CNC aluminium machining is a crucial technology in modern manufacturing, offering the advantages of high precision and efficiency. It can machine complex parts, ensure product quality, and is widely used in the aviation, automotive, and electronics industries. This article will introduce its machining principles, processes, materials, and main applications.

What is CNC Aluminium Machining?

CNC aluminum machining is an advanced manufacturing process that uses CNC machine tools to perform precision cutting, milling, drilling, and other machining operations on aluminum materials. CNC stands for Computer Numerical Control (CNC), which involves inputting pre-designed programs into the machine tool, enabling the equipment to automatically complete complex machining processes with high precision, strong repeatability, and fast efficiency.

Aluminum materials are widely used in CNC machining due to their lightweight, moderate strength, good thermal conductivity, and ease of machining. They are particularly suitable for manufacturing parts with high requirements for precision and appearance, such as electronic product housings, automotive components, and aerospace parts.

Common equipment used in CNC aluminum machining includes CNC lathes, CNC milling machines, and machining centers, which can achieve three-axis or even five-axis simultaneous machining, making them suitable for producing parts with complex shapes and precise structures. The machining process includes rough machining, finish machining, and surface treatment. Common post-processing methods include polishing, sandblasting, and anodizing, which enhance appearance and corrosion resistance.

In summary, CNC aluminum machining, with its high precision, efficiency, and excellent material compatibility, has become an important manufacturing method in industries such as aerospace, automotive manufacturing, electronics and communications, and medical equipment.

Advantages of CNC Aluminium Machining

1. High precision and consistency

One of the key features of CNC aluminum machining is its exceptional precision control. Traditional manual or semi-automated processes often involve human error, leading to inconsistent product quality. CNC machining, however, controls all process parameters—including tool paths, cutting depth, and spindle speed—through programming, enabling precise cutting at the micron level. This significantly enhances the dimensional accuracy and repeatability of parts. NOBLE offers custom CNC aluminum machining services.

Take the aerospace and medical industries as examples. These sectors demand extremely high precision and stability in products, as even minor dimensional deviations can impact performance or pose safety risks. CNC machining ensures that every batch and each workpiece maintains consistent structural dimensions and assembly precision, eliminating the common deviations associated with manual processing.

Additionally, aluminum itself has excellent machinability, with moderate hardness, good thermal conductivity, and low cutting resistance. It can be machined at high spindle speeds and feed rates on CNC machines while avoiding overheating or deformation. This material property, combined with the high-precision control capabilities of CNC equipment, results in outstanding performance in dimensional control, edge cleanliness, and surface finish for aluminum parts.

2. Design flexibility: Supports complex structures and customized manufacturing

Another key advantage of CNC aluminum machining is its high design flexibility. Traditional processes are often limited by molds or manual operations when machining complex geometric structures, frequently resulting in process bottlenecks. CNC machining, however, can efficiently cut complex three-dimensional surfaces, irregular holes, internal cavities, inclined surfaces, and chamfers, especially when using four-axis or five-axis CNC machines, which enable multi-angle three-dimensional machining, significantly expanding design possibilities.

Designers can create any geometric shape using CAD modeling software without being constrained by processing limitations, then use CAM software to generate machining programs directly input into CNC machines, thereby quickly turning designs into physical products. This “what you see is what you get” digital manufacturing approach significantly shortens product development cycles, enhances innovation efficiency, and is particularly suited for production needs involving multiple varieties, small batches, or customization.

Additionally, CNC machining allows for flexible changes to product designs without relying on molds. Once design optimizations or customer requirements change, only the program code needs to be updated to respond quickly, eliminating the need for repeated mold costs and reducing development costs.

3. Support various post-processing options: enhance functionality and aesthetics

After CNC machining, aluminum often requires further processing to enhance its mechanical properties, corrosion resistance, or aesthetic appeal. CNC-machined aluminum parts feature excellent surface quality with minimal burrs, providing an ideal foundation for subsequent surface treatments. A wide range of post-processing options is available to meet the diverse needs of industrial and consumer applications.

- Anodizing: One of the most common aluminum surface treatment methods. An anodized layer is formed on the aluminum surface through an electrochemical process, enhancing corrosion resistance and hardness. It can also achieve various colors (such as black, silver, gold, blue, etc.), and is widely used in high-end products like smartphone cases, camera housings, and instrument panels.

