What is Passivation?

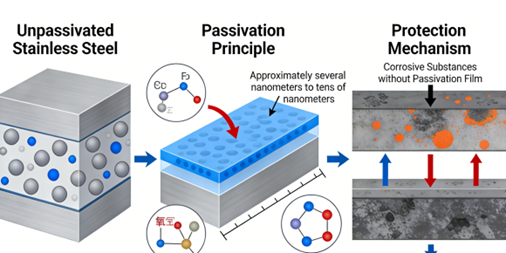

Passivation refers to the phenomenon where, under specific conditions, a dense protective film of oxides or other compounds forms on the surface of certain active metals or alloys, significantly reducing their chemical reactivity and transforming them into a relatively stable state. This film is usually very thin but dense, effectively preventing the internal substances from further reacting with the external environment.

Passivation can enhance the corrosion resistance and durability of materials and is widely used in metal machining and industrial protection.

Why Passivation is Critical for Corrosion Resistance in Stainless Steel

Restoring Passivation Film

Stainless steel itself has a layer of anti-rust film, but during machining and welding, this film can be damaged or weakened, exposing the active metal substrate.

Passivation treatment actively removes surface contaminants through chemical methods and promotes the reaction between chromium and oxygen to re-form a complete, uniform and firmly adhered passivation film, which is the fundamental guarantee for its corrosion resistance.

Removing Surface Contaminants

During the manufacturing and installation of stainless steel, some metal contaminants may be embedded or adhered to its surface. These pollutants may cause rust spots or pitting.

Passivation treatment effectively dissolves and removes these heterogeneous contaminants through steps such as pickling, making the surface chemical composition uniform and ensuring that the surface will not suffer unexpected corrosion damage due to contaminants.

Enhancing Corrosion Resistance

One of the most dangerous failure modes of stainless steel is local corrosion, such as pitting corrosion. Passivation treatment greatly enhances the film’s resistance to the penetration of corrosive ions by optimizing the chemical composition and structure of the surface oxide film.

A high-quality passivation film can significantly increase the pitting potential of materials and extend the service life of equipment in environments such as chemical engineering, Marine or food processing.

Improving Product Cleanliness

In industries such as food processing, pharmaceuticals, biotechnology, and semiconductors, the surface of equipment not only needs to be corrosion-resistant, but also must be extremely clean and free from contamination.

Passivation treatment can create an inert and smooth surface, preventing the product from being contaminated or undergoing chemical reactions. At the same time, this surface is also easier to clean and disinfect, meeting strict hygiene and purity standards.

Step-by-Step Instructions for Passivating Stainless Steel Parts

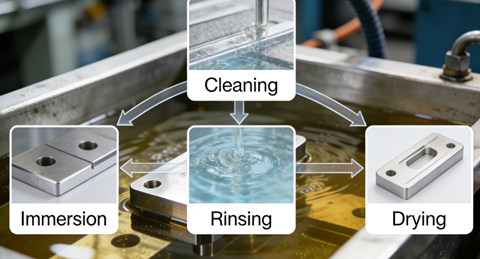

Cleaning

Cleaning usually begins with the use of alkaline cleaning agents or organic solvents, and then it must be thoroughly rinsed with clean water to provide a clean and activated surface for the next acid treatment.

The purpose of cleaning is to thoroughly remove all organic contaminants and inorganic particles from the surface of the parts. If the cleaning is not thorough, contaminants will form a barrier in the acid bath, leading to uneven passivation reactions and even the formation of corrosion points beneath the contaminants.

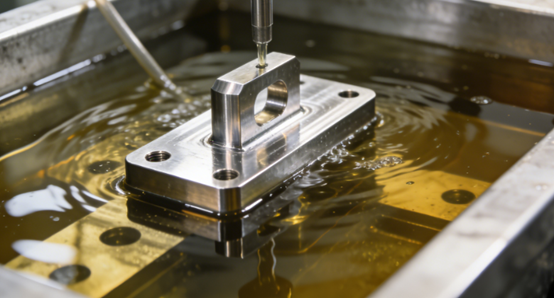

Acid Bath

After thorough cleaning, the stainless steel parts are completely immersed in a specific acid solution, commonly nitric acid or a mixture of nitric acid and chromic acid.

An acid solution can dissolve iron particles and other metal contaminants on the surface of parts. Through the oxidation effect of the acid solution, some iron elements on the surface of stainless steel are dissolved, exposing the chromium-rich layer and allowing it to combine with oxygen, thereby actively promoting the formation of a dense and uniform chromium oxide passivation protective film on its surface.

Rinsing

After acid bath treatment, acid liquid and dissolved metal ions will remain on the surface of the parts. If the residual acid solution is not completely removed, it will continue to react with the metal, causing corrosion and damaging the newly formed passivation film, which seriously affects the passivation effect.

The purpose of rinsing is to neutralize and remove these residual chemicals quickly and thoroughly. Usually, it is first rinsed vigorously with clean water, and then rinsed finally with deionized water or high-purity water.

