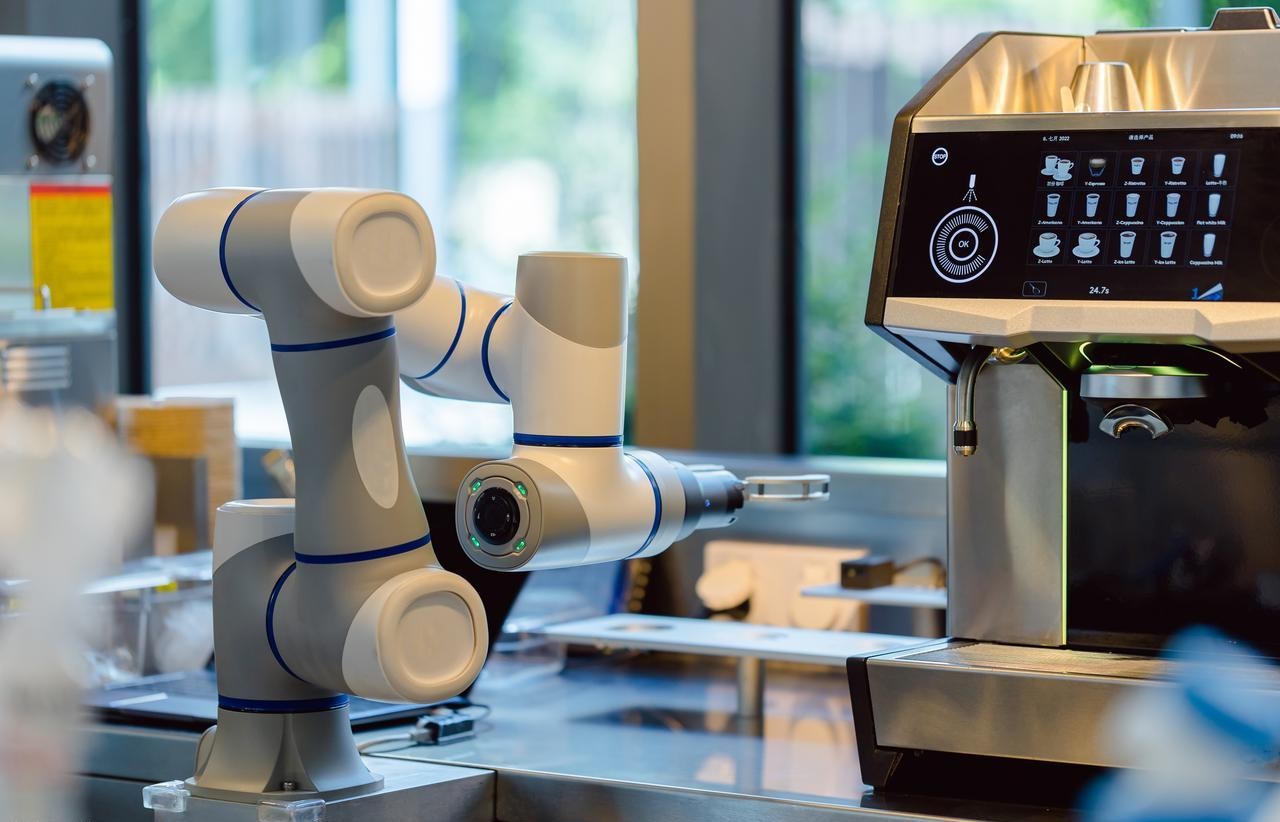

It’s like robotics is a symbol of how things are always changing in our world today. The ancient Greek philosopher Aristotle came up with the idea of robots as early as 322 BC. Ever thought about what mix of tech brings these creations, with human-like intelligence, to life? They range from simple tin men to “androids” whose movements are almost the same as those of real humans.

