Introduction

Ever wondered how flat pieces of metal become the intricate parts you see in cars, appliances, or even aircraft? That’s sheet metal processing. This method is a go-to in manufacturing because it’s fast, flexible, and effective in all kinds of industries.

Behind every breakthrough in modern manufacturing lies a set of precision techniques. Stamping. Welding. Panishing. These aren’t just steps—they’re strategies that fuel innovation across industries. In this section, we’ll show you how each method adds its unique value, transforming sheet metal into high-performance parts and products.

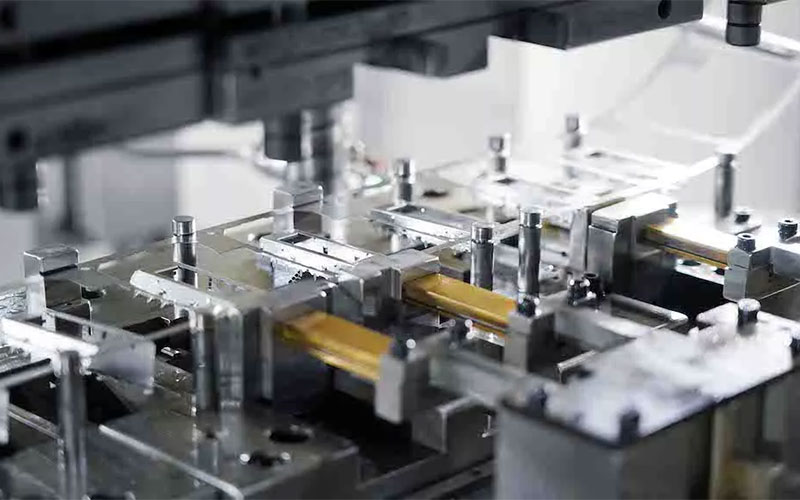

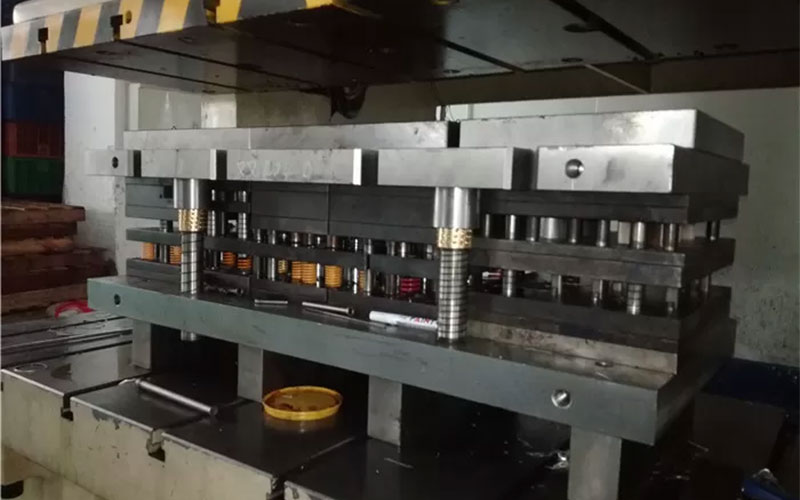

1. Sheet Metal Stamping: Precision in Mass Production

Stamping might sound simple, but a lot is going on behind the scenes. It starts with flat sheets of metal being fed into a stamping press, where they’re shaped using special tools and dies. The process can include anything from punching holes to bending edges or adding texture. Sometimes it’s done all at once; other times, the metal goes through a few stages to get it just right. Most of the time, stamping is done with cold metal sheets, though some parts may need heat and pressure, like in forging.

Types of Sheet Metal Stamping

Progressive Stamping: Looking for speed, precision, and consistency in mass production? Progressive stamping delivers all three. With each press stroke, the metal moves through multiple die stations, each shaping the part step by step until the final form is complete. It’s a smart solution for producing high volumes of complex parts—fast, accurate, and cost-effective.

Deep Drawing: Deep drawing is like stretching a metal sheet into a new shape using a punch and a die. If the depth of that shape ends up deeper than its width, it’s called “deep” drawing. Sometimes the part has to go through several stages to get just the right depth and form. You’ll find this method used in the manufacture of car panels, airplane parts, and even kitchen sinks.

