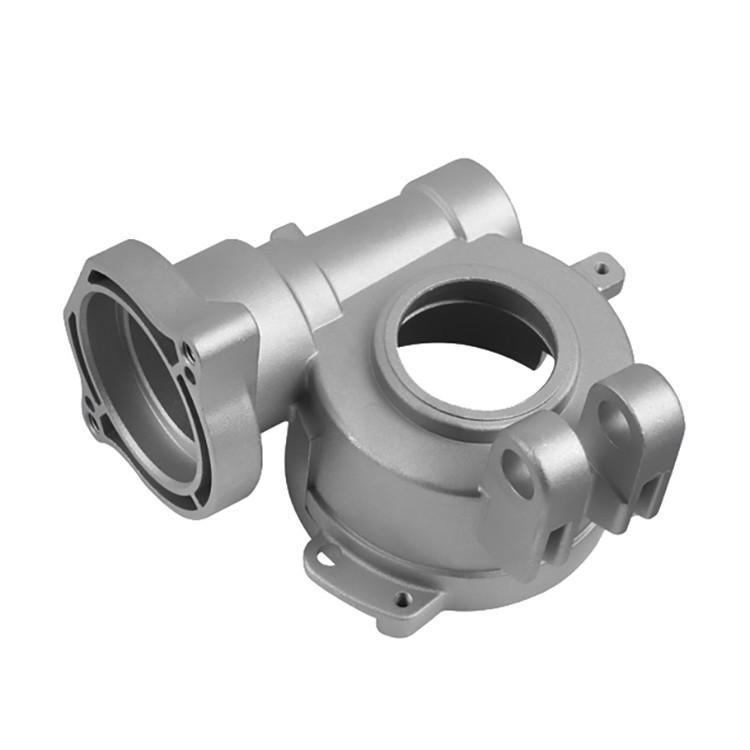

Among various manufacturing methods, die casting stands out as one of the most important. With die casting, companies can manufacture robust, precise, and complex metal components efficiently. The automotive, aerospace, electronics, and medical device industries make extensive use of these processes.

In this guide, we will explore the workings of die casting, commonly used materials, and how to select the appropriate alloy and surface finish. Additionally, it discusses mold production and criteria for choosing a trustworthy die casting partner. Whether you’re new to manufacturing or looking for improved production solutions, this article offers valuable insights to guide your decisions.

What Is Die Casting?

Die casting is a metal casting process that involves forcing molten metal under high pressure into a mold cavity. The mold cavity is formed using two hardened tool steel dies machined into shape, functioning like an injection mold during the process.

6 Types of Die Casting

🔩 1. Hot Chamber Die Casting

✅ Best for :

-

Low melting point metals: Zinc, magnesium, lead, and some copper alloys

🔧 How it works:

-

The injection mechanism is submerged in molten metal.

-

Metal is fed into the die cavity through a gooseneck system.

💡 Advantages:

-

Fast cycle times

-

High production efficiency

-

Long die life (especially with zinc)

-

Lower maintenance

❌ Disadvantages:

-

Not suitable for high melting point metals like aluminum (it would damage the gooseneck components)

❄️ 2. Cold Chamber Die Casting

There are four main types of die casting, each suitable for different applications depending on the metal type, part complexity, production volume, and required surface finish. The following are the 6 most common types of die casting:

✅ Best for:

-

High melting point metals: Aluminum, brass, copper alloys

🔧 How it works:

-

Molten metal is poured manually or automatically into a cold injection chamber and then forced into the die using a piston.

💡 Advantages:

-

Can handle metals that are too corrosive or hot for hot chamber systems

-

Good mechanical properties

-

Widely used in automotive and aerospace

❌ Disadvantages:

-

Slower cycle times than the hot chamber

-

More complex equipment and handling

🌀 3. Vacuum Die Casting

✅ Best for:

-

High-performance aluminum and magnesium parts (e.g., aerospace, automotive structural parts)

🔧 How it works:

-

A vacuum is created in the mold cavity before injecting the metal to reduce air entrapment.

💡 Advantages:

-

Minimizes porosity (better for welding and heat treatment)

-

Increases strength and structural integrity

-

Better surface finish

❌ Disadvantages:

-

More expensive machinery

-

Slower cycle times

🧬 4. Squeeze Die Casting (Liquid Metal Forging)

✅ Best for:

-

High-strength aluminum and magnesium components

🔧 How it works:

-

Molten metal is poured into an open die and squeezed under high pressure until solidified.

