Imagine you need a very small metal part for a medical tool or a special connector for an airplane. Swiss machining helps make these parts with great accuracy and detail. Swiss machining utilizes specialized equipment, enabling the production of precision parts as small as 0.5 millimeters. It is widely recognized that precision is critical in the medical, aerospace, automotive, and electronics industries. NOBLE is a top CNC machining company in China. They offer great service and skill for both sample parts and big orders.

| Industry | Common Swiss Machining Applications |

| Medical Devices | Implants, bone screws, and surgical instruments |

| Aerospace | Engine parts, hydraulic manifolds, and communication equipment |

| Automotive | Injector pins, transmission parts, engine parts |

| Electronics | Connectors, pins, intricate parts |

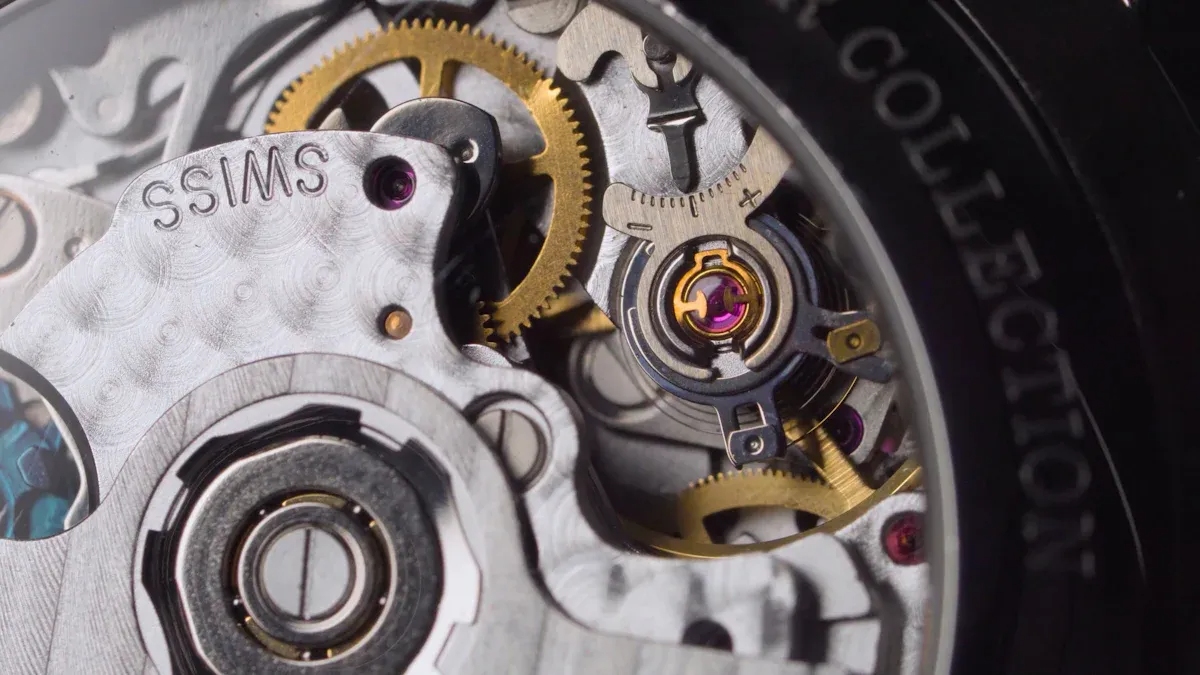

| Watchmaking | Gears, pins, complex watch parts |

Swiss Machining Overview

Origins of Swiss Machining

Have you ever wondered where Swiss machining began? It started more than 140 years ago in the Moutier area of Switzerland. The local watchmaking industry required extremely precise micro-parts, leading to the establishment of numerous factories in 1849. They built factories like La Société Industrielle in 1849. By the way, the industrial company La Société Industrielle was among them. These factories gave many people jobs. The contributions of inventor Jakob Schweizer were particularly significant—he created the first fully automatic Swiss-type lathe, enabling the efficient and precise production of micro-parts.

Here’s a simple timeline of how Swiss machining changed:

- The first big watch factory opened in 1849.

- Jakob Schweizer made the automatic Swiss-type lathe.

- Tornos made the M7 machine in 1930, which helped make more parts at once.

- Nicolas Junker started Junker & Cie in 1883 and helped improve automatic lathes.

- Junker made the first automatic lathe in 1891.

- When Junker’s company closed in 1905, André Bechler started Tornos.

- Tornos and Bechler joined together in 1981 and became leaders in Swiss machining.