- Sandblasting and Brushing: These mechanical processing methods are used to improve surface texture and tactile feel, making the surface more uniform and textured. They are commonly used in the consumer electronics industry. Sandblasting removes minor scratches and creates a matte finish; brushing forms regular linear patterns, giving products an industrial aesthetic appeal.

- Electroplating and Coating: For certain functional requirements, CNC-machined aluminum parts can undergo electroplating (e.g., nickel, chrome) or coating applications (e.g., corrosion-resistant coatings, conductive coatings) to achieve enhanced corrosion resistance, conductivity, wear resistance, or decorative effects.

- Laser engraving and screen printing: CNC-machined aluminum surfaces can undergo precise laser marking, logo engraving, or pattern printing for brand identification, product numbering, and decorative enhancement.

This diverse combination of post-processing techniques enables CNC aluminum machining to not only meet structural and precision requirements but also enhance aesthetic appeal, functional extensions, and brand identity, significantly enhancing the product’s market competitiveness.

NOBLE’s CNC machining supports multi-axis interpolation, mass production, customized aluminum machining services, and rapid prototyping, and is particularly skilled at processing irregularly shaped structures, parts with complex details, and parts with strict precision requirements. We also provide a complete range of post-processing services, including anodizing, sandblasting, polishing, and brushing, to meet customers’ diverse needs for appearance, texture, and performance.

How Aluminum CNC Machining Works

Aluminum CNC machining is a highly automated and precise manufacturing process that relies on computer-controlled CNC machine tools to perform operations such as cutting, milling, and drilling on aluminum materials. Due to its advantages of being lightweight, having fast heat dissipation, and being highly machinable, aluminum has become one of the most widely used metal materials in CNC machining. The following is a detailed description of the machining process and its working principles:

1. Product Design and Modeling

First, product design engineers use CAD (Computer-Aided Design) software to create a three-dimensional model of the part, defining its dimensions, structure, and functional requirements. Once the design is complete, CAM (Computer-Aided Manufacturing) software is used to convert the model into G-code, a programming language that guides the movement and machining paths of CNC machine tools.

2. Aluminum Material Selection and Blank Preparation

Aluminum alloys suitable for the product’s performance requirements are selected, such as 6061, 7075, or ADC12. Different grades of aluminum alloys have varying strengths, hardness, corrosion resistance, and machinability. After selecting the material, it is cut into suitable blank blocks for machining.

3. Fixture and Clamping Setup

Secure the aluminum blank to the CNC machine tool’s worktable or fixture to ensure the workpiece remains stable and does not move during processing. The selection and installation position of the fixture must be precise to prevent processing errors.

4. Tool Installation and Parameter Settings

Select appropriate tools based on the workpiece structure and processing requirements, such as end mills, ball-nose cutters, drills, turning tools, etc., and install them on the spindle. Then set key parameters such as spindle speed, feed rate, and cutting depth, as these settings directly affect machining efficiency and surface quality.

5. Machining Execution Process

Machining generally consists of two stages:

Rough Machining: The primary purpose is to quickly remove excess material and form the rough shape of the workpiece, with a faster speed but lower precision.

Finish Machining: Performs precise cutting based on rough machining to improve dimensional accuracy, surface finish, and edge quality, ensuring the finished product meets technical standards.

The entire process is automatically controlled by the CNC system to ensure precise execution of each step, with the tool moving along the pre-set path to achieve three-dimensional machining of the aluminum part.

6. Inspection and Quality Control

After processing, tools such as calipers, micrometers, and coordinate measuring machines are used to inspect the dimensions of the parts to ensure they meet the drawing requirements. If any errors are found, they can be corrected through program adjustments.

7. Surface Treatment (Optional)

To enhance appearance and functionality, aluminum parts often require surface treatment. For example:

Polishing: Improves surface finish

Anodizing: Enhances corrosion resistance and allows for coloring

Sandblasting: Removes minor burrs and creates a uniform matte texture

8. Final Inspection and Packaging

After surface treatment, a final inspection is conducted to ensure that all dimensions, appearance, and functional specifications meet standards. The parts are then cleaned, packaged, and stored in inventory.