Blanking & Coining: Blanking is basically like using a cookie cutter on metal—you cut out a flat piece, called a “blank,” from a bigger sheet. That blank then gets shaped or formed into the final part. Coining, on the other hand, is all about detail. It uses a ton of pressure to press fine patterns or textures into the metal—think of coins, medals, or anything with intricate designs. Simple, but super effective.

Operation

- Bending– This is where the metal is simply bent along a straight edge—think of folding a sheet in half.

- Flanging– Like bending, but along a curve instead of a straight line. It gives the metal a smooth, rounded edge.

- Embossing– Adds shallow patterns or textures by stretching the metal slightly—great for decorative finishes.

- Blanking– This is the cookie-cutter move: cutting a shape out of a metal sheet to use it for something else.

- Coining– Here, we press a detailed pattern right into the surface. It’s how traditional coins and medallions are made.

- Drawing– This is when the metal is pulled into a new shape, like forming a bowl or cup, by stretching it carefully.

- Stretching– Similar to drawing, but here the metal is just pulled outward—no material moves inward. It’s great for smooth, sleek car panels.

- Ironing– The metal is squeezed down thinner along vertical walls. You’ll see this in drink cans and bullet casings.

- Reducing/Necking– This gradually narrows the open end of a tube or container. Think of how a bottleneck forms.

- Curling– The edge of the sheet is rolled into a tube shape. You’ve seen this on door hinges or rolled edges.

- Hemming– The edge of the metal gets folded back onto itself, making it stronger and safer, like on a car door.

You can do things like punching holes (piercing) or making perimeter cuts directly inside a stamping press. But the real magic happens with progressive stamping: as the strip moves through successive dies, each one adds something—cutting, shaping, forming—until the final part is ready. It’s like a mini production line inside one press, giving you speed, precision, and automation.

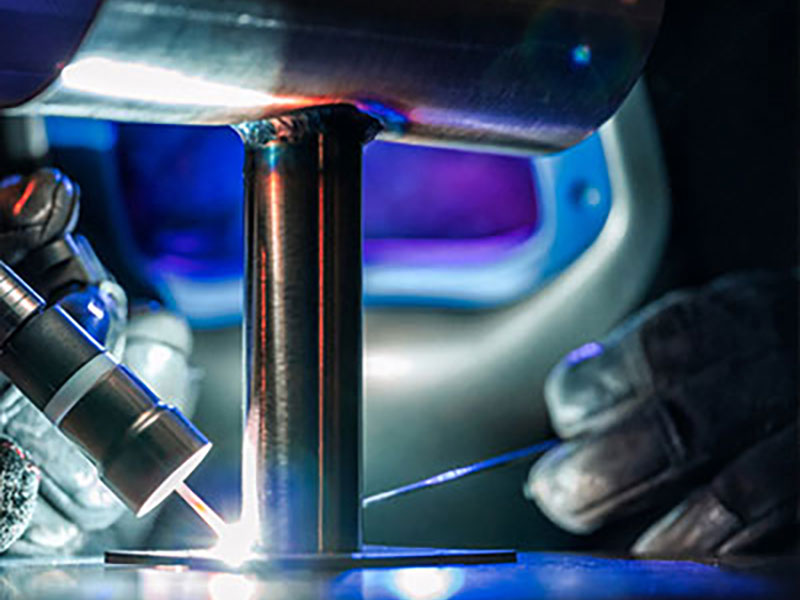

2. Sheet Metal Welding: Joining Techniques for Strength

Welding is more than just a technique—it’s the backbone of sheet metal fabrication. By using heat, pressure, or both, welding creates strong, lasting joints that are crucial in industries like automotive and aerospace. It’s the process that ensures your products are built to last.

Common Welding Methods

MIG (Metal Inert Gas) Welding, or Gas Metal Arc Welding (GMAW), is like the fast-food of welding—quick, efficient, and versatile. It uses a continuously fed wire electrode and an inert shielding gas, usually argon or a mix of argon and CO₂, to fuse metals. Perfect for thin to medium-thickness materials, it’s a go-to for high-volume production. Just keep in mind, it might create a bit more spatter than some other methods.

TIG (Tungsten Inert Gas) Welding: Also known as Gas Tungsten Arc Welding (GTAW), is like the precision tool in a welder’s kit. It uses a non-consumable tungsten electrode to create a clean, focused arc, with an inert gas like argon shielding the weld area. This method is perfect for thin metals and intricate work, delivering high-quality, spatter-free welds. It’s commonly used in industries where appearance and strength matter, like aerospace and automotive.

