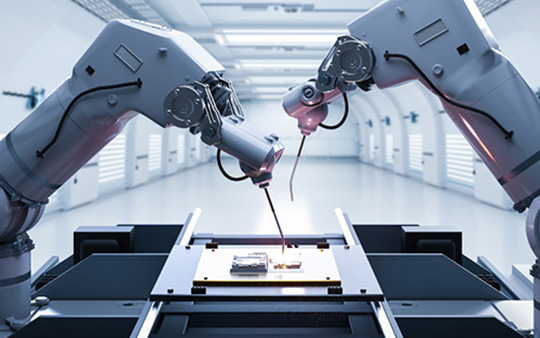

Assembly Services

Our Custom Assembly Service

Put your custom parts together! Our custom assembly services ensure quality, short turnaround times, and meet unique project specifications at competitive prices.

- Advanced Equipment & Cost-Effective Price

- 10+ Years of Assembly

- 1,000 m2 Dust-Free Workshop

- Instant Ensured Precision & Quality in Every Assembly

- Custom Assembly to Meet Project Demands

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

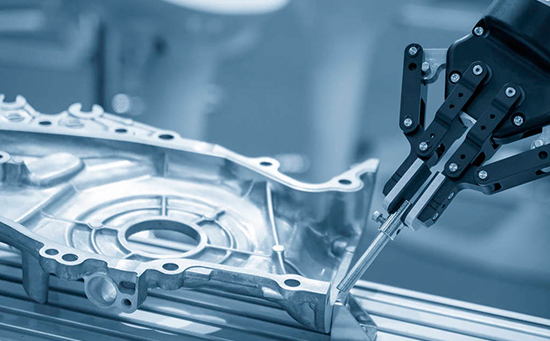

Our Assembly Methods for Metal and Plastic Parts

We offer personalized assembly techniques that are tailored to meet your unique project requirements, with fast turnaround times.

Our skilled technicals accurately piece together components, perfect for projects requiring personalized attention and meticulous craftsmanship.

- 100% Part Inspection

- Direct Delivery to You

- High Precision & Efficiency

- No Minimum Order Quantity

We use molding techniques to integrate parts, either by over-molding or insert molding for robust integration.

- Fast Lead Time

- Direct Delivery to You

- Quote Within 24 hours

- High Precision & Efficiency

Parts can be securely joined through physical methods such as riveting, welding, and screwing, resulting in long-lasting and durable connections.

- 1-to-1 Quote Analysis

- 100% Part Inspection

- Direct Delivery to You

- Durable & Long-lasting Connections

We use strong adhesive to join parts, resulting in a seamless and secure bond without any visible fasteners or marks.

- Precision Assembly

- 1-to-1 Quote Analysis

- Experienced Technicians

- No Minimum Order Quantity

Our Robust Assembly Service Capabilities

Quality Assurance

Easy to Use

Endless Assembly Options

Fast Lead Time

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Assembly Service

Unparalleled precision and precise assembly instructions are tailored to you at competitive prices, ensuring superior part quality on every project from concept to final completion.

Precision Assembly

Excellent assembly capabilities and complete quality inspection processes ensure precision assembly and each component is perfectly matched to optimize product performance and service life.

Strong Assembly Capability

Equipped with a 1000m2 dust-free assembly workshop, which can meet the assembly, testing and packaging requirements of various batch projects.

Tailored Solutions

Our engineering team evaluates your individual needs and matches them with custom assembly options and flexible processes to meet each project's unique specifications.

Expertise and Experience

With years of assembly experience, our experts consistently deliver products that exceed customer expectations, reflecting our mastery of assembled parts precision.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

CNC Machining Tolerances and Standards

With precision CNC machining services, NOBLE is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements for your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 2000×1500×600 mm | 200×500 mm |

| Minimum Part Size | 4×4 mm 0. 1×0. 1 in | 2×2 mm 0. 079×0. 079 in |

| Minimum Feature Size | Φ 0. 50 mm Φ 0. 00197 in | Φ 0. 50 mm Φ 0. 00197 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Hole Diameters | +/- 0. 025 mm +/- 0. 001 in. | +/- 0. 025 mm +/- 0. 001 in |

| Linear Dimension | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Shaft Diameters | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Threads and Tapped Holes | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| NOBLE can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0. 5 mm, depth of 0. 1 mm | NOBLE can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 3 business days | 3 business days |

Materials for Custom CNC Machining Parts

Various materials are available for CNC machines, giving you options for rapid prototyping and custom production runs of complex parts. We provide instant quotes on more than 150 metals and plastics for your manufacturing needs, and you can even compare prices on different processed materials.

Aluminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also a very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

Machinable Material Types: POM, HDPE, PET, Nylon, PTFE, PVC,

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If you don’t want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

