You may ask what metal forging is and why it is important in 2025. Metal forging changes metal by using force. It takes raw metal and turns it into strong, reliable parts. Did you know? Today, industries like automotive manufacturing and aerospace are driving the market size past $107 billion! And new technologies are fuelling this ongoing growth. More advanced simulation and automation techniques, along with cleaner processes, make forging faster and more environmentally friendly. NOBLE is a leader. They make custom parts very fast and with great accuracy.

Metal Forging Overview

What Is Metal Forging

You may wonder what metal forging is. Metal forging is all about shaping metal using force. You can achieve this by hammering, pressing, or rolling. This method makes durable and robust components. Metal forging gives parts a better grain structure. Once they’ve been forged, these parts are usually really durable and strong, so they’re great at preventing problems like cracking or perforation, making them really robust.

Here are the main ideas of metal forging:

- You use force to shape metal into whatever you need it for.

- The process makes the grain structure better and the parts stronger.

- Forged parts last longer and are more resistant to damage.

- You’ll have fewer problems with this than with other ways.

How Metal Forging Works

Let’s take a look at how metal forging works in a factory. First, you choose the right metal for your job. Steel and aluminium are both really strong and flexible, which makes them perfect for use in construction. Then, heat the metal until it’s soft. Hot metal is easier to shape. Hot metal is easier to shape. This step is important for making custom parts.

Then, we shape the metal using tools like hammers, presses, or rollers. The temperature decides whether we use cold forging, warm forging or hot forging (I will go through all of this later on). Hot forging is great for bending metal, so you can make all sorts of intricate shapes. Then, after shaping, the workpiece is just cooled and checked for quality. Every piece must meet high standards before leaving the factory.

Evolution to 2025

Metal forging has changed a lot over time. By 2025, new technologies will have made forging processes faster and smarter. Factories keep an eye on equipment status in real time using IoT devices. Predictive maintenance makes sure everything runs smoothly, and you don’t have any downtime. Automation is pretty much the norm these days, with CNC machines and robots working together to quickly produce components while making sure workers are safe.

Simulation software is great for designing better dies and showing how metal will move. Hybrid forging mixes additive manufacturing with old methods to give you more custom options. These changes mean:

- We’re using less material and making sure our shapes are spot on.

- The parts are stronger because the grains are better aligned.

- We’re committed to providing consistent quality and creating safer workplaces.

These updates are great for everyone, whether you need a single part for quick testing or multiple components. The metal forging industry keeps getting better. You’ll get higher-quality products, faster service, and greater confidence in the results.

Metal Forging Process Steps

You may wonder how metal forging works in a factory. Let’s take a look at each step, from picking the metal to finishing the part. NOBLE’s process is fast and reliable. You get custom parts in a jiffy.

Material Selection

First things first: you’ve got to pick the right material. The metal needs to be suitable for your project and able to handle stress.

Steel and Aluminum Choices

Steel and aluminum are the main choices for custom parts. Steel is strong and tough. It’s great for heavy-duty parts. Aluminium is great because it’s light and flexible. It’s perfect for parts that need to be strong but easy to move. NOBLE uses high-quality steel and aluminum. This means your parts will last longer.

Why These Metals Matter

When it comes to picking a metal, there are three things to think about:

- Strength– The metal’s gotta be strong enough to hold the weight.

- Ductility– It should be bendy and stretchy without breaking.

- Toughness– The metal’s gotta be tough. It needs to be able to take a beating without cracking.

These qualities make forged parts great for cars, planes, and robots. You can always rely on the parts.

Heating and Shaping

After picking your metal, you heat and shape it. This step basically turns raw metal into custom parts.

Temperature Control

Modern factories use special heating methods. These heat up quickly and only when you need them to. This saves energy and keeps things clean. NOBLE’s machines keep the heat just right. Every part is perfect.

Here’s a quick look at shaping methods:

| Method | Temperature Condition | Advantages | Applications |

| Cold Forging | Room Temperature | Very accurate, good for making many parts | Small parts in many industries |

| Hot Forging | High Temperatures | Easier to shape, makes strong parts | Cars, planes, and machines |

Shaping Techniques

We usually use presses, hammers, or rollers to shape metal. Hot forging is great for making strong and complex shapes. Cold forging is great for making small, precise parts. NOBLE uses machines for steady results and fast work.