- In the 1990s, CNC technology and thread whirling brought new changes.

Today, Swiss machining is used for more than just watches. It is used for medical tools, airplane parts, and electronics. NOBLE, a top factory in China, uses these machines to help with both small and large orders.

Definition of Swiss Machining

Swiss machining is a special way to make tiny, detailed parts. It uses a sliding headstock and a guide bushing to keep the material steady. This lets you cut, drill, and shape metal or plastic very accurately. At first, these machines were run by hand or with cams. Now, computers control them for even better results.

Here’s a table that shows how things have changed:

| Original Swiss Machining | Current Swiss CNC Machining |

| Manual operation or cam systems | Computerized control systems |

| Limited precision and complexity | High precision and complex shapes |

| Needed skilled operators | Less reliance on operator skills |

Swiss machining is special because it can make parts as small as 0.5 mm. It can also keep tolerances as tight as ±0.001 mm. NOBLE’s Swiss CNC machining service lets you use this advanced technology. You can get aluminum parts machining, metal parts machining, or precision parts machining for your projects.

Purpose of Swiss Machining

Why do people use Swiss machining? The main reason is to make parts that are very exact and smooth. This process is great for industries where accuracy is very important, like medical, aerospace, and electronics. You get parts that fit just right, even if you need thousands.

Swiss machining helps you:

- Make shapes that regular machines cannot make.

- Create high-quality machined parts quickly and easily.

- Meet strict rules for safety and performance, especially for medical devices like pacemakers and surgical tools.

NOBLE’s factory in China is good at CNC parts machining and low-volume machining. You can trust them for both small samples and big orders. They always give you reliable, high-quality parts for your needs.

Tip: If you want parts that look great and do not waste material, Swiss machining is a smart choice. NOBLE’s team can help you get the best results for any project.

How Swiss Machining Works?

Swiss Machining Process Steps

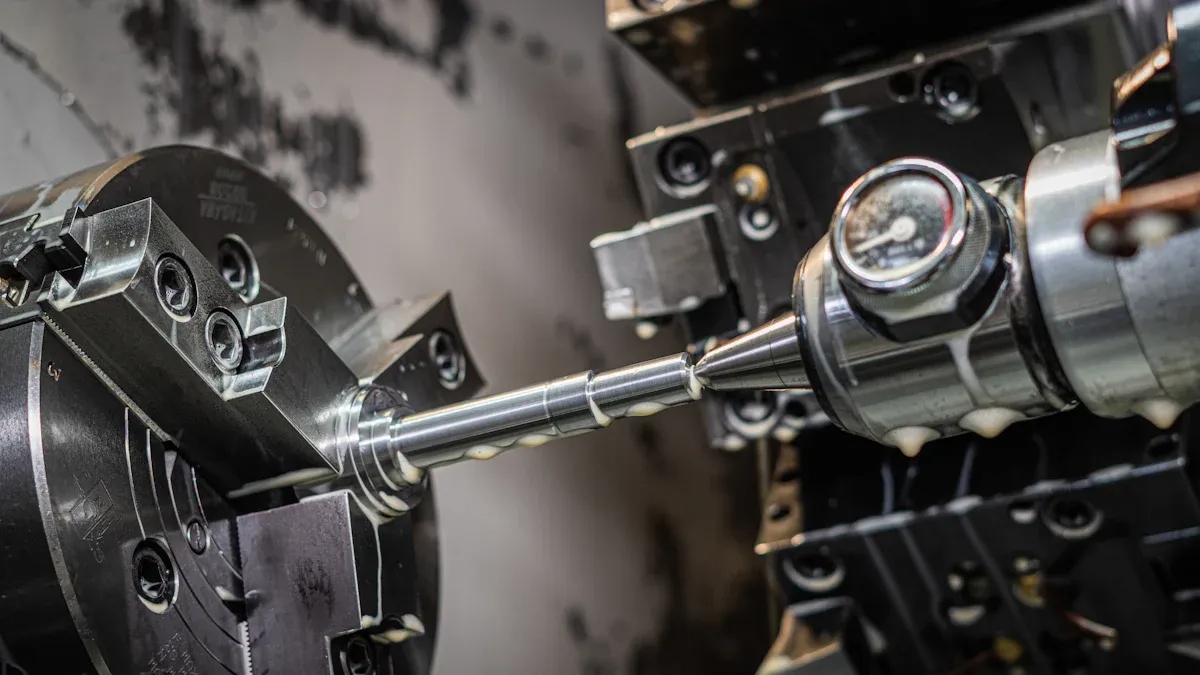

I was always fascinated by how a small metal rod becomes a finished part for a medical device or airplane. Swiss machining uses clear steps to make this happen. Here’s how you go from raw material to a perfectly machined part:

- Design: First, you make your part using CAD software. This digital plan shows every detail.

