So, anodizing is basically a cool electrochemical trick that beefs up the natural oxide layer on metals, mostly aluminum. It makes the metal tougher against rust and scratches, plus it creates a surface that’s perfect if you want to add color or seal it. Unlike painting or plating, the oxide layer becomes part of the metal, so it won’t chip or peel off easily.

Here’s how it works: the metal part acts like the anode in an electrolytic setup. When you zap it with electricity through a bath of acid, oxygen ions come out and bond with the metal’s surface, building a thick, porous oxide layer. This layer is built-in, not just slapped on, which means the metal gets way better protection from the environment.

How Anodizing Works

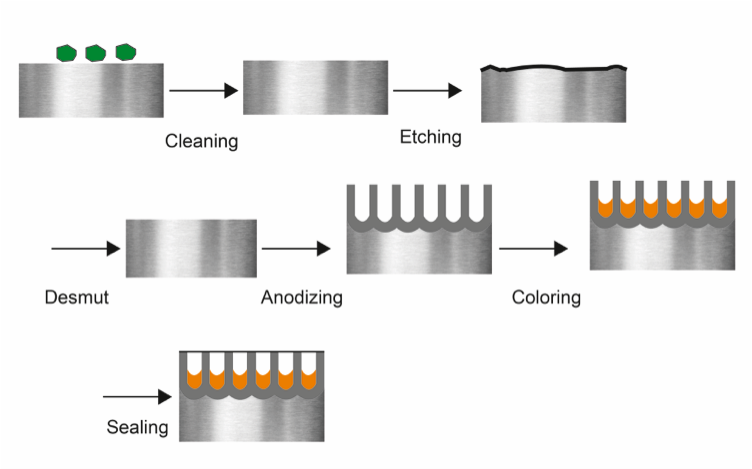

1. Surface Preparation

Before anodizing, you’ve got to prep the aluminum parts properly—this step makes all the difference in how well the finish turns out.

Degreasing: First, wipe away all the oils, grease, and dirt. This usually means using some alkaline cleaners or organic solvents. If you miss any grime, the anodizing won’t stick right.

Etching: Next, dunk the aluminum in a sodium hydroxide bath. This strips off oxidation and smooths out the surface, giving it a nice matte look. Plus, it helps the anodizing stick better. Just make sure you don’t leave it in too long or too short!

Desmutting: After etching, there might still be some smut left, especially if your alloy has silicon. A quick nitric acid rinse cleans it all off. Sometimes, greener alternatives are used to be more eco-friendly.

Rinsing: Don’t forget to rinse thoroughly after each step with clean water to wash away any leftover chemicals. This keeps everything clean and ready for the next stage.