Why CNC Machining is the Backbone of Precision Robot Manufacturing

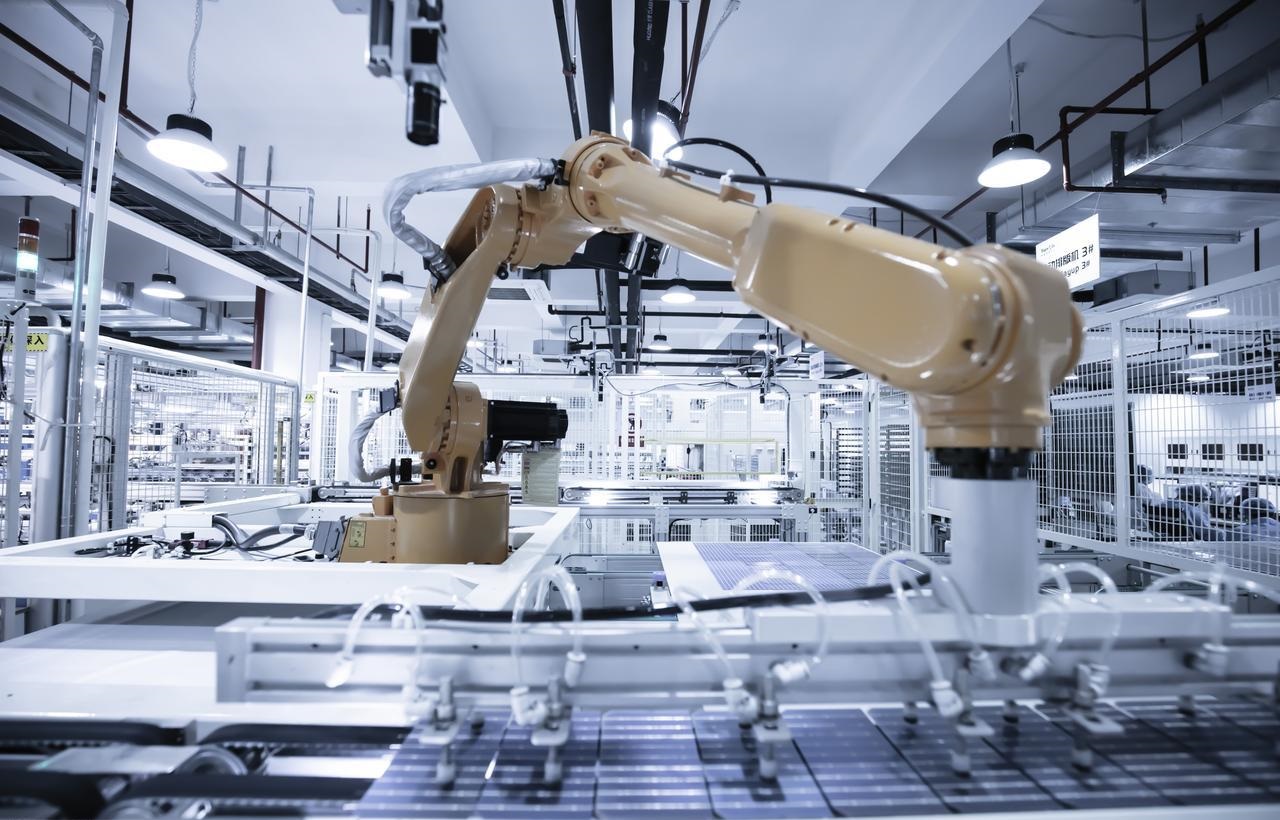

Think about a manufacturing robot performing the same weld thousands of times a day. We need that motion to be perfect, every single time. But that precision isn’t just about programming. It’s all about the physical parts inside the robot arm itself. If the internal gears wobble a bit or the housing bracket bends when there’s pressure on it, that tiny error gets bigger at the end of the arm.

Key CNC Processes for Critical Robot Manufacturing

Making a high-performance robot means using a bunch of specialised CNC machining processes, each chosen for specific part geometries and functional needs.

CNC Milling

Simply put, CNC milling is basically where you hold the workpiece in place, spin a cutting tool to machine it, and then make all sorts of complex features like grooves, slots, and mounting surfaces. This process is often used when manufacturing robot actuator housings and structural frames.

CNC Turning

So, unlike CNC milling, if you see parts spinning around really fast but the cutting tool is still, it’s probably doing CNC turning.

As you’d expect, it’s great at making precise, rotationally symmetrical parts, like connecting pins with tight diameter tolerances inside robot bodies, bearing rings, and motor shafts.

CNC Swiss Machining

Swiss turning is great at getting into the nitty-gritty. With CNC Swiss turning, both the workpiece and the cutting tool move, which means you can make loads of thin, complicated parts really precisely. We’re talking micro robot finger actuators and sensor probes here.

