Want to quickly turn your ideas into physical models? Prototyping machining is the preferred approach. You’ll get accurate prototypes to test and refine your designs. We are NOBLE, with years of experience in prototype machining. We are ISO certified and equipped with all the latest tools to bring your models to life. We employ various methods as needed, such as vacuum casting, silicone rubber molds, and rapid tooling. Many industries use these methods for fast model making. These include automotive, medical, aerospace, and robotics.

Prototype Machining Overview

What Is Prototype Machining

Prototype machining lets you make your ideas real. You begin with a digital model on a computer. Special machines then create a real part from this model. This way, you can see and touch your idea before making many copies. People often call this step model manufacturing. It helps you check if your design works in real life.

Prototype machining is useful for many jobs. If you work in cars, medicine, planes, or robots, you need models fast. A prototype supplier like NOBLE can give you these models quickly. You can use a vacuum casting mold, silicone rubber mold, or rapid mold. These tools help you make parts that look and feel like the final product.

Tip: To save time and money, pick a prototype company or provider with lots of experience and the right certifications.

Key Concepts

With prototype machining, you have many options. NOBLE offers CNC machining, 3D printing, vacuum casting, and sheet metal fabrication. Each method has its own good points. For example, a vac-casting mold or silicone rubber mold makes flexible parts. CNC machining gives you strong and exact parts.

NOBLE is a prototype maker in China with ISO 9001 and ISO 13485 certifications. These show the prototype plant follows strict quality rules. You can trust the parts you get. Many companies choose a prototype factory in China for fast service and good prices.

If you want a reliable prototype supplier, NOBLE can help. You get support for every step of model production. You can test your ideas, fix problems early, and get your product to market faster.

Prototype Machining Processes and Methods

When you want to turn your ideas into real parts, you need to know the main methods for prototype machining. Each method has its own strengths. You can choose the best one for your project. Let’s look at the main techniques you can use.

Rapid Vacuum Casting

Rapid vacuum casting uses a vacuum casting mold to make parts quickly. You start with a master model. You place it in a silicone rubber mold. The vacuum pulls liquid material into the mold. This method works well for small batches. You get parts that look and feel like the final product. Many people use this for model manufacturing and model production. If you need flexible or clear parts, this is a good choice.

