Slimming Instrument Shell Machining

If you would like to know what equipment we have, please click here.

Quick Details:Name Respiratory Instrument Shell Machining Materials Plastic Size Customer’s 3D/2D drawing Color As your requirement ProcessC

Quick Details

| Name | Respiratory Instrument Shell Machining |

| Materials | Plastic |

| Size | Customer’s 3D/2D drawing |

| Color | As your requirement |

| Process | CNC milling, turning, etc. |

| Drawing files | IGS, STP, STEP, IGES, STL, JPG, PDF, CAD, etc. |

| Brand name | Noble |

| Palace of origin | Shenzhen, China (mainland) |

What can we do

|  |  |  |

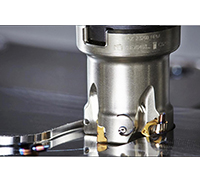

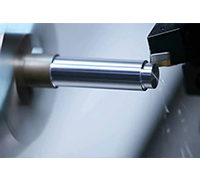

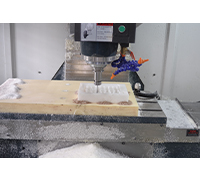

| Projects Supporting | CNC-Milling | CNC-Turning | CNC-Stamping |

|  |  |  |

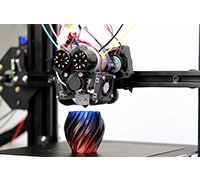

| Die-Casting | Plastic-Injection-Molding | Rapid Prototype | 3d-Printing-Service |

| Noble CNC Service | Include |

| Main service | 1, Structure design optimization; 2,CNC Machining: to make medium & low volume metal parts 3,Rapid Prototyping: CNC, 3D printing(SLA, SLS); Also we can provide the following service to meet your demand; Rapid Tooling, die-casting, Extrusion molding , Silicone mold vacuum casting, etc. |

| Drawings | 3D: step/stp, igs, prt , sld,etc. 2D:.dwg . pdf. cdr . ai, other pictures format. |

| 3D Software | Pro-e (Creo) UG Solid works Catia Rhinoceros 3dmax |

| 2D Software | AutoCAD Photoshop CorelDraw Adobe Illustrator |

| Plastic Material | ABS, Acrylic/PMMA, PP(Polypropylene),PC(Polycarbonate),PU(Polyurethane),POM(Delran,Acetyl),PVC, PE(Polyethylene), PA(Nylon, Polyamide) PEEK(Polyetheretherketone), Chemical Wood, etc; |

| Metal Material | aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, brass, bronze, stainless steel,SUS303, SUS304, 45 steel, iron, Galvanized steel sheet, sheet metal, SPCC, etc; |

| Manufacture process | 1. CNC Machining Center: Milling, drilling, turning, threading, tapping, boring, facing, spotting, counter boring. 2. CNC Milling: High precision milling, numerical control carving and milling, CNC engraving and milling. 3. CNC Bending: Bending-High precision seamless bending, sheet metal bending. 4. CNC Punching: Punching/stamping-High precision Sheet Metal Fabrication. 5. Welding: GMAW Welding, MIG Welding, Laser welding. 6. Laser cutting: High precision cutting. 7. Molding/Tooling: Rapid Tooling, die-casting, Extrusion molding, Silicone mold vacuum casting, etc. 8. 3D printing: SLA, SLS, FDM. |

| Our advantage | 1. Quick response: we will respond once we get your inquiry, then provide cost within 1 hour. 2. Low price: We can offer you the lowest price of the same quality. 3. Complex parts: Good at machining parts with complicated curved surfaces. 4. Perfect quality: Strictly control the machining and finish treatment quality, what you will get is what you designed. 5. Accurate delivery: Finish the parts in time to provide the strongest support for your R&D projects. 6. Rich experience: More than 10 years of professional machining and rapidv prototyping experience, provide you with the most professional and effective advice. 7. Professional team: Efficient and honest technical and service team, let you enjoy 24H professional services. 8. Fully equipped: Perfect supply chain, complete processes, one-stop solution to all requirements. |

FAQ

- Q

Can I get a sample in advance to check the quality?

ASamples are available. We can make samples for you around 7 days, once samples are confirmed, mass production will be arranged immediately after your authorization.

- Q

How can I know my order is going without visiting your company?

AWe will make the schedule for each order and send you photos of the machining progress.