Finishing and Inspection

Once that’s done, each part is trimmed and checked on its own. This step makes sure every part meets the required standards.

Quality Control Measures

NOBLE checks every part carefully. The parts are great, they meet world standards (like ASTM A29 and EN 10204). Here is a table of common inspection standards:

| Standard | Description |

| ASTM A29 | Rules for hot-wrought steel bars |

| ASTM A182 | Forged and stainless steel pipe parts |

| EN 10204 | Inspection papers and certificates |

| ASTM A388 | UT check for steel forgings and bars |

| ISO 643 / ASTM E112 | Grain size check |

| ASTM E45 | Checks for stuff inside the metal |

| ASTM E381 | Macroetch test for steel bars |

Surface Finishes

You can pick finishes like anodizing or powder coating. These post-processing steps prevent rust and keep your parts looking perfect. NOBLE has many finishes to choose from. Your parts will run smoothly and look great.

Upload your CAD design to NOBLE’s platform for a quick quote. Hey, why not have a look at how easy precision manufacturing can be?

Now you know how metal forging goes from raw metal to a finished part. NOBLE’s process is fast and gives you strong, custom parts for any job.

Types of Metal Forging

Open Die Forging

Think about a blacksmith hitting hot metal on an anvil. That is what open die forging is like. In Noble’s factory, large presses and hammers form metal between simple dies. This metal is not completely closed, allowing the manufacture of large or special parts.

Open die forging is best for large parts. It is used in aerospace, energy, heavy machinery, oil and gas, and marine fields. These industries opt for open die forging to produce strong yet lightweight parts. These parts are durable and resistant to breakage. You can also use special alloys that are hard to forge with other methods.

The following is an overview of how open die forging is used in different industries:

| Industry | Key Applications | Benefits of Open Die Forging |

| Aerospace | Landing gear, engine shafts, airframe elements | Superior strength-to-weight, fatigue resistance, exotic alloys |

| Energy | Turbine rotors, generator shafts, pressure vessels | Large size capability, uniform properties, high temp performance |

| Heavy Machinery | Crankshafts, mining gears, excavator arms | Exceptional durability, withstands high loads, cost-effective |

| Oil and Gas | Valve bodies, wellhead, subsea equipment | Corrosion resistance, high-pressure tolerance, and reliability |

| Marine | Propeller shafts, rudder stocks, ship components | Corrosion resistance, impact strength, and large complex shapes |

NOBLE’s engineers use open die forging for tough and reliable parts. You get strong parts made just for your needs, even if they are very big.

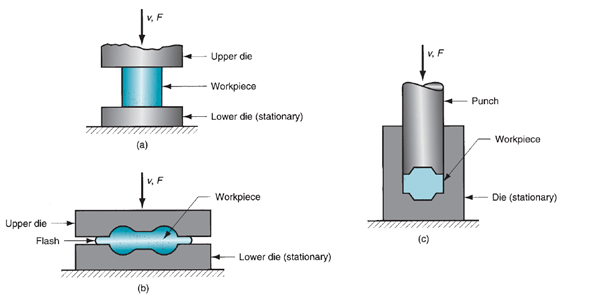

Closed Die Forging

Closed die forging is also called impression die forging. It uses dies that close around the metal. This produces parts with precise shapes and smooth surfaces. This process is ideal for producing large quantities of identical parts, such as gears or brackets.

Closed die forging gives you strong parts. It also gives you a nice finish. The shapes are almost finished, so you do not need much extra work. You can choose from a variety of metals, including popular choices like steel, aluminum, and titanium.

Now, let’s talk about the pros and cons:

| Advantages | Limitations |

| High strength | Higher tooling expenses |

| Close tolerances | Dimensional limitations |

| Net shapes | Size limitations |

| No material limitation | Potential working damages |

| Cleaner process | |

| Better surface finish |

NOBLE’s closed die forging gives you the same quality every time. You get parts that fit perfectly. If you need a lot of the same part, this is the best way.