- Programming: Next, you write a program for the CNC machine. The program tells the machine how to move and cut.

- Set-Up: You get the machine ready by picking the right tools and loading the material. NOBLE’s skilled team makes sure everything is set for your project.

- Machining: The machine shapes the material by cutting, drilling, and threading. You get exact results, even for tricky shapes.

- Finishing: After machining, you smooth rough edges and remove tiny burrs. This step makes your part look and feel clean.

- Inspection: Last, you check the finished part to make sure it meets all the rules and tight tolerances.

NOBLE’s factory in China helps with projects from samples to big orders. You can count on their skill for CNC parts machining, small batch machining, and low-volume machining.

Design of Swiss Machining Machines

Swiss machining uses a special CNC lathe. Its design is not like regular machines. Let’s look at the two main features:

Guide Bushing

The guide bushing sits close to the cutting tool. It holds the material steady while the machine works. This support stops the part from bending or shaking. You get better accuracy, especially for long, thin parts. NOBLE’s machines use this feature for top-quality metal parts machining and aluminum parts machining.

Sliding Headstock

The sliding headstock is another special part of Swiss machining. It pushes the bar stock through the guide bushing. The material moves while the cutting tool stays still. This setup lets you make parts with great precision. You can create very small and detailed parts. NOBLE’s precision parts machining service uses this design to make parts as tiny as 0.5 mm.

Here’s a quick comparison between Swiss-type and regular CNC lathes:

- Swiss-type lathes hold the workpiece close to the cutting tool for better stability.

- Regular CNC lathes use a fixed spindle and spin the workpiece.

- Swiss-type lathes have a sliding headstock and guide bushing for higher accuracy.

- Regular CNC lathes have a fixed headstock and a moving cutting tool.

Precision Capabilities

Swiss machining is known for its amazing precision. You can reach tolerances as tight as ±0.0001 inches. That’s much better than most regular CNC machines, which usually reach ±0.001 inches. This level of accuracy is important in aerospace and medical devices. Even a tiny mistake can cause problems.

You also get help from simultaneous operations. Swiss machining lets many tools cut at the same time. You save time and lower costs. NOBLE’s advanced machines can turn, mill, drill, and thread all at once. You get faster results and great quality.

| Feature | Benefit |

| Multiple tools cutting | Cuts down production time |

| Chip-to-chip time < 1 second | Reduces downtime during tool changes |

| Elimination of secondary ops | Makes workflow smoother and saves resources |

Tip: If you want high-quality machined parts for your projects, Swiss machining is a smart choice. NOBLE’s factory in China gives expert help for precision parts machining, metal parts machining, and aluminum parts machining. You get reliable results every time.

What Are the Features of Swiss Machining?

Continuous Support

Swiss machining keeps the workpiece steady all the time. The machine uses a guide bushing near the cutting tool. This helps stop the part from shaking or bending. You get parts that are very exact. This is important for medical devices and airplane parts.

- Swiss machining holds the workpiece while it turns. This stops extra shaking and helps make parts accurate.

- It makes parts with very tight tolerances. This is needed for products that must be exact.

Miles Free from the Precision Machined Products Association says, “the guide bushing in a Swiss-type machine ‘gives strong support right at the cut, making things stable and easy to predict.’ This means the size is always right and the material stays strong. That is very important for special parts.”

The machine keeps the loose part short. This lets you make long, thin parts without losing accuracy or smoothness. NOBLE’s factory in China uses this to make precision parts machining, aluminum parts machining, and metal parts machining for medical, electronics, and car projects.

Multi-Axis Operations

Swiss machining is special because it moves in many ways at once. The machine has many axes. You can cut, drill, and shape from different sides. You do not need to stop and change things. This saves time and helps you make hard shapes in one try.

You can make parts as small as 0.5 mm. Tolerances can be as tight as ±0.001 mm. NOBLE’s CNC parts machining uses these machines for small batch machining and low volume machining. You get great parts even if your design is hard or detailed.

Here’s a simple table to show how multi-axis operations help:

| Feature | Benefit |

| Simultaneous cutting | Faster production |

| Multiple tools | Complex shapes in one setup |

| Less handling | Better accuracy |

Automation

Swiss machining uses automation to handle big orders. These machines use bar feeders, robots, and sorting systems. You can run them for hours without stopping. This means you get more parts faster and with fewer mistakes.

