A brief overview of steel and cast iron as two of the most popular materials in engineering and manufacturing.

The article will compare the properties, advantages, disadvantages, and uses of each, offering guidance on choosing the right material.

Understanding Steel and Cast Iron

A Basic Understanding of Steel

Steel is an alloy of iron, with varying carbon content (typically between 0.15% and 2%) to meet different requirements. To adapt steel properties for specific applications, additional elements such as manganese, chromium, and vanadium are sometimes added. For instance, incorporating over 0.7% Mn during steelmaking yields manganese steel with enhanced strength and hardness.

Next, we will briefly introduce some properties of steel.

- Mild Steel: Mild steel contains approximately 0.05–0.30% carbon. This is soft and easy to work with. It is used in construction and structural applications, where flexibility is more important than hardness.

- Carbon Steel: This is one of the most common types of steel, with a carbon content ranging from approximately 0.05% to 2.1%. Carbon Steel is tougher but less ductile. It’s stronger and is used in high-stress environments, like bridges or machinery parts.

- Stainless Steel: This type of steel is alloyed with chromium, making it resistant to rust and corrosion. It’s used in kitchen appliances, medical tools, and chemical plants. By adding varying amounts of chromium, stainless steel can be further subdivided into numerous branches. It can also be alloyed with elements such as molybdenum, carbon, nickel, and nitrogen to enhance specific properties and withstand diverse environments.

A Basic Understanding of Cast Iron

Earlier, we mentioned that steel contains between 0.15% and 2% carbon. Have you ever wondered, “What if I add more carbon?” Someone did. And thus, cast iron was born. Cast iron contains 2% to 4% carbon, along with 1% to 3% silicon, making it relatively brittle compared to steel. This brittle material also comes in various types, with differences stemming from the specific formulations and processing methods used during smelting.

- Grey cast iron: The most commonly used type of cast iron. True to its name, its fracture surface appears gray.

- White cast iron: Sacrifices toughness for considerable hardness. Due to their high carbide content, they are termed cermets.

- Ductile cast iron: Often used in gear production. Its properties resemble those of sponge steel.

- Malleable cast iron: Made from white cast iron, it undergoes forging (annealing) and is commonly used for axles.

Mechanical Properties Comparison

It is worth noting that when comparing steel and cast iron, we find they differ in many aspects, despite their striking visual similarity. Regarding their strength, hardness, machinability, and so on… I just couldn’t resist sharing this with you.

| Steel | Cast Iron | |

| Tensile Strength | Typically ranges from 400 MPa to 2000 MPa, depending on grade and heat treatment | Generally ranges from 150 MPa to 500 MPa |

| Compressive Strength | Higher tensile strength, but lower than cast iron for compression | Typically ranges from 1500 MPa to 2500 MPa (better for compression) |

| Hardness | Varies based on heat treatment: can range from 100 HB to 700 HB | Typically ranges from 150 HB to 350 HB (higher hardness in some alloys) |

| Fatigue Resistance | High fatigue resistance, especially with alloyed or heat-treated steels | Lower fatigue resistance, more prone to cracking under repeated stress |

| Impact Toughness | Excellent, especially for high-alloy steels | Generally low—more brittle and prone to cracking under impact |

| Wear Resistance | Good, with the ability to be hardened for higher resistance | Excellent due to the graphite structure (self-lubricating effect) |

| Brittleness | Low brittleness, highly malleable, and ductile | High brittleness, less flexible, and prone to fractures |

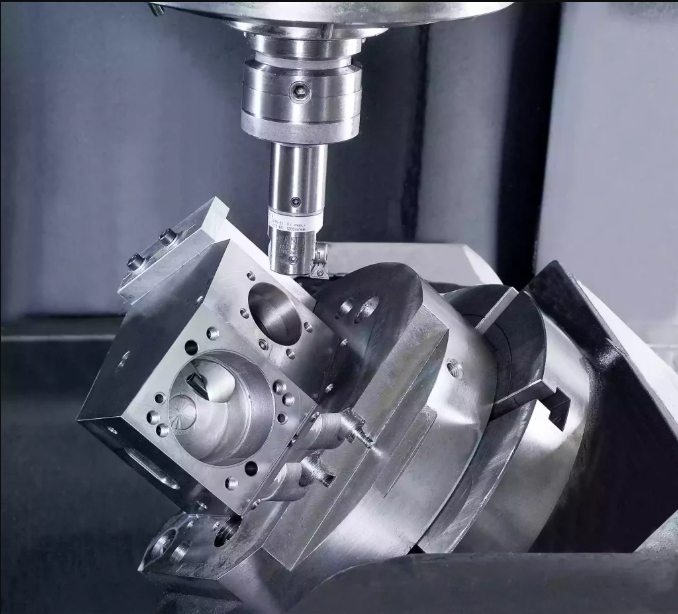

By combining specialized casting CNC machining capabilities with steel and cast iron materials, manufacturers like NOBLE can deliver tailored solutions for both prototyping and volume production needs. With our precision machining expertise, we assist clients in selecting the optimal material based on specific requirements—such as strength, durability, and machinability—to achieve peak performance.

