If you want to achieve satisfactory results in acrylic CNC machining, it’s best to understand all its aspects. As a senior engineer at NOBLE Manufacturing, I’ll now walk you through the details of acrylic (PMMA) and the CNC machining methods available for it—this will be your first step in starting your acrylic CNC machining journey!

Acrylic (PMMA) Material Properties

Basic Information

Acrylic, also called PMMA, is a popular plastic for many projects. You might see it in windows, signs, or even in car lights. It stands out because it is clear, strong, and easy to shape. When you use acrylic cnc machining, you get parts that look sharp and work well for many uses.

Here’s a quick look at what makes acrylic special:

| PMMA Property | Property Value | Benefit for CNC Machining and Complex Part Design |

| Transparency | Light transmission of up to 92% | Great for projects where you want to see through the part, like display cases or covers |

| Durability | Tensile strength of 8000 PSI | Handles moderate stress, so your parts last longer |

| UV Resistance | Only 3% degradation over 10 years outside | Perfect for outdoor signs or parts that face the sun |

| Chemical Resistance | Resists many acids and solvents | Good for labs or places with chemicals |

| Light Weight | Density = 0.043 lb/in³ | Easy to move and install |

| Machinable/Formable | Easy to cut and shape | Let’s you make detailed or custom parts |

| Easily Joined | Bonds well with adhesives | Simple to put pieces together for bigger projects |

| Thermal Stability | Max temp 170℉ | Works well in most places, but keep away from high heat |

Benefits of Acrylic

UV and Weather Protection

Acrylic stands up to sunlight and rain. You can use it outside for years, and it will not turn yellow or break down. It also resists scratches, so your parts stay shiny and new. The hard surface gives a high-gloss finish, which looks great in displays or signs.

Abrasion Resistance

You do not have to worry much about scratches. Acrylic keeps its smooth look even after lots of use. This makes it a smart choice for things people touch often, like touch screens or protective covers.

High Gloss and Hardness

Acrylic can be polished until it shines. You get a glossy, glass-like finish that grabs attention. The hard surface also means your parts will not wear out quickly.

Transparent

Acrylic lets in about 92% of visible light. That is almost as clear as glass! You can use it for windows, light covers, or anything where you want to see through the material. It stays clear over time, even in the sun.

Tip: If you want parts that look good and last, acrylic is a top pick. You can dye it, glue it, or shape it for many different projects.

Common Issues

Cracking

Acrylic is strong, but it can crack if you put too much pressure on it or use the wrong tools. Sharp corners or tight clamps can make this worse. Always use the right settings and tools to keep your parts safe.

Melting

If acrylic gets too hot while cutting, it can melt. This leaves rough edges and can ruin the look. Keep your tools sharp and use the right speed to avoid heat build-up.

Chipping

Sometimes, small pieces can chip off during machining. This happens if the tools are dull or the feed rate is too high. You can prevent this by checking your tools and slowing down when needed.

If you keep these properties and issues in mind, you can get the best results from your acrylic projects.

CNC Machining technology is suitable for acrylic

CNC Milling

CNC milling is a popular way to shape acrylic. You can use it for deep cuts or small grooves. It also helps smooth the edges of your parts. This process is very accurate. It lets you make shapes that look neat and professional. When working with acrylic, you need good tools. Sharp tools like O’Flute or single-flute spiral up cut bits work best. These tools help stop rough edges. They also keep the acrylic from chipping or cracking.

Here’s a quick look at some common milling tools and what they do:

| Tool Type | Common Applications | Advantages | Disadvantages |

| Single-Flute Spiral End Mill | Finishing, precision cutting | Smooth, burr-free edges, high transparency | Lower efficiency, higher cost |

| Double-Flute Spiral End Mill | Roughing, semi-finishing | Faster removal, higher efficiency | Lower surface quality |

| Compression Spiral End Mill | Multilayer or laminated sheets | Clean finish, prevents chipping on edges | Higher cost, limited speed |

| Ball Nose End Mill | 3D surface milling, relief carving | Great for curves and contours | Less suited for flat finishing |

| V-Bit Engraving Tool | Text and pattern engraving | Fine detail, sharp tip | Wears quickly, not for large areas |

You need to change feed rates, spindle speeds, and cutting depths. This depends on your tool and the acrylic sheet. If you go too fast or too deep, chips or cracks can happen. NOBLE uses advanced CNC acrylic machining and top tools for great results. Their team checks every detail. They make sure each part is made just right for your needs.

