What is Sheet Metal Stamping?

Sheet metal stamping is a metal machining method that mainly applies pressure to metal sheets through mechanical presses and special molds to cause plastic deformation or separation, thereby obtaining parts of the required shape and size.

How does Sheet Metal Stamping Work?

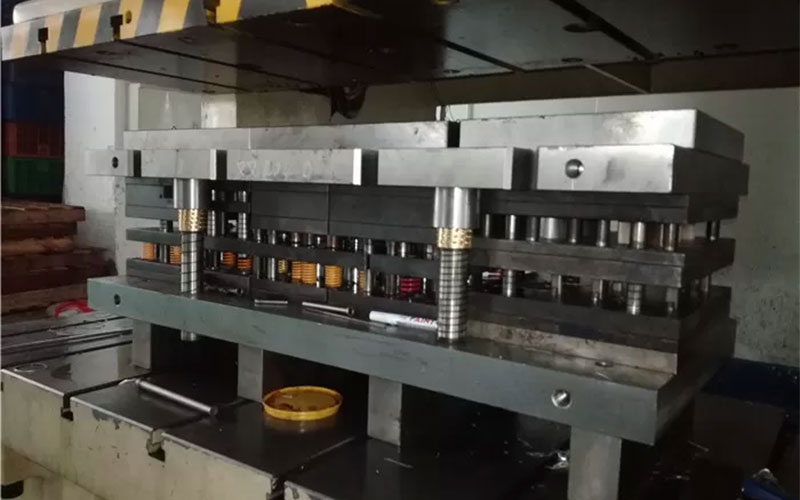

Mold Design

The mold is the core preparation stage of the stamping process. Molds are usually composed of a punch and a die, and their cavities precisely determine the final shape of the part.

The design of molds needs to take into account factors such as material flow and rebound comprehensively. Mold manufacturing demands extremely high precision and durability. It is typically made from high-strength tool steel through precise mechanical machining, heat treatment, and surface treatment to ensure stability and part quality during mass production.

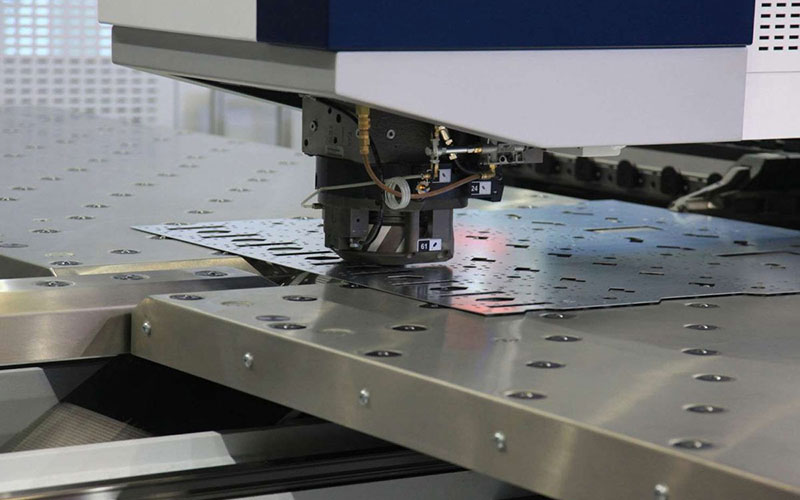

Material Preparation

The manufacturing of sheet metal requires the process of preparing raw materials into blanks of the required size. Common methods in sheet metal manufacturing include shearing by shearing machines, laser cutting, or blanking.

The objective of this step is to obtain a flat blank with accurate dimensions to prepare for the subsequent stamping forming. The precision of blanking and the quality of edges will directly affect the smooth progress of subsequent processes and the quality of the final product. Therefore, it is necessary to strictly control dimensional tolerances and burrs.