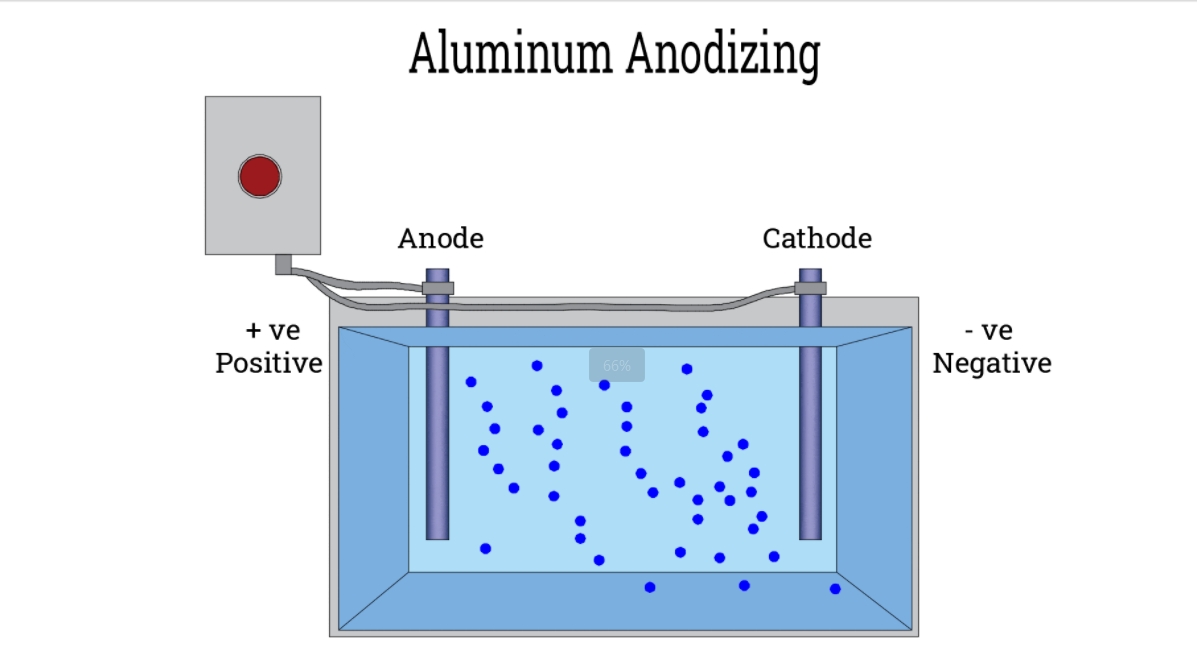

2. Anodizing (Electrolytic Oxidation)

To anodize, you dip the cleaned aluminum parts into an electrolytic bath and run an electric current through it.

Electrolyte Solution: The bath used for anodizing usually contains sulfuric acid at about 15% to 20% concentration. This acid works well to create a strong oxide layer on aluminum. Sometimes, a bit of aluminum ions is added to help the process along. For special uses that need extra corrosion protection, chromic acid might be used instead.

Voltage and Current: A direct current (DC) voltage is applied between 12 to 30 volts, depending on the desired thickness and type of anodizing. The current density typically ranges from 12 to 25 amperes per square foot (ASF). Higher current densities result in faster oxide growth but may increase the risk of burning the workpiece if not carefully monitored.

Temperature Control: Keeping the electrolyte temperature between 20 and 30°C (68–86°F) is key to getting a consistent oxide layer. This is usually done with heat exchangers that cool and stir the bath. Controlling the temperature well helps spread the current evenly and stops any hot spots from forming.

Process Duration: How long you anodize depends on how thick you want the oxide layer to be. Usually, it can take anywhere from 30 minutes to a few hours. The longer you leave it, the thicker and tougher the layer gets, which helps with corrosion resistance and wear. For most regular anodizing jobs, 20 to 60 minutes is enough, but if you’re going for hard anodizing with a thicker coating, it might take over two hours.

Agitation: Gently stirring the bath helps keep the current and temperature even throughout, which stops any hot spots and makes sure the oxide layer forms consistently. You can do this by using mechanical stirring or blowing air through the bath. The agitation needs to be just right—enough to keep things uniform and wash away used solution from tight spots, but not so strong that it knocks the parts off their racks.

3. Coloring (Optional)

After anodizing, aluminum parts can be dyed to improve how they look and add some extra practical benefits.

Dye Selection: Picking the right dye is important and depends on what color you want, how the part will be used outside, and how tough it needs to be. Generally, anodizing dyes fall into a few main categories:

- Organic Dyes: These dyes come in lots of bright colors like red, blue, green, and purple. They dissolve in water and are usually used in low concentrations, from about 0.025% to 1.0%. The downside is they don’t resist UV light very well, so the color can fade if left in the sun too long. Because of this, they’re best for indoor use or decorative items where having vibrant color is the main goal.

- Inorganic Dyes: These dyes are tougher and hold up better against UV light and harsh environments. You’ll often see colors like black, bronze, and gold. They’re a great choice when you need long-lasting color that can handle rough conditions.

Dyeing Process: The anodized part is dipped into a dye bath that’s usually kept between 40 and 60°C (104–140°F) for about 10 to 30 minutes. Because the anodized layer is porous, the dye soaks in and colors the metal.

Rinsing: After dyeing, the anodized part is rinsed with deionized water to wash away any extra dye and avoid stains. Good rinsing is important to make sure the color stays even and no leftover dye interferes with the next sealing step.

4. Sealing

Sealing is the last step in the anodizing process, and it’s key to making the aluminum more resistant to corrosion, locking in any dye, and improving overall durability. There are a few different ways to seal, each with its pros and cons to keep in mind.

Hot Water Sealing: This is one of the oldest and most common sealing methods. The anodized parts are placed in boiling deionized water—usually between 85 and 100°C (185–212°F)—for about 15 to 30 minutes. The heat causes a reaction that turns the oxide layer into a hydrated form called boehmite, which swells and seals up the pores. It’s a reliable way to boost corrosion resistance and help the dye stay put.

Nickel Acetate Sealing: In this method, anodized aluminum parts are soaked in a hot solution that contains nickel acetate—usually heated to around 85 to 95°C (185–203°F) for about 30 minutes. During this time, nickel ions turn into nickel hydroxide, which fills and seals the pores in the anodized layer. This creates a strong seal that offers excellent corrosion resistance, making it a great choice for parts that need to hold up under tough conditions. The solution usually has 1.4 to 1.8 grams of nickel acetate per liter and stays in a pH range of 5.5 to 6.0.

