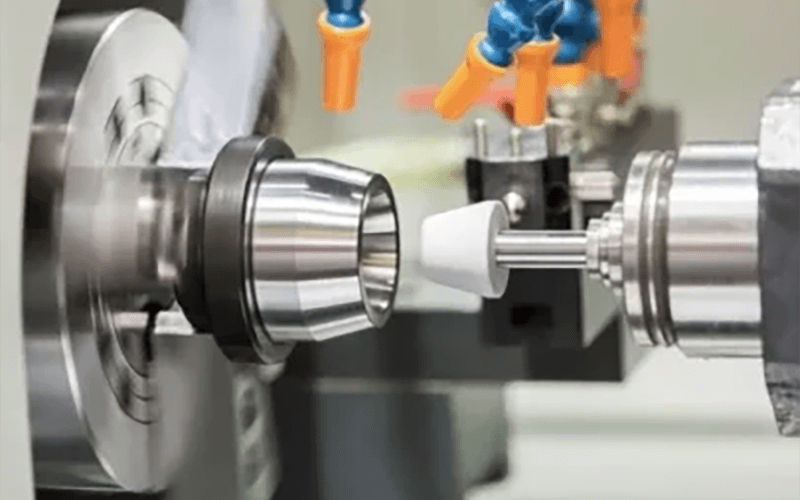

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Overmolding Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

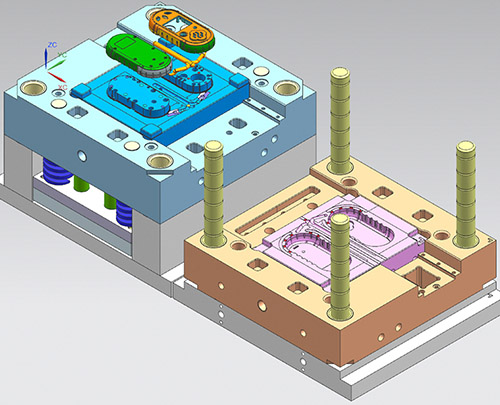

Mold Design & Engineering

Injection mold design is a key element of the injection molding process as it plays an important role in determining the quality and precision of the final injection molded parts. NOBLE has a professional design team to provide you with the best injection mold design solutions.

- 10+ years of Mold Design & Engineering

- State-of-the-Art Equipment

- 1-to-1 Quote Analysis

- Free DFM Feedback

- Strong R & D capability

- Free DFM and Mold Flow Analysis Report

Mold & Prototype Manufacturing

Once the mold design is approved, we begin manufacturing the mold. We then perform prototype injection molding to quickly and efficiently produce and test them for small batch production of plastic parts.

- 10+ Years of Mold & Prototype Manufacturing

- Thousands of resins to choose from

- Competitive & Affordable Price

- State-of-the-art Equipment

- 100% Part Inspection

- Fast Lead Time

Low-Volume & Medium Injection

NOBLE meets your small and medium batch injection molding needs through strict tolerance control, quality inspection, and complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium & Low Injection Molding

- Competitive & Affordable Price

- State-of-the-art Equipment

- Guaranteed Consistent Quality

- 100% Part Inspection

- Fast Turn-Around Production

Why Choose Us for Custom Overmolding Services?

At NOBLE, we take an approach designed to meet your custom overmolding needs. Our aim is to provide engineering specialists and project managers with long term prototype overmolding solutions from design to production. NOBLE combines cost-effective mold machining with technology driven overmolding services, which will improve quality parts, reduce part costs, and escort your machining projects.

Optical MOQ

No restrictive MOQ is needed, which is beneficial for you to make a flexible cash flow. And make sure molded parts are efficient from prototype to production.

Rapid Lead Times

Abundant raw materials supply and adequate machines to speed up production.

Reliable Quality

Owing fully furnished certification and a complete quality inspection process, NOBLE guarantees every component is in good and high precision.

Professional Overmolding Team

Equipped with 10+ Senior Engineers and a well-structured team, making an effective turnaround from prototype to production.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Advantages of Overmolding Process

Reliable Product Performance: Overmolded components are tightly connected, protecting themselves from moisture, and dust. Combining the excellent properties of multiple materials into one, overmolded components ensure better performance.

Slash Production Cost: By overmolding, multiple parts are combined into one. No need to do the assembly. Save time and labor costs, making production more efficient. Therefore, it helps to reduce overall manufacturing costs.

Enhanced design and aesthetics: Overmolding adds one material to another. Some designs and optimations can be made in materials and surface machining.

Overmolding Services Tolerances and Standards

With professional project managers and engineers in overmolding, we help to make your project come true from design to production. NOBLE’s overmolding service is dedicated to ensuring your product’s better performance.

| Standards | Metric Units | Imperial Units |

| Maximum Part Size | 200×400×100mm | 7. 87×15. 75×3. 94in. |

| Minimum Part Size | 2×2×2mm | 0. 08×0. 08×0. 08in. |

| Substrate Wall Thickness | From 0. 5 to 3mm | From 0. 20 to 0. 12 in. |

| Tolerance | +/- 0. 025 mm | +/- 0. 00098 in. |

| Radii | 0. 1mm | 0. 0039in. |

| Depth | 100mm from the parting line | 3. 94in. from the parting line |

| Mold Validation | Provide T0, T1, T2 samples before mass production | |

| Inspection and Certification Options | First Article Inspection, ISO 9001, ISO 13485 | |

| Lead Time | From mold making to sample delivery: 15-45 business days |

Materials for Overmolding

These are common molded plastics offered by our injection molding services. After knowing the basics of materials such as common grades, brands, advantages, and disadvantages, choose the appropriate injection molding material according to your application requirements.

