Picture a manufacturing process so efficient and precise that it shapes everything from life-saving medical devices to thousands of automotive parts with ease. Injection molding is a process, one of the most widely used techniques around the globe. In this article, we’ll explore its remarkable benefits, diving into how custom molds, plastic injection molding, and specialized services can completely overhaul your production capabilities.

What is Injection Molding?

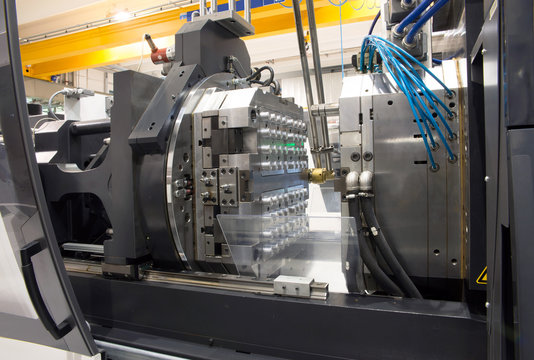

Injection molding is a manufacturing method where molten plastic is injected into a mold to fabricate parts. The efficiency and accuracy of this process depend on three key components:

- Injection Molding Mold: The mold represents the central element in the injection molding process, dictating the shape and precision of the final product. Typically manufactured from steel or aluminum, mold designs can be optimized for complex geometries and detailed features.

- Injection Unit: This unit performs two critical functions: melting the plastic material and injecting it into the mold under high pressure, which is essential for achieving consistent quality.

- Clamping Unit: The clamping unit maintains mold stability by holding it securely during the injection and cooling stages, ensuring dimensional accuracy and process integrity.

ABS, polypropylene (PP), polycarbonate (PC), and nylon—these are some of the materials typically employed in injection molding, prized for characteristics like toughness, flexibility, and heat endurance.

Key Benefits of Injection Molding

- High Precision and Consistency

One of the standout advantages of injection molding is its ability to produce parts with extremely tight tolerances, as low as ±0.005 inches. This level of precision is critical for industries like medical devices and aerospace, where even the smallest deviation can lead to product failure.

- Repeatable Production: With a finalized mold, manufacturers can produce thousands of identical parts with minimal variation, ensuring high-quality standards are met across large production runs.

- Example Use Case: Injection molding reliably meets the exacting standards required for medical devices like syringes and surgical instruments, where precision is paramount.

- Cost Efficiency for Mass Production

The initial investment in injection molding molds can be high, but as production quantities increase, the per-unit cost decreases dramatically. This cost efficiency makes injection molding ideal for mass production.

- Efficient Material Use: Compared to other manufacturing processes, injection molding produces minimal waste. Excess plastic is frequently recyclable, further cutting material expenses.

- Example in Industry: The automotive sector leverages injection molding to produce millions of parts, including dashboards and bumpers, at a reduced cost.

- Exceptional Design Flexibility

Injection molding provides unmatched design flexibility, enabling manufacturers to produce complex shapes, thin walls, and intricate details that would be challenging or impossible with other manufacturing methods.

- Customization Capabilities: Custom injection molding services allow businesses to tailor designs to their exact specifications, whether that involves unique shapes or integrated functionalities.

- Industry Example: The consumer electronics industry relies on injection molding for products like smartphone cases and laptop housings, where complex and precise designs are essential.

- Fast Production Cycles

Injection molding delivers incredibly fast production cycles, with parts often completed in just seconds. This makes it ideal for high-volume manufacturing scenarios.

- Rapid Prototyping: The ability to quickly test and refine designs through injection molding prototyping helps companies reduce product development timelines.

- Industry Example: The toy industry uses injection molding to swiftly produce and test new designs, ensuring products meet quality standards before full production begins.

- Wide Range of Materials

Injection molding offers the flexibility to use a wide variety of thermoplastics, each designed to meet diverse application needs with specific properties.

- Commonly Used Plastics: Typical plastics used in injection molding include ABS (known for its durability and impact resistance), polypropylene (renowned for chemical resistance), and polycarbonate (valued for its transparency and heat resistance).

- Specialized Materials: Industries like aerospace often use high-performance materials such as PEEK (polyether ether ketone), prized for its exceptional strength and heat resistance.

- Industry Example: The aerospace industry relies on injection molding to produce components that are both lightweight and exceptionally strong, meeting rigorous performance standards.

- Durability and Strength

Injection molding is known for producing parts that are both durable and strong, making it an ideal choice for applications requiring high performance over time.

- Quality and Toughness: Parts manufactured through injection molding are highly resistant to wear and tear, ensuring durability and reliability.

- Example in Industry: Industrial gears and valves, manufactured using injection molding, excel under harsh conditions, maintaining strength and durability in extreme environments.

- Scalability

Injection molding offers exceptional scalability, enabling both low-volume prototyping and large-scale production to meet evolving manufacturing needs.

- Custom Injection Molding Services: These services allow businesses to begin with small batches and increase production as demand grows, making it a flexible solution for startups and large corporations.

- Industry Example: A startup may use injection molding to create a small batch of prototypes for initial testing, while a large manufacturer can produce millions of parts when demand increases.

- Sustainability

Sustainability is a growing advantage of injection molding, offering environmental benefits alongside manufacturing efficiency.

- Material Recycling: Waste plastic from the process is recyclable, reducing environmental impact and material costs.

- Energy Conservation: Injection molding machines today are built to be more energy-efficient, reducing overall energy usage.

