What is Precision CNC Milling Service?

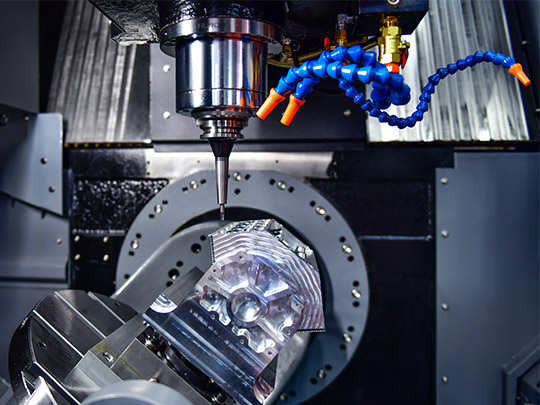

Precision CNC Milling is a machining process that uses computer-controlled rotating cutting tools to precisely shape workpieces by removing material. This technology automatically completes the cutting, drilling, and forming operations of materials such as metal, plastic, and wood based on pre-programmed design instructions.

How does Precision CNC Milling Service Work?

Analyze the Drawings

First of all, engineers need to conduct a detailed analysis of the two-dimensional engineering drawing or three-dimensional model of the part, clearly defining its geometric shape, dimensional tolerance, surface finish requirements, and the materials used.

CAD Model Design

Using computer-aided design software, create or finally confirm the precise three-dimensional digital model of the parts to be processed according to product requirements.

CAM Programming

Import CAD models into computer-aided manufacturing software. Programmers will plan according to the established process.

Program Verification

Before formal machining, the code program is usually verified to check for issues such as tool collision, overcutting, or undercutting. Sometimes, idle running is carried out on the machine tool, or trial cutting is conducted using cheap materials to further ensure that the program is flawless.

Carry Out Machining

After confirming that the program is correct, start the automatic loop. The numerical control system will automatically complete the entire cutting process from rough machining to finish machining according to the G-code instructions.

Quality Inspection

After machining is completed, remove the workpiece. Use measuring tools to inspect the key dimensions to ensure they meet the requirements of the drawings. Finally, carry out post-finishing work such as deburring and cleaning as needed.

Types of Precision CNC Milling Service Processes

Face Milling

Face milling is mainly used to cut a flat horizontal plane on the surface of a workpiece. It is a fundamental and common operation aimed at ensuring the surface finish and flatness of the workpiece. Large-area rapid milling is usually carried out using fly cutters or face mills.

Cavity Milling

Cavity milling is used to cut various shapes of grooves, cavities, or recessed areas inside a workpiece. The cutting tool starts from the inside of the cavity and forms the required pit shape by cutting the material layer by layer. It is widely used in the machining of mold cavities and shell parts.

Profile Milling

Profile milling is used to process the external vertical or inclined contours of workpieces. When the cutting tool moves along the outer boundary of the workpiece, it can create complex external shapes, such as bosses and irregular boundaries.

Thread Milling

Internal or external threads are machined inside the hole or on the cylindrical surface using a dedicated thread milling cutter. This method is highly flexible. The same tool can process threads of different diameters and pitches, and its precision is usually higher than that of traditional tapping.

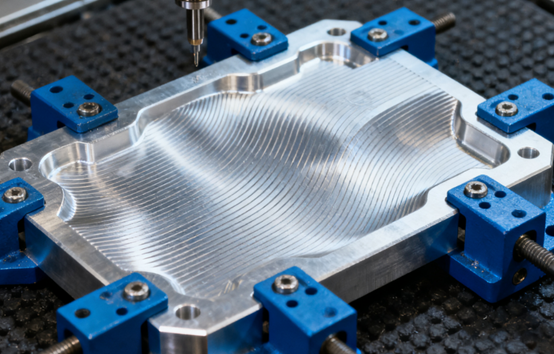

Surface Milling

Surface milling is used for machining complex three-dimensional surfaces, such as molds, blades, sculptures, and other surfaces with continuous changes.