Tip: Always use sharp tools and keep your machine clean. This helps you get a clear, glossy finish every time.

CNC Drilling

CNC drilling helps you make clean, accurate holes in acrylic. You can drill small or big holes. Each hole comes out smooth with no rough edges. This method keeps the acrylic strong. It lowers the chance of cracks or damage. You can change the speed and feed rate for your project. This helps you get the best finish.

CNC drilling protects the strength of your acrylic parts. NOBLE’s skilled workers set the right machine settings. Your parts stay strong and look good. Their experience means you get reliable results. This works for one part or many.

- Clean holes with no rough edges

- Less risk of cracks or chips

- Adjustable settings for different needs

If you want your acrylic cnc machining project to look professional, CNC drilling is a smart choice. NOBLE’s factory uses the latest machines and techniques to make sure every hole is perfect.

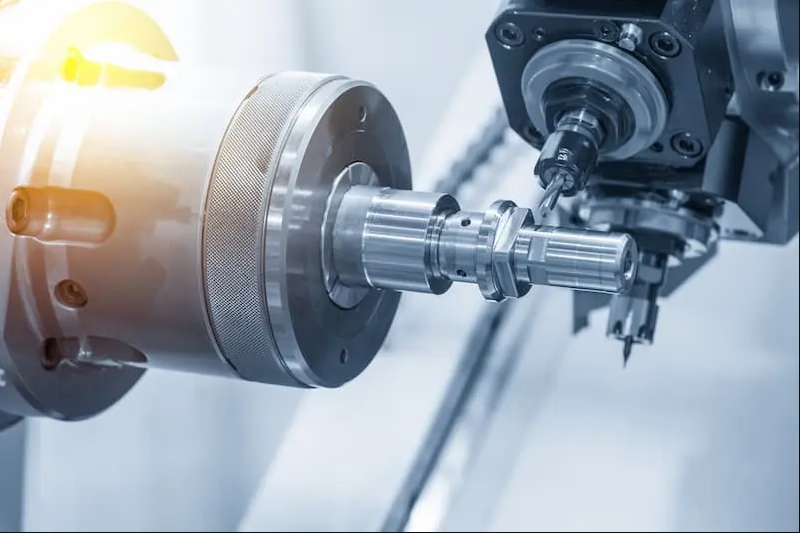

CNC Turning

CNC turning is another way to shape acrylic. You use it to make round parts like rods, tubes, or rings. This method is very precise and works fast. You can finish your project on time. Acrylic is more fragile than metal. You need to be gentle when working with it.

Here are some things to keep in mind:

- CNC turning gives you precise, smooth surfaces.

- You can make custom shapes for special projects.

- Acrylic can break if you use too much force, so gentle handling is key.

NOBLE’s team knows how to work with acrylic safely. We use special steps to protect the material. We still give you top-quality results. Their experience means you get exactly what you need.

If you want to make round acrylic parts, CNC turning is the best way. NOBLE’s skill in CNC acrylic machining makes sure your parts have no cracks or chips.

CNC Engraving

CNC engraving lets you put small details, logos, or words on acrylic parts. You can change a plain sheet into a special sign or a cool display. It can even become a piece of art. This process uses a fast spindle and a sharp engraving bit. The machine follows your design closely. Every line and letter comes out neat.

You might ask why CNC engraving is special in CNC acrylic machining. The main reason is accuracy. You get perfect lines, even with tiny letters or hard patterns. The machine does not slip or shake. You can make the same design on many parts, and each one will look the same.

Here are reasons why CNC engraving on acrylic works so well:

- Sharp, specialized tools: You need engraving bits with smooth edges. These bits move through acrylic without breaking or melting it. NOBLE’s factory uses V-bits and diamond-tipped tools for the best results.

- Controlled speed and depth: You set how fast and deep the bit goes. If you go too deep, the acrylic might chip. If you go too fast, it could melt. NOBLE’s workers change these settings for each job, so you get perfect engraving every time.

- Dust management: Engraving makes small chips and dust. NOBLE uses vacuums to keep the area clean. This keeps the lines sharp and the surface clear.

Tip: If you want your logo or words to stand out, ask about backfilling. This means putting colored paint or resin in the grooves. It makes the design pop and look more professional.