Ring Rolling

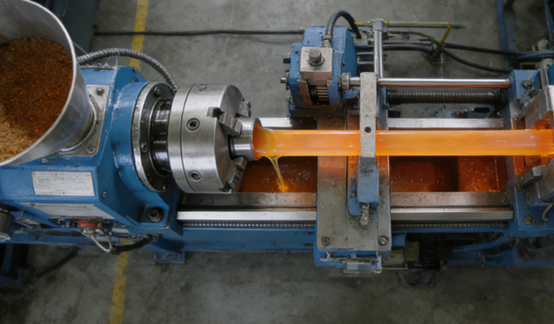

Ring rolling is a special way to forge metal. You start with a hot metal ring that looks like a doughnut. Then, rollers push and stretch the ring until it’s the right size. The grain is strong, so the ring is tough.

Ring rolling is great for making seamless rings. These rings are used in machines, pressure tanks, bearings, and jet engines. The rings are really strong, and they’ll last you ages. The grain is even, so the rings work well and don’t break.

Tip: NOBLE is very good at seamless ring rolling. You get rings that are the right size and very strong.

Ring rolling is a bit different because it makes rings with no seams. These rings are better at handling stress and pressure than welded rings. You get strong and safe parts for important jobs.

NOBLE’s factory has new ring rolling machines and skilled workers. You get custom rings, whether you need one or many. Every ring meets high standards for strength and accuracy.

Press Forging

Pressure forging is another great way to shape metal. Instead of rapid impacts, it uses slow and steady pressure, which means it can produce lots of strong components at the same time. Many factories use press forging to make lots of parts. The steady pressure ensures that each part of the guitar always looks the same.

Pick press forging is great for tough parts with smooth surfaces. This method lets you create simple or tricky shapes. Steel and aluminium are great options. NOBLE’s team uses special presses to meet your standards. You get speedy help and parts you can trust.

Let’s check the main good and hard things about press forging:

| Key Benefits | Key Challenges |

| Enhanced mechanical properties | High equipment costs |

| High strength-to-weight ratios | Material costs |

| Design flexibility | Process complexity |

| Reduced defects | Limited availability of titanium alloys |

Press forging gives you strong parts and flexible designs. You also get fewer mistakes in the parts. But, to be honest, it’s almost impossible to get this done on your own. You’ll need some specialised kit and the right people to do the job. NOBLE’s factory has new presses and smart engineers to solve these problems.

Tip: If you’re after a lot of strong, precise parts, press forging is the way to go. NOBLE’s press forging service helps your business get the best parts.

Hot vs. Cold Forging

You might wonder how hot forging and cold forging are not the same. They’re both important, but they use different heat and give different results.

Heating metal to a soft state in the process of forging it. The heat is between 700°C and 1,200°C. This makes it a breeze to shape into hard forms. When it’s cold, you can shape metal using this method. You get some very strong and hard parts, but the shapes are simpler.

Here’s a quick look at how they compare:

| Feature | Hot Forging | Cold Forging |

| Temperature | 700°C to 1,200°C | Room temperature |

| Material Properties | Improved ductility and impact resistance | Higher strength and hardness |

| Suitability for Shapes | Better for complex shapes | More reasonable for simpler shapes |

Hot forging changes the inside grain of the metal. The grains get better as the metal cools down. This makes the parts really strong and resistant to impact. The cold forging process keeps the metal’s grain structure, and the metal actually gets stronger during the extrusion and stretching process.

| Process | Hot Forging | Cold Forging |

| Grain Structure | Refined during recrystallization | Preserved original structure |

| Strength Mechanism | Does not strain harden | Increases strength through strain hardening |

NOBLE’s engineers help you choose the best way for your project. Our team of engineers is here to help, whether you need custom gears, rings, or brackets. Precision forging processes make your components more durable and improve their performance.

If you want to know more about which forging is best for you, you can ask NOBLE’s team. They help you from start to finish.

Forging Materials and Equipment

When you visit a modern factory, you’ll see a mix of old and new techniques. When it comes to metal forging, picking the right materials and equipment is key. Let’s take a look at the relevant info below.

Common Metals Used

There are many metals you can pick from. Each metal has its own good points. Here’s a quick look at the most used metals:

| Metal | Properties | Applications |

| Steel | Strong, durable, malleable | Industrial parts, automotive, machinery |

| Aluminum | Lightweight, strong, corrosion-resistant, malleable | Aerospace, cars, electronics |

| Titanium | High strength, low weight, corrosion-resistant | Aircraft, medical implants, military |

| Copper Alloys | Great conductivity, corrosion resistant, easy to shape | Electrical, plumbing, precision components |

Steel

Steel is everywhere you look. It’s really tough and can hold heavy stuff. That’s why you see it in cars, buildings, and big machines. Steel forgings last long and can take a lot of stress.

