It’s really important to get the right mold. The choice you make at the start has a huge impact on the whole project. It’s what determines the final product’s quality. It also affects your production cost. If you make the wrong choice, you could waste time and money.

There are two main options: soft molds and hard molds. You can’t just interchange them. They all have their own thing going on. It’s important to know the difference between them if you want to get the best results.

What Are Soft Molds?

Just think of soft molds. They’re the flexible ones. You make them from materials like silicone, rubber, or latex.

What are soft molds made of?

Most of them are made of silicone. You’ll also see rubber, latex and some urethane compounds. These materials stay flexible even after they’ve set.

Why would you use soft molds?

The best thing about it is how flexible it is. You can peel the mould away from a finished part, even if it has deep undercuts. This makes demoulding a breeze. The details are amazing. The textures are spot on and the features are super detailed.

The soft moulds capture every detail perfectly. They’re also pretty cheap to make. This makes them perfect for prototyping and low-to-medium production runs.

Where do soft molds work best?

They’re great for detailed craft work. Think sculptures, custom jewellery and food molds for chocolate and sweets. In medicine, they’re used to make prosthetic parts. If you need a silicone mold for detailed casting or a soft mold for a low-volume creative project, this is the tool for you.

What Are Hard Molds?

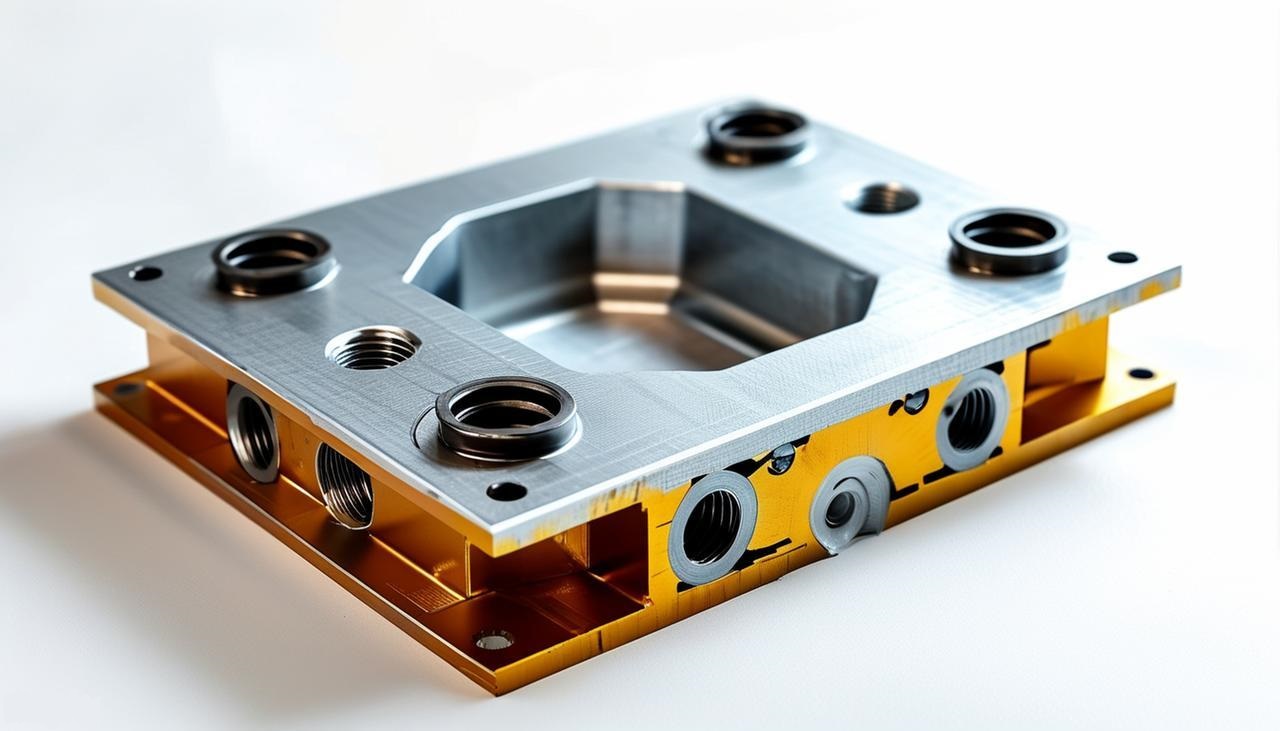

Now, let’s take a look at hard molds. These are the rigid, solid tools. They’re usually made from metal, hard plaster, ceramic, or rigid industrial resins.

