Soft machining helps you make exact parts fast and simple. You use special tools and gentle ways to cut softer materials. These can be plastics or light metals. You do not put too much pressure on them. Think about making a clay model before carving stone. Soft machining gives you that same kind of freedom. This method works best when you need quick samples. It is also good for testing new ideas in your factory.

What is Soft Machining

Core Principles

You may ask how soft machining is not like other ways to make parts. Why do I choose soft machining over conventional machining? Here are some main ideas:

- You use softer materials such as plastics, composites, and soft metals.

- You work with soft or temporary tooling. These tools are easy to switch out.

- You use less force when cutting. This keeps the material safe from damage.

- This method works best for prototypes and small batches. You can change your design fast.

- You keep the surface smooth and do not stress the material.

Soft machining lets you make parts quickly and with less waste. You can try new ideas without waiting a long time for hard tools. This way is great if you want to see your design before making many parts.

Tools and Equipment

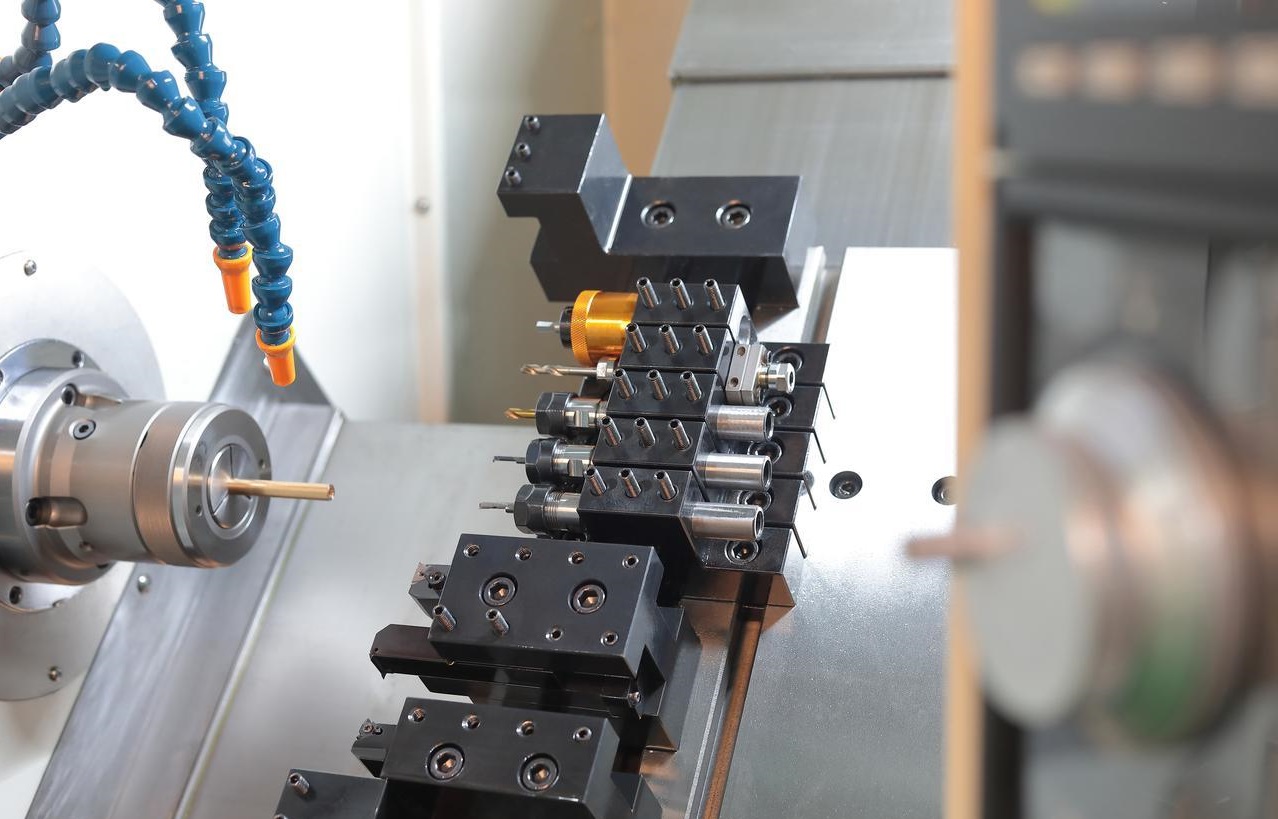

You do not need big heavy machines for soft machining. Instead, you use tools that are simple to set up and change. Here are some things you might see in a modern factory:

- CNC milling machines for shaping parts very accurately.

- Turning and drilling machines for making holes and round parts.

- Grinding tools for making surfaces smooth.

- Temporary or soft tooling that you can change quickly.