Drying

Parts that have been thoroughly rinsed must be thoroughly dried immediately. Drying should be carried out in a clean and pollution-free environment. Usually, a drying oven is used for hot air drying to ensure that the parts are completely dry and not subject to secondary pollution.

The purpose of drying is to completely remove all moisture from the surface and crevices of parts. If there is residual moisture, local damp environments during storage or transportation can cause pitting or rust.

Frequent Passivation Mistakes and How to Avoid Them

Incomplete Cleaning

Cleaning is a crucial step before passivation. If grease, fingerprints, or machining debris remain on the surface of the parts before passivation, these contaminants will hinder the uniform contact between the metal surface and the acid solution in the acid bath. This will lead to incomplete formation of the passivation film, uneven thickness, and even the formation of hidden corrosion starting points beneath the contaminants.

- Use appropriate degreasing agents and processes, and rinse and inspect after cleaning.

Improper Acid Bath Control

If the concentration of the acid solution is too low or too high, the temperature exceeds the process range, or the soaking time is insufficient or too long, it may all lead to poor quality of the passivation film or even cause corrosion, which may instead damage the substrate.

- Strictly adhere to the standards for specific materials or the process specifications provided by suppliers, use verified acid solution formulas, and strictly monitor and control the temperature, concentration, and time of the bath through instruments.

Inadequate Rinsing

After an acid bath, if the parts are simply rinsed with ordinary tap water, or if the rinsing time is insufficient and the water flow is not thorough, acid solution and dissolved metal ions will remain on the surface and in the crevices. These residues, after drying, will form highly corrosive salts, which can cause new corrosion during storage and use and undermine the passivation effect.

- Immediately carry out multiple thorough rinses, and finally, deionized water or high-purity water must be used for the final rinse

Improper Storage

After the parts have been passivated and dried, if the operators directly touch the surface of the parts with their hands, or store and transport them in a damp environment containing chloride ions or industrial pollutants, the newly formed passivation film will be seriously damaged.

- Passivated parts must be handled with clean gloves or tools and stored in a dry, clean, and pollution-free environment. For high-demand applications, it is recommended to carry out appropriate packaging protection.

Lack of Verification

Another common mistake is not to conduct any quality verification on the passivated product. The quality and integrity of the passivation film cannot be judged merely by its appearance.

- Verification tests must be carried out in accordance with the standards, such as using the copper sulfate titration method to check for free iron residues. At the same time, the parameters and test results of the entire passivation process should be recorded in detail to ensure the traceability and consistency of the process.

Passivation vs. Other Treatments: Electropolishing and Anodizing

Core Purpose and Principle

- Passivationcan enhance corrosion resistance. It is a purely chemical process. The free iron on the surface is removed by an acid solution to promote the formation of a chromium oxide protective film, but this film is very thin and does not change the physical dimensions or appearance of the parts.

- Electrolytic polishingis an electrochemical process, with its core being microscopic leveling and surface polishing. Through the action of electric current, the microscopic protrusions on the metal surface are selectively dissolved to achieve a smooth and bright effect, and at the same time, the corrosion resistance can also be improved.

- Anodizingis mainly used for aluminium and its alloys and is an electrochemical conversion process. The core is to generate a thick and porous layer of alumina ceramic, which can provide excellent wear resistance and corrosion resistance, and can achieve a decorative appearance through sealing and dyeing.

Impact on Substrate

- Passivationhardly changes the size, roughness, or appearance of the parts. It only alters the surface chemical properties and thus is suitable for high-precision parts that need to maintain precise dimensions.

- Electrolytic polishingcan remove a small amount of material, significantly reduce surface roughness, eliminate microscopic defects, and produce a mirror-like luster.

- Anodizingcan significantly increase the thickness of the material’s surface layer, ranging from a few micrometers to over a hundred micrometers. This oxide film is externally grown, which will slightly increase the size of the parts, and it has extremely high hardness and good wear resistance.

Material Scope

- Passivationis mainly applicable to stainless steel and relies on the chromium content of the material itself to form a passivation film.

- Electrolytic polishingis mainly applicable to stainless steel, and it is also used on copper, nickel, titanium, and some aluminum alloys, but there are requirements for the electrical conductivity of the materials.

- Anodizingis almost exclusively used for aluminium and aluminium alloys and is one of the most mainstream surface treatment methods for aluminium materials.

Key Performance

- Passivationfocuses on maximizing resistance to chemical corrosion and pitting, especially in harsh environments such as chlorides. Its main value lies in chemical stability.

- Electrolyticpolishing, while enhancing corrosion resistance, places more emphasis on reducing surface adhesion, improving cleanliness, and aesthetics. Its surface is extremely smooth and not prone to adhering to particles and bacteria, and it is often used in high-cleanliness industries.