This usually requires the linkage of more than three CNC milling machines, and through precise tool path control, high-quality free-form surface machining can be achieved.

Material Used in Precision CNC Milling Service

Aluminum Alloy

Aluminum is one of the most common materials in CNC milling, featuring light weight, high strength, easy machinability, and good heat dissipation performance. It is commonly used in aerospace, automotive, electronic housing, and other fields. The processed surface has a high degree of smoothness and is suitable for anodic oxidation treatment.

- Advantages: Fast machining speed, high surface finish, and anodized to enhance appearance and corrosion resistance.

- Disadvantages: Its strength is lower than that of steel, and it is not suitable for high-load structures.

Stainless Steel

Stainless steel is of high strength, corrosion-resistant, and heat-resistant, making it suitable for precision machinery, medical devices, and food equipment. Although it is difficult to machine, it can achieve excellent mechanical properties and durability. Common models include 304 and 316.

- Advantages: Excellent mechanical properties, wear-resistant,t and heat-resistant.

- Disadvantages: High cutting resistance, relatively low machining efficiency, and significant tool wear.

Copper

Copper has excellent electrical and thermal conductivity and is suitable for electrical parts, heat sinks, and mold inserts. It has good ductility but is relatively soft. During machining, tool wear and sticking phenomena need to be controlled.

- Advantages: Good ductility, high electrical conductivity, and beautiful appearance.

- Disadvantages: Soft material, prone to sticking to the knife, and the tool wears out quickly.

Brass

Brass, composed of copper and zinc, has excellent machinability and corrosion resistance, and is often used in decorative parts, valves, and electronic connectors. The machined surface is bright, and the cutting efficiency is high.

- Advantages: High machining efficiency, good corrosion resistance, and high dimensional accuracy.

- Disadvantages: Low strength, not suitable for structures subjected to high mechanical stress.

Carbon Steel / Alloy Steel

Carbon steel and alloy steel have high strength and wear resistance, making them suitable for machining structural components, shafts, and molds. The hardness can be increased through heat treatment, but the machining difficulty is greater than that of aluminum.

Titanium Alloy

Titanium alloys are lightweight, high-strength, and corrosion-resistant, and are often used in aviation, medical, and chemical equipment. The machining difficulty is great, and high-performance cutting tools and stable cutting parameters are required.

- Advantages: Lightweight, corrosion-resistant, heat-resistant, and high strength-to-weight ratio.

- Disadvantages: High machining difficulty, high cost, and severe tool wear.

Plastics

Common CNC plastics include POM, Nylon, PEEK, ABS, Acrylic, etc. It is light in weight, has good insulation and strong chemical resistance, and is widely used in prototypes, electronic and medical components.

- Advantages: Low cost, good insulation, and strong chemical resistance.

- Disadvantages: It has poorer thermal stability than metals and is prone to deformation.

Magnesium Alloy

Magnesium alloy is the lightest structural metal, featuring a good strength-to-weight ratio and shock absorption. It applies to aviation and automotive parts, but the risk of combustion needs to be prevented during machining.

- Advantages: Light weight, high strength-to-weight ratio, and excellent shock absorption performance.

- Disadvantages: Flammable during machining, and the cutting environment needs to be strictly controlled.

Advantages of Precision CNC Milling Service

High Precision

The CNC milling machine is driven by a computerized control system and can precisely execute pre-programmed instructions, eliminating errors caused by manual operation.

Once the program is verified, it can continuously and in batches produce parts with almost the same size and shape, ensuring extremely high product consistency and interchangeability.

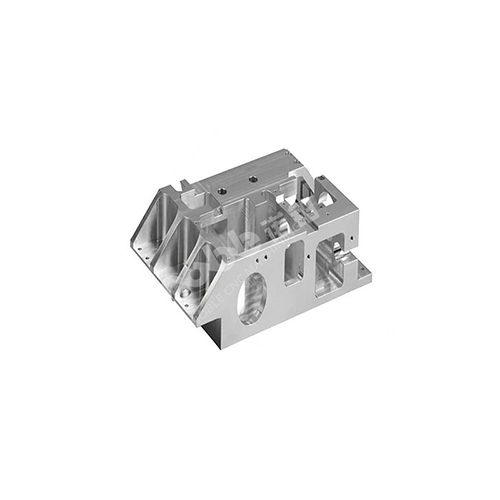

Strong Machining Capacity

CNC milling can easily complete complex geometric shapes that are difficult or even impossible to achieve through traditional manual machining, such as three-dimensional surfaces, complex cavities, and precision threads.

