What is Vacuum Casting?

Definition and Process Overview

Vacuum casting involves making parts by pouring liquid raw materials, such as silicone, polyurethane (PU), or other resins… into the molds under a vacuum environment. These molds are often 3D printed or made by hand. This method is especially popular in industries like automotive, medical devices, and aerospace, where it’s ideal for producing small batches. It stands out for its ability to support the early stages of production, giving manufacturers a chance to test and tweak parts before committing to full-scale production, reducing the risk of costly mistakes.

History and Evolution of Vacuum Casting

In earlier times, traditional casting methods, like metal casting I often mention, yet as technology advanced and the need for prototyping grew, vacuum casting gradually came into focus.

By the 1980s, as 3D printing and other rapid prototyping technologies became more accessible, the demand for cost-effective small-batch production surged. Traditional casting methods couldn’t meet the needs of prototyping, making vacuum casting a practical solution.

In the 1990s, with vacuum casting becoming more popular, the materials used in the process saw significant improvements. Engineers and scientists developed resins like silicone and PU, which allowed for more detailed, durable, and cost-efficient castings.

From the 2000s onward, the continued development of 3D printing led to high-quality prints, making vacuum casting even more satisfactory. The ability to directly use master models created from 3D printers for vacuum casting was exciting news, as it significantly shortened production cycles and enabled the creation of more complex designs.

How It Differs from Traditional Casting Methods

Vacuum casting differs from traditional casting methods in many ways, which is why we need to take careful consideration when advancing a project.

| Aspect | Traditional Casting | Vacuum Casting |

| Materials Used | Typically, metals (e.g., aluminum, steel, iron) or concrete | Liquid resins (e.g., PU, silicone) |

| Mold Type | Rigid molds made from sand, metal, or ceramic | Flexible molds made from silicone rubber |

| Casting Process | Involves melting and pouring molten metal into a mold, where it hardens. | Uses a vacuum to eliminate air bubbles and ensures precise casting. |

| Production Volume | Large-scale production runs | Low-volume production and prototypes |

| Lead Time | Longer lead time | Shorter lead time |

| Cost | Expensive due to permanent mold creation and metal material costs | Lower setup and material costs make it ideal for prototyping and small-batch production. |

How Does Vacuum Casting Work?

Materials Used in Vacuum Casting

-

Polyurethane Resins (PU):

The most commonly used material, often used to produce strong and durable parts, offering both rigidity and flexibility.

| Hardness | From very soft (shore A) to hard (shore D) |

| Tensile Strength | Ranges from 35 MPa to 80 MPa |

| Tear Resistance | Varies but generally excellent for rigid formulations; moderate for flexible grades |

| Heat Resistance | Generally has a heat deflection temperature (HDT) around 60°C–80°C |

| Color | Clear to opaque; can be easily colored using pigments |

| Density | Approximately 1.1–1.4 g/cm³ |

These resins are ideal for functional prototyping, and most of NOBLE’s vacuum casting orders utilize these two materials.

As can be seen, polyurethane (PU) has a very wide range of applications, from aerospace to consumer electronics. PU components are ubiquitous. These resins are ideal for functional prototyping, and NOBLE uses this material for most of its vacuum casting orders.

2. Silicone-Based Resins:

Silicone resins are valued for their flexibility, resistance to high temperatures, and smooth surface finish. These properties make them ideal for applications where parts need to resemble rubber or soft plastic.

| Hardness | From 10 to 80 Shore A (soft to medium firmness) |

| Tensile Strength | Generally 4–10 MPa |

| Elongation at Break | Can be as high as 500% (depending on grade), making it highly flexible |

| Temperature Resistance | High heat resistance, withstanding temperatures of up to 250°C |

| Tear Strength | Generally excellent due to its flexibility |

| Density | 1.1–1.3 g/cm³ |

Silicone-based resins have a very soft feel; we’ve used them before for handle bushings and gaskets in drones. It was a unique experience that I learned a lot from.