The types of CNC Aluminium Machining

According to the different processing methods and functions, CNC machine tools can be divided into a variety of types:

1. CNC Aluminum Machining Turning

CNC turning involves using a CNC lathe to machine aluminium in a rotating state into the desired geometric shape using a turning tool. This process is primarily used for machining shaft-type, circular, or cylindrical parts. It is suitable for machining outer circles, inner holes, end faces, threads, chamfers, and other components.

Aluminium is a relatively soft material, which allows for rapid heat dissipation and low cutting resistance during machining. As a result, high cutting speeds and excellent surface quality can be achieved during the turning process. By changing different tools or using CNC lathes with automatic tool-changing systems, complex curved surfaces such as inner and outer spherical surfaces and conical surfaces can also be machined.

In practical applications, turning is widely used in the manufacture of precision shaft components, knobs, and connecting parts, particularly suitable for parts with high requirements for coaxiality and surface finish.

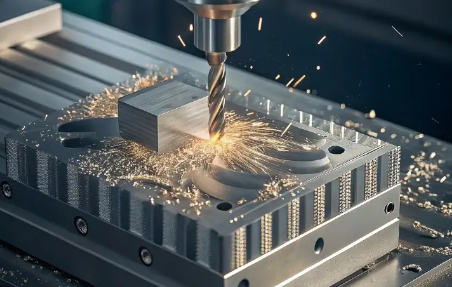

2. CNC Aluminum Machining Milling

CNC Milling is the most commonly used process in CNC machining, primarily involving the high-speed rotation of a milling cutter to perform multi-directional, multi-axis cutting operations on a fixed aluminum blank. CNC milling machines can process a variety of complex structures, including flat surfaces, grooves, contours, and curved surfaces, making them suitable for aluminum components with complex shapes and high precision requirements.

CNC milling can be categorized into three-axis, four-axis, and five-axis machining centers based on the number of axes. Among these, five-axis machining centers enable efficient processing of more complex angles and spatial surfaces, and are commonly used in industries such as aerospace, medical, and high-end electronics.

Aluminum alloys have excellent machinability and minimal material deformation, making milling the most common method for processing aluminum parts. Typical applications include smartphone casings, heat sinks, structural brackets, and precision molds.

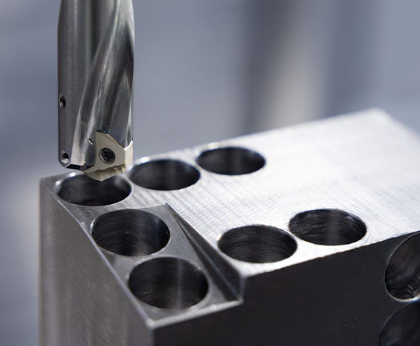

3. CNC Aluminum Machining Drilling

Drilling is a common process for creating circular holes in aluminium materials, typically used for screw holes, assembly holes, and positioning holes. CNC drilling equipment can precisely control parameters such as hole position, depth, and diameter, and can perform batch continuous processing, thereby improving efficiency and consistency.

Compared to traditional manual drilling, CNC drilling offers significant advantages in terms of precision and speed, making it particularly suitable for components with a large number of holes and precise spacing. Drilling can also be combined with threading, chamfering, and other processes to achieve composite machining.

When machining aluminium materials, due to their softer texture, burrs are prone to forming. Therefore, high-speed drills with coolant are commonly used to ensure smooth hole walls and stable dimensions. This process is widely used in the production of electronic enclosures, equipment brackets, panels, and other products.

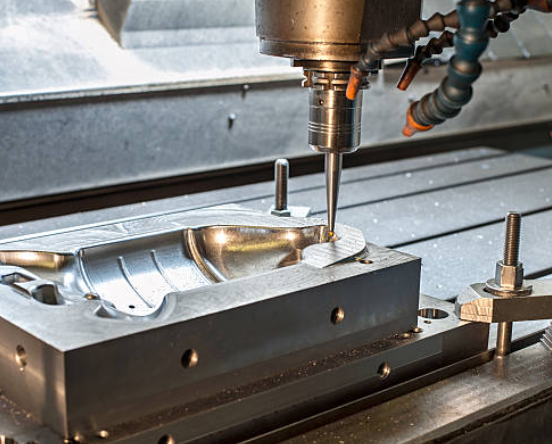

4. CNC Aluminum Machining Grinding

CNC Grinding is a machining process that uses a high-speed rotating abrasive wheel to perform micro-cutting on the surface of aluminium components, primarily to improve surface finish and dimensional accuracy. Due to aluminium’s softness and high thermal conductivity, it tends to adhere to the abrasive wheel during grinding, leading to surface burning or scratches. Therefore, special abrasives (such as white corundum) and appropriate coolants must be used to reduce processing heat and prevent wheel adhesion.