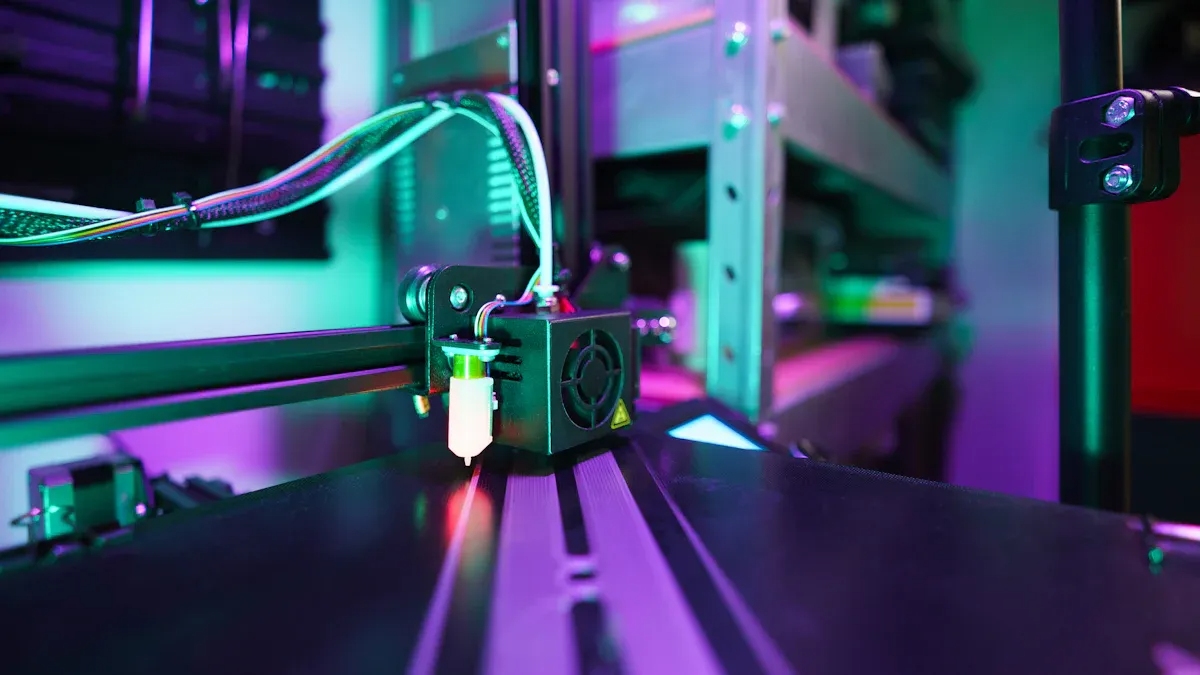

You also use computer software to plan each cut. This helps you get the shape you want. With soft machining, you can turn a digital design into a real part in just a day or two. This fast speed is why many factories like soft machining for their work.

How Soft Machining Works

You may wonder what happens in a factory with soft machining. The steps are easy, but each one is important. Let’s look at them together.

Process Steps

Here is how you turn a block into a finished part:

- Material Preparation

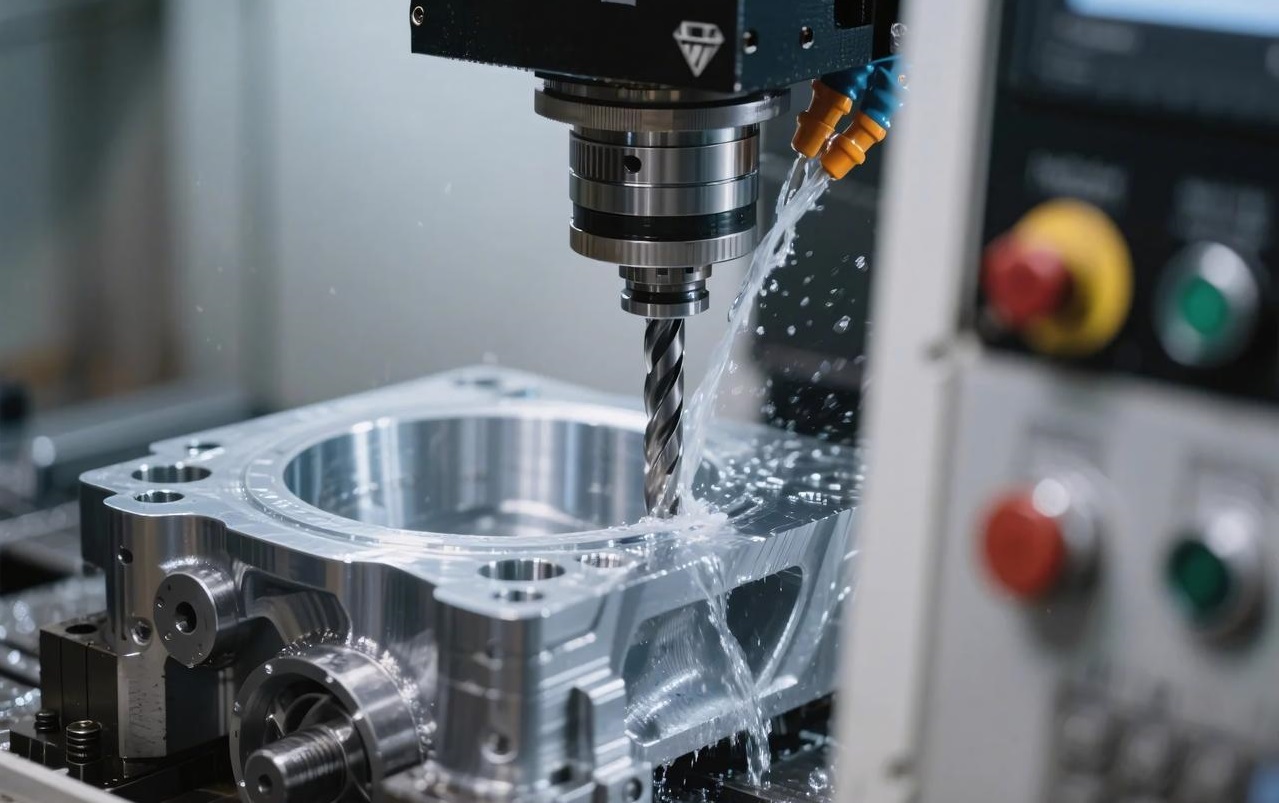

First, you pick the right material for your part. You might use aluminum 6061, brass C360, or POM plastic. The choice depends on what you need. Medical device makers often use POM plastic for a clean finish. Car factories may choose aluminum because it is light. - CNC Programming

Next, you use special software to plan the tool paths. This software helps you decide how the machine will move. It is like giving your CNC machine a set of directions. - Rough Cutting

The machine quickly removes most of the extra material. This step shapes the part but does not focus on small details. - Semi-Finishing

Now, the machine slows down and cuts more carefully. You get closer to the final size and shape. The goal is to match your design as much as possible. - Dimensional Inspection

Last, you check the part by measuring every detail. You make sure it meets your standards. If needed, you can fix things before moving on.

Tip: Checking early helps you find mistakes before they cost a lot. NOBLE, a outstanding Chinese maker, uses careful checks to make sure every part is right.

Key Techniques

In soft machining, we use a number of key processes. Each process helps our customers to get the shape and surface finish they want.

| Technique | Description |

| Milling | Takes away extra material and makes parts with tight tolerances. Good for custom machining and precision manufacturing. |

| Turning | Makes round shapes. CNC machining keeps every piece the same. |

| Drilling | Adds holes with high accuracy. Keeps your workpiece clean and ready for assembly. |

| Grinding | Makes parts smooth and fine. Great for prototype parts that must look and feel just right. |

CNC Milling

CNC milling is used a lot in factories. You use it to cut away material and shape your part. The machine follows the path you set in the software. This works for both simple and complex designs. In the medical field, CNC milling helps make custom implants with tight tolerances. NOBLE’s team uses this method to deliver parts fast, sometimes in just 24 hours.

CNC Turning & CNC Drilling

CNC Turning is best for making round parts like shafts or bushings. The part spins while the tool cuts it. Drilling makes holes that are very exact. This is important for car and electronics factories. You get clean and accurate results every time. NOBLE’s factory uses advanced turning and drilling machines to keep quality high and work fast.

CNC Grinding

CNC Grinding is used to make parts extra smooth. We use it when we need a part to fit just right. This step is common in precision manufacturing, especially for prototypes or parts that must fit together perfectly.

Technology Integration

Modern soft machining uses smart technology. Advanced CAM software makes your our easier and faster. Here is how it helps:

| Feature | Benefit |

| Automatic Feature Recognition | Finds part features from your CAD model right away. |

| Intelligence Based Tool Selection | Picks the best tools and makes toolpaths for you. |

| Complete Associativity | Keeps CAD and CAM data together, so changes update everything. |

| Reduced Errors | Lowers mistakes from manual updates. |

| Increased Productivity | Lets you spend more time on new ideas, less on fixing problems. |

| Technology Database | Saves your best settings for future projects. |

| VoluMill & VoluTurn | Makes toolpaths smoother and faster, saving time and machine wear. |

| PrimeTurning™ | Gives you more ways to do turning, making the process flexible. |

- The software does many steps for you, so you do not have to do everything by hand.

- You get faster production and less waiting time.

- You waste less material and save money on each job.