With the aid of multi-axis linkage technology, multi-surface machining can be completed in one clamping, greatly expanding the design freedom.

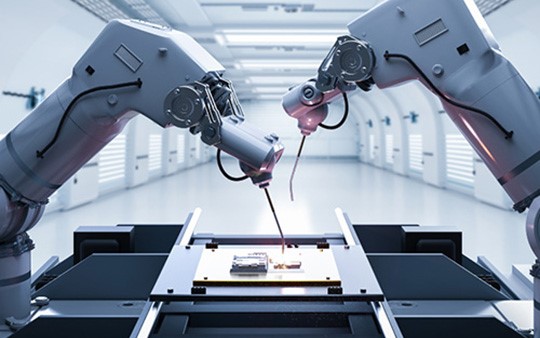

Highly Automated

The entire machining procedure is carried out automatically, including tool changing, cutting fluid switching, etc. The main responsibility of an operator is to clamp workpieces and monitor operations.

One device can even take care of multiple machine tools. This significantly reduces the machining time of individual products, especially in mass production, which can bring about extremely high efficiency improvements.

Flexibility

When it is necessary to change the processed parts, usually only the numerical control program and the corresponding cutting tools need to be replaced, without the need for complex physical modifications to the machine tool itself or the manufacture of special tooling fixtures.

Safety

As the machining is automatically completed within a closed protective door, the operator is isolated from the high-speed rotating tools, chips, and coolant, significantly reducing the risk of direct contact with dangerous areas. This has significantly improved the safety conditions of the working environment.

Quality Control

The machining path, parameters, and time consumption can all be simulated and optimized on the computer. By integrating modern measuring equipment, quality monitoring during the production process can be achieved, making the entire manufacturing process more predictable and traceable.

Disadvantages of Precision CNC Milling Service

High Equipment Cost

The cost of purchasing a CNC milling machine is extremely high. In addition, the initial investment also includes the supporting software, infrastructure, and dedicated tool systems. This is a huge financial burden for start-ups or small-scale workshops.

Highly Technical

The entire process is highly dependent on professional skills. Not only are operators needed, but also experienced programmers and process engineers to create efficient and error-free processing programs.

High Equipment Maintenance Cost

CNC milling machines are precise mechatronic equipment. Their key components, such as spindles, guide rails, and ball screws, require regular professional maintenance and calibration. Once a malfunction occurs, the maintenance cost is high, the cycle is long, and the technical level of maintenance personnel is strictly required.

Limited Variety of Machined Parts

For parts with very simple structures that only require a few processes, using CNC milling may actually be inefficient. The time spent on programming, preparing tools and clamping may far exceed that of manual machining or using dedicated equipment. In this case, its advantage of high efficiency cannot be demonstrated.

Shape Limitation

As a “subtractive manufacturing” process, CNC milling forms by removing material, which itself has limitations. For instance, it is unable to machine completely enclosed inner cavities. In addition, there must be a radius at the internal sharp corners, and it is impossible to directly process absolute right angles.

Material Waste

Unlike the “layer-by-layer stacking” approach in additive manufacturing, milling involves removing the majority of a single piece of raw material to form chips. This not only leads to the waste of raw materials but also increases the cost of waste treatment and the environmental burden.

Difference between Precision CNC Milling Service and CNC Turning

CNC Turning

Working principle: The workpiece is clamped onto the spindle chuck and rotates at high speed. The fixed turning tool moves along the radial (X-axis) and axial (Z-axis) directions of the workpiece to remove the material from the surface of the rotating workpiece.