CNC Grinding is typically used for the final machining of precision flat surfaces, outer circles, and inner holes, serving as a finishing process after turning and milling. Especially in applications requiring extremely high dimensional accuracy and flatness, such as optical components, mould accessories, and mirror-finished parts, grinding can significantly enhance product quality.

Additionally, CNC grinding of aluminium is often combined with other processes, such as surface preparation before anodising or as a pre-process for mechanical polishing, to further enhance surface performance and aesthetic appeal.

CNC Aluminium Machining Materials

NOBLE is familiar with the machining characteristics of various commonly used aluminum materials, including aluminum alloys such as 6061, 7075, 2024, 5052, and ADC12. We can provide customers with material selection recommendations and optimized machining solutions based on different application scenarios and performance requirements, offering customized aluminum machining services to ensure that products are both functional and cost-effective. Aluminium is one of the most commonly used metal materials in CNC machining due to its excellent physical and mechanical properties. Common aluminium materials are as follows:

1.6061 Aluminium Alloy

6061 is the most widely used general-purpose aluminum alloy in CNC aluminum machining. It belongs to the heat-treatable aluminum-silicon-magnesium alloy series, featuring moderate strength, excellent corrosion resistance, good weldability, and superior machinability.

| Model | Key Advantages and Features | Scope of application |

| 6061 | Medium strength, can be heat-treated for reinforcement | Structural components, electronic enclosures, bicycle parts, and automation equipment components

|

| Excellent corrosion resistance | ||

| Good machinability, easy to machine with CNC |

This material is lightweight and has good rigidity, making it suitable for parts that require both strength and aesthetic appeal. During CNC machining, it exhibits stable cutting performance, minimal deformation, and high surface quality. 6061 is widely used in structural components, mechanical parts, bicycle accessories, automotive components, aerospace parts, and electronic product housings. After anodizing, the surface of 6061 aluminum achieves an excellent decorative finish, commonly seen in consumer electronics exterior components.

2.7075 Aluminium Alloy

7075 is one of the strongest aluminum alloys, belonging to the aluminum-zinc-magnesium-copper alloy series. It can achieve extremely high strength through heat treatment, but its machinability and corrosion resistance are slightly inferior to those of 6061.

| Model | Key Advantages and Features | Scope of application |

| 7075 | Excellent heat treatment performance | Aerospace, military, high-strength mechanical components |

| Suitable for high-load structures | ||

| Moderate corrosion resistance |

This material has strength comparable to some steels, making it suitable for parts subjected to heavy loads and high stress conditions. It is widely used in aerospace structural components, military equipment, mold manufacturing, and other fields. When CNC machining, note that its high hardness causes rapid tool wear, so machining parameters must be set appropriately.

Although 7075 has lower corrosion resistance than 6061, its surface durability can be effectively enhanced through anodizing, coating, or other methods. Typical applications include aircraft joints, fuselage frames, bicycle components, and other high-strength demand scenarios.

3.2024 Aluminium Alloy

2024 is an aluminum-copper alloy known for its high strength and was widely used in the early days of the aviation industry. It has excellent fatigue strength and crack resistance, but poor weldability and average corrosion resistance.

This alloy has good machinability and is suitable for CNC precision machining of complex parts. However, due to its sensitivity to environmental corrosion, it generally requires coating protection or aluminum cladding. It is suitable for processing high-load structural components such as wing frames, landing gear components, and automotive chassis.

| Model | Key Advantages and Features | Scope of application |

| 2024 | Strong fatigue resistance | Aircraft structural components, landing gear, wing frames, precision load-bearing components |

| Good Machinability | ||

| Poor weldability |

Although the strength of 2024 is slightly lower than that of 7075, its better machinability makes it particularly suitable for applications requiring a balance between strength and machining efficiency.