- Anodizingprovides excellent wear resistance, corrosion resistance, and insulation. Its porous structure can store lubricants or adsorb dyes, thus combining functionality and decoration

Application Areas

- Passivationhas a wide range of applications, from medical implants, food processing equipment, to ship parts,s and general industrial fasteners. It can be used anywhere that requires the stability of stainless steel.

- Electrolytic polishingis widely used in high-cleanliness and hygienic-sensitive fields, such as semiconductor wafer fixtures, pharmaceutical pipelines, food and beverage equipment, high-end architectural decoration, and medical devices.

- Anodizingis a standard process for aluminum components, commonly seen in consumer electronics casings, automotive wheels, architectural profiles, aerospace parts and outdoor hardware.

Applications of Passivation for Stainless Steel

Medical Devices

Surgical instruments, dental instruments, and surgical equipment must all undergo passivation treatment. Passivation can thoroughly remove residual metal contaminants from machining and greatly enhance the resistance to fluid corrosion.

To prevent the precipitation of metal ions from causing toxic or allergic reactions to human tissues, and to ensure that the instruments are easily and thoroughly sterilized to meet biocompatibility standards.

Food Processing Equipment

In the food industry, passivation treatment is a standard process for stainless steel equipment such as pipes, tanks, and conveyor belts. The primary objective is to prevent the equipment from corroding when it comes into contact with acidic foods, salts or cleaning chemicals, avoid the contamination of food by corrosion products, and ensure flavor and safety.

Meanwhile, the smooth surface formed by passivation is not prone to adhering food residues and microorganisms, making it easy to clean and disinfect, and in compliance with strict hygiene regulations.

Pharmaceutical and Biotech

The pharmaceutical industry has extremely high requirements for the cleanliness and chemical resistance of production equipment.

Passivation treatment can effectively prevent the reaction between drug components and metals, eliminating the risk of corrosion of equipment during high-temperature and high-pressure sterilization or when it comes into contact with various acids, alkalis, and solvents.

More importantly, passivation creates a highly clean and inactive surface, which can minimize the growth of microorganisms and the shedding of metal particles to the greatest extent, ensuring the purity and quality of the drug.

Marine and Chemical

Stainless steel components exposed to high-salt seawater, humid atmosphere, or strongly corrosive chemical media, such as ship parts, offshore platform equipment, pumps, and pipelines, must be passivated.

Passivation films can significantly extend the service life and reliability of equipment in extremely harsh environments, reduce maintenance costs,s and potentially safety hazards.

Semiconductor

In semiconductor chip manufacturing, the photovoltaic industry, and precision instruments, all ultra-high-purity stainless steel systems involving gas transportation or chemical liquid treatment must undergo high-standard passivation.

The core objective is to prevent metal ions from contaminating the ultra-pure medium and ensure that the inner walls of the system are absolutely smooth, to maintain the high yield of the product and the stability of the process.

Architectural Application

Many high-quality consumer goods and building components also undergo passivation treatment to enhance their durability and aesthetic appeal. For instance, high-end kitchenware, watch cases, building exterior fasteners, and outdoor sculptures.

Passivation can effectively prevent rust spots or corrosion from appearing during daily use or in outdoor atmospheric environments, keeping items bright and new for a long time.

NOBLE: Professional Stainless Steel Passivation Manufacturer

NOBLE’s Stainless Steel Passivation Service is a specialized chemical treatment process designed to maximize the corrosion resistance and longevity of your stainless steel components. We follow industry-leading standards to ensure consistent, reliable results.

The service includes thorough pre-cleaning to remove contaminants, controlled acid bath treatment to enhance the natural chromium oxide layer, rigorous rinsing with high-purity water, and final drying in a clean environment. We also provide optional quality verification testing, such as salt spray or copper sulfate testing, to confirm performance.

FAQ

Why is passivation necessary if stainless steel is already “stainless”?

While stainless steel contains chromium for inherent corrosion resistance, machining, welding, or handling can embed contaminants or damage the protective layer. Passivation actively restores and strengthens this oxide film, ensuring uniform protection and preventing localized corrosion like rust or pitting.

What is stainless steel passivation?

Passivation is a non-electrolytic chemical process that enhances stainless steel’s natural corrosion resistance. It removes surface contaminants (like free iron) and promotes the formation of a thin, protective chromium oxide layer, making the steel more inert and durable in corrosive environments.

Can all stainless steel grades be passivated?

Most chromium-rich grades (e.g., 300 and 400 series) can be passivated. However, results depend on alloy composition. Austenitic grades like 304 and 316 respond exceptionally well, while martensitic or low-chromium grades may require evaluation.

Does passivation change the dimensions or appearance of parts?

No. Passivation is a microscopic chemical process that only affects the surface chemistry. It does not remove significant material, alter dimensions, or change the visual finish of the part—unlike processes like electroplating or grinding.

What standards govern passivation?

Common standards include ASTM A967 (commercial/industrial), AMS 2700 (aerospace/military), and ISO 16048 (international). These specify methods, testing, and acceptance criteria to ensure consistent, reliable results.