Machining capability: Extremely skilled in machining symmetrical parts with a common rotational axis. It can efficiently complete cylindrical surfaces, conical surfaces, end faces, threads , and various formed curved surfaces.

CNC Milling

Working principle: The workpiece is fixed on the worktable. The multi-edge milling cutter is installed on the spindle and rotates at high speed. The worktable can carry the workpiece to move in the X, Y, and Z directions, allowing the rotating tool to come into contact with different parts of the workpiece for cutting.

Machining capability: Highly flexible, it can process almost any geometric shape, including planes, grooves, cavities, contours, three-dimensional surfaces, etc. Modern multi-axis machining centers have pushed the milling capabilities to the extreme.

Applications of Precision CNC Milling Service

Aerospace Industry

This industry extensively employs high-strength aluminum alloys, titanium alloys, and composite materials, and has extremely high requirements for the lightweight, strength, and precision of parts.

CNC milling is used for machining complex structural components such as engine blades and rocket casings.

Automobile Industry

From prototype development to mass production, CNC milling is everywhere. It is used for machining engine blocks, transmission gears, molds, and high-performance custom parts.

The high efficiency of CNC milling machining can meet the rhythm requirements of large-scale production in the automotive industry and respond quickly to design changes of new models.

Mold Machining Industry

CNC milling is the absolute main force in mold machining. It can efficiently carve and mill mold cavities with complex curved surfaces and high surface finish.

The application of high-speed milling technology has further shortened the mold machining cycle and can directly mill a mirror-like effect, reducing the subsequent polishing process and significantly improving production efficiency.

Electronic Industry

Products in this industry tend to be miniaturized and more precise. CNC milling is used for machining metal frames, heat sinks, and connectors of smartphones.

Medical Industry

The medical industry has extremely strict requirements for the biocompatibility, surface finish, and sterility of materials.

CNC milling is used to manufacture surgical robot joints, orthopedic implants, and precision surgical instruments. It can handle medical materials such as stainless steel and titanium alloy, and achieve extremely complex ergonomic shapes to meet personalized customization needs.

NOBLE: Precision CNC Milling Services Provider

With state-of-the-art 3-, 4-, and 5-axis milling equipment, NOBLE provides reliable on-demand CNC milling services for rapid prototyping and production parts. Get high-precision, lifelike milled parts custom-made from a variety of metals and plastics at competitive prices. Advanced Equipment & Cost-Effective Price.

Generally speaking, the type of CNC milling machine is defined by its number of axes. The higher the number of axes, the greater the ability to create complex parts and create cutting angles. Efficiently bring your products to market faster with a reliable CNC milling company. From rapid prototyping to custom production, take advantage of premium 3-axis, 4-axis, and full 5-axis CNC milling for high precision and high-quality CNC milled products.

NOBLE provides high-quality CNC milling services to help you transform your designs into complex geometries. Take control of your CNC milling projects and obtain custom parts to your exact requirements by working with our in-house machining team.

FAQs

What tolerances can be achieved with precision CNC milling?

Typical tolerances range from ±0.005 mm to ±0.01 mm, depending on the material, part geometry, and equipment capability. Advanced 5-axis CNC machines can achieve even tighter tolerances for high-precision components.

What are the advantages of precision CNC milling services?

The main advantages include exceptional dimensional accuracy, repeatability, surface quality, and the ability to produce complex geometries. It’s ideal for both prototypes and high-volume production runs.

How does precision CNC milling differ from standard CNC milling?

Precision CNC milling focuses on achieving higher accuracy, tighter tolerances, and smoother finishes, often using more advanced machines, tooling, and quality control processes compared to standard CNC milling.

How long does it take to complete a precision CNC milling project?

Lead time varies depending on design complexity, material type, and production quantity. Simple parts may take 2–3 days, while complex components may require 1–2 weeks for completion.

Can precision CNC milling be used for prototype and mass production?

Yes. Precision CNC milling is highly flexible—it allows cost-effective prototyping for testing designs and can easily scale up for full production runs with consistent quality.