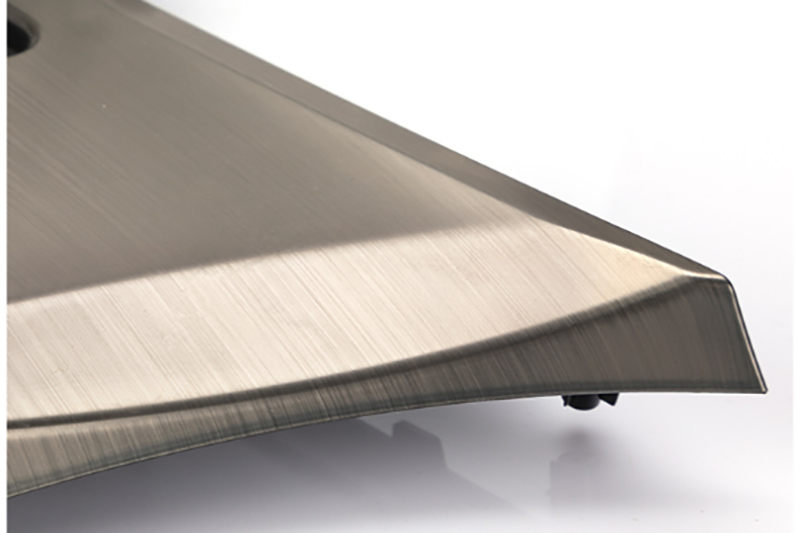

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

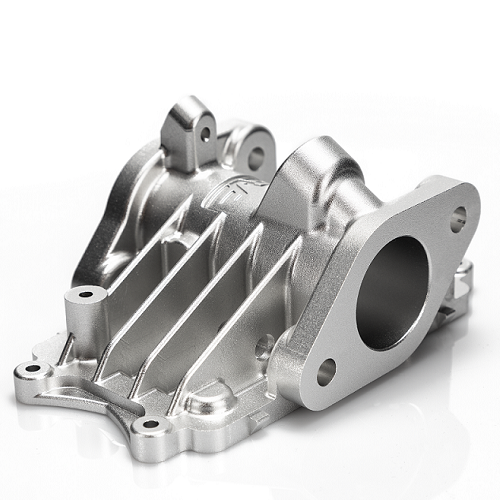

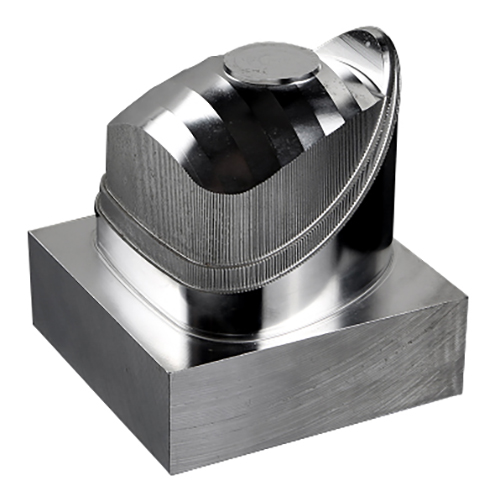

Custom Assembly Services Display

Check out our over a decade of precision custom assembly parts, including precision machined prototypes from our valued customers.

See What Our Customers Say About Us

The feedback of customers has a greater impact than a company’s advertising. Take a look at what our satisfied customers have to say about how we met their needs.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Stefan Hohmann

Product Manager

My experience with NOBLE has been nothing but exceptional. From the start, the communication has been accurate and fast. Specificities of the design that may meet production difficulties are promptly pointed out with suggested solutions. The price of CNC machined parts is competitive. The QC of the final product is also excellent. There is no doubt that I will go back again.

Our Assembly Service for Various Needs

We specialize in accurately assembling a wide range of steel structures, metal parts, and specialized equipment with care.

- Metal parts assembly

- Plastic products assembly

- Structural steel assembly

- Proprietary equipment assembly

- Electrical assemblies

- Inplant tools and tooling

Our Custom Assembly Service Case

Power Equipment Inspection Robot

A power equipment inspection robot was constructed by NOBLE for a leading industrial company, has been assembled by NOBLE, and is now functional. The robot has proven advantageous in terms of improving efficiency, and worker safety, and reducing labor costs, resulting in projects that are safer, more efficient, and more cost-effective. Our engineering team closely assembles the multiple components to ensure that they meet the customer’s specific requirements. To cater to the robot’s unique size and shipping concerns, NOBLE went beyond expectations and provided custom packaging. This not only guarantees quality but also ensures safe delivery, ultimately making projects more efficient and environmentally friendly.

Our Custom Assembly Applications

Providing unparalleled precision and custom assembly solutions at competitive prices to various industries including automotive, aerospace, electronics, appliances, telecommunications, and medical devices. NOBLE is committed to providing innovative assembly solutions, guiding customers on each project from initial concept to final completion, and maintaining the highest standards of product quality to meet the diverse needs of customers.

Oil & Gas

NOBLE's professionals have an in-depth understanding of parts assembly technology in industries such as oil and gas and use advanced assembly technology to ensure high product accuracy and shorten customer product development cycles.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our assembly services enhance a variety of components that help improve the performance, safety, and aesthetics of vehicles in the automotive industry.

Aerospace

Our custom assembly services provide high-quality, precise, and durable components that meet the stringent requirements for aircraft safety, performance, and reliability.

Medical Devices

Our custom assembly services are carefully designed to meet the stringent requirements of the medical industry, ensuring every part we produce meets or exceeds the highest standards, greatly increasing product performance and longevity.

Robotics

Our cutting-edge capabilities, innovative processes, and skilled engineering teams can be solved through advanced custom assembly services to better serve the robotics field and greatly improve robot performance and longevity.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Our Assembly Service FAQS

Our knowledge spans a wide variety of custom parts, from metal and plastic parts to electrical assembly and specialised machinery. With our cutting-edge methods and specialised tools, we are able to manage a variety of assembly projects that are suited to certain industry requirements.

Assembly services can be beneficial for several reasons. Firstly, they save you time and effort by handling the complex assembly process on your behalf. This is especially helpful if you lack the necessary tools, skills, or patience to assemble the item yourself. Additionally, professional assembly often ensures proper setup, reducing the risk of errors or damage that could occur during self-assembly.

Although we are capable of handling a wide range of sizes and weights, there are some restrictions to maintain the highest levels of quality and safety. The best way to determine the viability of your idea is to discuss its details with our experts.

At every level of our assembly process, we incorporate strict quality controls. We use cutting-edge testing techniques and thorough oversight from design review to final inspection to ensure the reliability and functionality of the manufactured parts.