4.5052 Aluminium Alloy

5052 is an aluminum-magnesium alloy with excellent corrosion resistance and good formability, and moderate strength. Although it cannot be strengthened through heat treatment, it has good weldability and polishability, and is commonly used to manufacture components for marine, chemical, and food equipment.

5052 performs stably in CNC machining and is suitable for sheet metal processing, bending, and punching. However, it is less commonly used than 6061 for the machining of precision complex three-dimensional structural parts. It is typically used for products with high aesthetic requirements and surfaces requiring anodizing or coating treatment, such as electronic enclosures, lighting structural components, and automotive trim strips.

| Model | Key Advantages and Features | Scope of application |

| 5052 | Excellent corrosion resistance | Marine equipment, car body panels, electronic enclosures, decorative parts |

| High weldability | ||

| Good surface treatment adaptability |

5. ADC12 Die-Cast Aluminum Alloy

ADC12 is a common aluminum-silicon die-casting alloy with good fluidity, making it suitable for die-casting molded parts. It has moderate mechanical properties but excellent castability, dimensional stability, and complexity of forming.

| Model | Key Advantages and Features | Scope of application |

| ADC12 | High-dimensional stability | Automotive parts, home appliance housings, power tool components, die-cast parts |

| Good corrosion resistance | ||

| Poor ductility, moderate strength |

ADC12 material is often used for CNC secondary machining after die-casting, such as removing flash, drilling, tapping, or local finishing. Due to its high silicon content and relatively high hardness, appropriate tools and cooling systems must be selected during CNC machining to minimize tool wear.

This material is suitable for mass production of complex parts with moderate precision requirements, such as automotive engine housings, appliance housings, and electric tool structural components.

The Application of CNC Aluminum Machining

CNC aluminium machining is widely used in a number of industries with high precision and high performance requirements. Typical applications include:

1. The application of aluminum parts in aerospace

Aircraft fuselage, seat structural parts, connectors, brackets, etc. CNC machined aluminium parts are widely used to achieve a balance between light weight and high strength.

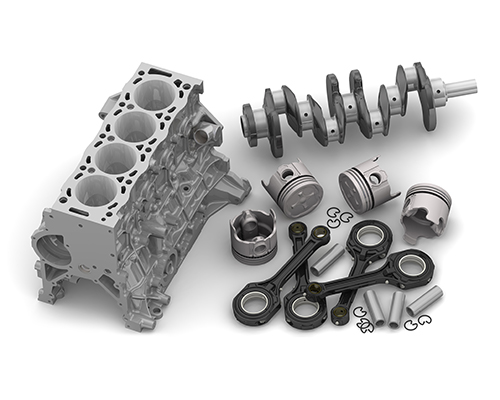

2. CNC aluminum parts in the automotive industry

Engine shells, suspension parts, electric vehicle structural parts, etc., require a balance between strength and lightweight, and CNC aluminium machining can achieve a precise match.

3. Electronic CNC aluminum components

Mobile phone cases, laptop shells, heat sinks, and other electronic equipment parts require exquisite appearance and high dimensional accuracy; CNC aluminium machining can meet these needs.

4. CNC aluminum components for medical equipment

Structural components, housings, brackets, etc. for medical equipment require materials that are non-toxic, corrosion-resistant, and can be machined with high precision, making aluminium the ideal choice.

5. Automation Equipment and Robotics

Aluminium parts are lightweight and strong in structure, which can effectively reduce the load of the equipment and improve the efficiency of movement, and are the first choice for robot skeletons, automation guide rails, and other components.

NOBLE: Your Professional Partner in CNC Aluminum Machining

CNC aluminum machining is a highly specialized and flexible process that requires precise technology and extensive experience to ensure the best possible product quality and machining results. This process places extremely high demands on process planning and execution standards.

NOBLE is committed to providing customers with reliable and efficient aluminum machining solutions. Whether it’s innovative development for large-scale projects or precision prototyping for small-batch products, our team can provide you with professional support to meet and even exceed your expectations.

Contact us today to embark on your ideal collaboration journey for aluminum CNC machining projects.