💡 Advantages:

-

Very low porosity

-

Excellent mechanical properties (almost like forging)

-

Ideal for parts requiring heat treatment

❌ Disadvantages:

-

Lower production rate

-

Higher equipment cost

🧬 5. Gravity Die Casting (GDC)

✅ Best for:

-

Gravity Die Casting is most suitable for non-ferrous metals with good fluidity and relatively low melting points.

| Material | Why It’s Suitable | Applications |

|---|---|---|

| Aluminum alloys | Lightweight, good fluidity, corrosion resistance | Engine parts, housings, cookware |

| Magnesium alloys | Very light, good strength-to-weight ratio | Automotive and aerospace parts |

| Copper alloys (e.g., brass, bronze) | Good thermal/electrical conductivity | Plumbing fittings, electrical components |

| Zinc alloys | Good fluidity, easy to cast fine details | Small complex components, hardware |

🔧 How it works:

-

The principle of gravity die casting is to fill the molten metal into the metal mold using only gravity, without any external force or pressure.

💡 Advantages:

-

Lower tooling and equipment cost compared to LPDC.

-

Faster cycle time, leading to higher productivity for simple parts.

-

Good surface finish and dimensional accuracy.

-

Permanent mold allows for repeated use and consistent parts.

-

Suitable for medium to large production runs.

-

Relatively simple process and machinery.

❌ Disadvantages:

-

Higher porosity due to uncontrolled, turbulent filling.

-

Limited design complexity, especially for thin-walled or intricate parts.

-

Less control over metal flow, which may lead to casting defects.

-

Mechanical properties may be lower unless further processed (e.g., heat-treated).

-

Manual pouring can introduce inconsistencies.

🧬 6. Low-Pressure Die Casting (LPDC)

✅ Best for:

Aluminum alloy is an ideal material for low-pressure die casting and is widely used in the automotive, consumer electronics, and medical industries.

| Material | Characteristics That Suit LPDC | Common Applications |

| Magnesium Alloys | Lightweight, good strength, decent castability | Automotive components, electronics casings |

| Copper Alloys | High conductivity, good strength, corrosion resistance | Electrical parts, plumbing fittings |

| Brass | Good fluidity, machinability | Valves, decorative hardware |

| Aluminum Alloys | Lightweight, good strength, decent castability

good strength, corrosion resistance, Good fluidity, and machinability |

Widely used in automotive wheels, engine components, and aerospace structures |

🔧 How it works:

-

Low-pressure die Casting works on the principle of forcing molten metal upward into a mold cavity using low-pressure air, resulting in smooth, controlled filling and high-quality castings.

💡 Advantages:

-

Very low porosity due to smooth, laminar metal flow

-

Excellent dimensional accuracy and surface finish

-

Better mechanical properties, suitable for heat treatment

-

Allows thin-walled and complex geometries

-

Highly controllable process, reducing scrap and improving repeatability

-

Good for large structural parts, like automotive wheels and chassis components

❌ Disadvantages:

-

Higher equipment and tooling costs

-

Longer cycle times compared to GDC

-

More complex setup and process control

-

Requires pressurized systems and greater operational expertise

Advantages & Disadvantages of The Die Casting Process

Die casting is a manufacturing process where molten metal is injected under high pressure into a mold cavity. It is widely used for producing complex metal parts with excellent surface finish and dimensional accuracy. Here’s a breakdown of the pros and cons:

✅ Pros of Die Casting

-

High Precision and Accuracy

-

Produces parts with tight tolerances and consistent dimensions.

-

Minimal machining or finishing is often required.

-

-

Excellent Surface Finish

-

Parts come out with a smooth surface, reducing the need for post-processing.

-

-

High Production Rate

-

Ideal for mass production—once the mold is ready, thousands of parts can be made quickly.

-

-

Durable and Strong Parts

-

Good mechanical properties, especially with non-ferrous metals like aluminum, zinc, and magnesium.

-

-

Design Flexibility

-

Complex shapes, thin walls, and fine details are easily achievable.

-

-

Material Efficiency

-

Minimal waste; excess metal can often be recycled.

-

❌ Cons of Die Casting

-

High Initial Cost

-

Expensive molds (dies) and setup make it cost-effective only for high-volume production.

-

-

Limited to Non-Ferrous Metals

-

Typically used with aluminum, zinc, and magnesium. Not suitable for steel or iron.

-

-

Porosity Issues

-

Trapped gas can lead to porosity, which can weaken the part and affect surface finish or plating.

