What is End Milling?

End milling is a commonly used mechanical machining technique. It uses a rotary cutting tool called an end mill, which has cutting edges on both sides and the end. The end mill is installed on the spindle of a milling machine or machining center. Through rotational and feed movements, it removes material from the workpiece.

The primary feature of end milling is its multi-functionality. It can not only process planes perpendicular to the tool axis, but more importantly, it can perform side wall milling, slot milling, contour machining, step milling, and cavity milling. This makes end milling a core technology for manufacturing various features on parts

How Does the End Milling Process Work?

Drawing Analysis

Engineers need to carefully interpret the part drawings, clearly identify all features that need to be machined by end milling, such as planes, steps, cavities, grooves, etc., and analyze their dimensional tolerances, positional tolerances, and surface roughness requirements. At the same time, based on the characteristics of the workpiece material, plan a reasonable machining sequence.

Workpiece Clamping

According to the shape of the workpiece and machining equipment, select the appropriate fixture to firmly and precisely fix the blank on the machine tool worktable. When clamping, it is necessary to ensure that the clamping force is sufficient to resist the cutting force to prevent the workpiece from moving, but it should not be too large to cause deformation of the workpiece.

CNC Programming

According to the established process route and tool path, computer-aided programming is carried out using CAM software, or G-code is written manually. Programming needs to generate efficient and safe tool movement trajectories, including reasonable tool advance and retreat methods, cutting paths, etc. After the program is completed, it must undergo strict verification to check for any logical errors, over-cutting, or risks of collision with fixtures, ensuring absolute safety.

Test Machining

Before batch machining by end milling, the first piece needs to be test-cut. During trial cutting, a conservative feed ratio is usually adopted, or key features are tested first in areas with more allowance on the blank. Immediately after machining, use measuring tools to measure the key dimensions of the trial-cut parts.

Production Machining

After the machine is debugged without error, formal batch or continuous machining begins. During the machining, the operators need to conduct continuous monitoring. The monitoring content includes: listening to whether the operation sound of the machine tool is smooth, and whether there is any abnormal vibration or screeching. Observe whether the color and shape of the chips are normal; Check whether the cutting fluid fully covers the cutting area; And randomly inspect the dimensions of the workpieces at regular intervals according to the preset tool life or machining quantity.

Final Inspection

After the finished workpieces are machined, a comprehensive final inspection is required. Use more precise inspection equipment, such as three-coordinate measuring machines, profilometers, surface roughness meters, etc., to quantitatively inspect all the dimensions, geometric tolerances, and surface qualities required by the drawings.

The test data should be formed into a report and compared with the quality standards to determine whether the product is qualified. This step is not only the final judgment on the quality of individual parts, but its data also provides an important basis for process optimization and quality traceability.

Types of End Mills

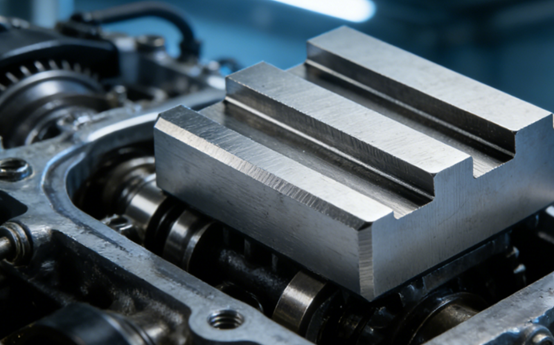

Flat End Mill

Flat end mills are the most fundamental and commonly used type of end mills. Its end cutting edge is flat, enabling effective vertical cutting and side milling. This type of cutting tool is mainly used for right-angle steps, contours, and regular-shaped cavities, and can produce a flat bottom surface and vertical side walls.

Ball Nose End Mill

Ball nose end mills cannot produce right-angle bottom surfaces, but their main advantage lies in their ability to process three-dimensional curved surfaces. Through tool path programming, it can precisely process complex mold cavities, blade shapes, and any curved surfaces that require smooth transitions.