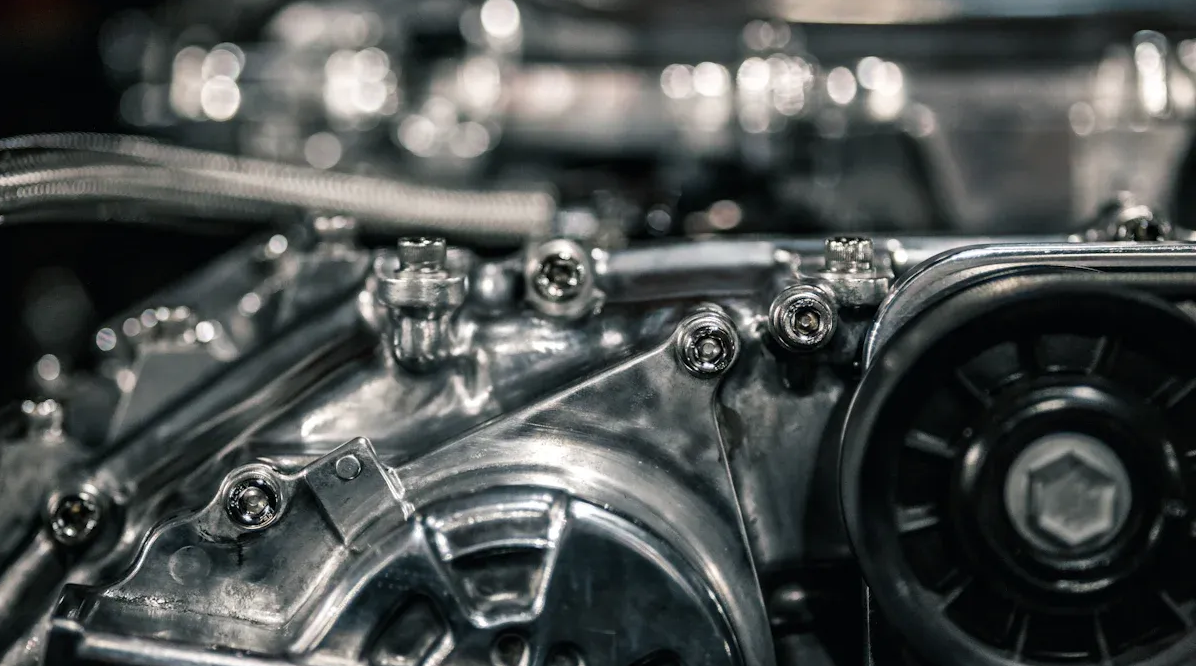

CNC Grinding

An abrasive wheel removes minute amounts of material to achieve ultra-fine surface finishes and the tightest possible tolerances, which is critical for hardening the surfaces of transmission gears and ensuring perfect sealing on hydraulic valve components.

5-Axis Machining

As its name suggests, 5-axis machining enables simultaneous movement along five distinct axes, allowing for the complete machining of complex shapes—all in a single setup. It is particularly well-suited for manufacturing robot arms and carving intricate end-effectors for robot arms.

| CNC Process | Best For | Key Robot Applications |

| CNC Milling | Complex 3D shapes, structural parts | Arm links, gripper bodies, base frames, sensor mounts |

| CNC Turning | Cylindrical, rotationally symmetric parts | Motor housings, ball screws, pins, bushings |

| CNC Swiss Machining | Very small, slender, high-precision parts | Surgical robot tools, miniature connectors, sensor housings |

| CNC Grinding | Ultra-fine finishes on hardened steel | Gear teeth for reducers, bearing races, and precision shafts |

| 5-Axis Machining | Complex, organic geometries in one setup | Topologically optimized arms, complex joint housings |

Advantages of CNC Machining in Robot Manufacturing

Choosing how to make a robot is a big decision that has a direct impact on how well it works, how long it will last, and how reliable it is. CNC machining has a bunch of benefits that make it the go-to choice for important robot parts.

Material Versatility

Robots are used in all kinds of industries and environments, so the materials used to make them need to be diverse too. NOBLE’s precision manufacturing processes are proven with all standard and exotic robot materials. When we’re manufacturing robot structural frames, we usually use lightweight aluminium alloys (like 6061) or extremely high-strength 7075 aluminium alloys. We work with durable steels, including 4140 and various stainless grades, for gears and shafts. For the ultimate strength-to-weight ratio in aerospace-inspired arms, we precision-machine titanium.