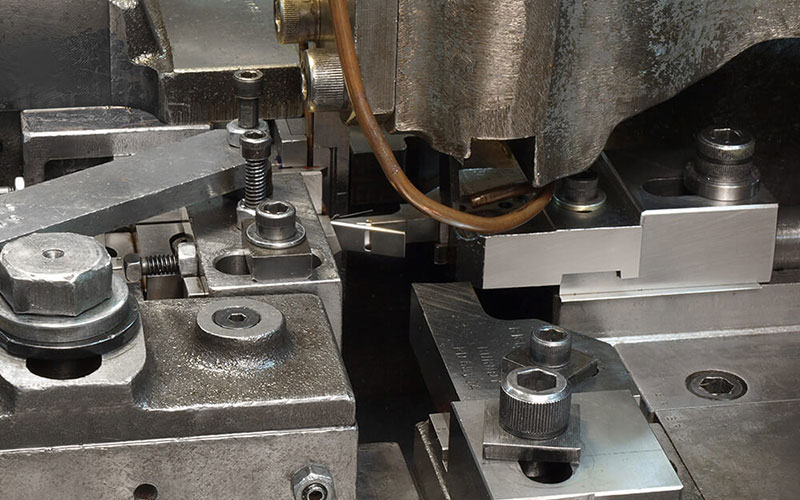

Sheet Metal Stamping

Stamping forming is the core processing step. The blank after blanking is placed in the pre-installed die, and a huge pressure is applied through a press to cause plastic deformation of the material in the die cavity.

According to the shape requirements of the parts, the stamping process may include various specific processes such as blanking, bending, drawing, and hole flipping, transforming flat material into structural components with three-dimensional shapes.

Subsequent Machining

The parts formed by stamping often need to undergo a series of subsequent treatments to meet the usage requirements.

The parts need to have burrs removed and sharp edges chamfered to enhance safety. It may also include other connection methods such as welding and riveting to assemble with other components; And surface treatment processes such as spraying and electroplating are used to enhance the corrosion resistance and aesthetic appeal of the parts.

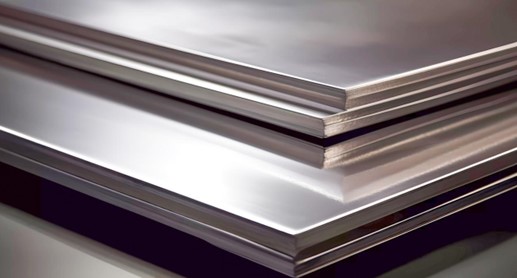

Material Used in Sheet Metal Stamping

Carbon Steel

Carbon steel is the most commonly used and cost-effective type of material, among which SPCC (cold-rolled steel plate) is the most typical.

Carbon steel has good strength and ductility, and is easy to form by stamping. However, its surface is prone to oxidation and rusting, so it usually requires surface protection treatments such as spraying and electroplating.

Stainless Steel

Stainless steel is highly favored for its excellent corrosion resistance and high strength. The most commonly used grade is SUS304, which contains chromium and nickel and can form a dense chromium oxide passivation film on the surface, with outstanding rust resistance. Magnetic stainless steels such as SUS430 can also be used for sheet metal stamping.

Aluminium

The greatest advantage of aluminium is its low density, light weight, and excellent electrical and thermal conductivity, as well as corrosion resistance. Commonly used grades include 1060, 5052, 6061, etc. These types of aluminium balance strength, formability, and corrosion resistance to varying degrees. Aluminum plates are easy to undergo stamping operations such as stretching and bending.

Copper

Copper has excellent electrical and thermal conductivity, and its ductility ranks among the top in all metal materials, making it highly suitable for the stamping forming of complex shapes.

Brass (such as H62) and phosphor bronze are commonly used copper alloys. Besides having good electrical conductivity, they also have excellent appearance and wear resistance.

Types of Sheet Metal Stamping

Sheet Metal Shearing Processes

The shearing processes, also known as blanking, aim to separate one part of the material from another along a certain contour line. The key to this process lies in utilizing the gap between the punch and the die to cause shear deformation of the material until it breaks.

Sheet Metal Forming Process

The forming process refers to the process of changing the shape and size of the blank by causing plastic deformation without damaging the integrity of the material, thereby obtaining the required three-dimensional parts.

Sheet metal forming processes encompass a variety of specific techniques. For instance, bending involves bending sheet metal into a certain Angle or shape. Stretching is the process of transforming a flat blank into an open hollow part, such as a cup-shaped body.