-

-

Size Limitations

-

Best for small to medium-sized parts; large parts may require specialized, costly equipment.

-

-

Lead Time

-

Designing and producing the die takes time, which can delay initial production.

-

-

Limited Post-processing (e.g., Heat Treatment)

-

Some die-cast alloys can’t be heat-treated easily, limiting mechanical property enhancements.

-

Die Casting Pros and Cons Summary:

| Aspect | Die Casting |

|---|---|

| Cost (setup) | High |

| Cost (per unit) | Low (in volume) |

| Tolerance/Accuracy | Excellent |

| Production Volume | High |

| Suitable Metals | Non-ferrous only |

| Surface Finish | Very Good |

| Environmental Impact | Moderate (recycling helps) |

Die Casting Compared to Other Manufacturing Processes

Here’s a comparison of die casting with other common manufacturing processes, highlighting where it excels and where alternatives might be better suited:

🔧 1. Die Casting vs. Sand Casting

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Surface Finish | Smooth, high-quality | Rougher surface |

| Dimensional Accuracy | High | Moderate |

| Tooling Cost | High (expensive dies) | Low (cheap molds) |

| Production Volume | High | Low to medium |

| Material Types | Non-ferrous (mainly) | Ferrous and non-ferrous |

| Setup Time | Long (due to die design) | Short |

| Part Size | Small to medium | Small to very large |

| Cycle Time | Very short (fast production) | Long (slow cooling, manual handling) |

| Reusability of Mold | Thousands of cycles | One-time use |

🔹 Summary:

-

Use die casting for high-volume, precise, and aesthetic metal parts.

-

Use sand casting for large, low-volume, or ferrous metal parts.

🛠️ 2. Die Casting vs. Injection Molding

| Feature | Die Casting | Injection Molding |

|---|---|---|

| Material | Metals (mainly aluminum, zinc, etc.) | Thermoplastics (plastics) |

| Tooling Cost | High | High |

| Production Volume | High | High |

| Surface Finish | Excellent | Excellent |

| Weight of Products | Heavier (metal) | Lighter (plastic) |

| Strength | High (metal) | Lower (plastic) |

| Applications | Automotive, electronics, tools | Consumer goods, medical, and packaging |

🔹 Summary:

-

Die casting is best for strong, durable metal parts.

-

Injection molding is best for plastic parts with similar production advantages.

⚙️ 3. Die Casting vs. CNC Machining

| Feature | Die Casting | CNC Machining |

|---|---|---|

| Material Waste | Low (recyclable sprues/runners) | High (material removed) |

| Tolerance | High | Very high (precise) |

| Complexity of Design | High (complex shapes possible) | High, but often limited by tools |

| Speed (per part) | Very fast (after setup) | Slower |

| Cost (per part) | Low in volume | High (especially in volume) |

| Setup Time | High | Low to medium |

🔹 Summary:

-

Die casting wins for the mass production of complex shapes.

-

CNC machining excels at low-volume, high-precision, or prototype work.

🧰 4. Die Casting vs. Forging

| Feature | Die Casting | Forging |

|---|---|---|

| Strength | Good, but can have porosity | Very high (grain structure improved) |

| Design Complexity | High (complex shapes, thin walls) | Low to moderate |

| Surface Finish | Excellent | Rough |

| Dimensional Accuracy | High | Moderate |

| Cost | Lower in high volume | Higher per unit |

🔹 Summary:

-

Forging produces very strong parts for structural use.

-

Die casting offers better design flexibility and finish.

✅ Conclusion: When to Use Die Casting

Choose die casting if you need:

-

High-volume metal parts

-

Complex geometries and fine details

-

Excellent surface finish and dimensional control

-

Economies of scale after initial tooling investment

For lower volumes, large parts, or materials like steel, other processes (like sand casting or CNC machining) may be more suitable.

Let me know if you want a downloadable comparison chart or industry-specific recommendations!