Aluminum

Aluminium is light but still strong. It doesn’t rust and is easy to shape. You find it in planes, cars, and even phones. Aluminium parts are great because they make things lighter but still strong.

Titanium

Titanium is strong but not heavy. It doesn’t rust easily, which is great. You see titanium in jet engines, doctor tools, and army gear. When you need the best, titanium is a good choice.

Copper Alloys

Copper alloys, like brass and bronze, are perfect for wires and pipes. They’re great at conducting electricity, and they don’t rust. You can also find them in musical instruments and small, precise parts.

If you choose the right metal, your part will last longer and work better. NOBLE’s team can help you choose the best metal for your job.

Essential Equipment

We all know that factories need more than just high-quality metal. The right tools and machines are what turn metal into finished parts. Here is what you find in a great forging shop:

Presses and Hammers

Presses and hammers shape metal with force. Our presses are perfect for working with big or complicated parts because they apply pressure bit by bit. Hammers, on the other hand, are great for delivering rapid and forceful blows to metal, making shaping a breeze. NOBLE’s presses and hammers make custom parts quickly and with care.

Dies and Tooling

Dies are basically molds that shape the metal. Skilled engineers design dies for each job. CNC mills and lathes make these dies really precise. This makes sure every part matches your design.

Heating Furnaces

High temperatures make metals softer, which makes them easier to shape. Modern factories use electric furnaces to get more precise temperature control and save energy. NOBLE’s electric furnaces heat metals quickly and evenly, reducing waste and delivering outstanding results.

New tools like AI and robots help NOBLE’s team keep an eye on everything. This helps keep quality high and delivery faster.

Pick NOBLE, and you’ll get more than just parts. You get a team with the latest equipment and smart tools. Skilled workers help your project from start to finish. We make sure every component is just right. That’s the secret behind metal forging’s ability to produce robust, high-quality parts.

Benefits and Applications of Metal Forging

Strength and Durability

Metal forging is the process that creates these amazing parts that can handle hard work. These parts have a special grain structure. The way the grains line up with the shape of the component makes it stronger and less likely to break. On the other hand, welding or machining can sometimes create weak points in the component. Forged parts do not have these problems. That is why car axles and airplane landing gear use forged parts. Heavy machines also use them.

Here’s how forging differs from other methods:

So here’s how forging is different from other methods:

| Key Point | Description |

| Strength | Forged parts are stronger because the grain is lined up correctly. This lowers the chance of holes being found in welded parts. |

| Metallurgical Properties | Forged parts have even properties. They do not have weak spots like welded seams. |

| Grain Orientation | The grain in forged parts is set to make them strong and flexible. They do not get tired as fast as machine parts. |

Precision and Reliability

It’s really important that the parts fit just right. Forging has gotten much better over time. Now, you get parts that are really precise and smooth. Forged gears, brackets, and rings are a great all-round option. Tests show that forged gears last longer than other types.

Here is why forged parts are reliable:

| Evidence Description | Key Point |

| The new methods of forging make really precise parts. | Forged parts are now just as precise as cold forged ones, so there really is no need to choose |

| Forged parts are well-known for being reliable and strong. | Forging is the most trusted way to make parts. |

| Tests show that forged gears last longer under stress. | Forged parts are more durable than other parts. |

Custom forging gives you what you need. NOBLE uses new tools to make sure every part is just right.

Cost Efficiency

Saving money is important for every company. Metal forging helps you spend less in many ways. Forged parts last longer, so there is less need to fix or replace them. They also need less work after forging, which saves time and money. Order in bulk and you’ll pay less per part.

Here’s how forging will save you money:

| Factor | Explanation |

| Enhanced Product Quality | Forged parts are strong and last longer. You do not have to fix them as often. |

| Reduced Machining Requirements | Forged parts need less extra work, so you save time and money. |

| Economies of Scale | Making many parts at once makes each one cheaper. |

| Improved Material Utilization | New forging ways use more of the metal, so there is less waste. |

Everyone wants to get their money’s worth. Metal forging technology provides strong components that can save you money. NOBLE’s fast and smart process keeps your costs down.