Spot Welding: This is the go-to method for joining metal sheets quickly and efficiently. By applying pressure and a burst of electric current, it melts the metal at the contact points, forming strong welds in mere milliseconds. It’s widely used in automotive manufacturing for assembling car bodies, thanks to its speed and reliability.

Cold Metal Transfer (CMT): CMT is like the cooler cousin of MIG welding—you still use the same inert gas and wire, but the magic happens in how the wire briefly retracts during a short circuit. This drop-by-drop method lets each little bit cool, which keeps the heat super low. That means thinner metals don’t warp or burn through. It’s perfect for precise, minimal spatter work on thin sheets

Considerations

When selecting a welding method for sheet metal, several factors must be considered:

Material Compatibility: Every metal behaves a little differently when exposed to heat. Some melt quickly, others resist; some expand more than others. So when you’re joining two different metals, it’s like pairing dance partners—if they move at different speeds, the routine falls apart. Careful filler selection and thermal balancing are essential to keep the weld stable.

Joint Design: The secret to a long-lasting weld? Start with smart joint design. Whether you’re working with lap or T-joints, precision in weld sizing and fit-up ensures structural performance and reliability. Lap joints, a staple in sheet metal fabrication, demand exact overlaps to ensure a strong connection.

Desired Strength and Durability: When durability is non-negotiable, welding must deliver. From aircraft to industrial machinery, high-stress applications need welds that can stand the test of time. High-strength steels require equally strong welds, and without proper strength matching, even the toughest materials can fail.

3. Sheet Metal Bending: Shaping with Precision

By bending sheet metal, we transform plain, flat stock into angles and curves with deliberate precision. This humble yet vital process underpins the creation of components we rely on—whether brackets that hold things together, enclosures that protect electronics, or structural parts that bear loads.

Techniques

Air Bending: In air bending, you don’t fully press the sheet into the die—instead, it kind of perches on the die’s shoulders, leaving a little bit of “air” underneath. You control the bend by how deep the punch goes into the die, so with one tooling set, you can dial in all sorts of angles. It’s flexible, easy on the equipment, and great for small production runs. Just keep in mind, though—metals usually spring back a bit, so you’ve got to over-bend just enough to land on your target angle

Bottoming: Bottom bending, also known as bottom pressing or bottom forming, is a sheet metal bending technique where the punch presses the material fully into the die, ensuring complete contact. This method offers higher precision and consistency compared to air bending, making it ideal for applications requiring tight tolerances and minimal springback. However, it requires more force and specialized tooling, and may not be suitable for all materials or thicknesses.

Coining: So, coining is this super precise way to bend metal — the punch pushes the sheet into the die hard enough to permanently shape it. Because of that, you don’t get any springback, and the bends come out sharp and accurate. It’s perfect when you need parts with really tight specs and lots of tiny details.