The core of the forming process is to control the flow and thinning of the material to prevent wrinkling or cracking.

Progressive Die Sheet Metal Stamping

The progressive die stamping is not an independent procedure but a clever combination of two different types of processes, separation and forming, in a set of dies, which are completed simultaneously in one stamping stroke.

For instance, at one workstation, stretching can be carried out first to form a cup shape, and then punching can be done immediately afterwards. This process greatly enhances production efficiency, reduces the number of equipment and molds, and ensures the relative positional accuracy among the various features of parts. It is particularly suitable for the production of parts with complex structures and large output volumes. However, the requirements for mold design and manufacturing are also more complex.

Deep-draw Sheet Metal Stamping

Deep-draw sheet metal stamping is a metal-forming technique that creates seamless, three-dimensional components with significant depth. The process involves using a die and punch set to transform a metal sheet into complex shapes by drawing it into a cavity. This method is commonly used to produce cylindrical or box-shaped parts with high accuracy.

Fourslide Sheet Metal Stamping

Four-slide sheet metal stamping, also referred to as multi-slide stamping or four-way stamping, is a specialized method of metal stamping. The manufacturing process is used to create intricate shapes and complex, small to medium-sized components with multiple bends. It is ideal for parts that require precise forming, tight tolerances, and high-speed production.

Fine blanking Sheet Metal Stamping

Fine blanking sheet metal stamping is a precise method of forming metal components that produces smooth edges all the way around the workpiece. Unlike traditional blanking, this method only requires one step and a small die clearance. Furthermore, no additional secondary operations are required, reducing both production time and costs. As a result, fine-blanking is a popular manufacturing technique for a variety of products, including automotive, aircraft, and precision machine components.

Embossing Sheet Metal Stamping

Embossing is a sheet metal stamping technique that produces raised or indented patterns or designs on sheet metal. It entails applying pressure to the material with the desired pattern using a die, resulting in a raised or depressed area. Embossing is frequently used to add decorative or functional features such as grip surfaces or identification marks.

Compound Die Stamping

Compound die stamping is a high-efficiency and low-cost precision metal stamping manufacturing process. It is suitable for small and medium-sized metal stamping projects. It can ensure the precision tolerances required for part design and has a lower manufacturing cost than progressive die molds.

Surface Finishes for Sheet Metal Stamping

Anodizing

Anodizing is a surface treatment technology specifically designed for aluminum and its alloy sheet metal parts. Anodizing is a process that generates a hard layer of aluminum oxide coating on the surface of aluminum materials through electrochemical methods.

This layer of aluminum oxide coating is not only dense, significantly enhancing the corrosion resistance and wear resistance of the workpiece, but also, due to its porous structure, can adsorb dyes to achieve a wide range of color options.

Powder Coating

Powder coating is a process in which dry powder coatings are sprayed onto the surface of parts through electrostatic adsorption and then cured at high temperatures to form a coating. The coating formed by powder spraying is relatively thick and has excellent corrosion resistance, wear resistance, and mechanical strength.

Electroplating

Electroplating is a process that uses the principle of electrolysis to deposit a thin layer of metal or alloy film on the surface of sheet metal parts, such as galvanizing, nickel plating, chromium plating, or gold plating.

The electroplated coating can significantly enhance the rust prevention ability and surface hardness of parts, and endow them with special surface properties, such as the high reflectivity and wear resistance of chromium plating, or the excellent electrical conductivity of gold/silver plating.

Sand Blasting

Sandblasting is a physical process that uses high-speed gas flow to spray sand grains or other abrasives onto the surface of parts, and cleans and roughens them through impact.

Sandblasting can effectively remove the oxide scale, oil stains, and old coatings on the surface, and form a uniform and fine uneven matte texture on the metal surface. This not only enhances the adhesion of the coating but also provides an ideal base for subsequent spraying or anodizing.

Polishing

Polishing is a process of machining the surface of sheet metal through mechanical, chemical, or electrochemical actions to reduce its roughness and thereby achieve a mirror-like bright surface effect.