Industry Applications in 2025

Did you know that metal forging is used to make loads of the stuff we use every day? It’s going to be a big deal in loads of industries by 2025. Let’s take a look at how different jobs use forged parts and what new trends are happening.

Automotive

You ride in cars all the time. For cars to be safe and strong, they need forged parts. Car makers use forged crankshafts, gears, and axles. These parts can take a beating and last for ages. More people are buying cars, so the need for forged parts is growing. Electric cars use lightweight, strong aluminium parts to save energy. Car companies are always on the lookout for better alloys and lighter materials. This makes cars safer and helps them use less energy.

Did you know? More cars and electric vehicles mean factories need more custom and exact parts for cars.

Aerospace

When you see a plane, you see metal forging in action. Aircraft need parts that can handle extreme heat and pressure. Forged titanium and aluminum are used for landing gear, engines, and wings. These components have to be lightweight yet really strong – that’s a key requirement. The aerospace industry needs materials that can handle the toughest environments. NOBLE’s facilities use advanced forging techniques to produce components that are shaped perfectly and have no weak points.

| Industry Application | Trends Driving Demand |

| Automotive | More cars are made, and more electric cars are on the road |

| Aerospace | Need for strong materials in hard conditions |

| Medical | Exact parts for new medical devices |

| Robotics | Need for strong, light, and exact parts |

Medical

You count on medical devices to keep you safe. Doctors use tools and implants made by metal forging. These parts have to be spot on and work perfectly. Forged stainless steel and titanium implants are longer-lasting and a better fit. Hospitals want parts that don’t rust and work inside the body. Precision manufacturing makes sure every part meets health rules.

Robotics

Robots are an amazing part of our lives. They work tirelessly in factories, hospitals, and homes. They need strong and light joints and gears. Forged parts are the secret to making sure your robots move as smoothly and reliably as possible. As more robots are made, there is a greater need for custom and exact parts. Engineers use special processing to design new parts for smart robots.

NOBLE’s Quality Assurance

You want every part to be just right. NOBLE checks quality at every step. Skilled engineers check every part to match your design and do even better than you expect.

| Location | Quality Commitment |

| Pennsylvania | Careful checks to make sure every part is what you need |

| Texas | Strong rules so every product meets and beats your standards |

| Minnesota | Extra checks so every product is better than you hope |

NOBLE uses advanced tools and checks every part. You get reports and certificates for each order. You can trust every forged part, whether you need one or many, because we focus on quality. Pick NOBLE. Get peace of mind.

Choose NOBLE for Metal Forging

NOBLE’s Streamlined Workflow

You want your project to go fast and stay on track. NOBLE’s workflow helps make this happen. You start by uploading your CAD design on their website. You’ll get a quote super quickly, with no waiting around. This’ll help you plan your time and budget without any hassle.

After you say yes to the quote, NOBLE’s team starts working. Skilled engineers will take a look at your design and suggest ways to make improvements, such as making it stronger or more cost-effective. You always know what is happening with your order. Real people will answer your questions – not computers.

Every order from NOBLE’s factory is tracked digitally. You can see where your part is from start to finish. This system helps to stop things going wrong and making mistakes when our engineers are using machinery. You get your custom parts on time, every time.

NOBLE’s Specialized Techniques

You need more than simple shapes. NOBLE uses special techniques that make them stand out in metal forging and precision manufacturing. These advanced methods have the potential to assist you in achieving your desired results, even for complex designs.

Here are some of the special techniques NOBLE uses:

| Technique | Description |

| CNC Press Brake Bending | Robotic and manual bending for precise angles. |

| Tube Bending | Accurate shaping of tubes for many uses. |

| Roll Forming | Continuous shaping of metal strips for efficiency. |

| Corner Forming | Sharp, clean corners and edges for quality parts. |

You might find that a custom bracket with sharp corners or a tube with a perfect curve would be useful. NOBLE’s team uses these techniques to make parts that fit your needs. You get custom processing without extra trouble.

NOBLE’s engineers have lots of experience. We know how to combine these methods for the best results. You’ll get tough, reliable parts that are good to go as soon as you take them out of the box.

NOBLE’s State-of-the-Art Machinery

You want your parts made with the best machines. NOBLE’s factory has state-of-the-art machinery. These machines do everything from seamless ring rolling to press forging. Our state-of-the-art CNC machines are top-notch for cutting and shaping metal. Robots are great for jobs that need to be done over and over again, because they can do each part the same every time.

