CNC Machining changed how we make things today. It lets machines create detailed parts on their own, with great accuracy. The system works through computer software that controls every move. In this piece, we’ll go over four key CNC Machining methods: Milling, Turning, Routing, and Grinding. These are used in many industries, from planes to phones, and each has its strengths.

What is CNC Machining?

CNC Machining means using computers to control machines that cut, drill, or shape materials. First, someone makes a digital design using CAD software. Then, the computer changes it into G-code, which tells the machine exactly what to do.

How CNC Machines Operate:

- Programming: First, the design is created and loaded into CAD/CAM software for CNC Machining.

- Tool Selection: Next, the right tools are picked depending on the material and the job requirements.

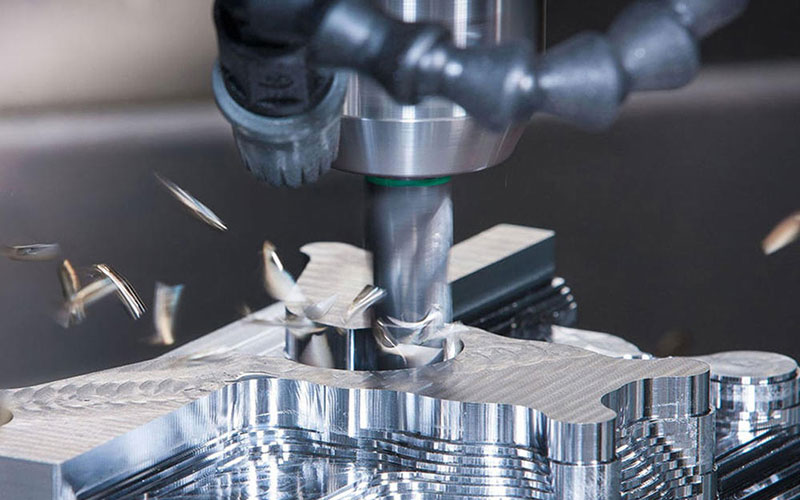

- Machining: Then, the CNC machine follows the program to do tasks like cutting, drilling, or grinding.

- Finishing: Finally, the part goes through final steps like cleaning or coating to finish the process.

Advantages of CNC precision machining:

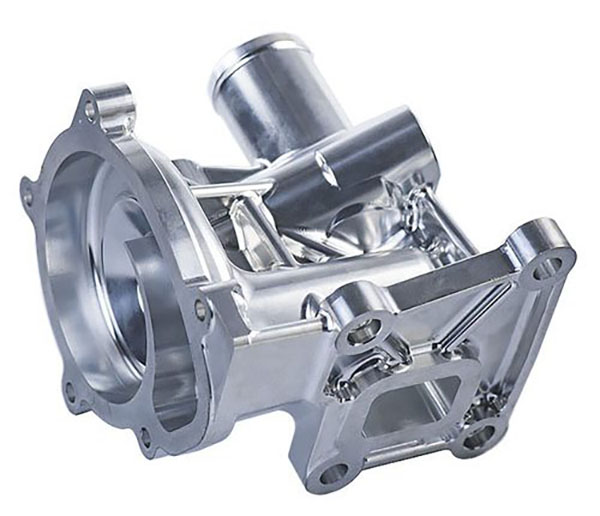

- Precision: CNC Machining can achieve very tight tolerances and make complex shapes that are hard to do by hand.

- Repeatability: Once programmed, CNC Machining produces parts that stay the same every time, ensuring steady quality.

- Efficiency: CNC Machining works faster than manual methods and cuts down on human errors.

Application of precision CNC machining

- Automotive: CNC Machining is used to produce precise engine components, transmission parts, and chassis parts, thereby enhancing performance and safety.

- Aerospace: CNC Machining produces high-precision turbine blades, structural frames, and landing gear that meet strict industry standards.

- Electronics: It is used to create detailed components, such as enclosures, connectors, and heat sinks, which are essential for the function and protection of electronic devices.

- Medical Devices: CNC Machining helps make surgical tools and implants with exact specifications to ensure safety and compatibility with the human body.