-

Transparent Resins

Transparent resins are made to transmit light, making them ideal for applications where appearance and visual clarity matter. These are usually clear PU or specialized epoxy resins.

| Optical Clarity | High optical clarity and transparency (up to 90% light transmission) |

| Tensile Strength | Similar to regular PU or epoxy resins—35 MPa to 80 MPa |

| UV Resistance | Often treated with UV inhibitors to prevent yellowing or degradation over time |

| Impact Resistance | Moderate, with higher resistance than glass but lower than metals |

| Hardness | Similar to standard PU (Shore D 70–85) |

The parts made with transparent resins have a beautiful finish. I remember when we used them to create snowflake-shaped ornaments. The final result was crystal clear, and the client was extremely pleased.

-

Epoxy Resins

Epoxy resins are chosen for parts that need higher strength, chemical resistance, and durability. Though not as frequently used as PU or silicone in vacuum casting, they are still essential for applications that demand high-performance qualities.

| Hardness | High hardness, typically Shore D 70-90 |

| Tensile Strength | Around 60–100 MPa |

| Chemical Resistance | Excellent chemical and solvent resistance |

| Heat Resistance | Heat deflection temperature (HDT) of approximately 100–120°C |

| Density | Typically 1.1–1.4 g/cm³ |

| Surface Finish | Excellent surface finish with minimal post-processing required |

This material is less common than the three mentioned above. It often faces extreme conditions in the industry, such as being used as high-strength aircraft parts, high-performance engine structural components, and, to my knowledge, even in military applications.

Choosing the right material for your project

If you’re struggling to decide which material to choose for your vacuum casting project, NOBLE’s experts can offer some guidance. Of course, feel free to contact us anytime—we’d be delighted to assist you!

Mechanical Properties:

Need strong, durable components? Choose rigid PU or epoxy resins; these materials ensure structural integrity.

Need flexible components? If you’re making seals or gaskets, silicone or flexible PU are ideal choices.

Temperature Resistance:

Do your parts need to withstand high temperatures? If so, please choose a high-temperature resistant resin that can withstand temperatures above 250 degrees Celsius.

Surface Finish:

If you require a smooth and glossy finish, or have requirements for optical transparency (such as lenses or displays), you can choose transparent PU or epoxy resin.

Chemical Resistance:

Do your parts need to come into contact with solvents, greases, or harsh environments? If so, epoxy resin or high-temperature-resistant PU are good choices!

Cost and Volume:

For small-batch or prototyping, PU offers the advantages of both economy and rapid prototyping. High-performance parts require epoxy or silicone resins with better durability, but it should be noted that their cost is relatively high.

Step-by-Step Breakdown of the Process

The vacuum casting process is actually not complicated, but it is crucial to pay close attention to the details. Below is a brief introduction to these steps:

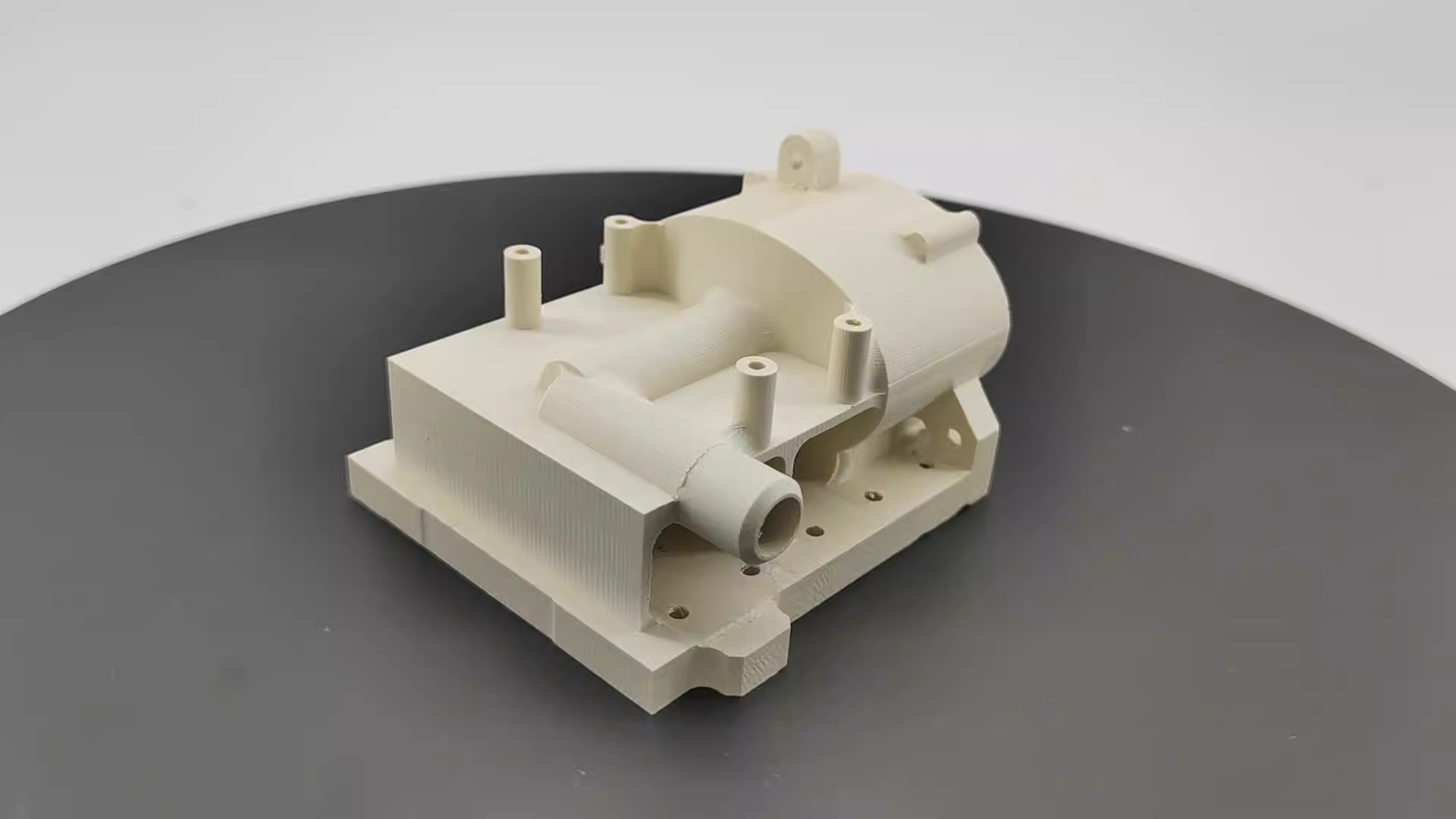

Step 1: Design the Model

In the early stages of designing a part for casting, NOBLE engineers usually rely on CAD (Computer-Aided Design) modeling. During this phase, engineers must ensure the part can be easily removed from the mold, avoiding any undercuts or features that could make demolding difficult.