What are hard molds made of?

For heavy-duty work, you’re better off using metals like aluminium or steel. For special projects, you could use ceramics or reinforced plaster. These materials don’t bend.

Why would you use hard molds?

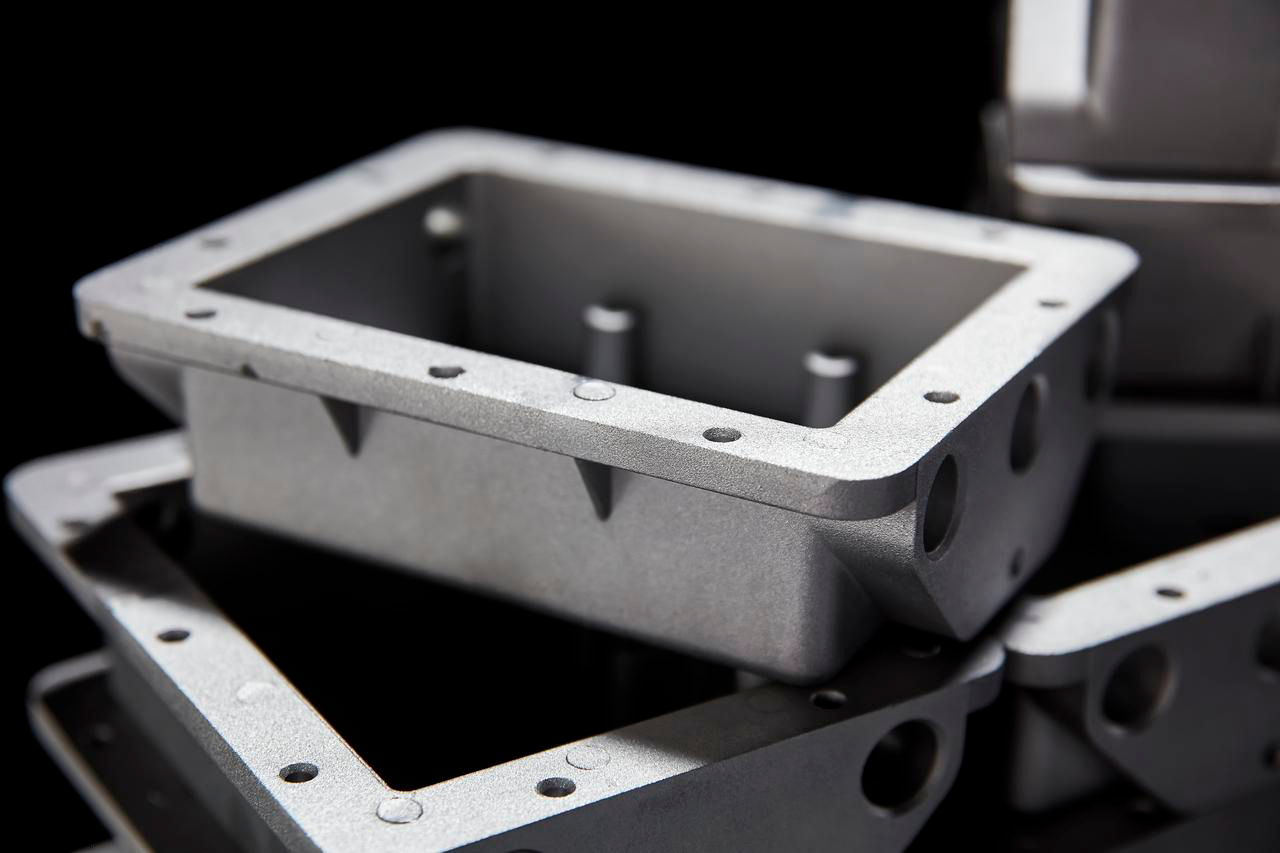

The main perk is that they’re really durable. A hard mold can last for thousands of cycles. It won’t wear out quickly. This makes it perfect for really high-volume production runs. It can handle extreme heat and pressure. This is a must for casting molten metals or high-temperature resins. They’re really precise and consistent, which is vital for mass production where every part has to be identical.

Where hard molds they work best?

Their home is in industrial manufacturing. You’ll find hard molds for industrial casting in places like automotive part foundries and aerospace component shops. They’re the basis of all metal casting molds and plastic injection molding. If you’ve got to make 10,000 of the same engine brackets or plastic housings, you need a hard mold.

Soft Molds vs. Hard Molds: Key Differences

Deciding between a soft and a hard mold is a key choice. It tells you how many you can make, how much they’ll cost and what the limits are. The point is not to decide which one is better overall, but to choose the one that’s right for your specific job.