Material Selection for Die Casting

🧪 Introduction to Die Casting Materials:

Die casting involves forcing molten metal into a mold cavity under high pressure. The choice of material is critical because it affects mechanical properties, corrosion resistance, surface finish, machinability, and cost. Die casting typically uses non-ferrous metals due to their lower melting points and better flow characteristics.

| Factor | Aluminum | Zinc | Magnesium | Copper |

|---|---|---|---|---|

| Strength | Moderate | High | Moderate | High |

| Weight | Low | Moderate | Very Low | High |

| Cost (material) | Moderate | Low | High | Very High |

| Corrosion Resistance | High | Moderate | Low to Moderate | High |

| Machinability | Good | Excellent | Excellent | Moderate |

| Die Life | Moderate | Very High | High | Low |

| Melting Point (°C) | ~660 | ~390 | ~650 | ~1080 |

Aluminum die casting Service

Aluminum, a primary material in die casting, is used in cold-chamber die casting with alloys containing magnesium, copper, and silicon. Aluminum die casting is ideal for producing intricate and finely detailed parts, as it is lightweight and has great dimensional stability. It also provides benefits like resistance to high temperatures, excellent conductivity, and corrosion resistance.

Common die-casting aluminum alloys include:

| 360 | A360 | 380 | A380 | 383 | |

| Density | 2.63g/cm³ | 2.63g/cm³ | 2.74g/cm³ | 2.71g/cm³ | 2.74g/cm³ |

| Melting Range(℃) | 557-596 | 557-596 | 540-595 | 540-595 | 516-582 |

| Electrical

Conductivity |

30% IACS | 29% IACS | 27% IACS | 23% IACS | 23% IACS |

| Thermal

Conductivity |

113 W/(m’ K) | 113 W/(m’ K) | 96.2 W/(m’ K) | 96.2 W/(m’ K) | 96.2 W/(m’ K) |

| Ultimate Tensile Strength | 300 MPa | 320 MRa | 320 MRa | 320 MRa | 310 MRa |

| Yield Strength | 170 MPa | 170 MPa | 170 MPa | 170 MPa | 170 MPa |

| Hardness | 75 BHN | 75 BHN | 75 BHN | 75 BHN | 75 BHN |

| Fatigue Strength | 140 MPa | 140 MPa | 140 MPa | 140 MPa | 140 MPa |

| Shear Strength | 190 MPa | 190 MPa | 190 MPa | 190 MPa | 190 MPa |

| Elongation | 2.5% | 2.5% | 2.5% | 2.5% | 2.5% |

-

Advantages of Aluminum for Die Casting:

-

Lightweight yet strong

-

Excellent corrosion resistance

-

Good thermal and electrical conductivity

-

Recyclable

-

-

Applications of Aluminum Die Casting: Automotive parts, electronics housings, power tools

Zinc Die Casting Service

Zinc alloys are a key material for die casting applications. Zinc casting is favored for its excellent plating qualities, along with added benefits like high impact strength and ductility. It is a popular choice for manufacturers because it is easy to cast with a hot-chamber die casting machine, and its castability minimizes wear on the die. Zinc is often mixed with copper, magnesium, and aluminum, as it is denser than magnesium and aluminum.

Common die-casting Zinc alloys include:

| Alloy Grade | Zamak 2 | Zamak 3 | Zamak 5 | Zamak 7 | ZA-8 |

| Density (g/cm³) | 6.7 | 6.6 | 6.7 | 6.8 | 6.9 |

| Melting Point (℃) | 383-386 | 381-387 | 379-386 | 380-386 | 381-387 |

| Thermal Conductivity (W/m`K) | 109 | 116 | 113 | 113 | 116 |

| Coefficient of Thermal Expansion (10^-6/K) | 26.5 | 27.5 | 26.9 | 26.5 | 26.5 |

| Electrical Conductivity (% IACS) | 27 | 27 | 27 | 27 | 26 |

| Main Chemical Composition | 3.5-4.3% Al 0.02-0.05% Mg 0.035-0.06% Cu |

3.5-4.3% Al 0.03% Mg 0.03% Cu |

3.5-4.3% Al 0.035% Mg 0.035% Cu |

3.5-4.3% Al 0.03-0.06% Mg 0.03-0.06% Cu |

3.5-4.3% Al 0.05-0.5% Mg 0.005-0.03% Cu 0.005-0.03% Ni 0.005-0.03% Fe |

| Tensile Strength (MPa) | 295 | 255 | 310 | 345 | 380 |

| Yield Strength (MPa) | 240 | 215 | 230 | 275 | 320 |

| Elongation (%) | 2 | 3 | 6 | 3 | 1 |

| Hardness (HB) | 82 | 70 | 90 | 95 | 100 |

| Main Differences | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains more Mg and Cu, suitable for complex-shaped parts | Contains Mg, Cu, Ni, and Fe, with higher strength and hardness |

| Main Casting Applications | Automotive, furniture, appliances, and mechanical parts | Electrical, hand tools, toys | Machinery, architectural, and automotive | Automotive, electrical, hardware | Industrial, automotive, electrical |