Cold Sealing: Cold sealing is a more energy-efficient option because it’s done at room temperature. The anodized parts are dipped in a solution that contains metal salts like nickel acetate or cobalt acetate. These metal ions turn into hydroxides that settle into and seal the pores. It’s a faster and more cost-effective method than hot water sealing, though it might not provide quite as much corrosion resistance. It’s a good fit for projects where saving energy and cutting costs matter most.

Rinsing and Drying: Once sealing is done, the anodized parts need a good rinse with deionized water to wash off any leftover sealing solution. After that, they should be left to air dry in a clean area to avoid contamination and keep the sealed surface in top shape.

5. Inspection and Quality Control

Making sure anodized aluminum parts meet high standards is key to how well they perform and how long they last. That’s why we use several inspection and quality control methods to check that the anodizing process worked the way it should.

Visual Inspection: The first step is a careful look at the parts to check for even color, a smooth surface, and to make sure there are no visible flaws like streaks, spots, or discoloration.

Thickness Measurement: We use a coating thickness gauge to check how thick the anodized layer is, usually between 10 and 25 microns for standard anodizing. This helps make sure the layer is thick enough to provide the right corrosion resistance and durability.

Adhesion Testing: We check how well the anodized layer sticks to the aluminum by doing tests like tape pulls and scratches. These tests show if the coating can handle stress without peeling or coming off.

Benefits of Anodizing Aluminum

Enhanced Durability

Anodizing makes aluminum much harder on the surface, so it stands up better to scratches, wear, and general wear-and-tear. Since the anodized layer is part of the aluminum itself, it sticks well and won’t peel or flake off. This makes anodized aluminum perfect for tough uses like car parts, building materials, and outdoor gear.

Corrosion Resistance

Anodizing forms a thick, protective oxide layer on aluminum that acts like a shield against moisture, salt, and chemicals. This extra corrosion resistance is especially useful for parts used in marine settings, aerospace, and other industries where they face tough, corrosive conditions.

Aesthetic Flexibility

Anodizing creates a porous oxide layer on aluminum that can be dyed in lots of different colors. You can get bright shades like red, blue, gold, and black, or softer colors like bronze and gray. Because the color is part of the oxide layer itself, it won’t peel or fade over time. This makes anodized aluminum great for products where both looks and performance matter, like electronics, buildings, and car parts.

Improved Adhesion

The porous surface of anodized aluminum increases its area, making it easier for paints, primers, and adhesives to stick well. This stronger bonding is especially helpful for parts that need durable coatings, like in aerospace, cars, and electronics. Because the anodized layer bonds so well, it finishes last longer, and peeling or flaking is less likely.

Environmental Considerations

Anodizing is greener than many other metal finishing methods because it doesn’t use harmful chemicals like chromium or nickel, and the waste it creates can often be recycled. It also uses less energy than options like painting or powder coating. Plus, anodized aluminum can be recycled over and over without losing its quality, making it a great choice for sustainability.

Types of Anodizing Aluminum

Type I – Chromic Acid Anodizing

Known as Type I under the MIL-A-8625 standard, this specialized anodizing method uses chromic acid (CrO₃) as the electrolyte. It’s especially valued in industries where it’s important to keep dimensional changes to a minimum while still achieving excellent corrosion resistance.

Coating Thickness: The oxide layer usually ranges from 0.00005″ to 0.0002″ (1.27 to 5.08 microns), making it quite thin.

Corrosion Resistance: It provides excellent protection against corrosion, especially in places where parts are exposed to chemicals and moisture.

Dimensional Stability: Because the oxide layer is thin, it barely changes the size of the part, which is perfect for applications that need tight tolerances.

Adhesion Properties: This layer creates a good surface for primers and paints to stick to, improving how well later coatings bond.

Electrical Insulation: The anodized layer doesn’t conduct electricity, so it also acts as an electrical insulator.

Type II – Sulfuric Acid Anodizing

This is the most common anodizing process for aluminum and is known as Type II under the MIL-A-8625 standard. It uses sulfuric acid as the electrolyte to create a protective oxide layer on aluminum surfaces. This layer boosts durability, corrosion resistance and offers plenty of options for color and finish.