You can get tight tolerances by using slow feed rates and shallow cuts. This lowers tool bending and heat, which keeps your parts accurate. For example, a normal part might take 10 minutes to machine. A high-precision part could take 30 minutes or more. NOBLE’s experts work with you early to help save money and improve your design.

With soft machining, you can often get finished parts in just 24 to 48 hours. This speed is very helpful for medical and car companies. They need to test and improve designs quickly. NOBLE is known as a top Chinese maker because we deliver fast and reliable service every day.

Benefits of Soft Machining

Precision & Quality

You want your parts to fit just right. Soft machining helps you do that. CNC machining makes parts with very close tolerances. For plastics, this can be as close as ±0.005 inches. Every part matches your design, even if it has small shapes or details. NOBLE uses advanced machines and skilled workers to make sure your parts are always correct.

If you work in medicine, you need custom machining for tools or device covers. Doctors need these parts to be exact. Soft machining makes sure every curve and hole is in the right place. In cars, precision manufacturing helps you make light aluminum parts that fit well. You do not have to worry about gaps or rough spots. You get good quality you can see and touch.

Reduced Tool Wear

Running a factory means you know tool wear is a problem. It can slow you down and cost money. Soft machining uses less force and softer materials, so tools last longer. This means you do not stop often to change tools. You also do not need to buy new ones as much. NOBLE’s team picks the best tools for each job to keep things moving.

Here is a table to show how tool wear is different:

| Method | Tool Life (Average) | Maintenance Needed |

| Traditional Machining | Shorter | Frequent |

| Soft Machining | Longer | Less Often |

Soft machining saves you money and keeps your CNC machining equipment working well. This is very important in electronics, where even a small tool mistake can ruin many parts.

Fast Production

Speed is important today. People want to go from idea to finished part fast. Soft machining lets you do this. With NOBLE’s custom machining, you can get samples or small batches in 24 to 48 hours. This is great for companies testing new ideas or launching products quickly.

If you are making a new medical device, you send your CAD file to us. Our factory starts making your parts right away. You get your parts back in days, not weeks. In cars, this speed lets you test new engine or inside parts before others. Fast production helps you stay ahead and change quickly.

By the way, I’ll just add this: Getting parts fast does not mean you lose quality. NOBLE checks every part, so you get both speed and accuracy.

Soft machining is a smart choice when you need good parts fast. You get the benefits of CNC machining, help from a superior Chinese manufacturer, and you know you are working with experts.

Environmental & Safety

Protecting the Earth is everyone’s duty. You must also be very concerned about the safety of employees in the factory. Soft machining helps you do both. When you use CNC machining, you make better choices. These choices help the environment and keep your team safe.

Let’s talk about the environment first. Soft machining uses less energy than older ways. Machines work better, so you save power every day. Many factories now use solar or wind power for their CNC machines. This change means less non-renewable energy is used. Your carbon footprint gets smaller. You also save money on energy bills over time.

You want to waste less material. Soft machining helps you use only what you need. Less scrap means less trash goes to landfills. Some factories, like NOBLE, recycle metal scraps and coolants. They also use biodegradable materials and recycled metals when they can. This keeps your factory clean and green.

Here’s what you get with soft machining:

- You use less energy with efficient CNC machines

- You waste less because you use just enough material

- You recycle metal scraps and coolants

- You use biodegradable and recycled materials

- Your factory has a smaller carbon footprint

- You save money on energy bills

Safety is important too. In busy factories, accidents can happen quickly. Soft machining, especially with CNC machining, keeps workers safer. Machines do most of the work. Team spends less time near sharp tools or moving parts. This means fewer injuries. In medical factories, safety is even more important. NOBLE’s custom setups use strict safety checks and automation. This protects workers and products.

You see these safety benefits:

- Workers touch tools less

- Fewer accidents happen

- Workspaces are safer, even for hard jobs

- Results are reliable for medical and car factories

Factories using soft machining, like NOBLE’s, lead the way in safe and green production. You get good parts, protect your team, and help the planet at the same time.

Common Materials for Soft Machining

Aluminum Alloys

Aluminum alloys are used a lot in soft machining. They are light and strong. You can shape them easily. Factories use them for test parts and real products. NOBLE, a top Chinese company, we uses these alloys for quick jobs.

- You can choose from many types: 1xxx, 2xxx, 3xxx, 5xxx, and 6xxx.

- These alloys are easy to machine and do not rust easily.

- They are strong but do not weigh much, so parts stay tough.

Some alloys, like 2011 and 5056, are special. They let you cut parts very fast. Their machinability can be as high as 280%. This means you finish work quickly and your CNC machining tools last longer. Series 5xxx alloys are good for bridges and boats. They are strong and can bend without breaking.

Car makers use 6061 aluminum for engine parts. Medical companies use aluminum for covers and brackets. You get clean and exact parts every time.