You can use CNC engraving for many things:

| Application | Benefit | Example Use Case |

| Signage | High clarity, custom shapes | Storefront signs, nameplates |

| Awards & Trophies | Detailed graphics, polished finish | Custom awards, plaques |

| Control Panels | Precise labels, durable markings | Machine panels, button labels |

| Decorative Panels | Artistic patterns, smooth surfaces | Wall art, lighting features |

NOBLE’s skill in custom machining means you get what you want. The team checks every step, from the first drawing to the last polish. You can trust their careful work to give you parts that look great and last a long time.

CNC engraving is good for small or large orders. You can get one special part or many that match. The process stays quick and correct, no matter how many you need. If you need help with your design, NOBLE’s experts can help you. We know how to turn your ideas into real, eye-catching acrylic products.

Why Choose NOBLE for Acrylic CNC Machining?

Expertise

When you choose NOBLE, you get a team with years of hands-on experience in acrylic cnc machining. NOBLE started over 15 years ago and has grown into one of China’s top manufacturers for acrylic parts. You can trust their engineers to handle both simple and complex projects. We know how to avoid common problems like cracking, melting, or chipping. You get advice from experts who have seen almost every challenge in the field.

NOBLE’s team works with clients from many industries. You might need a prototype for a new product, or you might want thousands of parts for a big order. NOBLE can help you with both. Their engineers use the latest CAD/CAM software to turn your ideas into real parts. You get support at every step, from design to delivery.

NOBLE’s experience means you get fewer mistakes and faster results. You save time and money on every project.