Coating Thickness: The oxide layer usually ranges from 0.0002 to 0.0012 inches (5.1 to 30.5 microns). About two-thirds of the coating penetrates into the metal, while the other third grows outward.

Corrosion Resistance: This layer offers strong protection against environmental damage, helping aluminum parts last longer.

Wear Resistance: The thicker oxide increases surface hardness, making the aluminum more resistant to scratches and wear.

Dyeability: Because the oxide layer is porous, it soaks up dyes easily, allowing for a wide variety of color options.

Electrical Insulation: Like other anodized layers, it doesn’t conduct electricity, so it also works as an electrical insulator.

Type III – Hard Anodizing

Also called Hardcoat Anodizing, this specialized process uses sulfuric acid but runs at high current density and low temperatures to create a thick, dense, and very hard aluminum oxide coating. It greatly improves wear and corrosion resistance, making it perfect for parts that face extreme conditions.

Coating Thickness: The oxide layer typically ranges from 0.0005 to 0.003 inches (12.7 to 76.2 microns), with some processes reaching as thick as 0.0045 inches (114.3 microns).

Hardness: This coating reaches a surface hardness of about 60 to 70 on the Rockwell C scale, similar to hardened tool steels.

Corrosion Resistance: It offers outstanding protection against the environment, with salt spray resistance that can exceed 1,000 hours in ASTM B117 tests.

Electrical Insulation: The anodized layer doesn’t conduct electricity and has a high dielectric strength of up to 2,000 VDC.

Thermal Insulation: It also helps with heat dissipation, which is useful in high-temperature applications.

Type IC – Boric-Sulfuric Acid Anodizing

This process usually creates a clear, transparent oxide layer that can be treated further for color. However, because it’s naturally transparent, it doesn’t offer as wide a range of colors as some other anodizing methods.

Thin oxide layer: The layer is very thin, about 0.0001 inches (2.5 microns), which means it causes almost no change in the part’s dimensions.

Corrosion resistance: Despite its thinness, it still provides good protection against environmental damage.

Paint adhesion: It also offers excellent bonding, making it a great base for paint or other coatings.

Phosphoric Acid Anodizing

This process uses phosphoric acid as the electrolyte to treat aluminum surfaces and is especially good for preparing aluminum for adhesive bonding. It’s commonly used in aerospace and defense industries where strong bonds are essential.

Surface Structure: The anodizing creates a porous oxide layer that increases surface area and provides spots for adhesives to grip onto. The oxide layer is usually thin and non-porous, making it perfect for bonding.

Environmental Considerations: PAA is seen as a greener alternative to chromic acid anodizing because it doesn’t use hexavalent chromium, which is harmful to the environment.

Anodizing vs. Other Metal Finishing Methods

When choosing a metal finishing method, it’s important to think about things like how well it works with your material, the properties you want to achieve, the environmental impact, and the cost. Here’s a quick comparison of anodizing with other common metal finishing techniques:

| Feature | Anodizing | Electroplating (e.g., Chrome, Nickel) | Powder Coating | Paint |

| Process | Electrolytic oxidation of the metal surface | Electrochemical deposition of a metal layer | Electrostatic application of dry powder, then curing | Application of liquid pigment via spray or brush |

| Coating Thickness | Thin (microns) | Thin to moderate | Thicker, uniform | Thin to moderate |

| Corrosion Resistance | High (especially for aluminum) | High (depends on plating type) | Very high (impact & wear resistant) | Moderate (depends on paint type) |

| Wear Resistance | Moderate to high | Very high (especially with hard chrome) | Very high (abrasion-resistant) | Low to moderate |

| Electrical Conductivity | Non-conductive | Can enhance conductivity (e.g., gold plating) | Non-conductive | Non-conductive |

| Aesthetic Options | Limited color range (earth tones) | Bright, metallic finishes (chrome, gold, etc.) | Wide variety of colors and textures | Wide variety of colors and finishes |

| Environmental Impact | Low (minimal VOCs, recyclable by-products) | High (use of toxic chemicals like hexavalent chromium) | Low (no solvents, recyclable powder) | Moderate (solvent-based paints emit VOCs) |

| Cost | Moderate to high | Moderate to high | Moderate | Low to moderate |

| Best For | Aerospace, automotive, architectural | Decorative items, electrical components, and tooling | Outdoor equipment, industrial machinery, furniture | Consumer goods, appliances, and construction |

Recommendations

- Choose Anodizing: This is the best option when working with aluminum or magnesium alloys, especially if you need strong corrosion resistance and want to keep dimensional changes to a minimum.