Brass & Copper

Brass and copper are important in precision manufacturing. You might pick brass if you want easy cutting and strong parts. Copper is best when you need to move heat or electricity.

- Brass is easy to cut and gives smooth surfaces.

- Brass is strong, with tensile strength from 338 to 469 MPa.

- Its yield strength is 95 to 124 MPa, higher than copper.

- Brass does not rust, so it lasts longer in hard places.

Copper is softer than brass. It can be hard to cut, but it is great for electronics. You can make thin wires or tricky shapes with it. Copper moves electricity and heat very well.

In factories, brass is used for valves, gears, and connectors. Car companies use copper for wires and heat parts. NOBLE’s CNC machining team knows how to work with both metals. You always get strong and good parts.

Plastics

Plastics give you many choices for soft machining. You get parts that are light and last a long time. NOBLE’s factory uses CNC machining to shape plastics for many products.

Here’s a table of top plastics and what they do:

| Plastic Type | Key Properties | Applications |

| Nylon | Stands up to chemicals, heat, and wear, slides easily | Gears, bearings, wear pads, nozzles |

| Polyethylene | Does not soak up water, resists chemicals | Packaging, construction, automotive parts |

| Polypropylene | Resists chemicals, is light | Lab equipment, medical devices, food packaging |

You might use nylon for car gears or medical parts. Polyethylene is good for packaging and car parts. Polypropylene is used in labs and hospitals. These plastics let you make detailed shapes that fit well. Your parts last, even when used a lot.

NOBLE’s team helps you pick the best plastic for your job. You get fast service, smart advice, and parts that meet tough rules. That is why many companies trust this Chinese maker for custom machining.

Composites

You can find composites in many modern factories. These materials mix things like fibers and resins together. This makes parts that are strong, light, and tough. For example, race cars use carbon fiber. Medical devices use glass-filled plastics. Composites help products last longer and weigh less.

CNC machining lets you shape composites in many ways. You can make curves, holes, and thin walls. This is great for custom machining in medicine. Doctors need tools and implants that fit well. Car makers want lighter parts to save fuel. Composites help make this happen.

NOBLE is a top Chinese manufacturer for composites. Their factory uses advanced CNC machining to cut and finish these materials. You get precision manufacturing every time. NOBLE’s team knows how to work with composites. Your parts always meet strict standards.

Let’s see what makes composites special in soft machining. There are big benefits and some challenges too. Here is a table to show both sides:

| Benefits | Challenges |

| Cost-effectiveness for prototyping and low volume production | Tool selection and optimization issues |

| High dimensional accuracy and superior surface finish | Heat dissipation and thermal expansion problems |

| Ability to handle complex and delicate geometries | Risk of material deformation and burr formation |

| Versatility in material processing | Unsuitability for hard or tough materials |

| Low energy consumption |

You save money when making prototypes or small batches. Composites let you make shapes that metals cannot. You get smooth surfaces and tight tolerances. This is important for medical devices. In car factories, you can test new ideas fast and save money.

But you must pick the right tools. Composites can get hot or change shape if not careful. Sometimes, you see small burrs or rough edges. NOBLE’s experts use special tool paths and cooling to keep parts perfect. Their CNC machining setups handle these problems well.

Here is what you get with composites:

- Lightweight parts that are still strong

- Custom machining for special shapes

- Fast turnaround for prototypes

- Less energy use in your factory

- Help from a professional machining team

NOBLE’s precision manufacturing means fewer mistakes. Our Chinese factory gives you parts that work right the first time. You can get one prototype or thousands of parts. NOBLE helps you go from idea to finished product fast. Many companies trust them for CNC machining and custom work.

Tip: If you want to use composites in your next design, talk to NOBLE’s team. We will help you choose the best material and process for your needs.

Soft Machining vs. Traditional Machining

Process Differences

You may wonder how soft machining is different from traditional machining. The main difference is the tools used for each method. Soft machining uses soft or temporary tooling. These tools are easy to change and cost less at the start. You can switch designs quickly, which is great for making prototypes or testing ideas. Traditional machining uses hard tooling. These tools last longer but cost more and take longer to make. Hard tooling is good if you need to make thousands of the same part. But if you want to change things often, soft machining is better.

At a NOBLE factory, you see CNC machining centers for both types. Soft machining uses gentle force and smart software. This keeps your materials safe and lets you change things fast. Traditional machining uses more force and needs more manual setup. You get strong and repeatable parts, but it takes longer to change designs.