NOBLE also provides engineering plastic solutions: We’ve got PEEK for electrical insulation components and ultra-high molecular weight polyethylene for wear-resistant assemblies. This is exactly what makes our custom CNC machining for manufacturing robot services so great.

Precision and Repeatability

This is the non-negotiable core of robotic function. CNC machining is the only method that consistently delivers the sub-millimeter to micron-level accuracy required for robots to perform tasks reliably, cycle after cycle. The difference between a successful weld path and a collision is often a few hundredths of a millimeter. NOBLE’s CNC machining protocols make sure that every actuator housing and every sensor mount is produced not just to the print, but to the high standard of repeatability that high-volume automation needs. This is the bedrock of our work as a professional machining partner.

Strength and Durability

Unlike with additive manufacturing, where internal stresses and anisotropy issues can sometimes occur, CNC-machined parts are cut from solid, homogeneous material blocks. If you’re talking about robot joint bearings that are put under a lot of pressure, the components need to be really strong and able to handle wear and tear.

NOBLE’s manufactured parts are more than just shapes; they’re made from materials with proven metallurgical processes, making sure they can handle the non-stop demands of 24/7 production lines.

Consolidation

We’ve got some pretty advanced CNC machining here, especially when it comes to 5-axis technology, and that lets us totally re-engineer assemblies. We can consolidate what would be multiple fabricated and assembled pieces into a single, monolithic component. This gets rid of weak points on parts, like fasteners and welds, and speeds up assembly.

Materials of Robot Manufacturing: From Strength to Smarts

When picking materials for robot manufacturing, it’s tricky to find one solution that’s always best. To be honest, this whole process is all about making trade-offs. The final choice will be a bit of a compromise, but it’ll be worth it. We’ll get the strength we need, it’ll be lightweight, and it’ll be good value for money.

We can’t have it all: heavier components may be more durable but need more powerful motors to drive them; cheaper materials might reduce initial costs but could fail prematurely.

Metal Alloys

Metals provide the foundational skeleton and muscle for the vast majority of robotic systems, prized for their structural integrity and durability.

Aluminum Alloys (6061, 7075): These are the undisputed champions for structural components. The main perk is that they’re super strong for how little they weigh. 6061 offers excellent all-around machinability and is our most common choice for robot frames and housings. When a design needs to be extra strong, our engineer uses 7075, which is almost as strong as steel but much lighter. This is a core material we handle daily in our factory for the precision manufacturing of critical parts.

Steel (4140, Stainless): When robot parts need to be able to handle extreme forces, impact loads, or continuous wear and tear, we go for steel.

4140 alloy steel is perfect for making heavy-duty gears, axles, and hydraulic components. If your robot operates in corrosive environments such as food processing or medical settings, NOBLE’s range of stainless steel grades can help. It’s strong and resistant to corrosion, making it perfect for shafts and joints that need to be extra durable.

Titanium Alloys: When it comes to top performance in extreme situations, titanium is the go-to material. It’s got an amazing strength-to-weight ratio, and it’s really resistant to corrosion. But it’s pretty tricky to machine, so you need specialised CNC machining techniques and parameters.