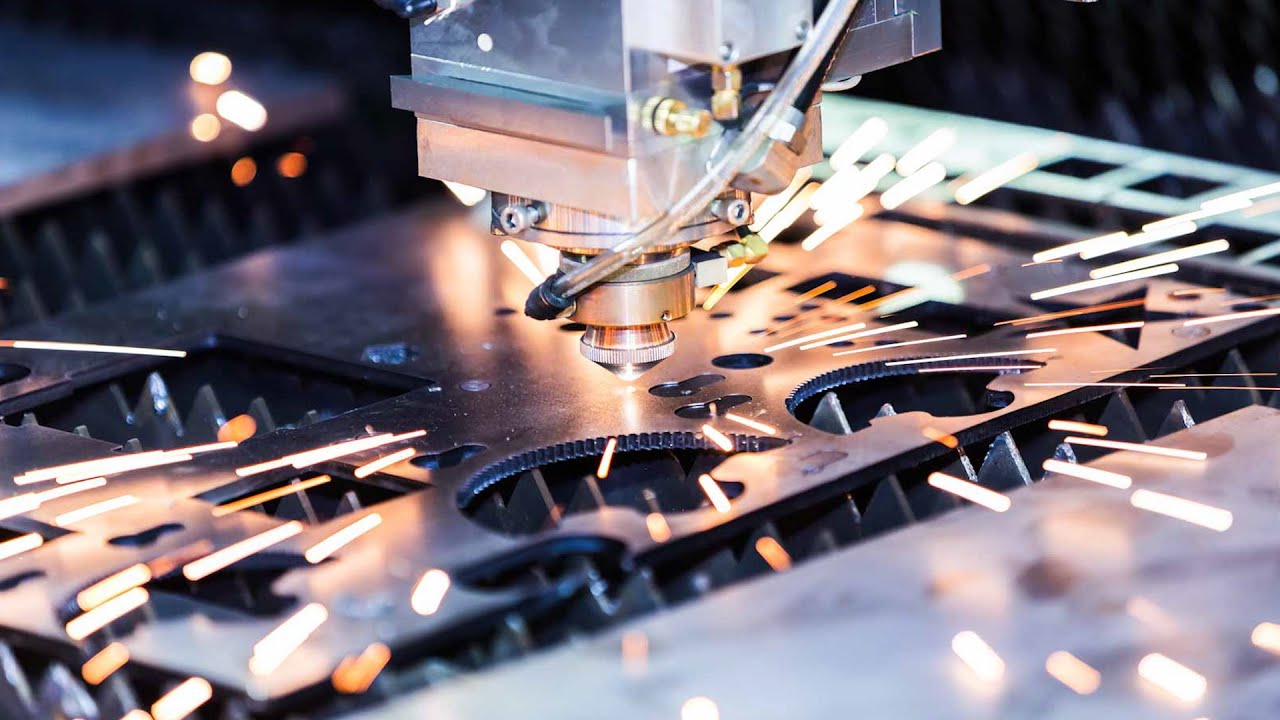

4. Sheet Metal Cutting: Techniques for Precision and Efficiency

Cutting sheet metal is super important in making parts — it turns flat metal into all kinds of shapes. How you cut it matters for how exact, fast, and good the final thing comes out.

Methods

Laser Cutting: Laser cutting uses a powerful laser beam to burn through materials, making super clean and exact cuts. It’s perfect for detailed stuff and works best on thin to medium-thick sheets. The cuts are really precise, with barely any heat damage to the edges.

Waterjet Cutting: Waterjet cutting shoots out a strong jet of water mixed with grit to slice through materials without heating them up. That’s great for stuff that can’t handle heat, like aluminum. It’s pretty accurate too, and can make tricky cuts with sharp corners.

Shearing: Shearing’s a quick and cheap way to cut straight lines in sheet metal. It’s great for basic shapes, but you might get rough edges or burrs that need to be cleaned up afterward.

Plasma Cutting: Plasma cutting’s like slicing metal with lightning — it shoots a super-hot jet to cut through thick steel fast. It’s awesome for big jobs, but the edges can be a bit rough, and it doesn’t have the same precision as lasers or waterjets.

Considerations

When you’re picking a way to cut metal, think about what kind of stuff you’re cutting, how thick it is, how nice you want the edge to look, and how many pieces you need. Laser’s great for fine details, waterjet’s best if the material can’t take the heat, shearing’s fast and simple for basic cuts, and plasma’s perfect for big, thick pieces that need to be cut quickly. Need professional help? Contact NOBLE and we’ll give you the solution that’s best for you!

5. Sheet Metal Notching: Creating Precise Cuts

Notching is cutting out small sections from the edges or surface of a metal sheet to shape it the way you need. You’ll see it used a lot in industries like cars, planes, and HVAC systems. It helps get parts ready for assembly, saves material, and makes the rest of the manufacturing process smoother.

Techniques

Punch Press Notching: Punch press notching is a method where a punch and die are used to cut or shear material from sheet metal. It’s great for making the same notch over and over with perfect precision, especially if you need to do it a lot. And the best part? It’s cost-effective for simpler shapes when you’re making a lot of them!

Rotary Notching: Rotary notching uses spinning tools to make smooth, continuous cuts in sheet metal. It’s perfect for when you need curved or complicated notches because it gives you a lot of design flexibility. You’ll usually find it used for jobs that need detailed shapes.

Laser Notching: Laser notching is when a powerful laser beam cuts through sheet metal with crazy precision. It’s great for super detailed designs and doesn’t waste much material, which makes it a smart option for jobs that need exact measurements

Design Considerations

When designing for sheet metal notching, several factors should be considered:

Notch Dimensions: When you’re cutting notches, make sure the width is at least the same as the material thickness, or 1.0 mm if that’s bigger. The depth shouldn’t go more than five times the thickness of the material. Keeping that width-to-depth ratio balanced helps keep everything strong.

Notch Location: Try to place the notches away from the bends or any high-stress points. That way, the material stays strong and doesn’t risk failing..