Comparative Advantages

Let’s look at what each method does best. Here is a table to show the differences, We hope you can find the best solution using this information:

| Type of Machining | Advantages |

| Traditional Machining | – Lower Initial Cost: Good for small shops starting out. |

| – Flexibility: Handles many tasks without much programming. | |

| CNC Machining | – High Precision and Consistency: Delivers exact parts every time, key for medical and auto. |

| – Increased Efficiency: Makes parts faster, so you meet tight deadlines. | |

| – Reduced Labor Costs: Needs less hands-on work after setup. |

If you work in medicine, you know precision manufacturing is important. One mistake in a tool can cause big problems. NOBLE’s CNC machining makes sure every part fits just right. In car factories, speed is important. You want to test new parts fast. Soft machining helps you do this without waiting for new tools.

When to Use Each

You may ask, “When should I use soft machining, and when is traditional better?” Here is a simple guide:

- Choose soft machining when:

- You need prototypes or small batches.

- Your design changes a lot.

- You want to save money at the start.

- You use plastics, aluminum, or composites.

- You need parts in 24-48 hours.

- Choose traditional machining when:

- You want to make thousands of the same part.

- Your design will not change.

- You want the lowest cost per part for big jobs.

- You use very hard metals.

In real factories, both ways are used. For example, a car company might use soft machining to test a new gear. When the design is ready, they use traditional machining for mass production. In a medical factory, you may need custom machining for a new implant. NOBLE’s team can make a prototype in days, then make more when you are ready.

Tip: To stay ahead, use soft machining for quick changes and traditional machining for big jobs.

With NOBLE, you get a partner who knows both methods. Their Chinese factory uses the latest CNC machining, so you always get quality, speed, and value.

Applications of Soft Machining

Soft machining is used in many places. Factories use it for lots of jobs. Let’s look at how different industries use this process. It helps you go from an idea to a finished part fast.

Industry Examples

Aerospace

Aerospace needs parts that are light and strong. Every gram matters in planes. Soft machining makes cabin panels and sensor housings. It also makes brackets for wires. You can test new designs quickly. You do not wait weeks for hard tooling. NOBLE helps aerospace companies with CNC machining. They make custom prototypes and small batches. You get parts that meet strict safety rules.

Medical Devices

Medical factories need parts that are exact and quick. You might need a clear housing for a new tool. Or you want to test a prototype for surgery. Soft machining gives you both speed and accuracy. You send your CAD file to NOBLE’s factory. You get finished parts in just a few days. Our team uses CNC machining for tight tolerances. We also have ISO 13485:2016 and ISO 9001:2015 certifications. Thus, hospitals and labs trust NOBLE for custom machining. Every detail is important in medicine.

Consumer Electronics

Phones and tablets must look good and feel strong. Soft machining helps make heat sinks and connector housings. It also makes device casings. Electronics factories use soft machining to test new designs. They launch products quickly. NOBLE’s precision manufacturing gives smooth finishes and exact fits. Our CNC machining works with plastics, aluminum, and copper.

Here’s a table showing how industries use soft machining:

| Industry | Typical Applications |

| Aerospace | Light parts like cabin panels and sensor housings |

| Medical Devices | Clear housings, surgery prototypes, and custom parts |

| Consumer Electronics | Heat sinks, connector housings, device casings |

| Automotive Industry | Prototypes, tooling for car parts, molds, and light brackets |

If you need to change a design fast, soft machining helps you do it without waiting or spending a lot.

Product Types

Factories make many kinds of parts with soft machining. You see shafts, wheels, rings, housings, gears, and splines. These parts are used in cars and farm machines. NOBLE’s factory works with copper, aluminum, steel, and stainless steel. Their custom machining covers small gears and big blanks up to 2,000 kg.

Check out this table for a quick look:

| Product Type | Industries Served | Material Types |

| Shafts | Heavy Industry | Copper, Aluminum, Steel, Stainless Steel |

| Wheels | Passenger Cars | Copper, Aluminum, Steel, Stainless Steel |

| Thin Rings | General Industry | Copper, Aluminum, Steel, Stainless Steel |

| Housings | Farming, Mining, Construction | Copper, Aluminum, Steel, Stainless Steel |

| Gears and Splines | Many Industries | Copper, Aluminum, Steel, Stainless Steel |

| Bearing Surfaces | Many Industries | Copper, Aluminum, Steel, Stainless Steel |

Soft machining gives you lots of choices. Need custom aluminum brackets for a new car? NOBLE’s CNC machining team can help. Want a prototype gear for a medical device? Our experts help you pick the best material and process. You can order parts from 2 kg to 2,200 kg.

NOBLE is a Chinese manufacturer known for speed and quality. Our factory does fast prototyping and full production. You get the parts you need, when you need them, with no surprises.