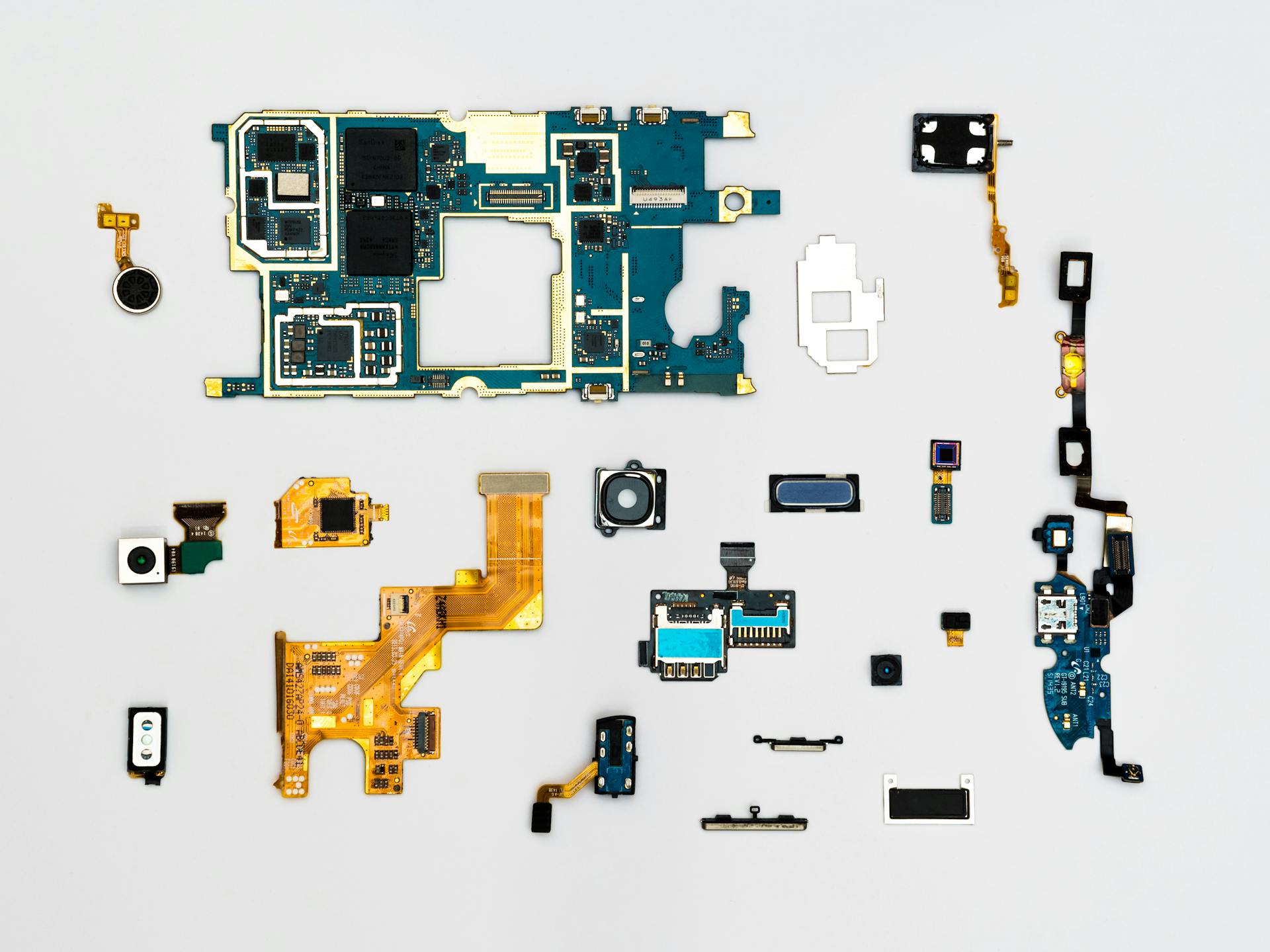

Plastics & Polymers

ABS & Polycarbonate: ABS and PC are the go-to materials for impact-resistant outer casings, protective covers, and for creating functional prototypes quickly. They’re tough, cost-effective, and easy to customize.

POM (Acetal/Delrin): Polyoxymethylene (POM), commonly known as “engineering plastic,” is highly reliable—featuring low friction, high rigidity, and excellent dimensional stability. NOBLE engineers often use it to make low-friction gears, durable bushings, and complex sensor mounts, which stop wear caused by direct metal-to-metal contact.

PEEK: This is a high-performance polymer for the most demanding environments. PEEK keeps its mechanical properties at high temperatures, is chemically resistant, and can be sterilised. We use it for components in cleanroom automation, high-temperature end-effectors, and other challenging precision manufacturing applications.

Composites

Composites represent the cutting edge, combining materials to achieve properties that single materials cannot.

Carbon Fiber: Sometimes customers ask for carbon fibre. These composite materials are perfect for components that need to be lightweight but also really rigid. We usually do precision trimming and drilling on carbon fibre structures, adding mounting points and hardware to advanced robot arms and frames, which really reduces weight.

Silicone & Rubber: They are not machined via CNC in a traditional sense but are critical for creating compliant grippers that can handle delicate objects, as well as for vibration-isolating mounts throughout a robotic system.

Surface Finishes for Robot Parts

It’s not a matter of if, but when, when it comes to surface treatment. The right surface treatment protects robot components from harsh factory environments, makes sure electrical connections are reliable, reduces friction resistance, and even enhances the robot’s public image.