-

Advantages of Zinc for Die Casting:

-

High strength and toughness

-

Excellent dimensional accuracy and surface finish

-

Lower melting point (saves energy)

-

Long die life (less die wear)

-

-

Applications of Zinc Die Casting: Consumer electronics, automotive interior parts, locks, gears

Magnesium Alloys Die Casting:

-

Popular grades: AZ91D, AM60B

-

Advantages of Magnesium for Die Casting:

-

Very lightweight (lightest structural metal)

-

Good strength-to-weight ratio

-

Good machinability

-

-

Disadvantages of Magnesium for Die Casting:

-

More expensive

-

Susceptible to corrosion without coating

-

-

Applications of Magnesium Die Casting: Aerospace, automotive, mobile devices

Copper Alloys Die Casting:

-

Less common in high-pressure die casting but is sometimes used in specialized low-pressure or gravity casting.

-

Advantages of Copper for Die Casting:

-

High strength and wear resistance

-

Excellent electrical and thermal conductivity

-

-

Disadvantages of Copper for Die Casting:

-

High melting point (more stress on the die)

-

Expensive

-

-

Applications: Electrical connectors, plumbing components

What to Look for When Selecting Die Casting Alloys

The alloy you choose has a direct effect on how the final product performs and how much it costs to produce. To make the right choice, keep these five points in mind:

1. Mechanical Properties

Choose an alloy that meets the strength, hardness, and durability requirements of the final part. Mechanical performance will vary between alloys.

2. Corrosion Resistance

Think about the environment the part will face. Exposure to chemicals, moisture, or temperature shifts may affect the alloy. Zinc and aluminum offer good natural corrosion resistance, but some alloys may need extra coatings.

3. Thermal Conductivity

If the part needs to manage heat or maintain stable temperatures, consider an alloy with high thermal conductivity. Copper-based alloys are often used when efficient heat transfer is important.

4. Machinability

If CNC machining or other post-processing is needed, make sure the alloy can be machined without too much difficulty. Some alloys are easier to work with, while others may require special tools or techniques.

5. Cost: Evaluate

Look at the total cost, not just the material price. Include production efficiency, machining needs, and finishing steps. Some alloys are more expensive to process, even if the raw material cost is low.

How to Make a Die Casting Mold

A die casting mold has two main parts: the cover side, fixed on a stationary plate, and the ejection side, attached to a movable plate. To produce complex parts with features like holes or threads, some molds include extra components such as slides and cores.

Depending on the part size, a mold may contain multiple cavities to produce several pieces in one cycle. These can be multi-cavity molds, with identical cavities, or family molds, which include different cavity shapes to make various parts at once.

Die casting molds must be strong, heat-resistant, and wear-resistant. They also need good ductility to withstand repeated use. Most are made from hardened tool steel that has been heat-treated. These molds are built to handle thousands of casting cycles per hour and can last up to two million cycles during their lifespan. They also need to endure high clamping forces.

The mold-making process starts with CAD (Computer-Aided Design) and casting-specific simulation tools. Like injection molds, die casting molds need gates, runners, and vents to guide molten metal into the cavity. Ejection pins and locking systems are also needed to release parts and keep the mold closed during casting.

CNC machining is widely used to make die casting molds. The process usually begins with rough cutting the mold shape, followed by heat treatment, then finishing to achieve the final dimensions. For quick-turn or prototype molds, rapid tooling can be used. This may involve CNC machining or methods like Selective Laser Sintering (SLS).

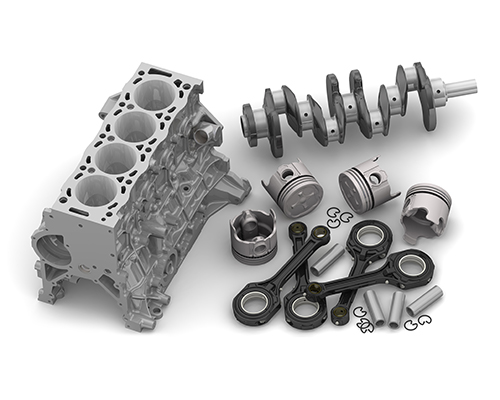

Applications of Die Casting Processes

Die casting is widely used to produce durable and versatile parts, such as engine components and electronic housings. The process offers a variety of material choices, a large build area, and the ability to create intricate, precise, and thin-walled components.

