Plastic injection molding of transparent materials may seem daunting, but with precision and diligence, it becomes entirely achievable. Remember, every minor error can alter the final product’s clarity, making meticulous attention to detail paramount. As a senior engineer at NOBLE, I will guide you through each stage—from selecting the right materials to ensuring the critical post-processing methods needed for success.

What is Transparent Plastic Injection Molding?

Definition of Injection Molding

We occasionally receive orders for transparent plastic injection molding. Transparent plastic injection molding is a type of injection molding process. We inject molten plastic into molds for mass production. The unique feature of transparent plastic injection molding is its ability to produce parts with high light transmission and clarity, which are frequently used in medical devices, automotive components, electronics, and numerous consumer goods.

The injection molding process itself is not too complicated, but achieving high-quality transparent parts requires careful attention to various factors. The plastic is first heated to a molten state and injected into a mold cavity under high pressure. Once the mold cools and solidifies, the part is ejected, ready for further processing. However, transparency is more than just a visual property; it is heavily influenced by how the molding process is controlled. The temperature of both the plastic and the mold, as well as the injection speed, must be precisely calibrated to avoid defects such as streaks or cloudiness.

Focus on Transparent Plastic

It’s worth noting that when discussing transparent plastics, the choice of material plays a pivotal role. Common transparent plastics include polycarbonate, acrylic, and polyethylene terephthalate (PET). These materials are selected not only for their clarity but also for their strength, impact resistance, and durability. Polycarbonate, for example, is highly regarded for its toughness and optical clarity, while acrylic is valued for its excellent surface finish and UV resistance. Choosing the right material depends on the intended use of the part—whether it’s for durability, clarity, or environmental resistance.

Common Applications

Industries that rely on transparent plastic parts demand high standards of quality. For example, in the automotive industry, clear plastic parts may be used in interior components, lighting systems, or even exterior lenses. The ability to produce transparent parts that are both visually flawless and functionally durable is a significant advantage. We’ve also handled orders for plastic casings, bottles, medical device housings, syringe barrels, light guides… Evidently, many industries rely on these components. Transparent molding allows for intricate, detailed designs while maintaining clarity, a balance that would be difficult to achieve with traditional materials or methods.

Why Transparent Plastic Injection Molding is Challenging

Transparent plastics such as PMMA, PC, and PET are highly valued for their excellent optical properties, but they are extremely sensitive to defects. We must consider these important factors:

1. Surface Quality Requirements

Defects to Avoid: Streaks, bubbles, cloudiness, black spots, discoloration, and inadequate gloss.

Impact: Due to the high transparency of the parts, even minor defects are clearly visible, significantly reducing the overall quality of the product. Therefore, even the slightest defect may render the final product unusable.

2. Material Properties

High Melting Point: These materials have a high melting point, meaning they need higher processing temperatures, often surpassing the typical limits for injection molding.

Poor Flowability: Their poor flowability—due to low flow characteristics—makes it crucial to carefully manage injection pressure and speed to maintain consistent results.

3. Internal Stress

Causes: Uneven cooling rates, excessive injection pressure, or improperly designed molds.

Effects: Internal stress can arise from uneven cooling rates, excessive injection pressure, or poorly designed molds. This stress can cause warping, cracking, or a loss of optical clarity, all of which significantly affect both the appearance and functionality of the final product.

Best Practices for Transparent Plastic Injection Molding

1. Material Preparation and Drying

- Cleanliness: It’s vital to keep raw materials free from contaminants. Use sealed containers for both storage and transportation to maintain cleanliness.

- Drying: To prevent material degradation, moisture must be removed. A dry hopper system that uses filtered and dehumidified air is ideal for this process.

Tips:

- Dry materials like PMMA at 80-90°C for 3-4 hours.

- Avoid over-drying, as it can lead to brittleness in the material.

2. Machine and Screw Cleaning

- Contamination Prevention: To prevent cross-contamination, thoroughly clean the barrel, screw, and nozzle both before and after use.