Automation helps NOBLE’s factory in China make lots of parts and test new ideas. You get the same quality every time and safer work. The machines work fast, so you finish projects on time.

Swiss machining uses steady support, multi-axis moves, and automation to give you stable, exact, and quick results. NOBLE’s skill in precision parts machining makes them a great choice for anyone who needs high-quality machined parts.

Swiss Machining vs. Conventional CNC Machining

Introduction to Traditional CNC Machining

Maybe you have seen a CNC machine in a video or at a factory. Traditional CNC machining uses computers to control tools that shape metal or plastic. The machine holds the material in a chuck or collet and spins it. Cutting tools shape the spinning material into the part you want. You can make many kinds of parts, like car engine pieces or electronic connectors. Most factories use these machines for bigger, simpler parts. NOBLE is a top machining company in China. They use traditional CNC machines for small batch machining and low volume machining. This is helpful when you need to do different jobs.

Traditional CNC machining works well for many industries. You get good accuracy and can use materials like aluminum and steel. This process is great for aluminum parts machining and metal parts machining. If you want a part fast and do not need super tight tolerances, this method is a good choice.

Design Differences

When you look at Swiss machining and traditional CNC machining, you see big differences. Swiss machining uses a guide bushing close to the cutting tool. This keeps the workpiece steady and stops it from shaking. Traditional CNC machines hold the material in a chuck or collet. This works well for short, thick parts. But it can cause problems with long, thin pieces.

Here’s a table to help you see the main design differences:

| Aspect | Swiss Machining (Swiss Type CNC Lathe) | Traditional CNC Turning (CNC Turning Machine) |

| Workpiece Support | Guide bushing near the cutting tool | Workpiece held in a chuck or a collet |

| Best for | Small-diameter, long, complex parts | Larger, shorter, less complex parts |

| Precision | Ultra-high accuracy (tight tolerances) | High accuracy, but less ideal for micro parts |

| Vibration Control | Minimal due to the guide bushing | Higher risk with long, slender parts |

| Industries | Medical, aerospace, electronics | Automotive, industrial, general machining |

| Cost | Higher machine investment is efficient for mass production | Lower machine cost, flexible for varied jobs |

Swiss machining is best when you need precision parts machining for tiny, detailed parts. NOBLE’s factory in China uses both types of machines. This means you get the best choice for your project. If you need CNC parts machining for long, thin, or tricky shapes, Swiss machining is the best way.

Tip: If your project needs parts with tight tolerances and smooth finishes, ask NOBLE about their Swiss machining. You will get stable, accurate results every time.

Accuracy

Accuracy is very important for parts used in medical devices, airplanes, or electronics. Swiss machining keeps tolerances as tight as ±0.0003 inches. This means your parts fit perfectly, even if they are very small. Traditional CNC machining is accurate, but it usually cannot match Swiss machining for tiny parts.

Check out this table to see how the two methods compare:

| Feature | Swiss CNC Machining | Conventional CNC Machining |

| Accuracy | Maintains tight tolerances (±0.0003 in) | Varies, generally less precise |

| Complexity Handling | Excels at intricate features | Limited in handling complexity |

| Scrap Rates | Lower due to the single-setup process | Higher due to multiple setups |

| Cycle Times | Faster with simultaneous operations | Slower, sequential operations |

| Setup Time | Reduced with all features in one pass | Longer due to multiple setups |

| Repeatability | High consistency | Varies, generally less consistent |

Swiss machining lets you make complex shapes in one setup. You save time and reduce waste. NOBLE’s skill in precision parts machining means you get high-quality results for every order, whether you need a few samples or thousands of parts.

Note: If you want to avoid mistakes and get the same quality every time, Swiss machining is your best choice. NOBLE’s team can help you with projects for the medical, aerospace, and electronics industries.

Complexity

When you compare Swiss machining and regular CNC machining, you see a big difference in making hard parts. Both can make simple shapes and basic pieces. But Swiss machining is better for detailed work. It is great for tiny grooves, thin shafts, and parts with many features.

Swiss machining is good at making complex parts for many reasons:

- You can make parts with very small details. These can be tiny holes, threads, or slots that must be in the right spot.

- It works well for long, thin pieces. These are parts like pins or shafts with a high length-to-diameter ratio. Regular CNC machines can have trouble with these because the parts might bend or shake. Swiss machining keeps them steady, so you get perfect parts.