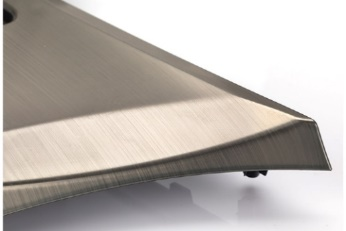

What NOBLE Can Do for Your Product’s Finish

At NOBLE, we provide a wide variety of surface treatments to enhance your parts. These surface finishes boost appearance, hardness, and resistance to corrosion and chemicals. They also smooth out rough tool paths and cover any marks left during CNC machining.

Here are some finishing options that might be the right fit for your custom parts.

| Name | Description | Materials | Color | Texture | |

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating can be functional, decorative, or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

|

Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

|

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Die Casting in the Automotive Industry

Die casting is commonly applied in the automotive sector, especially for aluminum parts like gearbox cases and engine brackets. Magnesium die casting works well for seat frames and panels, while zinc die casting is suitable for fuel and brake parts.

Die Casting in the Aerospace Industry

The aerospace industry depends on die casting to produce high-quality, lightweight parts. Manufacturers prefer this method for its cost efficiency and ability to meet the industry’s exacting standards.

Die Casting in the Medical Industry

Die casting plays a vital role in the medical industry. It ensures the production of lightweight, high-quality parts that meet strict standards, making it the method of choice for critical components.

Die Casting in the Energy Industry

Die casting is a key technique in the energy industry for creating durable, high-precision parts for applications like fuel cells, heat exchangers, and renewable energy systems. It’s popular because it meets the industry’s need for efficiency and cost-effectiveness.

How to Choose the Right Die Casting Manufacturer

Picking a die casting manufacturer isn’t just about price—it’s about finding the right partner for your product. Here’s how to make the right choice:

1. Know What You Need

Start by clearly outlining your project needs. This includes part specifications, order quantity, quality standards, surface treatment, and delivery timeline. Having a clear plan will help you communicate better with suppliers and assess whether they can meet your expectations.

2. Check Their Background

Look for manufacturers with proven experience in die casting. Review their track record, especially in working with the materials relevant to your project. It’s also useful to check what industries they’ve served and whether they’ve produced similar complex parts.

3. See What They Can Handle

Examine the manufacturer’s equipment and production capacity. This includes machine size, available tooling, and support for secondary processes like CNC machining, surface finishing, and assembly. Make sure their facilities match your production scale and technical needs.

4. Ask About Quality

Ask about their quality control systems. Look for companies that follow recognized standards, such as ISO certifications. Also, check their inspection routines, testing procedures, and how they ensure product quality at every stage.

5. Get Engineering Help

See if the manufacturer can support you in the design and engineering phases. A skilled partner can offer suggestions to improve the design for manufacturability, reduce costs, and select the best materials and processes.

6. Talk, Often

Good communication is crucial. Choose a manufacturer that is responsive, open to feedback, and willing to provide updates throughout the project. A cooperative attitude helps avoid delays and misunderstandings.

Final Thoughts

For mass-producing durable and detailed metal components, die casting is a smart choice. When enhanced with CNC machining, it becomes a highly precise and versatile manufacturing solution.

Key success factors include smart material selection, efficient mold design, and proper surface finishing. A good grasp of each step in the process helps you make better decisions and optimize both cost and performance.

NOBLE brings the expertise and capabilities needed to deliver reliable die casting solutions tailored to your project.

Ready to get started? Reach out to us—we’re here to help!

FAQs

1. Why is die casting better than sand casting?

Die casting is often considered better than sand casting for certain applications due to its superior precision, speed, and finish, especially in high-volume production.

2. What is the difference between casting and die casting?

Casting is a general manufacturing process where molten material is poured into a mold to solidify into a desired shape, while die casting is a specific type of casting that uses high pressure to force molten metal into a reusable metal mold (die) for producing high-precision, high-volume parts.

3. Is die casting a permanent mold?

Yes, die casting uses a permanent mold, as it involves injecting molten metal into reusable steel dies (molds) under high pressure, allowing for consistent, high-volume production of complex and precise metal parts.

4. Is die casting cost-effective?

Die casting is cost-effective for high-volume production because, despite its high initial tooling cost, it offers low per-unit costs, fast cycle times, minimal material waste, and excellent repeatability.

5. Is die casting good for the Environment?

Die casting can be environmentally friendly when managed properly, as it allows for efficient metal use, high recyclability of materials (especially aluminum and zinc), and minimal waste, though it requires significant energy input and proper handling of emissions and waste heat to reduce its environmental impact.