- Cleaning Agents: Use specialized screw cleaning agents or resins like PE/PS to ensure a deep and effective clean.

- Temporary Shutdown: If a temporary shutdown occurs, lower the barrel and dryer temperatures to reduce the risk of material degradation.

3. Mold Design and Product Design

- Uniform Wall Thickness: Ensuring consistent wall thickness allows for even cooling, which helps reduce the development of internal stresses.

- Draft Angles: Proper draft angles are essential to make the demolding process smoother and prevent part damage.

- Smooth Transitions: Sharp corners should be avoided in favor of rounded edges, as they help reduce stress concentrations within the mold.

- Gate and Runner Design: It’s best to use wide, short gates and runners for optimal flow, adding cold slug wells where necessary to prevent material waste.

- Surface Finish: For the best finish, the mold surface roughness should remain below 0.8 µm to achieve a smooth final product.

- Venting: Sufficient venting is crucial to allow the escape of air and gases during the molding process, preventing defects.

4. Injection Molding Process and Machine Settings

- Machine Selection: Choose machines with dedicated screws and temperature-controlled nozzles to ensure better precision and performance.

- Temperature Control: Set barrel temperatures high enough to prevent material degradation, but ensure they stay within safe limits for the specific material.

- Pressure: High injection pressure is required to overcome material viscosity, but excessive pressure must be avoided to prevent inducing stress within the material.

- Speed: Use low to moderate injection speeds, as some materials may require multi-stage injection to achieve optimal results.

- Cycle Time: Reduce holding and cycle times to prevent unnecessary material degradation.

- Screw Speed and Back Pressure: Keep screw speed and back pressure low to prevent the breakdown or degradation of the material during processing.

- Mold Temperature: Maintain accurate control over mold temperatures, as higher mold temperatures improve flow and reduce internal stress.

5. Additional Considerations

- Mold Release Agents: Apply release agents in minimal amounts to prevent any surface defects or imperfections on the final product.

- Regrind Usage: Keep regrind material usage below 20% of the total material mix to avoid compromising material properties and clarity.

- Post-Processing: NOBLE’s professional engineers recommend annealing parts (excluding PET) to relieve internal stresses and enhance material stability.

Material Selection Guide of Transparent Plastic Injection Molding

1. Polymethyl Methacrylate (PMMA)

Advantages: PMMA has exceptionally high transparency and excellent weather resistance, making it particularly popular in outdoor products and transparent applications.

Disadvantages: The material is naturally brittle and has low impact resistance, which restricts its use in high-stress environments where durability is critical.

Applications: PMMA is commonly used in products like lamp covers, optical lenses, and other items that demand clear, weather-resistant properties.

2. Polycarbonate (PC)

Advantages: Polycarbonate (PC) is known for its high impact strength and excellent heat resistance, making it well-suited for demanding applications.

Disadvantages: However, PC is susceptible to stress cracking, especially when exposed to environmental factors like UV radiation and moisture.

Applications: Due to its strength and heat resistance, PC is commonly used in the manufacture of bulletproof glass, eyewear lenses, and medical devices.

3. Polyethylene Terephthalate (PET)

Advantages: Polyethylene Terephthalate (PET) offers high tensile strength and strong chemical resistance, which makes it highly suitable for various packaging applications.

Disadvantages: A key drawback is its tendency to absorb moisture, which can affect material integrity under specific environmental conditions.

Applications: PET is widely used for beverage bottles, food containers, and other products that require both durability and resistance to chemicals.

4. Cyclic Olefin Copolymer (COC)

Advantages: Cyclic olefin copolymers (COCs) have excellent transparency and extremely low moisture absorption, making them useful in many precision optical and medical applications.

Disadvantages: Its relatively high cost can be a limiting factor, especially in projects where cost efficiency takes priority.

Applications: COC is commonly used in medical packaging, optical films, and other high-clarity components that demand moisture resistance and dimensional stability.