To help you make the right choice, here’s a simple side-by-side look at their main features.

| Aspect | Soft Molds | Hard Molds |

| Flexibility | Flexible. You can bend and peel them. | Rigid. They are solid and do not bend. |

| Upfront Cost | Lower cost. Cheaper and faster to make. | Higher cost. A significant initial investment. |

| Durability | Wears out faster. Good for dozens to a few hundred casts. | Extremely durable. Built for thousands of cycles. |

| Temperature Resistance | Low. Can’t handle high heat. | Very High. Made for molten metal or hot plastics. |

| Ease of Use for Detail | Excellent. Easy to demold complex, delicate shapes. | Difficult. Complex parts may not release from a rigid mold. |

| Best Production Volume | Low to Medium volume. Prototypes, crafts, short runs. | High volume. Mass production in a factory. |

As you can see, the pros and cons are pretty clear and practical. Each type of mold is designed for a specific purpose. They’re not that similar in the ways they’re used.

Use this comparison as a filter for your project’s requirements. If you’re after capturing fine detail for a limited run on a budget, soft molds are the way to go. If you’re after high-temperature resistance and making tens of thousands of identical, durable parts, then you’ll need a hard mold that’s rigid and long-lasting. The right tool exists; picking it correctly from the start is what leads to better, more cost-effective results.

Common Mistakes to Avoid When Using Soft and Hard Molds

Soft Molds

Using the wrong release agent

This is a common mistake. Not all release sprays or gels are compatible with silicone or rubber. Some of them have chemicals in them that’ll slowly break down the soft mold material, making it sticky and unusable. Just remember to check compatibility.

Overloading the mold

Just so you know, soft molds are pretty flexible, but they’re not indestructible. If you pour in too much material, like heavy resin or plaster, it can create too much weight and pressure. This can cause the mold walls to bulge, leading to leaks, distorted parts, or even tears along seams.

Not allowing the mold to fully cure

When you make a new silicone mold, it might feel firm. But it often needs more time to fully cure internally. If you use it too soon, it can stick or leave residue on the casting. It can also mean the mold deforms permanently under stress. Let it sit for as long as the instructions say.

Hard Molds

Not properly maintaining the mold

A hard mold is a big investment, but it’s not maintenance-free. This is especially true for metal molds. If you don’t clean them properly after use and apply protective coatings, they’ll rust or corrode. This damage ruins the mold’s surface and destroys the fine details on your castings.

Using hard molds with the wrong casting materials

You can’t use every material in every hard mold. The surface of the mold has to be right for the job. If you pour a certain molten metal into a plaster mold designed for a different alloy, it can cause a reaction. It might make the part stick permanently or even crack the mold from thermal stress. Just remember to match the material to the mold type.

Failing to use proper mold release

The problem with hard molds is that they’re rigid, which makes demolding tricky. People often think that a smooth metal or ceramic surface will release easily. It often doesn’t. Some materials, like resins, waxes and even certain metals, can fuse to tiny pores. If you don’t apply the right release agent before each pour, you’ll have a hard time removing the part. If you’re not careful, you might damage both the casting and the expensive mold when you’re trying to force it out.

The idea isn’t just to avoid errors, but to build a reliable process. No matter if you’re using a soft or hard mold, these mistakes all come from the same place: treating the mold like a simple container instead of a precision tool that needs specific care.

Basically, you need to know your tool. Each type of mold has its own rules. Following them isn’t extra work; it’s the most direct path to consistent quality, longer tool life, and a smoother workflow from your first prototype to your thousandth production part.

Environmental Considerations in Mold-Making

The environmental impact is a real factor in the workshop and factory today. The materials you choose and how you handle waste matter. Unfortunately, there’s no such thing as a completely zero-impact mold material. Every option has its pros and cons. The idea is to make a conscious choice that fits with the size of your project and your environmental priorities.

Soft Molds

Silicone is a popular choice. It’s generally non-toxic and stable during use, which is a bonus. But there’s a catch. Most standard silicones aren’t biodegradable. When you throw away a silicone mold that’s seen better days, it ends up in a landfill site. You’ll have to plan for that disposal problem.

Other materials, like certain latex rubbers, can cause problems too. They often contain chemical additives that might be allergens. Their production and eventual breakdown can have a bigger environmental impact. It’s worth checking the specific formulas from your supplier.