- You can make parts with tricky shapes. This means parts that twist, curve, or have lots of small features. Medical, aerospace, and optics companies need these kinds of parts.

Here’s a table to show the difference:

| Feature | Swiss Machining | Conventional CNC Machining |

| Intricate details | Excellent | Limited |

| Long, thin parts | Handles easily | Often struggles |

| Complex shapes | High capability | Moderate capability |

| Consistency for small parts | Very high | Varies |

This matters for your projects because some industries need small and complicated parts. Swiss machining helps you get these parts fast and with great accuracy. You do not have to worry about parts bending or changing shape. This is important for CNC parts machining, where every detail is important.

NOBLE is a top factory in China. They use Swiss machining for small batch machining and low volume machining. Their team can do aluminum parts machining, metal parts machining, and precision parts machining for hard designs. If you need a few samples or thousands of parts, NOBLE’s skill makes sure you get the best results.

Tip: If your part has lots of tiny features or needs to be long and thin, ask NOBLE about Swiss machining. You will save time, use less material, and get parts that fit your needs.

Materials Used in Swiss Machining

When you make small, detailed parts, the material is important. Swiss machining works with many materials, such as metals and plastics. You can choose what fits your project best. Some materials are strong, some are light, and some are easy to shape.

NOBLE is a top machining company in China. They can use many materials for CNC parts machining. You get good results for small batches and big orders. Their factory uses advanced machines. Every part meets your standards, no matter the material.

Here’s a table showing common materials for Swiss machining. It lists how easy they are to machine and what they are used for:

| Material | Machinability Rating | Best For |

| Inconel (Nickel Alloy) | 10–15% | Jet engines, nuclear reactors, extreme environments |

| Free-Cutting Brass (C36000) | 100% | Precision parts, fittings, and electrical parts |

| Aluminum (6061-T6) | 90–95% | Aerospace, automotive, electronics, and custom parts |

| Mild Steel (AISI 1018) | 70% | Structural parts, machinery parts, gears |

| Stainless Steel (304) | 30–40% | Medical tools, food machining equipment, and marine applications |

| Titanium (Grade 5, Ti-6Al-4V) | 20–25% | Aerospace, medical implants, high-performance parts |

| Polyethylene (HDPE) | 90% | Food containers, mechanical parts, and lightweight parts |

| PVC (Polyvinyl Chloride) | Moderate | Plumbing parts, chemical-resistant parts, and medical applications |

Swiss machining is great for these materials because of its design. The guide bushing holds the material steady. You can cut close to the collet. This means you waste less material. You can use up to 95% of your raw material. Regular machining might only use 60-70%. That saves money and helps the environment.

Here’s how Swiss machining helps you waste less and get better parts:

- The guide bushing allows you to cut closer to the end, resulting in shorter leftover pieces.

- You get more parts from each bar, which saves money.

- Chips are removed quickly, so scrap stays low.

- You get smooth surfaces that often need no extra work.

NOBLE’s team helps you pick the right material for your project. You can get aluminum parts machining, metal parts machining, or precision parts machining. You get great finishes and tight tolerances, even for hard designs. If you need low-volume machining or want to make lots of parts, NOBLE makes it easy and saves you money.

Tip: If you want to save material, spend less, and get nice machined parts, Swiss machining is a smart choice. NOBLE’s factory in China helps with all project sizes and gets you the best results every time.

Wide Applications of Swiss Machining

Medical

Swiss machining is used a lot in the medical field. Doctors need implants and tools that must fit just right. This process makes sure every part is perfect. You get things like hip and knee implants, forceps, clamps, and tiny stents or catheters. These parts must follow strict rules. Even a small mistake can cause big problems. That’s why medical companies utilize CNC part machining for these tasks.

Here are some medical parts made with Swiss machining:

- Implants for hips, knees, and spines

- Surgical tools like forceps, handles, and clamps

- Parts for electronic equipment, such as buttons, housings, and switches

- Tiny products like catheters, stents, and tubes

Every part needs to be smooth and safe. NOBLE’s factory in China helps with both small and large orders. Their team is skilled at precision parts machining for medical devices. You can trust them for good quality and quick delivery, whether you need a few or many parts.

Tip: If you want medical parts that meet high standards, NOBLE’s skill in low-volume machining and mass production makes your project simple.