Choose NOBLE for Transparent Plastic Injection Molding

You need a partner who truly understands transparent plastic injection molding. NOBLE is a leading mold manufacturer in China. You get more than just transparent plastic parts; you get a team with over ten years of experience. Our engineers can handle complex designs and tight deadlines.

- Advanced Equipment & Cost-Effective Price

- 10+ years Experience of Transparent Plastic Injection Molding

- ISO 9001 & ISO13485 Certified Factory

- Rapid Tooling Production as fast as 2 weeks

- Provide Free DFM Report within 12 Hours

- Instant Transparent Plastic Injection Molding Quotes

Our Injection Molding Procedure

As a well-known transparent plastic injection molding manufacturer in China, NOBLE’s transparent plastic injection molding service is a manufacturing process for mass production of plastic parts. Molten plastic material is injected into the mold cavity, allowed to cool and solidify, and then ejected from the mold to produce high-precision parts that meet your order requirements. Our injection molding process is as follows:

Request Instant Quote

From the moment we receive your inquiry email, our professional engineers will respond within 24 hours to ensure a smooth process.

↓

Engineer Evaluation

To ensure we can produce functional molds, we conduct a feasibility review of your design to ensure we can meet the requirements before commencing production.

↓

Mold Flow Analysis

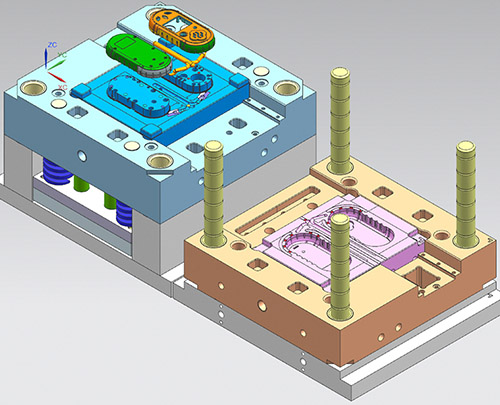

Predictive modeling software helps us understand how the molten material moves and acts within the mold, which helps us make improvements.

↓

Mold Tooling Production

Using your preferred materials enables us to make mold tooling that is of high quality and can readily fit your applications.

↓

Sample Inspection

Sampling will be delivered for you to review before manufacturing plastic parts to ensure precision and quality.

↓

Low Volume Production

After the trial production phase, we begin batch production, which uses powerful machining to manufacture parts at fast rates to save on time and costs.

↓

Strict Inspection

We follow international tolerance standards to ensure our parts meet your parameters.

↓

Delivery

As our team handles packaging to secure our parts neatly for transport, we partner with logistics companies to schedule a timely delivery to your region.

Our Support

You want support that makes your work easier. NOBLE gives quick quotes and a simple design submission process. You get a full Design for Manufacturing report before starting. Their support team helps from testing to big production. You never feel confused or alone.

NOBLE’s customer service covers every step:

| Service Type | Description |

| Technical Support | Help from testing to production. |

| Design Submission Process | An easy way to send in your designs. |

| Quality Assurance | Focus on quality all through production. |

The End

Although transparent plastic injection molding is complex, following the right steps in preparation, design, and process control can lead to stunning, defect-free parts. Partnering with an expert will give you that extra edge for top-notch results.

Take Action Now: Drop us a line and let our experts help you create the perfect solution for your transparent plastic injection molding needs. We’ve got you covered!

FAQs of Plastic Injection Molding

What are some of the common defects in transparent plastic injection molding?

You’ll often run into issues like bubbles, flow marks, internal stress cracks, and discoloration. These can all mess with the clarity and overall look of the plastic.

How do I pick the right material for transparent injection molding?

It depends on what you’re making! For optical components, go with PMMA. If you need something tough and impact-resistant, PC is the way to go.

How can I avoid internal stress in transparent plastic injection molding?

Try to optimize your mold design, manage the cooling process carefully, and don’t forget about post-processing, like annealing, to relieve stress.

What are the upcoming trends in transparent plastic injection molding?

We’re seeing some exciting trends like smart molding technology, eco-friendly manufacturing practices, and micro molding taking center stage.