Corner Radius End Mill

Corner radius end mill combines some advantages of flat end mill and ball nose end mill cutters. Their arc angles are more robust than sharp angles, less prone to chipping, and can withstand greater cutting forces. They are commonly used in rough and semi-finish machining of steel and cast iron. The surface machined by it will have arc transitions, but through small-step programming, nearly vertical side walls and flat bottom surfaces can also be processed, making it an efficient choice for rough machining of cavities.

Chamfer Mill

The chamfer mill is specially designed for chamfering or deburring. Its cutting edge is at a specific Angle, which can directly process precise chamfers on the edge of the part, preparing for subsequent assembly or safety handling. Some chamfering knives are designed to allow the chamfering width to be controlled by adjusting the axial depth, making them very flexible to use.

Roughing End Mill

Rough machining end mills can enhance the material removal rate. There are many chip grooves on the tool body, which divide long chips into small sections, facilitating chip removal and heat dissipation. Its wavy edge or unequal pitch tooth design can reduce cutting vibration, allowing for greater cutting depth and feed for efficient rough machining, and quickly leaving uniform allowance for subsequent finish machining.

Advantages of End Milling

Versatility and Flexibility

End mills are one of the most comprehensive processes on machining centers. A single end mill can perform a variety of operations, including milling planes, steps, cavities, grooves and complex three-dimensional contours. This “one tool for multiple uses” feature greatly reduces the number of tool changes during the machining, simplifies programming and tool management, and is particularly suitable for machining complex parts with multiple geometric features. It is the core for modern CNC machining to achieve highly integrated production.

High Finish Quality

End mills can achieve extremely high dimensional and geometric accuracy. During finish machining, using multi-tooth, high-precision end mills in combination with a strategy of high speed, small cutting depth, and high feed rate can achieve an excellent surface finish, reduce or even eliminate subsequent grinding or polishing processes, and improve overall efficiency.

Wide Material Compatibility

End mills can machine all engineering materials. By choosing the appropriate tool material and dedicated coating, and matching the suitable cutting parameters and cooling methods, it can efficiently process a wide range of materials from soft metals such as aluminum and copper, to die steel, stainless steel, and even difficult-to-machine materials like high-temperature alloys and titanium alloys, as well as composite materials and non-metallic materials. Its applicability is extremely extensive.

High Material Removal Rate

End milling uses large-diameter or roughing end mills with corrugated edges, combined with high axial depth of cut and radial width of cut, which can achieve extremely high metal removal rates. Modern high-speed cutting and high-performance machining technologies have further tapped into its potential, enabling the rapid machining of blanks to a shape close to that of the finished product, significantly reducing the overall machining time and enhancing production efficiency.

Disadvantages of End Milling

Tool Fragility and Wear

End mills, especially small-diameter tools, have a large length-to-diameter ratio, overhanging elongation, and relatively poor rigidity. When machining hard materials or being subjected to uneven cutting forces, vibration, chipping, or overall breakage is highly likely to occur. The wear of cutting tools is also relatively fast, especially when machining difficult-to-cut materials. It is necessary to frequently monitor the condition of the cutting tools and change them, which increases costs and downtime.

Cutting Force Deflection

The radial cutting force generated during end milling is relatively large, especially when using long-edge tools for deep cavity or side wall machining. This radial force is prone to cause deformation of slender or thin-walled parts, affecting the machining accuracy. At the same time, it is also the main cause of inducing cutting chatter.

Chip Evacuation Challenges

When performing end milling in closed or deep cavities, the removal of chips is a key challenge. The retained chips will be re-cut by the tool, leading to deterioration of the machined surface quality, a sharp increase in tool temperature, rapid wear of the cutting edge, and even chipping.

Corner Machining Issues

When using a flat-bottom end mill to machine inner right angles, the cutting contact arc length and cutting thickness at the corner of the tool will suddenly increase, resulting in a sharp increase in cutting force and poor heat dissipation. This will cause intensified tool vibration, accelerated local wear, and at corners, it is prone to tool deflection, overcutting or residual material, affecting dimensional and shape accuracy.