Polishing can thoroughly remove scratches, burrs, and other defects left during stamping and machining, greatly enhancing the appearance, texture, and grade of the product.

- Applications: Kitchenware, bathroom hardware, jewelry, and decorative parts for high-end consumer electronics

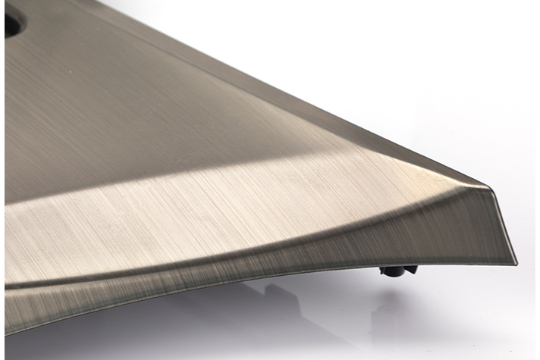

Brushing

Brushing is a processing technique that uses tools such as abrasive belts or nylon wheels to rub the metal surface directionally and continuously, thereby creating a matte surface with a linear texture.

Brushing can effectively cover the scratches produced during the production process and has a fine touch. Brushing treatment can highlight the texture and grain of metal, creating a modern and simple visual effect, and at the same time, it is less likely to leave fingerprints like high-gloss surfaces.

- Applications: Mobile phone frames, electrical appliance panels, elevator cabins, decorative strips

Advantages of Sheet Metal Stamping

High Production Efficiency

Stamping machining is extremely fast, and the production quantity of small and medium-sized parts can reach hundreds of pieces per minute. The high-speed production capacity of stamping significantly reduces the manufacturing time cost of individual parts, providing a solid foundation for the delivery of large-scale orders.

Low Unit Cost

Once the stamping die is made, the production cost of a single part is mainly concentrated on the material itself. In mass production, the initial cost of the mold is spread out to each product, making the unit cost very low. Highly automated stamping production lines have also saved a significant amount of labor costs.

Consistent Quality

The stamping process relies on precision dies, which means that every part produced in the same die has the same shape and size. This high precision and excellent consistency guaranteed by molds are crucial for modern assembly and product quality control, effectively avoiding errors caused by human operation.

High Material Utilization

Stamping production typically employs coil or sheet materials. Through ingenious layout design, the materials can be utilized to the greatest extent. The leftover materials generated during the stamping production process can also be recycled and reused, which, to a certain extent, reduces the waste of raw materials and lowers the overall material cost.

Complex Part Capability

The stamping process can cause plastic deformation of metal materials in the cold state, not only enabling the production of complex-shaped parts, but also enhancing the strength and rigidity of parts through deformation strengthening mechanisms.

Challenges of Sheet Metal Stamping

Wrinkling and Tearing

Wrinkling occurs when the material flows too fast under compressive stress, causing local accumulation of the sheet metal and forming wrinkles. Tearing is exactly the opposite. It occurs when the material becomes overly thin under tensile stress until it tears.

To address these two issues, a delicate balance needs to be struck in process parameters such as mold design, blank holder force control, and lubrication, to prevent the material from flowing too quickly and wrinkling, while also avoiding insufficient flow and tearing.

Springback

Springback is an elastic recovery phenomenon in which the shape and size of parts deviate from the die cavity after the material is formed by stamping due to the release of internal elastic stress. This is the most significant factor affecting the precision of parts, especially on bent parts.

Accurately predicting and compensating for springback is highly challenging and requires the use of advanced simulation software, empirical data, and combined with the overcorrection design of the mold surface to overcome it.

Surface Damage

During the stamping process, the relative movement between the sheet metal and the die may cause surface defects such as scratches and roughness. This is mainly caused by insufficient surface finish of the mold, improper lubrication, or inadequate hardness of the mold, etc.

These minor damages not only affect the appearance of the product but may also become stress concentration points, reducing the fatigue strength and corrosion resistance of the parts.

Burrs and Dimensional Deviation

In the blanking or trimming process, if the die clearance is unreasonable and the cutting edge becomes blunt, sharp burrs will form at the cut.

