When it comes to modern manufacturing, keeping things efficient and affordable is the name of the game. Stamping molds? They’re the heart of metal shaping processes, and they’re key for cranking out products quickly, precisely, and at a low cost. Whether you’re in car manufacturing, making home gadgets, working in electronics, or even in aerospace, these molds are everywhere. This guide breaks down everything you need to know about stamping molds, injection molding, and precision molding, showing you why they matter and how they’re used.

What Are Stamping Molds?

Stamping molds are the tools that help shape metal sheets. They work alongside presses to turn flat metal into the shapes and sizes you need. The stamping process involves punching, bending, stretching, and forming, and these molds are the key to making it all happen.

Advantages of Stamping Dies

1. High Efficiency

Mass Production: Stamping dies are perfect for fast, nonstop production, making them a go-to for large-scale manufacturing.

Example: In car manufacturing, a single stamping die can shape body panels in just a few minutes, which really speeds up the whole process and helps get more done in less time.

2. High Precision and Consistency

Dimensional Accuracy: Stamping molds make sure every part comes out with the same precise dimensions and smooth finish. This is especially important in industries like electronics and medical devices, where accuracy really matters.

3. High Material Utilization

Optimized Design: Stamping molds help cut down on material waste, which in turn lowers production costs

Example: With progressive dies, you can do multiple operations in one press cycle, making the most of the material and improving efficiency even more.

4. Wide Applicability

Versatile Materials: Stamping molds can work with all sorts of materials like steel, aluminum, copper, and stainless steel.

Industries: They’re used in all kinds of industries, from automotive and home appliances to electronics and construction, and pretty much everywhere in between.

5. Cost-Effectiveness

Long Lifespan: While the upfront cost of stamping molds can be high, they last a long time and are perfect for mass production, which helps bring down the cost of each unit in the long run.

Types of Stamping Dies

1. Single-Stage Dies

Function: These dies perform one operation each time the press cycles.

Applications: They’re typically used for producing simple parts.

Single-stage dies are straightforward tools that handle a single task per press stroke, making them ideal for basic manufacturing needs. However, for more complex parts requiring multiple operations, other die types like compound or progressive dies might be more suitable.

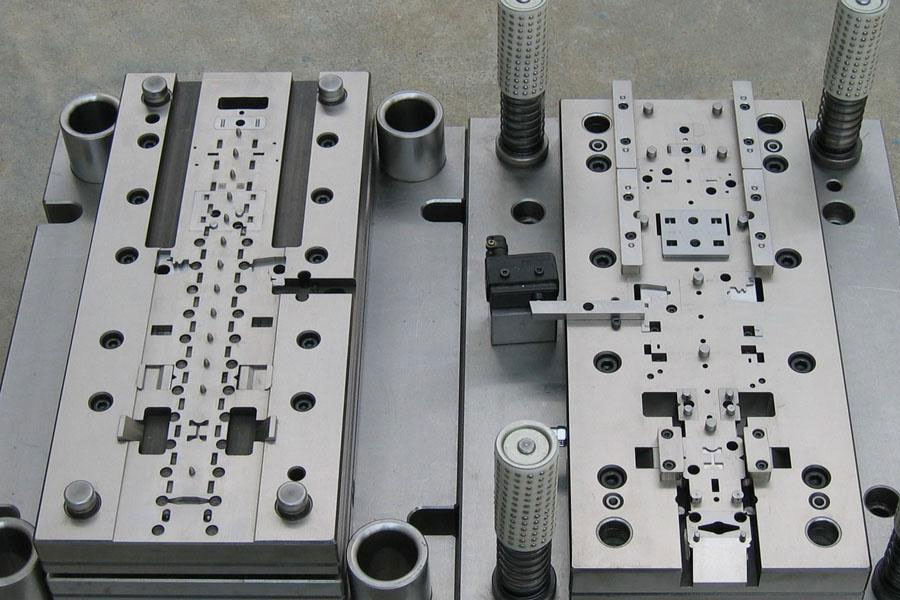

2. Compound Dies

Function: These dies handle multiple tasks—like punching and bending—all in one press cycle.

Applications: They’re great for making parts that are a bit more complex than simple ones.

Compound dies are designed to perform several operations simultaneously, making them efficient for producing more intricate parts in a single press stroke. This design reduces the need for multiple dies and shortens production time.

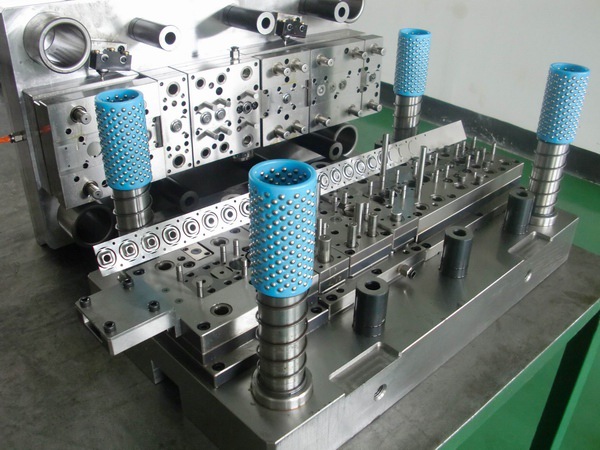

3. Progressive Dies

Function: These dies perform multiple operations across several stations in a single press cycle, efficiently transforming a flat metal strip into a finished part.

Applications: Ideal for producing complex parts in high volumes, progressive dies are commonly used in industries like automotive, electronics, and appliances.

Progressive die stamping is a metalworking process that involves feeding a metal strip through a series of die stations, each performing specific operations such as punching, bending, or coining. This method allows for the efficient production of intricate parts with consistent quality, making it a popular choice for mass production.