Notch Shape: When you’re cutting notches, rounded corners are much better than sharp angles. They help spread the stress evenly, which means fewer cracks later on.

Tool Clearance: You need to give enough room for the notching tool to work properly. If it’s too tight, it could mess up the precision of the notch..

Symmetry: Symmetry is your friend when designing notches. Not only does it make everything easier to manufacture, but it also saves you money on tools.

7. Sheet Metal Finishing: Enhancing Surface Finish

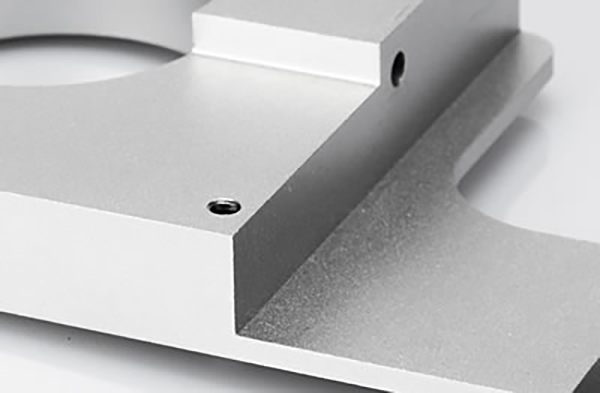

Planishing is a technique where you smooth out the surface of sheet metal, making it look even and flawless. It’s great for getting rid of any imperfections, improving the material’s strength or qualities, and making it ready for the next steps, like coating or shaping.

Techniques

Hammering: With hammering, whether you’re doing it by hand or with a machine, you use controlled strikes to smooth and shape the metal. It’s a quick way to fix small dents and imperfections, and it’s common in auto body work and creative metal projects.

Roller Planishing: Roller planishing is when metal is passed through rollers that press down on it, flattening and smoothing the surface. This method is awesome for getting that even finish on flat or slightly curved sheets of metal..

Polishing: Polishing is when you use an abrasive to smooth out imperfections and give the metal a shiny, glossy look. It’s usually the last step in planishing, making the metal surface perfect for decorative uses..

Considerations

When you’re planishing, you’ve got to keep a few things in mind—like the type of metal you’re working with, how thick it is, and how smooth you want the finish to be. Picking the right tools and techniques for the job will make sure your metal turns out strong and looks awesome.

Applications of Sheet Metal Maching Techniques

Sheet metal processing is a process that includes techniques like stamping, welding, bending, cutting, riveting, notching, and planishing. These methods are used in tons of industries to make the parts that are essential for products to work properly, be safe, and look good.

In automotive manufacturing, sheet metal processing is pivotal for producing body panels, chassis components, and structural elements. Techniques like stamping and welding are employed to fabricate parts that ensure vehicle safety and performance. For instance, deep drawing is utilized to form complex shapes, while welding techniques such as MIG and TIG welding are used to join components securely. Additionally, bending processes are applied to create precise angles and curves in parts like brackets and frames.

Sheet metal processing is essential in car manufacturing, helping create everything from body panels to chassis components and structural elements. Stamping and welding ensure the parts are strong and safe. Deep drawing shapes those tricky, complex parts, while MIG and TIG welding hold things together securely. And bending creates the precise angles and curves needed for parts like brackets and frames, making the whole process come together perfectly!

- Electronics Industry

In electronics, sheet metal processing is essential for creating enclosures, brackets, and heat sinks that keep electronic components safe and well-supported. Techniques like laser cutting and shearing ensure precise cuts, while bending forms the right shapes for enclosures. Welding and riveting hold everything securely, making sure it’s built to last. Notching helps create the perfect slots and tabs for components, and planishing adds a smooth, polished finish for that extra touch of quality.

- Construction and Architecture

In the construction industry, sheet metal processing is really important for making things like roofing, siding, and HVAC systems. Bending and rolling shape roofing panels and beams, while cutting techniques like shearing and laser cutting make sure components like ducts and panels are precise. Welding and riveting keep everything solid and stable. Notching is used to make joints for easier assembly, and planishing smooths out surfaces to make architectural features look clean and polished.

Sheet metal processing is super important in the medical and food processing industries! It’s used to make equipment that needs to follow strict hygiene and durability rules. Stainless steel is a popular choice because it won’t rust and is super easy to clean. Laser cutting, bending, and welding are used to make things like surgical instruments, medical device covers, and food machinery. Planishing smooths everything out, making the surfaces easy to clean and ensuring everything complies with health and safety standards.