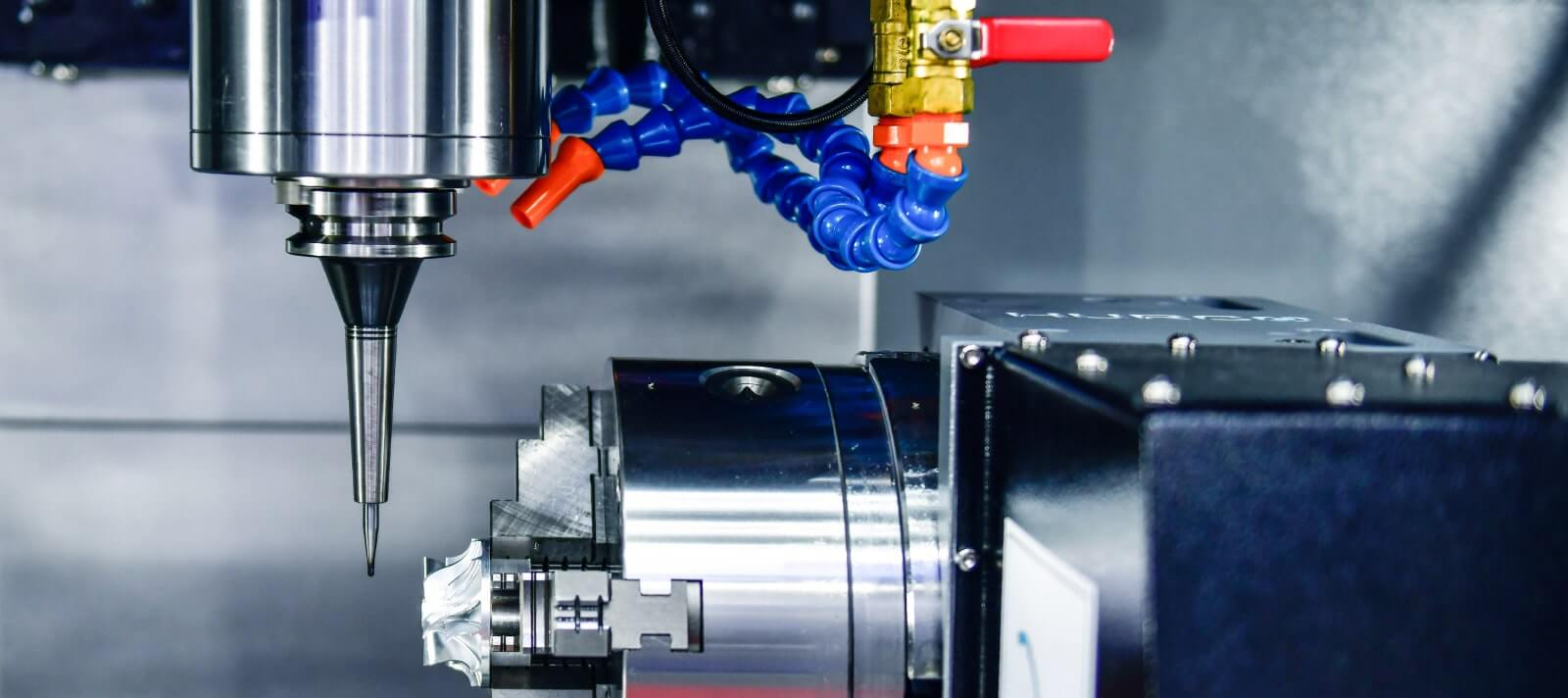

CNC Machining Equipment

You want your parts made with the best machines. NOBLE’s factory uses advanced CNC equipment from trusted brands like Haas and DMG Mori. These machines cut acrylic with high speed and accuracy. You get smooth edges and tight tolerances every time.

Here’s a quick look at what NOBLE’s equipment can do:

| Machine Type | Main Feature | Benefit to You |

| 5-Axis CNC Mills | Cuts at any angle | Makes complex shapes easy |

| High-Speed Routers | Fast, clean cutting | Shorter lead times |

| Precision Lathes | Perfect for round parts | Consistent, smooth surfaces |

| Automated Engravers | Detailed logos and text | Custom branding made simple |

NOBLE’s machines run 24/7. You get your parts on time, even for large orders. The factory can switch quickly from one job to another. This means you can order a single prototype or a full production run without delay.

Quality Assurance

You want every part to meet your standards. NOBLE takes quality seriously. Their team checks each part at every stage of production. We use digital calipers, micrometers, and 3D scanners to measure every detail. You get a report with your order, showing that your parts match your drawings.

NOBLE follows strict ISO 9001 quality rules. The factory uses a step-by-step checklist for each job. You can see the difference in the final product. Parts are clear, strong, and free from defects.

- Every batch gets tested for strength and clarity.

- The team inspects for cracks, chips, and surface flaws.

- You get photos and data with your shipment.

If you ever have a question, NOBLE’s support team answers fast. You get help from real people who know your project. This focus on quality and service makes NOBLE a leader in acrylic cnc machining.

These stories show how NOBLE’s CNC acrylic machining turns ideas into real parts. You can see the value of precision manufacturing and skilled factory work in every finished piece.

You can get great results with acrylic cnc machining if you follow some easy steps. Pick the best material for your project. Make sure your tools are sharp. Set up your work area and plan your process with care. Focus on finishing so your parts look clear and smooth. Use a simple checklist to help you avoid errors. NOBLE is always ready to give you good advice and dependable help. Keep looking for new tips and stay interested—your next project can be even better!

FAQ of CNC Acrylic Machining

What is CNC acrylic machining?

CNC acrylic machining means using computers to control machines that cut acrylic sheets. These machines make parts that fit well and have smooth edges. You can make special shapes and designs with this process.

How do you stop acrylic from cracking during machining?

You need to use sharp tools and set the machine to the right speed. Keep the acrylic cool by blowing air or using a mist. Hold the sheet gently so it does not break. These steps help keep your parts strong and stop cracks.

Can you use CNC acrylic machining for small batches?

Yes, you can use CNC acrylic machining for just a few parts. It is great for making samples or small orders. You get good quality fast, and you do not need to buy expensive molds. The factory can change designs quickly if you want.

What finishing methods make acrylic parts clear?

You can use flame polishing, vapor polishing, or buffing to make acrylic clear. These ways take away scratches and make the surface shiny like glass. The factory uses these steps to give you smooth, clear parts.

Why choose cast acrylic for CNC machining?

Cast acrylic is clearer and chips less than other types. It works well for custom jobs. Your parts are stronger and have fewer problems. Most factories say cast acrylic is best for CNC machining.

How do you clean CNC-machined acrylic parts?

Clean acrylic parts with a soft cloth and mild soap in water. Avoid using rough pads or strong cleaners. This keeps your parts clear and stops scratches. Clean parts show the good work done at the factory.

What industries use CNC acrylic machining?

CNC acrylic machining is used in various industries, including medical, automotive, electronics, and retail. Factories make display cases, light covers, control panels, and signs with it. Custom machining helps many different needs.