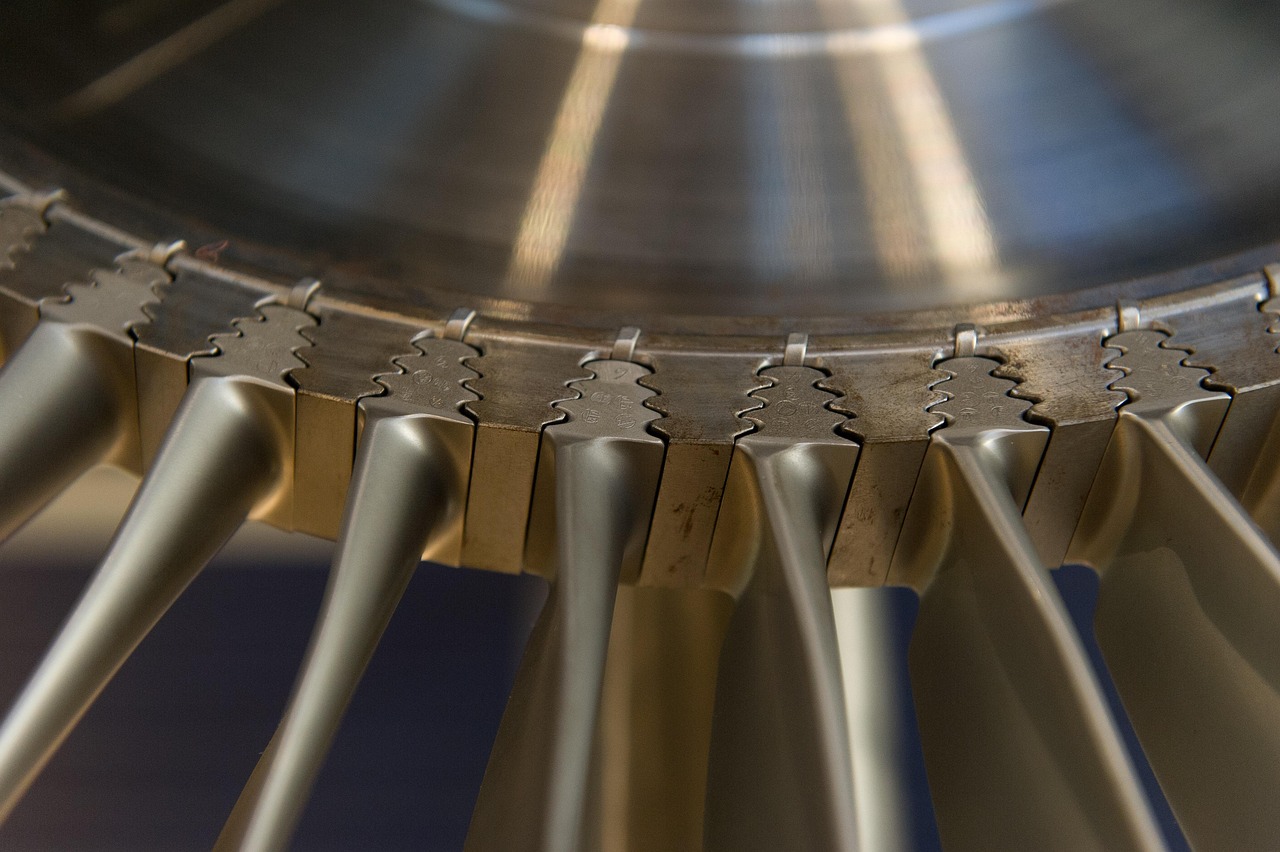

Aerospace

Aerospace engineers use Swiss machining for important parts. These parts must work well under tough conditions. You need turbine blades, engine manifolds, and fuel system parts that fit together perfectly. Swiss machining works with hard materials like titanium and aluminum, which are used in planes. The process makes shapes and surfaces that regular machines cannot do.

You get many good things:

- Tight tolerances for important parts

- Can use aluminum, titanium, and special alloys

- Fast testing and quick mass production

- Fewer mistakes because of automation

NOBLE’s factory in China has worked on aerospace projects for both small orders and big orders. Their aluminum parts machining and metal parts machining help you meet strict rules. You save time and get good results for every order.

Electronics

Think about your phone or computer. Inside, some tiny connectors and pins must work well. Swiss machining helps make these small, detailed parts with great accuracy. You can make connectors, micro-pins, and other tiny parts that keep your devices working.

Here’s why electronics companies pick this process:

- Makes small, exact parts for tiny devices

- Handles tricky shapes and tight spaces

- Combines many steps in one setup for faster work

- Makes sure every part passes strict checks

NOBLE’s precision parts machining helps electronics companies stay ahead. Their team works on both small and big projects. You always get high-quality machined parts.