- Eco-Friendly Materials: The industry is shifting towards biodegradable plastics and recycled materials to reduce environmental impact.

- Industry Example: Packaging companies use injection molding to produce sustainable containers and lids, helping reduce plastic waste.

Applications of Injection Molding

Injection molding is essential in many industries due to its precision and efficiency:

- Automotive: Parts like dashboards, bumpers, and interior trim are made with injection molding for enhanced quality and safety.

- Medical: High-precision items such as syringes, surgical instruments, and implantable devices rely on this manufacturing method.

- Consumer Goods: Toys, kitchen utensils, and electronic housings benefit from the process’s consistency and efficiency.

- Industrial Equipment: Gears, valves, and connectors are produced with the durability and precision required for industrial use.

Injection Molding Mold: Design and Maintenance

A well-designed and maintained mold is key to the success of injection molding processes. Consider the following:

- Mold Design: Designing parting lines, gating systems, and cooling channels correctly is crucial to ensure optimal mold function and part accuracy.

- Mold Materials: Steel molds offer high durability for large-scale production, while aluminum is ideal for lower volume or simpler parts due to its cost-effectiveness.

- Mold Maintenance: Regular maintenance practices, such as cleaning, lubrication, and detailed inspections, are essential to prolong mold life and maintain product quality.

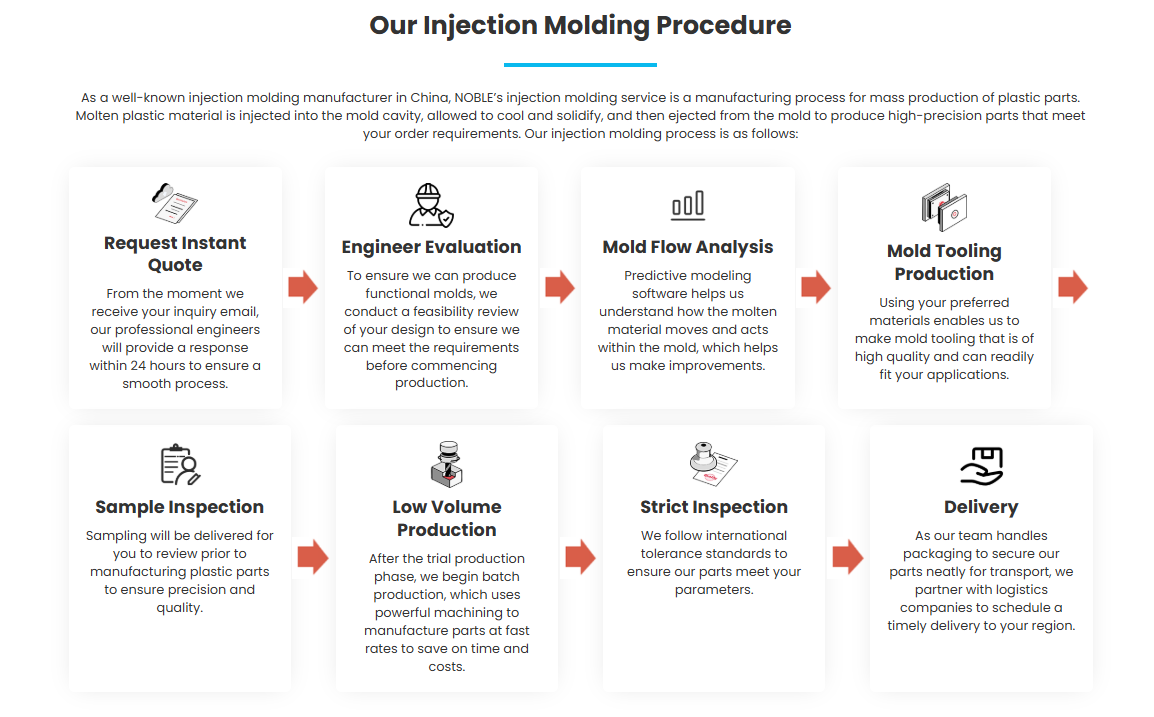

Our Injection Molding Procedure

As a well-known injection molding manufacturer in China, NOBLE’s injection molding service is a manufacturing process for the mass production of plastic parts. Our injection molding process is as follows:

NOBLE Custom Injection Molding: Precision Solutions, Personalized for You

At NOBLE, our custom injection molding services combine flexibility with precision, ensuring efficient production of your unique components.

- Tailored Design Solutions: We customize designs to your injection molding parts—whether intricate details, unique shapes, or integrated features—boosting both functionality and appearance.

- Scalable Production: From prototype testing to mass production, we adjust our processes to meet your needs without compromising quality.

- Technical Expertise: Our expert engineering team, supported by cutting-edge injection molding technology, delivers components that meet the highest industry standards.

Future Trends in Injection Molding

The future of injection molding is being shaped by technological advancements and sustainability initiatives:

Automation and Smart Manufacturing: AI and IoT technologies enable real-time process monitoring and optimization, improving efficiency and product quality.

Sustainability: The Adoption of biodegradable plastics and energy-efficient machinery is increasing, reducing the environmental impact of injection molding.

Advanced Materials: The development of high-performance polymers is broadening the range of applications, offering stronger, more heat-resistant, and lightweight components.

Take Your Manufacturing to the Next Level with Injection Molding

Ready to explore injection molding for your next project?

Contact NOBLE today for a free consultation or quote and discover how custom services can streamline your production and achieve your manufacturing targets.