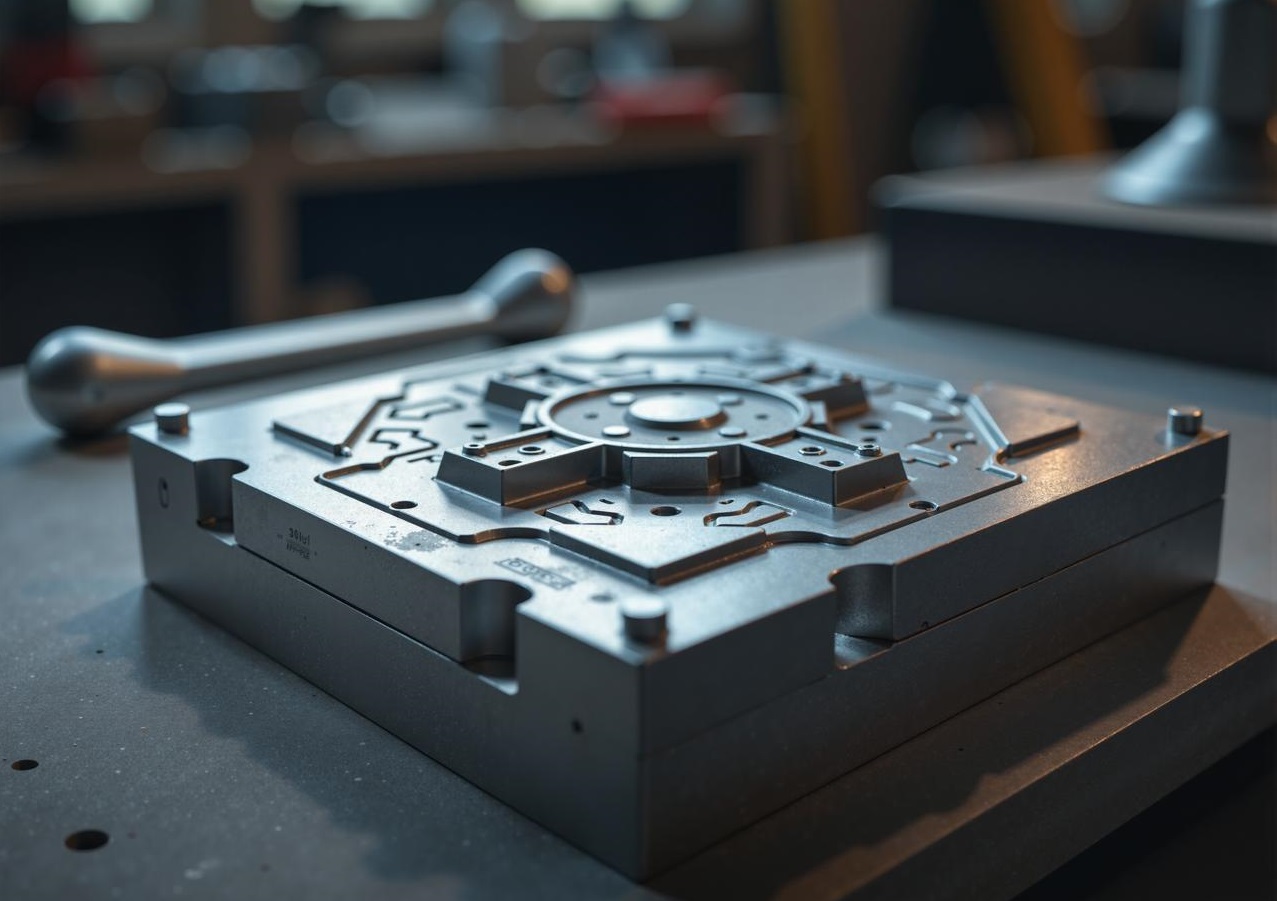

Step 2: Mold Making

After the engineers finalize the design, the next critical step is creating the mold, which plays a key role in the vacuum casting process. At NOBLE, we typically use 3D printing, which precisely captures the geometry of the part. The mold material is selected based on the complexity of the part and material requirements, but we most often use flexible materials such as silicone or rubber to make the mold.

Step 3: Resin Pouring and Vacuum Sealing

Simply put, this step involves pouring the selected resin into the mold and then placing it in a vacuum chamber to remove air bubbles.

First, we mix the selected resin and necessary additives according to the customer’s requirements in the correct proportions. Then, the mixed resin is poured into the mold cavity and placed in a vacuum chamber to stand. During the curing process, air bubbles in the resin mixture are removed. Finally, we obtain a smooth, bubble-free part!

Step 4: Post-Processing and Finishing (If Required)

Once the casting has solidified, the part can be removed from the mold. Next, we will perform post-processing and finishing as needed, such as grinding, polishing, painting, and coating. For complex parts, further assembly may be required, such as adding fasteners, labels, etc. If the part has very stringent specifications (e.g., for medical or aerospace applications), additional testing or quality checks will be necessary.

How Vacuum Casting Excels Over Other Processes?

Cost-Effective Prototyping

Vacuum casting uses flexible silicone molds, which are much cheaper to produce than the rigid steel molds required for injection molding. This makes it an affordable option for small-scale production and prototyping, where traditional tooling costs can be prohibitive.

Vacuum casting is ideal for producing small-volume runs (10-500 parts), unlike traditional methods that often require large production runs to be cost-effective. It allows you to produce small batches economically without the need for expensive machinery.

High Precision and Quality

Silicone molds in vacuum casting can replicate intricate details, textures, and complex shapes with high accuracy. This is especially useful for parts with fine features that need precise replication.

The vacuum process eliminates air bubbles, resulting in parts with smooth, high-quality finishes directly from the mold. There’s no need for extensive post-processing, making it perfect for applications requiring a professional, polished look.

Speed and Efficiency

Vacuum casting dramatically reduces lead times. Mold creation and casting can be completed in just days, compared to the weeks it takes for traditional methods like injection molding or CNC machining, which involve longer setup and tooling times.

Flexibility with Materials

Vacuum casting offers a wide range of material choices, including rigid, flexible, and transparent resins. This flexibility allows you to select materials that meet specific functional or aesthetic needs, such as heat resistance, strength, or color.