Cost-Effectiveness and Material Availability

Material Costs: Steel vs. Cast Iron

The prices of steel and cast iron can vary significantly due to factors such as quality, grade, and market demand. Generally speaking, however, steel tends to be more expensive than cast iron, especially specialized steels like high-strength or alloy steels.

Cast iron types like gray cast iron involve simpler production processes, require fewer resources, and do not necessitate the complex special treatments needed for steel manufacturing. This makes cast iron the preferred choice for many manufacturers when mass-producing parts where tensile strength is not a primary concern, such as engine blocks, brake discs, or pipes.

Availability and Sourcing

When it comes to material availability, steel has a global presence and is produced in vast quantities worldwide—you can source it almost anywhere. The widespread availability of steel makes it a reliable choice for industries requiring stability and global coverage, such as the automotive or construction sectors.

In contrast, while cast iron is relatively inexpensive, it is typically sourced from regions with strong foundry capabilities and access to high-quality scrap iron. Furthermore, the supply chain for cast iron is influenced by specific alloys or premium formulations—such as ductile iron or white cast iron—which carry certain manufacturing barriers.

Applications of Steel and Cast Iron

When to Use Steel

If your project requires high-strength, durable, and versatile materials, steel is your best choice. Its high tensile strength and ductility are also indispensable in the industry.

| Characteristic | Details | Applications |

| Tensile Strength | Typically ranges from 400 MPa to 2000 MPa, depending on grade and heat treatment | Heavy-duty machinery, automotive frames, aerospace components, high-rise buildings, structural frameworks |

| Compressive Strength | High, but not as high as cast iron | Bridges, reinforced structures, industrial machinery, steel beams |

| Hardness | Varies based on heat treatment, typically 100 HB to 700 HB | Gears, shafts, suspension systems in automotive, turbine blades, and aircraft parts |

| Fatigue Resistance | High, especially with alloyed or heat-treated steels | Aerospace components, automotive parts, and machinery exposed to repetitive stress |

| Impact Toughness | Excellent, especially in high-alloy steels | Impact-resistant parts in automotive and aerospace (e.g., landing gear, engine components) |

| Wear Resistance | Good, enhanced through heat treatment | Automotive parts, high-performance machinery (e.g., engine blocks, valves) |

| Brittleness | Low, highly malleable and ductile | Structural supports, construction beams, aircraft wings, machinery components |

When to Use Cast Iron

The high carbon content and graphite structure endow it with unique properties, giving cast iron significant advantages in applications demanding high compressive strength, wear resistance, and ease of casting. This makes it the material of choice for certain specific uses.

| Characteristic | Details | Applications |

| Tensile Strength | Generally ranges from 150 MPa to 500 MPa | Engine blocks, brake rotors, heavy machinery bases |

| Compressive Strength | Ranges from 1500 MPa to 2500 MPa, higher than steel | Engine components under compression, piping systems, and structural foundations |

| Hardness | Typically ranges from 150 HB to 350 HB | Wear-resistant components like brake drums, piston rings, and cylinder heads |

| Wear Resistance | Excellent, especially due to the graphite flakes that reduce friction and wear | Brake components, engine blocks, heavy-duty equipment, and medical device housings |

In summary, the differences between cast iron and steel are significant. Which one to choose? That depends entirely on your project.

NOBLE’s engineers possess extensive experience in material selection. We leverage our expertise in precision manufacturing and CNC machining to assist clients across diverse industries, from automotive to medical.

Environmental Impact and Sustainability

Steel Recycling and Sustainability

Steel is currently one of the world’s most recycled materials. Statistics show that nearly 90% of steel produced today comes from recycled scrap steel. This provides significant support for global environmental protection efforts. Furthermore, in terms of energy consumption, recycling scrap steel requires approximately 75% less energy compared to smelting iron ore into steel—an encouraging statistic.

Environmental Impact of Cast Iron

In contrast, the environmental impact of cast iron depends on energy consumption during the casting process and its recyclability. Cast iron production typically requires high energy input, especially in traditional processes like cupola furnaces, where melting iron ore and other raw materials consumes significant energy. Additionally, the casting process involves high temperatures, resulting in substantial carbon emissions.