Note: If you need tiny, strong parts for electronics, NOBLE’s CNC parts machining and small batch machining services help you win in a fast market.

Automotive

Many car parts are made with Swiss machining. This process helps each piece fit well and work right. When you drive, you want your car to be safe. Car makers use this method for important parts.

Some car parts made with Swiss machining are:

- Carburetors

- Brackets

- Engine parts

Car companies pick this process for many reasons:

- Precision and Accuracy: You get parts with very tight tolerances, sometimes as close as ±0.0001 inches. Every piece fits well, which is important for engines and safety.

- Complex Geometries: The machines make hard shapes in one step. You do not need extra steps, so you save time.

- High Production Efficiency: You can make many parts fast. There is less waste, so you use materials wisely.

- Improved Surface Finish: The parts come out smooth. You do not need to polish or finish them further.

- Material Versatility: You can use many metals and plastics. This helps when you need strong or light parts.

NOBLE’s factory in China helps with small batches and big orders. Their team uses CNC parts machining to meet strict rules. If you need aluminum parts machining or metal parts machining, NOBLE gives you high-quality machined parts. You can trust their precision parts machining for new designs and big runs.

Tip: If you want car parts that last and work well, Swiss machining is a smart choice. NOBLE’s skill helps you get great results for any car project.

Other Industries

Swiss machining is not just for cars, planes, or medical tools. Many other industries use this process for tiny, detailed parts. As products get harder to make, companies need better machines. You see this in factories everywhere.

Here are some industries and what they need:

| Industry | Description |

| Medical Device | Needs high precision for small, complex parts like implants and tools. |

| Aerospace | Demands tight tolerances for safety and performance in flight parts. |

| Electronics | Uses tiny, intricate parts for gadgets and computers. |

| Watchmaking | Relies on making miniature gears and pins with perfect finishes. |

You can see some new trends in these industries:

- More companies use automation to make parts faster.

- Machines do more jobs in one setup, saving time.

- Factories want better speed and higher accuracy.

- Collaborative robots help workers and make production safer.

NOBLE’s factory in China uses the newest technology. They help with low-volume machining, small batch machining, and big orders. Their CNC parts machining and precision parts machining help you meet new needs. If you need aluminum parts machining or metal parts machining, NOBLE’s team gives you great results for every project.

Note: As products get smaller and smarter, Swiss machining helps you keep up. NOBLE’s experience makes your job easier, whether you are testing a new idea or making thousands of parts.

Challenges Facing Swiss Machining

Skill Requirements

Swiss machining needs special skills. You cannot learn it in one day. Operators must know how to set up Swiss-style CNC lathes. They need to run the machines correctly. You must understand machining basics and how to design tools and fixtures. Reading technical drawings is important. You need to know how to program Swiss-type turning centers for hard parts.

Here’s what you need to do well:

- You should know how to use and set up Swiss-style CNC lathes.

- You need to understand machining basics, tool design, and fixture design.

- You must read and understand technical drawings and instructions.

- You need strong programming skills for Swiss-type turning centers.

If you work with NOBLE’s factory in China, you get help from experts. Their team knows CNC parts machining very well. They help with small batch machining, low volume machining, and precision parts machining. You can trust them to help you at every step.

Tip: Skilled operators are important for tight tolerances. NOBLE’s team has lots of experience for every project.

Investment

Starting Swiss machining costs more money at first. Swiss machining machines cost more than regular CNC machines. These machines use advanced technology and special parts. That makes them more expensive. Regular CNC lathes are cheaper for small shops. If you make lots of parts, Swiss lathes save money over time. They work fast and waste less material. Your cost per part goes down when you make many parts.

NOBLE’s factory in China uses the best Swiss CNC machines. They do aluminum parts machining, metal parts machining, and precision parts machining. Their investment means you get good results for every order. You can get prototypes or mass production.

Note: Swiss machining is smart for big orders and saves money. NOBLE’s team helps you get the most from your machines.

Part Constraints

Swiss machining is great for small, detailed parts. But it has some limits. You must use bar stock with the same diameter. The size is usually between 2mm and 38mm. Special tools can cost a lot. This can limit the shapes you make. Oil helps the process, but it does not cool as well as water. This can be hard for some materials. Setting up the machine takes time. You need to set up and program many tools.