Hard Molds

Metal molds, like aluminium or steel, last for ages. One well-made mold can produce parts for years. When it finally wears out, the metal can be fully recycled. This reduces long-term material waste. The trade-off is the initial cost. Making that mold – by machining or casting – uses a lot of energy. The environmental impact is highest during the manufacturing phase.

Plaster and ceramic molds are different. They’re often made from natural, abundant minerals and are biodegradable. This seems like the greener choice. But they can be fragile. A plaster mold might only last a few dozen casts before it cracks or wears down. The problem is, they don’t last very long, so you have to keep making new molds, which ends up creating more physical waste during a project. How eco-friendly it is depends on how much you produce and how you dispose of the used mold material.

Choose NOBLE for Mold Manufacturing

Here at NOBLE, we get that the key to turning a great idea into a product that people want to buy is making sure we make it right. Choosing between soft and hard tooling is one of the most important decisions you’ll make, and it’ll cost you.

We’re not just about supplying molds, we’re all about making manufacturing clear.

Our Expertise:

- End-to-End Guidance: Our engineers will work with you from your first 3D-printed prototype to mass production, to make sure you get the best tooling path, saving you time and money.

- Dual-Capability Shop: We’re one of the few partners with both state-of-the-art silicone RTV molding stations and a full CNC machining and hard tooling workshop. You get unbiased advice and a smooth transition between stages.

- Getting to market quickly: We’re all about low-volume production with soft tooling, so you can test out your designs, raise money, or drop a limited edition without having to break the bank.

- Production-Ready Hard Tooling: When you’re ready to scale, our toolmaking excellence ensures your steel or aluminium molds deliver millions of parts with precision.

If you need help choosing between soft and hard molds, we can help you out with a free Design-for-Manufacturability (DFM) review.

FAQ

I’ve never done this before. What kind of mold should I use for my first product?

Start with a simple question: how many do you plan to make in your first year? If your answer is under 200 or 300 pieces—maybe you’re testing the market or making a niche item—then begin with soft tooling. This approach lets you tweak your design and see if customers want it without a huge upfront investment. For most people launching a product for the first time, this is the smartest, lowest-risk path.

How do I know when it’s time to switch from soft to hard tooling?

Keep an eye out for these signs:

- Demand that stays the same: You’re confident your sales forecasts can predict volumes of over 500-1,000 units a year.

- Your part design hasn’t changed for a few months now and it’s already doing well in the market.

- You need a specific, durable thermoplastic (like PP or ABS) that can’t be mimicked with casting resins.

- The cost per unit pressure is becoming a bit of a problem. Your soft mold costs per part are getting too high, but we can amortise the high initial cost of a hard mold.

If it’s actually possible to sell products made from a soft mold?

Yes, you can. This is a common misunderstanding. For a lot of businesses, the soft mold is the go-to production tool. The parts you cast from it, especially with modern urethanes or resins, are often the final, sellable product. This is standard for crafted goods, detailed decor, limited-edition collectibles, and specialty props. The quality is top-notch. The type of mold doesn’t define the quality of the part, it’s the casting material and technique that do.

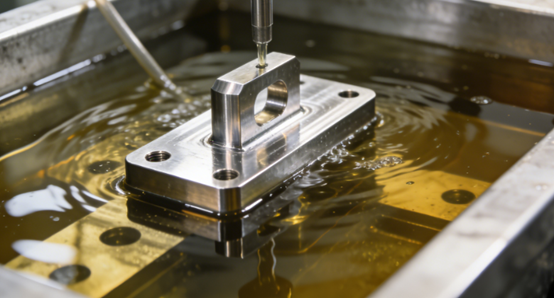

Why the lead time for hard tooling is so much longer?

Hard tooling is all about precision engineering. It’s a process involving CNC programming, machining (often hundreds of hours of work), heat treatment, meticulous polishing, and assembly. Every step takes time and needs to be checked by an expert. Soft tooling is a simpler casting process, where you start with a master model.

My part has severe undercuts. Does this mean a more expensive hard mold?

With soft silicone molds, severe undercuts are often no problem – you can just peel away the flexible rubber. This is a huge plus. With hard molds, each undercut needs extra “side-actions” or “slides,” which make the mold more complex, expensive, and in need of more upkeep.

What file format do your engineer need to start with?

We need a 3D CAD file in STEP or IGES format for the engineering review. And for soft molds, we can also work from a high-quality physical master pattern (which can be 3D printed).

Can you handle the whole process, from my sketch to the finished product?

NOBLE offer full product development services. This includes things like design assistance, prototyping, tooling, production, quality control, and fulfillment. You can get us to take care of just one step or the whole thing.