Although cast iron is also recyclable, its recycling process consumes more energy than that of steel.

While cast iron has a lower recycling rate than steel, cast iron components are more durable and have a longer lifespan than steel parts. This helps mitigate its environmental impact. Products like engine blocks and pipes can be used for decades.

| Factor | Steel | Cast Iron |

| Recyclability | Highly recyclable (about 90%) | Recyclable, but less efficient than steel |

| Energy Consumption | Reduced through electric arc furnaces and recycling | High energy consumption during production and casting |

| Carbon Emissions | Lower carbon footprint with modern production methods | Higher emissions due to traditional casting processes |

| Use of Renewable Energy | Increasing use of renewable energy in production | Less focus on renewable energy integration |

| Longevity and Durability | High durability, widely reused in construction | Long lifespan, especially in infrastructure |

| Environmental Impact of Recycling | 75% less energy is required than in primary production | More energy-intensive recycling process |

It is evident that while steel possesses more pronounced sustainability characteristics—particularly in terms of recycling efficiency and energy consumption—cast iron still holds a place in manufacturers’ eyes when considering strength, wear resistance, and cost-effectiveness.

NOBLE is committed to rigorously managing the recycling and energy consumption of materials such as steel and cast iron, thereby helping clients in industries like automotive and medical device manufacturing optimize the sustainability of their production processes.

Factors to Consider When Choosing Between Steel and Cast Iron

At this point, I trust you have gained some understanding of steel and cast iron. Let’s summarize what we’ve covered. Imagine your project is currently at a crossroads—what factors would you need to consider? I’ll offer some guidance next.

Project Requirements

First, functionality and strength requirements must be considered. Second, the operating environment of the components is also crucial for the final selection.

Steel

Steel is often the preferred material for projects requiring high tensile strength, ductility, and the ability to withstand dynamic loads or impact. Steel is also suitable for structural applications that will be exposed to high stresses or fatigue, such as in bridges, aerospace parts, and automotive components. If your project involves heavy-duty machinery or load-bearing structures, steel is likely the best choice due to its high strength-to-weight ratio and flexibility in shaping.

Cast Iron

Cast iron, on the other hand, excels in compression and wear resistance. It is often selected for applications where the material will be exposed to static loads, abrasion, or high temperatures. For instance, engine blocks, cylinder heads, and brake components in the automotive and industrial sectors are commonly made from cast iron. Its excellent wear resistance and ability to handle thermal cycling make it ideal for these environments.

By the way, will your project be exposed to corrosive environments? Because these two materials have different levels of corrosion resistance, steel may require coatings or treatments, while cast iron naturally offers better protection against wear.

Cost and Budget Constraints

Budget is another critical factor we must consider.

Steel

As mentioned earlier, steel manufacturing processes are relatively complex, resulting in typically higher initial costs. However, steel’s high customizability may sufficiently offset these additional expenses for specialized applications. For instance, in aerospace components or high-end automotive parts, steel’s performance may deliver value far exceeding its cost!

Cast Iron

Because the casting process for cast iron is simpler and typically does not require special heat treatment, it is generally more affordable.

It is a cost-effective choice for parts such as piping, brake components, or engine blocks, where strength requirements may not need to match the high standards of steel, but durability and wear resistance are crucial. For large-scale production, such as in the automotive industry, the cost savings of cast iron can be substantial.

When working within a tight budget, cast iron may be a better option for applications where strength and wear resistance are more important than the ability to handle dynamic loads or high tensile stresses.

Maintenance and Longevity

Third, the maintenance and service life of the materials are also critical. The life cycle of the material in question can influence both the total cost of ownership and how often components need to be repaired or replaced.

Steel

Steel has a long lifespan but is typically more prone to corrosion unless properly treated or alloyed (e.g., stainless steel). It is, however, much more malleable and easier to repair than cast iron, especially when it comes to welding and reforming damaged parts. Well-maintained steel parts can last a very long time in applications like machinery, automotive parts, or structural components.

Additionally, steel’s ability to undergo heat treatment to increase hardness or improve wear resistance means that, with the right care, its performance can be tailored and maintained throughout its life cycle.

Cast Iron

Cast iron, while durable, is more brittle and can crack under stress or impact, especially in high-stress applications. However, its longevity in static load and high-wear applications is excellent. Cast iron engine blocks and piping systems can last for decades when properly maintained.

But, repairs can be more difficult due to its brittleness—cracked cast iron is harder to fix compared to steel, and welding is often not an option. In the case of high-wear components like brake rotors or engine parts, cast iron tends to maintain its functionality for a long time, but its brittleness means that part replacements or repairs may be needed more frequently if damage occurs.