Functional Finishes:

Anodizing (for Aluminum): This is our standard and most recommended finish for aluminum components. It electrochemically grows a hard, porous oxide layer on the surface. Our engineers usually use Type II anodizing for robot manufacturing, but for parts that need to be really resistant to wear and tear, like robotic grippers, we use Type III hard anodizing.

Hard Coating: If your robot parts operate in harsh environments where they’re likely to get worn out, we suggest applying a hard coating. This treatment creates a really thick and dense oxide layer on the surface of the part, making it much harder.

Nickel/Gold Plating: In robot manufacturing, it’s really important that signals are reliable. We use a thin layer of gold on top of a nickel base for electrical connectors and communication ports.

Passivation (for Stainless Steel): Stainless steel can naturally resist corrosion, but it’s worth noting that CNC machining processes can sometimes damage its protective oxide layer. Passivation is a chemical bath that removes free iron from the surface and restores the protective chromium oxide layer. It’s a key step that won’t cost a lot to make the most of the natural corrosion resistance of stainless steel shafts and housings.

Aesthetic & Protective Finishes:

Powder Coating: This is our top choice for a tough, colorful, and durable finish on robot exteriors, covers, and structural frames. Powder coatings adhere to surfaces through electrostatic spraying and form a thick, resilient coating after thermal curing. Compared to traditional paints, this coating offers superior resistance to peeling, scratching, and chemical corrosion. The available colors and textures are virtually limitless.

Bead Blasting & Brushing: These are mechanical processes we use to create a uniform, matte aesthetic. Brushing creates a directional, satin grain. Both are excellent for providing a clean, professional look to visible aluminum or stainless steel components and are often used as a pre-treatment before other finishes like anodizing.

Managing Costs CNC Machining in Robot Manufacturing

Here at NOBLE, we think costs should be cut by planning and designing better. If we want to keep costs down without affecting the quality of the final product, we need to ask ourselves: what exactly drives these high costs?

Key Cost Drivers:

Material Choice: There’s a big difference in the raw material costs. While choosing 7075 aluminium alloy over 6061 costs more, the extra strength it provides often makes it a good deal. The best solution is to match the material properties exactly with the functional requirements of the part – not too much and not too little, but just right.

Part Complexity: Complexity is the second big thing that’s driving up costs. Deep grooves, thin walls, and intricate contours mean engineers have to spend longer programming, and specialised tools and more machining time are needed.

Quantity: The unit cost is highly dependent on volume. One prototype costs the same as the programming and setup. When we’re making lots of units, we spread this cost across thousands of pieces, which makes the price per unit much lower.

DFM Tips for Robot:

Simplify Geometry: Just ask yourself: Do you think it would be possible to break this complex part down into two or three simpler components? It’s often cheaper to make a simple part than a complex one. This approach also makes future maintenance and repairs easier.

Avoid Sharp Internal Corners: You can avoid sharp internal corners by using a rotary milling cutter. If you set the radius to match the standard end mill dimensions (e.g., 3 mm, 5 mm), the tool can efficiently complete the path machining in a single pass. So, if you’re designing something, it’s worth using these standard tool radii to save time and avoid using small tools that aren’t as efficient. Designing with these standard tool radii in mind eliminates the need for slow, small tools that drive up machining time.

Specify Realistic Tolerances: NOBLE engineers recommend that you apply strict tolerances to critical features and load-bearing surfaces. For non-critical decorative surfaces or clearance holes, tolerances can usually be relaxed to standard ranges. This not only speeds up the machining process but also takes a lot of the financial pressure off. While you’re working on your project, we’ll work with you to figure out which dimensions are really important for the function and which can be changed a bit.

Design for the Manufacturing Process: A part destined for CNC machining should be easily fixturable. You can make setting up your design more secure and repeatable by using a temporary tab or a large, flat datum surface. Try to avoid features that need complicated, custom fixtures or require you to reposition the part loads of times, as each setup can cause errors and cost more.

Tailored Solutions: Robot Parts for Different Industries

Surgical robots in sterile operating rooms, robot arms on food processing lines, and robots in aerospace assembly plants – robots have become a key part of frontline operations in many industries.

Medical/Surgical Robots

In this field, failure is not an option. The demands for precision, reliability, and biocompatibility are unparalleled.

Materials: The material selection is based on the need for biocompatibility and repeated sterilisation. We often use stainless steel (316L) because it’s really resistant to corrosion, titanium because it’s really strong and biocompatible for implants, and high-performance plastics like PEEK for components that need to be compatible with MRI and high-temperature autoclaving. We even work with advanced ceramics for their extreme wear resistance and electrical insulation.