Why Soft Machining is Trending

Efficiency & Speed

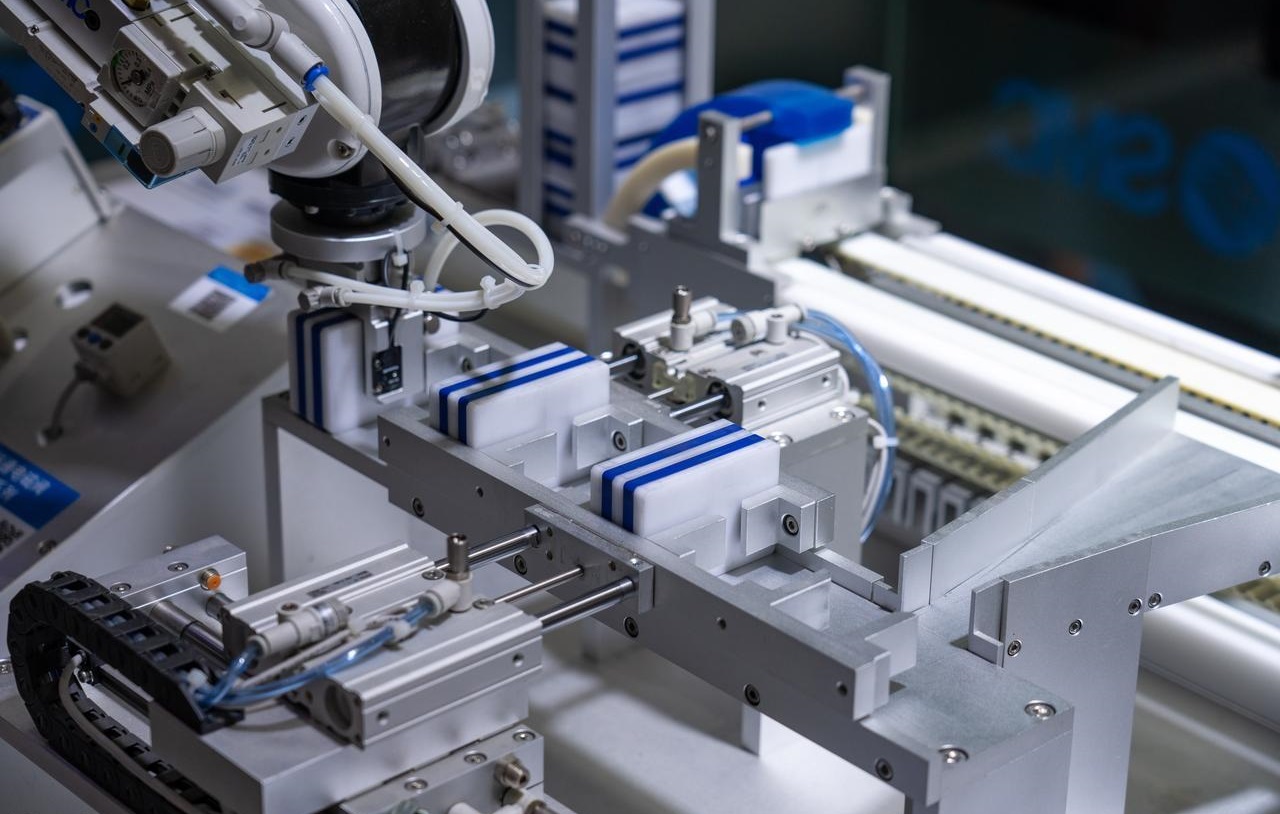

Factories want to work fast. Soft machining helps them do this. High-speed machining makes parts quicker. It cuts down the time each part takes. NOBLE uses robots and machines that run all day and night. This means you get your parts sooner. You do not have to wait long.

If you’re curious about how we achieve fast, exact machining, here’s the answer:

| Strategy | Impact on Efficiency and Speed |

| High-speed machining techniques | Makes parts faster and increases how many you make |

| Automation and robotics | Machines work all the time and keep things steady |

| Optimizing machining processes | Makes machines work better and more often |

| Improved material handling | Uses machines more and stops them from sitting idle |

You can see these results in real places. Hospitals need new device parts quickly. NOBLE’s team can make these in one or two days. Car makers also need fast parts. We test new engine pieces quickly to stay ahead.

Picking the right tool shape is important. It helps you cut faster and easier. Tools with fewer flutes clear chips out quickly. This is good for soft materials. Coated tools last longer, so you do not stop work. A high helix angle lets you feed material faster. This makes CNC machining smoother.

Cost Savings

Factories want to save money when trying new ideas. Soft machining helps with this. You pay less at first because you use soft tools. You do not need expensive hard tools for every change.

For example, a car company needed a new bracket. Soft machining let them make many versions in just days. They did not pay a lot for hard tools. Medical startups also save money this way. They can test and fix products without spending too much.

You also save on fixing tools. Tools last longer because you use less force. You do not need to buy new ones often. This means less downtime and more parts for your money.

Flexibility & Adaptability

Markets change quickly. Factories need to keep up. Soft machining lets you change designs fast.