Modern furnaces heat metal quickly and evenly. This keeps the grain structure strong and reduces waste. Digital sensors are always checking temperature and pressure. You get the same high quality, whether you order one part or a thousand.

NOBLE buys new technology every year. This means you always get the latest in precision manufacturing. Your project’ll get finished quicker and with better fits and finishes.

NOBLE’s Quality Assurance

You want your parts to be just right. NOBLE checks every part to make sure it meets your needs. Our team is meticulous in its approach, ensuring that every detail is perfect before sending anything out. Skilled engineers use special tools to check each piece. We make parts with care and never skip a step.

NOBLE uses strict rules in its factory. They follow a quality system that matches ISO 13485. This system reliably tracks each step from start to finish. Your parts get checked often by BSI with regular audits.

Here’s how NOBLE’s process stands out in 2025:

| Aspect | NOBLE’s Process | Industry Standard Comparison |

| Quality Management System | Complies with ISO 13485 | Aligned with recognized standards |

| Auditing | Regular audits by BSI | Meets the requirements of competent authorities |

| Inspections | Inspected by the FDA | Exceeds industry expectations |

You get more than just a part from NOBLE. Each piece is meticulously checked for size, shape, and strength. NOBLE inspects every single part before it leaves. If you need special reports or certificates, just ask. The team gives you all the paperwork you need to show your parts meet world standards.

NOBLE’s engineers use digital tracking for every order. You get updates at each step. If you need any special reports or certificates, just let me know. The NOBLE team will sort out all the paperwork you need to show that your parts meet world standards.

If you work in aerospace, medical, or robotics, you’ll know that these industries all need durable components that perform well. NOBLE’s quality checks give you peace of mind. Your project will meet the precise manufacturing standards we’re known for.

Pick NOBLE, and you’ll have a partner who really values quality. Our team will be with you every step of the way, from the initial design to the final inspection. That’s how NOBLE helps you do well in 2025.

So, you get how metal forging turns metals into strong parts. By 2025, we’ll be using hot forging, warm forging, and cold forging techniques to manufacture all kinds of items. These include car shafts and small fasteners. Here is a simple chart:

| Forging Type | Temperature Range | Key Features | Applications |

| Hot Forging | 950–1260°C | Easy to shape, needs less force | Big shafts, hubs |

| Warm Forging | 650–950°C | Smooth look, shapes are very exact | Gear blanks, small pieces |

| Cold Forging | Room temp to ~150°C | Very strong, works best with bendy metals | Bolts, screws |

Forged parts are strong and exact, and they save money in lots of different areas. These fields include cars, planes, and robots. If you want quick, custom help, NOBLE’s factory can help you. You can upload your design or ask for a price to begin your project in precision manufacturing!

FAQ

What is metal forging?

Forged parts are strong and exact, and they save money in lots of different areas. These fields include cars, planes, and robots.

When should I choose forged parts over cast or machined parts?

When your parts require higher strength and longer service life, it’s time for forging to take center stage. These parts exhibit no weak points or cracks. Components manufactured through forging can withstand greater stress and deliver superior performance.

How fast can I get custom forged parts from NOBLE?

You upload your design and get a quote right away. NOBLE’s factory works fast with a simple process. Most orders are ready in just a few days.

Which industries use metal forging the most?

Metal forging is used in cars, planes, medical tools, and robots. These jobs need strong and exact parts. Custom processing can help you meet tough rules.

I was wondering if it would be possible to order small batches or prototypes from NOBLE?

Yes! NOBLE lets you order just a few or test new ideas. Why not try making a sample of your design first to see how it turns out? There’s no need to rush into mass production. Our factory can handle orders of all sizes, so whatever you need, we can deliver.

What materials can I use for custom forging?

You can choose steel, aluminum, titanium, or copper alloys. Each metal has its own good points. NOBLE’s team helps you pick what works best.

How does NOBLE ensure quality in every part?

NOBLE checks every part with careful inspections and tracking. Skilled engineers always look at every detail. You get reports and certificates with your order.

What surface finishes are available for forged parts?

You’ve got loads of options when it comes to finishes. Whether you’re into anodising, powder coating, or something else entirely, we’ve got you covered! These choices are great for stopping rust and making parts look better. I’m sure your parts will last and look great!