Processes: The components are often incredibly small and complex. We rely on high-precision CNC machining and specialized CNC Swiss machining to produce the tiny, intricate parts for surgical instruments. The tolerances are exceptionally tight, and the surface finishes must be flawless to facilitate cleaning and prevent any bacterial entrapment.

Food & Beverage Robots

Here, the enemies are corrosion, contamination, and the constant need to wash. The most important things for clients are durability and hygiene.

Materials: It’s really important that it can resist corrosion. We primarily use Stainless Steel grades 304 and 316 for all structural and contact components. We pick FDA-approved, food-grade plastics for parts that aren’t metal, and these plastics can take a real beating from strong cleaning chemicals without breaking down.

Finishes: It’s really important to have a smooth surface that doesn’t allow bacteria to set in. We’re not just your regular engineers; we go the extra mile with high-polish finishes on all the important surfaces. This makes them simple to clean and stops the growth of harmful microbes, making sure they meet the strict food safety standards.

Aerospace & Defense Robots

In this field, every gram of added weight can end up costing a lot, so it’s just not an option to compromise on strength.

Materials: The key to picking the right material is making sure it’s as strong as possible for its weight. Engineers usually suggest using high-strength aluminium alloys like 7075 for the frame, but titanium alloys are becoming more popular for critical parts that are under a lot of stress. Carbon fibre materials are perfect for arms and structural elements that need to be lightweight but still strong.

Processes: The complex, organic shapes required for lightweighting are ideally suited for 5-axis CNC machining, which allows us to machine a part from nearly every angle in a single setup.

Choose NOBLE for The Best CNC Machining in Robot Manufacturing

NOBLE provides fast and reliable robot manufacturing services, promotes the research and development and launch of innovative products in the robot manufacturing industry, selects advanced technologies and materials to manufacture robot prototypes or parts, and ensures that your products enter the market as soon as possible.

- Advanced Equipment & Cost-Effective Price

- Tight Tolerance of 0.001 mm

- 10+ years of Robot Manufacturing

- ISO 9001 & ISO13485 Certified Factory

- Free&Professional DFM Report

- 24/7 Engineering Support

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We’ve made the innovation cycle into four simple steps that really work.

Upload Your Design

Simply upload your CAD files and submit RFQs with clear information online.

↓

Receive Design Analysis

We’ll send you a design for manufacturability analysis and transparent pricing.

↓

Start Manufacturing

Our experts will produce your parts with the required technologies and materials.

↓

Receive Your Parts

Your parts will be delivered to your door directly with stringent deadlines.

FAQ

We need to reduce the weight in our robot arm. What is the best material upgrade from aluminum?

For a direct upgrade while maintaining manufacturability, 7075 aluminum offers significantly higher strength with a minimal weight increase. If you’re looking to shed some pounds in the right places, titanium alloy is the way to go. It’s super strong but still really light, although the material and processing costs can be a bit of a stretch.

Why’s CNC machining such a big deal in robotics?

comes to robot manufacturing, precision and repeatability are non-negotiable standards. CNC machining is the only process that can reliably produce high-precision complex internal components like actuator housings and gearboxes.

Can robot exteriors be made from plastic?

Absolutely. Robots usually have a metal frame, but they often have durable plastics like ABS or polycarbonate for their outer shells, covers, and enclosures. Plastic is great at insulating electricity, which is why it’s used so much in electrical engineering. For functional components like low-friction gears and bushings, you might also come across engineering plastics such as POM (polyoxymethylene, also known as Delrin).

Our design has sharp internal corners. Is this a problem for CNC machining?

Yes. A rotating milling cutter can’t create a perfectly sharp internal corner; it’ll always leave a radius. If you design with a specified internal radius that matches a standard end mill size, you can get faster, more efficient machining and a higher-quality result. If you really need sharp corners, we can do EDM services, but this will cost more and take longer.

What’s the difference between anodizing and powder coating for robot parts?

Anodizing is a hard surface treatment that makes aluminium stronger and more resistant to wear and corrosion. It’s thin and keeps precise dimensions. So, powder coating is like a thick layer that’s put on to protect the robot’s outside against colour fading and damage from chemicals. It can sometimes affect tight tolerances, though.