Surface Tool Marks

When end milling is used for the fine machining of large-area planes or curved surfaces, tiny step marks will be left between adjacent tool paths. When changing tools or altering machining strategies, visible “tool marks” may also occur at the junctions of surfaces processed by different program segments or tools.

End Milling vs. Face Milling

| Feature | End Milling | Face Milling |

| Primary Cutting Edges | On the peripheral sides and the end of the tool. | Primarily on the end face/axis of the tool. |

| Typical Tool | Long, cylindrical End Mill with a smaller diameter. | Short, disc-shaped Face Mill or shell mill with a large diameter. |

| Primary Motion | Rotates on its axis and moves laterally (X, Y, Z). | Rotates on its axis and moves primarily perpendicular to its axis (Z-axis feed). |

| Main Application | Profiling, slotting, pocketing, contouring, and machining complex vertical features. | Facing large, flat surfaces to create a smooth, horizontal plane. |

| Surface Finish on Flat Face | Can be good, but may show tool path lines. | Typically excellent and very uniform across the entire surface. |

What Factors Affect the Surface Quality of End Milling

Tool Geometry and Condition

The geometric design of the cutting tool directly affects the cutting process. Sharp cutting edges and appropriate helix angles can ensure smooth cutting and smooth chip removal, thereby achieving a better surface. The wear condition of the cutting tool is also of vital importance. A worn cutting edge will increase the cutting force, produce burrs, and deteriorate the surface quality.

Cutting Parameter Settings

Cutting speed, feed rate, and depth of cut are the core process parameters. Too low a cutting speed may cause a built-up edge and damage the surface. If it is too high, it may cause vibration or accelerate tool wear. The feed rate per tooth determines the cutting thickness. If the feed rate is too high, it will leave obvious feed marks. If it is too low, it may cause excessive friction between the tool and the workpiece, instead of abnormal cutting, resulting in work hardening.

Machine Tool

The precision, rigidity, and dynamic response of the machine tool itself are the foundation. The radial and axial runout of the spindle must be controlled at an extremely high level; otherwise, it will be directly replicated onto the surface of the workpiece.

If the overall rigidity of the machine tool is insufficient, it will produce slight elastic deformation and vibration under the action of the cutting force. This kind of vibration, especially high-frequency flutter, is one of the primary reasons for the appearance of vibration marks on the surface and the deterioration of roughness.

Workpiece Material

The properties of the workpiece material, such as hardness, toughness, tendency to work hardening, and thermal conductivity, have a fundamental impact on the surface quality. For instance, when machining soft and sticky materials, built-up edge is prone to occur, while when machining hard and brittle materials, chipped chips are likely to scratch the surface.

Lubrication Conditions

The function of cutting fluid or lubricant is not only to cool and lubricate. Effective cooling can lower the temperature in the cutting zone, reduce the thermal wear of the cutting tool, and reduce the thermal deformation of the workpiece. Good lubrication can reduce cutting force, inhibit the formation of built-up edge and burrs, and help achieve a smoother surface.

Tips for End Mill Maintenance and Longevity

Proper Tool Selection

End milling machining should select matching tool materials, coatings, and geometric parameters based on the materials and procedures. For rough machining, sparsely toothed tools with large helix angles are selected to facilitate chip removal, while for finish machining, closely toothed tools are needed to ensure surface finish. Before installation, clean the tool holder and the taper hole of the spindle. Use high-precision chucks or hydraulic tool holders and try to shorten the overhang length of the tool to enhance rigidity.

Optimizing Cutting Parameters

The operator should set reasonable parameters such as rotational speed, feed rate, and depth of cut based on the recommended values by the tool manufacturer. In actual machining, it is necessary to avoid using excessive radial cutting depth for full-width cutting, especially when machining corner areas; the feed rate should be actively reduced. Targeted adjustment strategies should be adopted for different workpiece materials.

Effective Cooling

End milling machining should select an appropriate cooling method based on the characteristics of the processed material. For cemented carbide tools, it is recommended to use oil-based coolant during intermittent cutting to reduce thermal shock. When performing deep cavity machining, dedicated nozzles should be designed or internally cooled tools should be used to ensure that the coolant reaches the cutting edge directly, preventing secondary cutting damage caused by poor chip removal.