Challenges and Considerations in Vacuum Casting

While vacuum casting offers many advantages, it also has some limitations; after all, no process is perfect. These aspects need to be considered when deciding whether it’s suitable for your project.

Material Limitations

Although vacuum casting offers a variety of materials, including rigid and flexible resins, the mechanical properties of cast parts often don’t match the strength of those made through injection molding, CNC machining, or die-casting. Vacuum-cast parts may not hold up as well in high-stress applications.

Mold Limitations

Silicone molds, although cost-effective and precise, have limited durability. After repeated use, they degrade due to material shrinkage, wear from pressure, and the curing process. This means they can only be used for a finite number of castings before they need to be replaced.

Size Constraints

Vacuum casting is typically more suited for small to medium-sized parts. The size of the mold and the vacuum chamber can limit the ability to cast very large parts. For larger components, more complex mold-making techniques may be necessary, or they might not be feasible given the constraints of the available equipment.

Vacuum Casting in Prototyping

Vacuum casting is a flexible, fast, and affordable solution for prototyping, enabling the production of high-precision, functional prototypes in a short time. With a wide range of materials available and the ability to quickly refine designs, it’s an essential tool for designers and engineers looking to test concepts, validate designs, and bring products to market faster—all without the high costs of traditional manufacturing methods.

| Feature | Advantage for Prototyping |

| Precision | High accuracy, fine detail replication, and tight tolerances. |

| Quick Turnaround | Fast mold creation, resin pouring, and curing process. |

| Material Versatility | Wide range of materials to mimic final production materials. |

| Low-Cost Prototyping | Affordable for functional prototypes and small-batch production. |

| Functional Testing | Enables testing for fit, form, function, and performance in real-world conditions. |

Choose NOBLE for the Best Vacuum Casting

Why NOBLE is a Leading Provider of Vacuum Casting Services

Vacuum casting is used across various industries—from automotive and packaging to medical and aerospace. It’s also ideal for creating a range of prototypes.

Your project is in the works, and you’re looking for a clear, precise view of your product. NOBLE is the premier vacuum casting service for you. We specialize in producing accurate prototypes at a fraction of the usual cost and time. We offer reliable custom vacuum casting services, ranging from prototyping to low-volume part manufacturing, all at competitive prices. Our vacuum-forged parts deliver high precision, stable performance, and excellent quality, with faster turnaround times to meet your project needs.

NOBLE’s Vacuum Casting Process and Advantages

Expertise: With years of experience in rapid prototyping and small-batch production, NOBLE’s team guarantees the highest levels of precision and functionality.

Advanced Equipment: NOBLE employs cutting-edge technology, such as vacuum chambers and precision molds, to produce accurate, high-quality parts. They offer a wide range of materials, including rigid, flexible, and transparent resins, to meet various requirements.

Customer Satisfaction: NOBLE is committed to meeting customer needs by offering customized solutions, fast turnarounds, and stringent quality control to ensure every project is delivered to spec.

Get in Touch with Us for Your Next Project!

FAQs of Vacuum Casting

What is vacuum casting?

Vacuum casting is a manufacturing process where liquid raw materials, typically silicone, polyurethane, or other resins, are poured into a mold under vacuum. It’s commonly used for prototyping and small-batch production, producing parts with high precision and smooth finishes.

What surface treatments can be applied to plastic prototypes after vacuum casting?

For vacuum-cast parts, surface treatments, including deburring, polishing, electroplating, laser engraving, and all other surface treatment methods applicable to plastic parts, can be applied to vacuum-cast plastic prototypes.

What is the minimum tolerance achievable with vacuum casting?

Our minimum tolerance is approximately ±0.1 mm. However, the specific circumstances of each project are different, and we will need to discuss this with you in detail.

How can NOBLE assist with my vacuum casting project?

NOBLE offers reliable custom vacuum casting services, from prototyping to low-volume manufacturing, providing high precision, fast turnaround, and tailored solutions to meet your specific project needs. Their team uses advanced technology and offers a variety of materials to suit different applications.

What is NOBLE’s minimum order quantity?

Given that many projects require rapid prototyping, our minimum order quantity is 1 piece. However, as order quantities increase, our discounts become more substantial.