- Opt for Electroplating: Pick this if you need a shiny metallic finish with high hardness and good electrical conductivity, but be aware of environmental regulations around plating processes.

- Select Powder Coating: Go for powder coating when you want a tough, impact-resistant finish that comes in lots of color choices, ideal for outdoor or industrial use.

- Consider Paint: Paint is a cost-effective choice if you want a wide variety of colors and the parts won’t be exposed to harsh conditions.

Common Applications

Anodizing boosts aluminum’s natural qualities, making it a great fit for many industries. Here are some of the most common uses:

Aerospace & Defense

Anodized aluminum is widely used in aerospace and defense because it’s lightweight, corrosion-resistant, and very durable. The anodizing process thickens the aluminum oxide layer, offering extra protection against harsh environmental conditions. Some key applications include:

Aircraft Components: Parts like landing gear, fuselage panels, and engine components benefit from anodizing, which helps resist wear and extends their lifespan.

Spacecraft Thermal Control: Black anodizing is used to control heat by adjusting how surfaces absorb and emit energy, which helps manage temperature inside spacecraft.

Military Equipment: From vehicle armor to weapon parts, anodized aluminum provides the durability and corrosion resistance needed in tough military environments.

Architecture

Anodized aluminum is a popular choice in architecture thanks to its great looks and long-lasting durability. The anodizing process offers a range of finishes and colors, helping buildings stand out visually. Some common uses include:

Building Facades: Aluminum panels with anodized finishes are used for exterior cladding, giving buildings a sleek, modern look while protecting against weather and wear.

Window Frames and Doors: Because anodizing improves corrosion resistance, it’s perfect for frames that face constant exposure to the elements.

Interior Fixtures: Items like handrails, elevator panels, and decorative trims benefit from anodized aluminum’s blend of style and toughness.

Consumer Electronics

Anodized aluminum is widely used in consumer electronics because it combines strength, light weight, and a stylish look. The anodized finish is tough enough to handle everyday wear and tear. Some typical applications include:

Smartphones and Tablets: The anodized aluminum cases give these devices a premium feel and protect them from scratches.

Laptops and Audio Equipment: Products like laptops, headphones, and speakers use anodized aluminum for its durability and sleek design.

Wearable Devices: Smartwatches and fitness trackers benefit from the lightweight and corrosion-resistant qualities of anodized aluminum.

Automotive & Marine

Anodized aluminum is popular in the automotive and marine industries because it offers a great strength-to-weight ratio and resists corrosion well. Here’s how it’s used:

Automotive Parts: Wheels, trim, and engine components are often anodized to cut weight while boosting durability.

Marine Hardware: Parts like boat hulls, cleats, and deck fittings get anodized to withstand the harsh saltwater environment and last longer.

Off-Road Vehicles: Components exposed to tough conditions rely on anodized aluminum for strength and protection against environmental wear.

Medical Devices

Anodized aluminum is important in the medical field because it’s biocompatible, durable, and easy to sterilize. Some common uses include:

Surgical Instruments: Tools like forceps and scalpels use anodized aluminum for a surface that’s non-reactive and helps reduce contamination risks.

Medical Equipment Enclosures: Devices such as MRI machines and diagnostic equipment feature anodized aluminum for strength and protection against environmental damage.

Implants and Prosthetics: Anodized aluminum is chosen for dental implants and joint replacements because it’s lightweight and resistant to corrosion.

Conclusion

To wrap things up, anodizing doesn’t just improve the performance and durability of metal parts—it also meets today’s needs for sustainability and cost-effectiveness. Its versatility across so many industries, from aerospace to consumer electronics, shows just how important it is for pushing technology and design forward.

If you want your aluminum parts to perform better and look great too, anodizing is a trusted, effective choice!

Why Choose Us

At NOBLE, we focus on providing top-notch CNC machining and surface finishing services for a variety of industries like aerospace, automotive, electronics, and consumer goods. We’re dedicated to precision, durability, and outstanding aesthetics, making sure every part we produce meets the highest standards for both performance and appearance.

From Prototyping to Manufacturing

NOBLE is your go-to partner for custom manufacturing, covering everything from prototype design all the way through to full-scale production. With our extensive manufacturing resources, the right technology, streamlined processes, expert guidance, and thorough quality inspections, we’re ready to help turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote: Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

At NOBLE, we’re excited to work with you on your next project. Whether you have questions about our CNC machining and surface finishing services, need a custom quote, or want to talk through your specific needs, we’re here to help.

Contact Us – Let’s Bring Your Ideas to Life!