4. Deep Drawing Dies

Function: Deep drawing dies are designed to shape flat metal sheets into deep, hollow forms. This process involves pulling the metal into a die using a punch, stretching it to the desired depth.

Applications: This technique is commonly used to manufacture items like automotive fuel tanks and stainless steel sinks. It’s also utilized in creating various kitchenware and aerospace components.

Deep drawing is particularly effective for producing complex shapes with high precision, making it a preferred method in industries where such specifications are crucial.

Design and Manufacturing Process of Stamping Dies

Designing and manufacturing stamping dies is a meticulous process that involves several critical phases to ensure the production of high-quality stamped parts. Below is an overview of each phase:

1. Design Phase

Requirement Analysis: Begin by defining the product’s specifications, including dimensions, material types, and production volumes. This step is crucial for selecting appropriate materials and designing dies that meet production demands.

Die Design: Utilize Computer-Aided Design (CAD) software to create detailed structural designs of the stamping dies. This process ensures that the dies are both functional and manufacturable, aligning with the product’s requirements.

Simulation Analysis: Employ Computer-Aided Engineering (CAE) software to conduct mold flow and stress analyses. These simulations help optimize the die design by predicting potential issues and allowing for adjustments before physical manufacturing begins.

2. Manufacturing Phase

Material Selection: Choose suitable die steels, such as Cr12 or H13, based on factors like durability, material hardness, and the specific requirements of the stamping process.

Processing Techniques: Apply high-precision manufacturing processes, including CNC (Computer Numerical Control) machining and Electrical Discharge Machining (EDM). These techniques ensure the dies are crafted with the necessary accuracy and surface finishes.

Surface Treatment: Implement heat treatments and apply coatings to the dies to enhance their lifespan and performance. These treatments improve hardness, wear resistance, and overall durability.

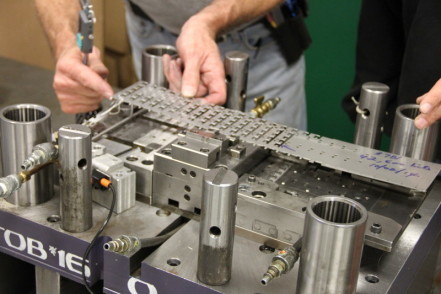

3. Testing and Validation

Trial Molding: Perform trial runs using the dies to validate their performance. This step helps identify any design or manufacturing issues, allowing for necessary adjustments before full-scale production.

Quality Inspection: Utilize tools like Coordinate Measuring Machines (CMM) to inspect the dimensional accuracy of the stamped parts. Ensuring that the parts meet specified tolerances is essential for maintaining product quality.

This comprehensive approach to die design and manufacturing ensures that stamping dies are optimized for efficient production, leading to high-quality stamped components that meet all required specifications.

Key Elements of Injection Mold Design

Designing an injection mold involves several critical elements to ensure efficient production and high-quality molded parts. Here’s an overview of key considerations:

Parting Line Design

Function: The parting line defines where the two halves of the mold meet. Its placement affects the ease of part removal and the quality of the part’s surface.

Optimization: Positioning the parting line strategically can minimize defects like flash (excess material) and burrs, leading to smoother demolding and better surface finishes.

Gating System Design

Gate Types: Selecting appropriate gate types—such as point gates, edge gates, or direct gates—is essential. The choice depends on factors like the part’s geometry, material flow requirements, and desired aesthetics.

Runner Design: Designing the runner system (the channels that direct molten plastic to the mold cavities) for optimal size and shape ensures uniform material flow, reduces waste, and improves cycle times.

Cooling System Design

Cooling Channels: Efficiently designed cooling channels within the mold help maintain consistent temperatures, reduce cycle times, and prevent defects like warping.

Temperature Control: Ensuring uniform mold temperature throughout the cavity minimizes thermal stresses, leading to parts with consistent quality and dimensional accuracy.

Ejection System Design

Ejector Pin Layout: Strategically placing ejector pins facilitates smooth and uniform ejection of the molded part, reducing the risk of damage or deformation.

Ejection Force Control: Designing the ejection system to apply appropriate force ensures that parts are ejected without distortion or damage, preserving their integrity and quality.

Applications of Stamping Dies

Stamping dies are essential tools in manufacturing, enabling the production of precise and durable components across various industries. Here’s how they are applied in different sectors:

Automotive Manufacturing

Components Produced: Stamping dies are used to manufacture body panels, chassis components, engine parts, doors, hoods, and seat frames.

Benefits: The process reduces weight while maintaining strength, contributing to vehicle performance and fuel efficiency.

Home Appliance Industry

Components Produced: Parts such as refrigerator shells, washing machine panels, and air conditioning components are crafted using stamping dies.

Benefits: Stamping ensures high-volume production of durable and precisely shaped parts, essential for the functionality and aesthetics of home appliances.

Electronics

Components Produced: Stamping dies are employed to create phone casings, computer chassis, connectors, and other electronic housings.

Benefits: The process allows for the mass production of intricate parts with tight tolerances, crucial for the miniaturization and performance of electronic devices.

Aerospace

Components Produced: Aircraft skins, structural components, and engine parts are fabricated using stamping dies.

Benefits: Stamping provides lightweight yet strong components that meet the stringent safety and performance standards of the aerospace industry.

Conclusion

In conclusion, both stamping dies and injection molds are indispensable in modern manufacturing, offering significant advantages in efficiency, precision, and cost-effectiveness. By comprehending their respective designs, applications, and benefits, businesses can optimize production processes, enhance product quality, and maintain a competitive edge in the market.