Applications of End Mills

Part Contouring

End milling can precisely process the two-dimensional or three-dimensional complex contours of parts. Whether it is the complex outer edge of mechanical parts or the curved surface parting line of molds, they can all be completed through 3-axis or 5-axis linkage end milling.

Slot and Pocket Milling

End milling is the preferred method for machining all kinds of grooves and cavities. It can efficiently mill various functional grooves such as T-slots and tool withdrawal grooves, as well as complex irregular cavities in molds. End milling can efficiently remove materials and process closed or semi-closed Spaces with precise dimensions and good surface quality, and is widely used in the manufacturing of mechanical parts and molds.

Face and Step Milling

End milling has unique advantages when machining small-area planes, discontinuous planes, and multi-step side surfaces. It can complete the fine machining of the side walls and bottom surfaces at one time, ensuring the verticality and dimensional accuracy between each step surface.

When machining the partition walls, bosses, and multi-stage stepped shafts in the inner cavities of box-type parts, the vertical milling process demonstrates extremely high flexibility and precision.

Hole Making

End mills can produce high-precision round holes, threaded holes, and large-diameter countersunk holes. Compared with traditional drilling and tapping, thread milling has the advantages of high machining accuracy, no burrs, and the ability to process threads of the same pitch with different diameters with one tool. Its advantages are particularly obvious when machining threads of difficult-to-cut materials.

Thin-Wall Machining

For parts with poor rigidity, such as thin-walled aluminum alloy components and the casings of precision electronic components in the aerospace field, end milling is the main subtractive forming method.

End milling adopts a light cutting strategy featuring small-diameter tools, small cutting depths, and high rotational speeds. Combined with dedicated tool path planning, it can effectively control the cutting force, prevent part deformation, and produce high-precision thin-walled, ribbed, and micro-grooves and other precise features.

Deburring and Chamfering

Specialized chamfering end mills can efficiently and consistently perform chamfering and deburring on the edges of parts. Through simple programming, the passivation treatment of all sharp edges can be automatically completed, enhancing the safety of parts and the convenience of assembly. It is an indispensable subsequent process in modern automated production lines.

NOBLE

We provide high-precision CNC end milling solutions for a wide range of industries. Utilizing advanced multi-axis machining centers and a comprehensive inventory of premium carbide end mills, we machine complex features with exceptional accuracy.

From rapid prototyping to high-volume production, we deliver components with superior surface finishes and tight tolerances, ensuring reliability and performance for your most demanding applications. Partner with us for efficient, high-quality milling results.

FAQ

What is the basic definition of End Milling?

End milling is a fundamental machining process where a rotating cutting tool, called an end mill, is used to remove material from a workpiece. Unlike a drill bit that primarily cuts in the axial direction, an end mill’s cutting edges are located on both its periphery and its end face.

What are the main advantages of using End Milling?

The key advantages of end milling include its high versatility in creating diverse part features, excellent precision and surface finish when optimized, compatibility with a vast range of materials from plastics to superalloys, and efficient material removal rates, especially with modern tooling and CNC strategies.

What are the key factors affecting tool life in End Milling?

Tool life in end milling is primarily influenced by the workpiece material hardness and abrasiveness, cutting parameters, tool material and coating selection, cooling and lubrication effectiveness, and machining stability.

How important is coolant/lubrication in End Milling processes?

Coolant and lubrication are crucial in end milling for multiple reasons. They help dissipate heat from the cutting zone, reduce friction between the tool and workpiece, prevent chip welding, and improve chip evacuation.

How does End Milling compare to other common machining processes like Drilling or Turning?

End milling differs fundamentally from drilling and turning in its cutting motion and application scope. While drilling is designed specifically for creating round holes through axial force, and turning rotates the workpiece against a stationary tool to create cylindrical shapes, and end milling rotates the tool to cut in multiple directions. This makes end milling uniquely capable of producing slots, pockets, complex contours, and 3D surfaces that are not feasible with drilling or turning alone, offering greater geometric flexibility on machining centers.