In the renewable energy sector, sheet metal processing is essential for producing components for solar panels, wind turbines, and energy storage systems. Techniques like stamping and deep drawing create the structural parts, while welding and riveting are used for assembly. Cutting methods like laser and waterjet cutting ensure precision for parts such as frames and brackets. Notching prepares edges for bending and assembly, and planishing enhances the surface finishes, improving both durability and performance.

Surface Treatment of Sheet Metal: Enhancing Performance and Aesthetics

Surface treatment plays a vital role in sheet metal processing by enhancing properties like corrosion resistance, wear resistance, appearance, and adhesion capabilities. The right treatment is selected based on the specific needs of the application, taking into account factors like environmental exposure, mechanical stresses, and aesthetic requirements.

Common Surface Treatment Methods

- Powder Coating

- Process: Electrostatic application of dry powder followed by heat curing.

- Benefits: Provides a durable, uniform, and eco-friendly finish with excellent resistance to scratches, chipping, and fading.

- Applications: Outdoor furniture, machinery, and building materials.

- Electroplating

- Process: Depositing a thin layer of metal onto the sheet metal surface using an electrolytic solution.

- Common Metals Used: Zinc, nickel, and chrome.

- Benefits: Enhances corrosion resistance, wear resistance, and aesthetic appeal.

- Applications: Hardware components, automotive parts, and electronic housings.

- Anodizing (Aluminum Only)

- Process: Electrochemical treatment that forms a protective oxide layer on aluminum surfaces.

- Benefits: Increases corrosion resistance, surface hardness, and allows for dyeing to achieve various colors.

- Applications: Aerospace components, electronic enclosures, and architectural elements.

- Sandblasting

- Process: Propelling abrasive particles at high velocity to clean and roughen the metal surface.

- Benefits: Removes contaminants, rust, and old coatings; prepares the surface for subsequent treatments.

- Applications: Surface preparation before painting or coating applications.

- Galvanization

- Process: Coating steel or iron with a layer of zinc by immersing it in molten zinc.

- Benefits: Provides excellent corrosion protection, especially in outdoor and marine environments.

- Applications: Structural steel, utility poles, and guardrails.

- Laser Texturing

- Process: Using a laser beam to create micro- or nano-scale textures on the metal surface.

- Benefits: Enhances surface properties such as adhesion, wettability, and friction.

- Applications: Preparation for bonding or coating applications.

- Shot Peening

- Process: Bombarding the metal surface with small spherical media to induce compressive residual stress.

- Benefits: Improves fatigue strength and resistance to stress corrosion cracking.

- Applications: Automotive components like crankshafts and connecting rods.

Selecting the Appropriate Surface Treatment

The choice of surface treatment should align with the specific requirements of the application:

- Corrosion Resistance: Galvanization, anodizing, and electroplating are effective for environments prone to corrosion.

- Wear Resistance: Shot peening and anodizing enhance surface hardness and wear resistance.

- Aesthetic Considerations: Powder coating and anodizing offer a range of finishes and colors.

- Adhesion Enhancement: Laser texturing and sandblasting improve surface roughness for better adhesion of coatings or paints.

Choosing the right surface treatment and applying it correctly can seriously improve how well sheet metal parts perform, how long they last, and how they look!

Conclusion: Integrating Techniques for Optimal Sheet Metal Fabrication

A holistic approach to sheet metal processing means using different techniques together to make sure the components are high-quality and functional. By customizing the processes to match the needs of industries like aerospace, automotive, and electronics, NOBLE can improve both efficiency and quality. And with advances in automation, robotics, and materials science, sheet metal processing is getting better and better, making manufacturing even more accurate and efficient.

NOBLE – From Design to Mass Production, Always by Your Side!

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

Economical Price & Perfect Quality

We can offer you the lowest price for the same quality. Strictly control the machining and finish treatment quality, and what you will get is what you designed.

Experienced & Capabilities

More than 10 years of professional machining and rapid prototyping experience, providing you with the most professional and effective advice. From prototyping to mass production, NOBLE combines high-quality materials with state-of-the-art technologies to bring products to life.

Fast Lead Time

Not only do we have a digital CNC machining services platform that provides a faster ordering process, but we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engineering support all year round. Our experienced engineer can provide you with the most appropriate solution for your part design, material selection, surface finishing options, and even lead time.