How NOBLE Can Assist Your Metal Casting Project

Expertise in Material Selection

We understand how crucial materials and choices are to a project.

At NOBLE, our engineers bring deep expertise in material selection to every project, ensuring that your components are made from the most suitable material for the job.

- Steel vs. Cast Iron: Whether you’re working on a high-performance automotive part, a structural component, or a wear-resistant industrial tool, our team can evaluate the needs of your project and recommend the best material. We take into account factors like strength, durability, impact resistance, and cost-efficiency to help guide you toward the right decision.

- Customized Recommendations: Beyond steel and cast iron, our engineers can help you explore specialty alloys or composite materials if your project demands something unique. Whether it’s about reducing the carbon footprint or enhancing performance, we have the technical knowledge to support your material choices.

Custom Casting Solutions

NOBLE’s engineers specialize in custom casting solutions designed to meet the specific demands of your project. Whether you need precision cast iron components or high-strength steel parts, our team has the skills to produce parts that are tailored to your exact specifications.

- Tailored Solutions: From initial design to finished product, we work with you to ensure that each part meets your exact functional and dimensional requirements. Our expertise in customized machining ensures that even the most intricate designs can be brought to life.

- Material-Specific Expertise: Whether you need cast iron parts for high-wear applications like brake components or steel parts that require high tensile strength for aerospace or automotive applications, we have the machining techniques to deliver high-performance parts.

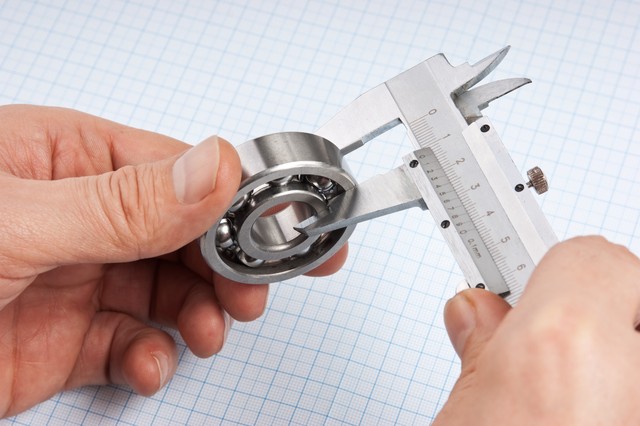

High-Quality Casting and Precision Manufacturing

Of course, in the fields of metal casting, precision manufacturing, and high-quality parts delivery, NOBLE has achieved considerable success in the industry through its advanced casting techniques and years of experience.

- Casting Processes: We employ advanced CNC casting machining to create parts with extreme precision. Our casting techniques allow us to produce parts that not only meet but often exceed industry standards. Whether it’s for high-precision automotive components or heavy-duty industrial machinery, we provide the accuracy you need.

- Quality Assurance: Each part undergoes strict quality checks to ensure it meets both design specifications and performance standards. From dimensional accuracy to material properties, we take every measure to ensure your parts will perform reliably over time.

FAQ: Steel vs Cast Iron

What is the main difference between steel and cast iron?

The difference in carbon content distinguishes the two. Steel is preferred for dynamic loads, while cast iron is ideal for static, high-wear applications.

Which is stronger: Steel or Cast Iron?

Steel offers greater tensile strength, while cast iron provides superior compressive strength. Cast iron is more brittle, whereas steel is better suited for high-stress, dynamic environments.

Can steel be used in place of cast iron?

Sometimes it is possible. In high-intensity applications, steel is the better choice. For applications requiring high wear resistance or compressive strength, I recommend using cast iron.

Is cast iron more brittle than steel?

Obviously, yes, cast iron is more brittle due to its higher carbon content. It is prone to cracking under tensile stress or impact, while steel is more flexible and can withstand more dynamic stress.

How long does cast iron last compared to steel?

Cast iron can last a long time in static, low-impact environments, but is more prone to cracking under stress. Steel tends to have longer longevity in dynamic or high-stress applications, especially when treated for corrosion resistance. Both materials can last for decades when properly maintained.

Can cast iron be welded?

However, due to cast iron’s brittleness and high carbon content, welding cast iron is more challenging than welding steel. Special techniques, such as preheating, are required to prevent cracking.

What is the cost difference between steel and cast iron for large-scale projects?

Cast iron is generally less expensive than steel, especially when producing parts in large quantities. The casting process for cast iron is simpler and requires less energy than steel production. However, steel’s additional costs are often justified by its performance in high-stress applications.