Here’s what you get:

- Fast prototypes for new ideas

- Easy design changes with no long wait

- Small or medium batches made quickly

- Works with many materials like plastics and aluminum

If you work in precision manufacturing, you must meet customer needs. NOBLE’s custom machining helps you do this. Their factory can make one part or thousands. You stay flexible and your business stays ahead.

Why NOBLE Choosing NOBLE for Soft Machining

You want a partner who knows what you need. NOBLE is a top CNC machining company in China. When you work with NOBLE, you get more than just parts. Their team listens to you and helps solve problems. They use advanced machines and skilled engineers. Every project shows their hard work.

NOBLE works with many industries. In medicine, a client needed custom machining for a new tool. NOBLE made prototypes in only 36 hours. The hospital tested the parts and gave feedback. NOBLE sent better versions in two days. This fast work helped doctors save time and help patients.

Car companies trust NOBLE too. One car maker needed precision manufacturing for light engine brackets. NOBLE’s team used CNC machining to make samples with tight tolerances. The client tested the brackets and liked them. They ordered a small batch for real tests. NOBLE’s quick work kept the project on track.

When you pick NOBLE, you get a Chinese manufacturer with a strong record. You see quality, speed, and flexibility in every order.

NOBLE’s Solutions

NOBLE gives you many professional machining services. You can order prototypes, small batches, or big runs. Their custom machining fits your needs. You send your CAD file to them. NOBLE’s engineers check it, suggest changes, and start making parts fast.

Here’s what you get with NOBLE:

- Fast Prototyping:Get parts in just 24-48 hours.

- Precision Manufacturing:Tolerances as close as ±0.005 inches for plastics and ±0.01 mm for metals.

- Material Flexibility:Pick from plastics, aluminum, brass, copper, and composites.

- Scalable Production:Order from 2,000 to 70,000 units without big upfront costs.

- Expert Support:Get advice on design, materials, and process choices.

| Service | Benefit for You |

| CNC Machining | Same, accurate parts every time |

| Custom Machining | Special solutions for unique projects |

| Professional Machining | Reliable quality and fast delivery |

NOBLE’s factory uses the newest CNC machining centers. You get help from automation and strict quality checks. Their team wants you to succeed. Many global brands trust NOBLE for their big projects.

Want to move your ideas forward? NOBLE’s team can help you turn designs into real parts—fast, accurate, and at the right price.

Soft machining helps factories do better in today’s busy world. It lets you work fast and change things easily. You also get very accurate parts without spending too much money. Here are some reasons why more factories use soft machining now:

| Benefit | What It Means for You |

| Customized Solutions | Tools match your parts, so results are better. |

| Workpiece Protection | Soft machining keeps delicate surfaces safe every time. |

| Improved Precision | Parts are held tight, so they turn out right. |

| Cost-Effective Production | You save money by wasting less and working faster. |

| Expert Support | Skilled workers help you finish jobs quickly and well. |

Are you thinking about using soft machining? It can help you make more parts and stay ahead of others. These smart ways make the future of factories look great.

FAQs of Soft Machining

What is soft machining?

Soft machining shapes soft materials like plastics or aluminum. It uses gentle cutting and temporary tools. You get quick samples and small batches that are very exact. NOBLE’s factory does this for car and medical parts.

How fast can I get my parts with NOBLE?

You can get finished parts in just 24 to 48 hours. NOBLE’s CNC machining team works day and night. This helps you test new ideas fast, like for cars or medical devices.

Which industries use soft machining the most?

Soft machining is used in medical, car, airplane, and electronics factories. Hospitals need custom tools for surgery. Car makers use it for engine parts and test pieces. NOBLE helps all these groups as a top Chinese maker.

What materials work best for soft machining?

Plastics, aluminum alloys, brass, copper, and composites work well. NOBLE’s experts help you pick the best one for your job. Medical factories often use POM plastic. Car teams like aluminum 6061.

How does soft machining save money?

You save up to half on starting costs with soft machining. You do not need expensive hard tools. NOBLE’s factory lets you change designs easily. You spend less on new tools and get more from each job.

Can I order both prototypes and large batches?

Yes! NOBLE makes prototypes, small runs, and big orders. You can order from 2,000 up to 70,000 parts. Their team keeps quality high for every order size.

How does NOBLE ensure quality and accuracy?

NOBLE uses advanced CNC machines and strict checks. You get very close tolerances, like ±0.005 inches for plastics. For metals, it is ±0.01 mm. Their team checks every part before it ships.

Is soft machining safe and eco-friendly?

Soft machining helps keep workers and the planet safe. It uses less energy and makes less waste. NOBLE’s factory recycles metal scraps and uses safe machines. Hospitals and car companies trust their green ways.