Here’s a table showing the main limits:

| Limitation Type | Description |

| Bar Stock Constraints | Only works with bar stock sizes from 2mm to 38mm. The diameter must stay the same. |

| Tooling Costs | Special tools cost more and limit tool size and shape. |

| Heat Dissipation Dilemma | Oil does not cool as well as water. |

| Setup Complexity | Takes more time to set up and program many tools. |

Swiss lathes are made for small, detailed parts with high accuracy. If you want big or simple parts, regular CNC machines may be better. For tiny, complex parts, Swiss machining is best.

NOBLE’s factory in China does CNC parts machining for many industries. Their team helps you pick the right process. You can get small batch machining, low volume machining, or mass production.

Tip: Swiss machining is perfect for tiny, complex parts. NOBLE’s experts help you solve problems and get great results for every part.

Select NOBLE for the Finest Swiss Machining

Do you want a company that always gives you great parts? NOBLE is a top machining company in China. You get more than just parts from them. Their team helps you with your project from start to finish. If you need CNC parts machining for samples or big orders, NOBLE’s factory has the right skills and machines to help you.

When you pick NOBLE, you use their many years of experience. Their experts know how to do aluminum parts machining, metal parts machining, and hard designs. You can trust them for small batch machining and low volume machining. They make sure every part is made right, no matter how many you order.

NOBLE’s Swiss CNC Machining gives you many good things:

- You get parts with tight tolerances and smooth surfaces.

- Your parts come fast because their work is efficient.

- You save material and make less waste.

- You can pick from many materials for your project.

Let’s see how NOBLE has helped other customers:

- A customer in the luxury industry changed from using many machines to just one Swiss CNC machine. This stopped all field failures and helped them get more customers.

- Another client had problems with a vacuum chamber. NOBLE’s team made a new two-part seal. This fix cut maintenance costs by 90% and made things work better.

- Northern Precision needed a tricky part for a vending machine lock. With a Swiss CNC machine, they finished it in 15 steps in only 3 minutes. Regular machines would have taken much longer and needed more setups.

You get more than just parts from NOBLE. Their team listens to what you need and finds the best way to help. They use advanced machines and check every part for quality. You can count on fast delivery and good service, whether you need a few parts or thousands.

Tip: If you want your project to go well, contact NOBLE’s factory in China. Their skill in CNC parts machining and precision parts machining will help you get the results you want.

NOBLE is ready to help with aluminum parts machining, metal parts machining, and any custom design. You get a partner who cares about your project and always gives you quality. Pick NOBLE for your next job and see how Swiss machining can help you.

Swiss machining helps fix hard problems in making things. You can use many kinds of materials for your parts. It gives you better accuracy for small pieces. It also makes it easier to keep track of your parts. Here’s why experts think Swiss machining is important:

- You can choose from lots of materials for your ideas.

- You get very tight tolerances for tiny pieces.

- You can control how many parts you make for quick shipping.

- You spend less money on setup and tools for small jobs.

- You do not need much extra work after the parts are made.

- You can create very small and tricky parts.

NOBLE’s factory in China has skilled people to help every time. You get good parts quickly, whether you need a few or a lot.

FAQs of Swiss machining

What is Swiss machining?

Swiss machining uses special machines to make tiny parts. These machines can make detailed shapes. You get very accurate and smooth parts. NOBLE’s factory in China uses this process for CNC parts machining and precision parts machining.

Why should I choose NOBLE for my projects?

NOBLE’s team gives you expert help. They support both new ideas and big orders. Their factory in China does small batch machining and low volume machining. You also get fast delivery for your parts.

What materials can Swiss machining handle?

You can use metals like aluminum, stainless steel, and titanium. Plastics work with Swiss machining, too. NOBLE’s aluminum parts machining and metal parts machining give you many choices for your project.

How small can the parts be?

Swiss machining makes parts as tiny as 0.5 mm wide. You get tight tolerances for medical, electronics, and aerospace projects. NOBLE’s precision parts machining makes sure every detail fits your needs.

Is Swiss machining good for big orders?

Yes! Swiss machining works for small batches or thousands of parts. NOBLE’s factory in China does low-volume machining and mass production. You get the same quality every time.

What industries use Swiss machining?

Swiss machining is used in medical, aerospace, automotive, electronics, and watchmaking. NOBLE’s CNC parts machining helps many industries with hard designs and strict rules.

How does NOBLE ensure quality?

NOBLE checks every part for accuracy and smoothness. Their team uses advanced machines and strong controls. You get reliable machined parts for every project, big or small.

Can I get help with design changes?

Yes! NOBLE’s experts help you change your designs. You get support for new ideas, samples, and changes during production. Their factory in China makes your projects easy and smooth.