Tooling Materal

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

| Tool Steel: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

| Stainless Steel: | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

| Aluminum: | 6061, 5052, 7075 |

Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

| UV | absorbers | Colorants |

| Flame | retardants | Glass fibers |

| Plasticizers |

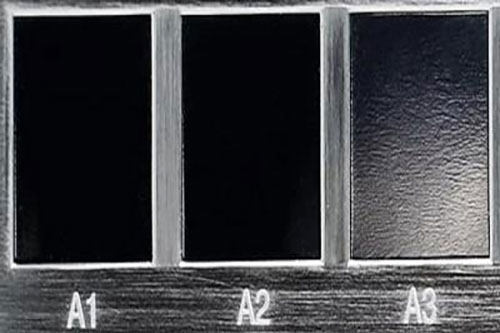

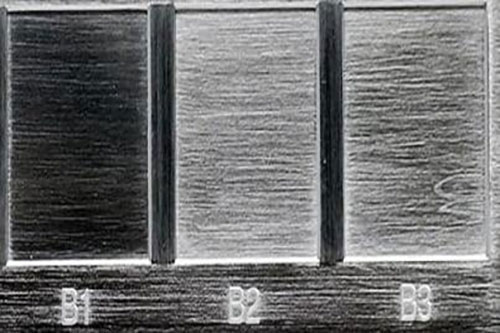

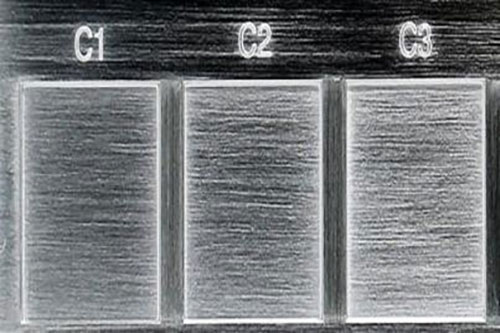

Surface Finishes for Overmolding

Improve the quality of your overmolded parts with excellent surface finishes. NOBLE offers a long list of surface finishing options to improve the cosmetic quality of your products. We provide exceptional secondary operations to improve the overall quality of products.

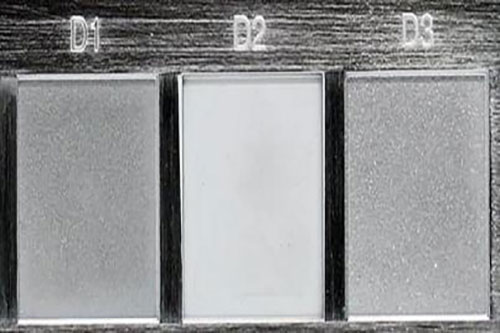

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Custom Overmolded Parts Display

Our custom overmolded parts are designed to enhance performance and durability. Check out our precision custom overmolded parts, including our valued customers’ precision machined prototypes and parts.

See What Our Customers Say About Us

NOBLE’s custom overmolding services ensure the creation of plastic parts that look and perform better. Our production line consists of an overmolding injection molding process that allows us to combine several different materials into one, ensuring you get superior-quality products. Check our valuable customer feedback.

Aaron Nave

Tooling Engineer

We have cooperated with NOBLE for 3 years.NOBLE helped us with overmolded parts. Professional service from design to the product meets our quantity, we will build a long-term partnership with NOBLE

Senior Engineer

Dave stashko

Thanks to all of the staff in NOBLE. Their staff has professional knowledge and is responsible and patient so that we have a smooth process from ideas to manufacturing, This is also one reason we have had business with NOBLE for many years.

Designer

Andy Mandarino

NOBLE is our top supplier of overmolded parts. We have good communication about design. when we received the final product they were so pretty. I recommend it to anyone who wants to custom parts.

Project Engineer

Greg Reginelli

We have been working with NOBLE for 4 years. They help us with many products. They will also provide suggestions for your remanufacturing. And we also are impressed with their skillful knowledge and swift response.

Applications of Overmolding

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Overmolding FAQs

Overmolding is a manufacturing process in which a substrate or pre-existing part is encased in a second material to create a composite part with improved functionality, aesthetics, or durability. The process typically involves two or more stages of injection molding, in which the substrate or first material is molded first and then a second material is molded over it.

Traditionally, overmolding involves placing a part formed in one tool/machine into a second tool to mold a second material over the original part. The result is a part with a strong bond between the two materials. Modern overmolding is now called 2K or overmolding.

Traditionally, overmolding involves two injections of material to form the substrate and overmolding. Insert molding involves only one injection of molten plastic, but metal inserts need to be purchased or fabricated separately.

According to NOBLE’s more than ten years of experience in injection molding, the thickness of the overmolding material should be less than or equal to the thickness of the substrate below it, and at the same time, the melting temperature of the overmolding material should be lower than that of the substrate. Of course, chemical bonding of overmolded materials is not feasible or successful.

Based on the overmolding experience of NOBLE engineers, the overmolding design needs to pay attention to the following two major matters: 1. The wall thickness of the base material and secondary molding should be as uniform as possible to obtain cycle time. 2. Wall thickness should be controlled within the range of 0.711 to 3.81 mm to ensure good adhesion in most overmolding applications.

Overmolding is a manufacturing process that involves molding one material over another to create a composite part with improved functionality, aesthetics, or durability. The process typically involves two steps:

1. First, a substrate material is molded into a specific shape using injection molding or another molding process. The substrate material can be made of metal, plastic, or any other material that can withstand the molding process.

2. Next, a second material, called the overmold material, is molded over the substrate material to create a composite part. The overmold material is chosen for its compatibility with the substrate material, its mechanical properties, and its processing characteristics. The overmold material can be a thermoplastic or thermosetting material, depending on the specific requirements of the application.