Burrs not only affect operational safety and assembly accuracy, but also reduce the fatigue life of parts. The wear of molds, the precision of equipment, and the performance fluctuations of materials can all lead to dimensional deviations of parts, affecting subsequent assembly.

Applications of Sheet Metal Stamping

Automotive Industry

The automotive industry is one of the fields where stamping processes are most widely applied. From the body panels of the vehicle, such as doors, hoods, and trunk LIDS, to structural components like chassis and frames, and even to the internal seat frames and brake pedals, a large number of stamping parts are used. The application of stamping technology has achieved lightweighting, safety, and the manufacturing of complex structures of automobiles.

Aerospace

In the aerospace field, extremely high requirements are placed on the weight, strength, and precision of parts. The sheet metal stamping process is used to manufacture aircraft skins, wing ribs, frames, fairings, as well as various brackets and connecting parts. These parts need to be as lightweight as possible while ensuring extreme reliability.

Electrical Appliances

The electronic products we use daily are filled with precisely stamped parts. For instance, mobile phones and their middle frames, shielding covers, connector terminals, the hard disk drive casings of computers, as well as household appliances such as air conditioners’ heat sinks, the casings and internal structural components of microwave ovens, etc.

Home Appliances

The outer shells and internal drums of white goods such as refrigerators and washing machines, the air ducts of range hoods, as well as stainless steel sinks and cookware in kitchenware, are all typical products of the stamping process. Hardware parts such as door locks, hinges, and tools also rely heavily on stamping.

Medical Equipment

The medical field demands that equipment be highly clean, sterile, and reliable. Sheet metal stamping can be used to manufacture surgical instruments, implant shells, precision structural components for various diagnostic equipment (such as CT machines), and adjustment mechanisms for hospital beds, etc.

Energy and Industrial

In the energy and industrial sectors, sheet metal stamping is used to manufacture the cores of motors, heat sinks for transformers, electrical cabinet bodies, connectors for various industrial pipelines, as well as control panels and casings for heavy machinery, etc.

NOBLE’s Sheet Metal Stamping Service

Our sheet metal stamping services manufacture intricate stamping parts accurately and deliver products that surpass customer expectations at an affordable cost and quick turnaround time.

Our sheet metal stamping services could design and create progressive dies and four-slide tools, as well as precision machining. We are also able to perform any necessary secondary manufacturing processes, such as deburring and tapping. Our team has a deep understanding of metallurgy, and we are committed to providing exceptional customer support for all of our metal stamping and forming products. We can shape and form your workpiece to the optimal geometry and can achieve precision tolerances down to one-thousandth of an inch.

- Tolerance Down to 0.001mm

- 10+ Years of Experience in Stamping

- ISO 9001 & ISO13485 Certified Factory

- Lead Time As Fast As 3 Days

- Advanced Equipment & Competitive Price

FAQs of Sheet Metal Stamping

What is the sheet metal stamping process?

Sheet metal stamping is a cold-forming manufacturing process that uses specialized presses and tooling, known as dies, to shape and cut flat sheet metal into desired forms.

What are the main types of sheet metal stamping operations?

The main operations can be categorized into three types: cutting, bending, and drawing. Cutting operations, like blanking and punching, separate material.

What materials are commonly used in metal stamping?

A wide range of materials can be stamped, but the most common include cold-rolled steel (SPCC) for its cost-effectiveness, aluminum for its light weight and corrosion resistance, stainless steel (like SUS304) for its strength and durability, and copper alloys for their excellent electrical conductivity.

What are the advantages of using the stamping process?

Sheet metal stamping offers key advantages, including high production efficiency and speed for mass production, low per-unit cost after the initial tooling investment, excellent part consistency and repeatability due to the precision of the dies, high material utilization with minimal waste, and the ability to produce strong, complex parts from a single piece of metal.

What is “progressive die stamping”?

Progressive die stamping is a highly efficient method where a coil of metal strip moves through a series of stations within a single press. Each station performs a different operation—such as punching, bending, or cutting—in sequence. With each press stroke, a finished part is produced from the end of the strip, allowing for complex parts to be made rapidly and continuously.