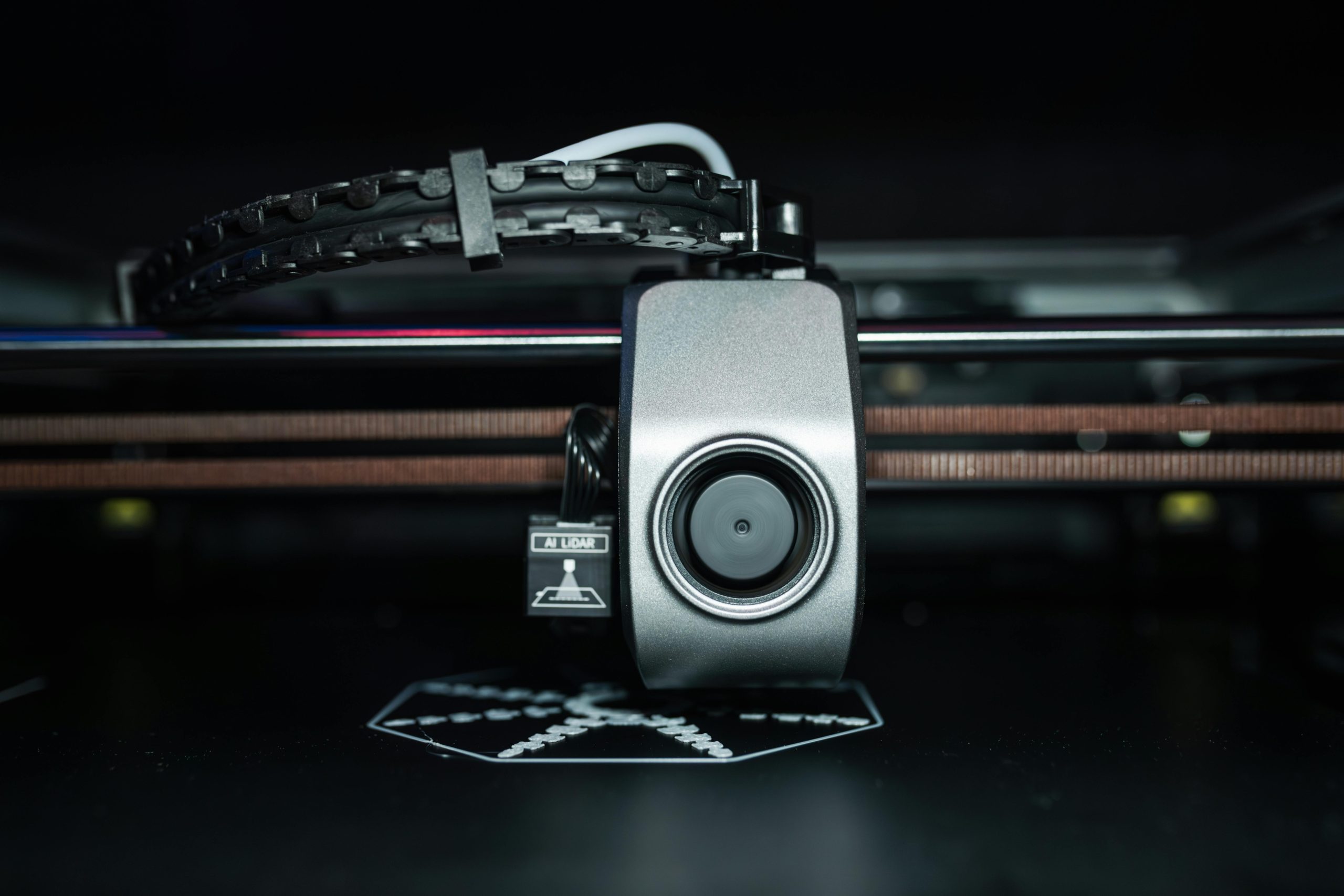

3D Printing Prototyping

3D printing is a fast way to make prototypes. You upload your design to a machine. The printer builds your part layer by layer. You can use many materials, like plastic or metal. This method is great for testing shapes and sizes. You can change your design and print a new part quickly. Many prototype suppliers use 3D printing for early model production.

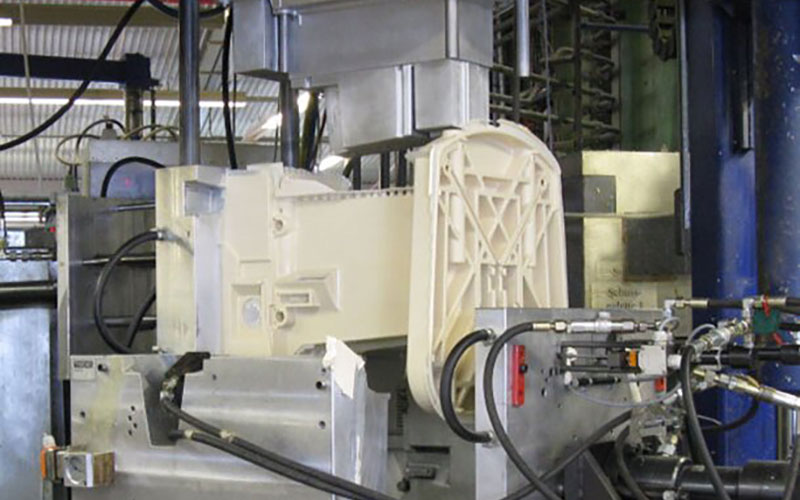

Die Casting Prototyping

Die casting prototyping uses metal molds to make strong parts. You inject molten metal into a rapid mold. The metal cools and hardens. You get parts with high strength and good detail. This method is common in the automotive and aerospace industries. If you need tough parts, die casting is a smart pick.

RIM (Reaction Injection Molding)

RIM stands for Reaction Injection Molding. You mix two liquids and inject them into a mold. The liquids react and form a solid part. RIM works well for large, lightweight parts. You can use it for covers, housings, and panels. Many prototype companies use RIM for special projects.

Equipment Used

You need the right equipment for prototype machining. Here’s a quick look at what you might use:

| Equipment | What It Does | Best For |

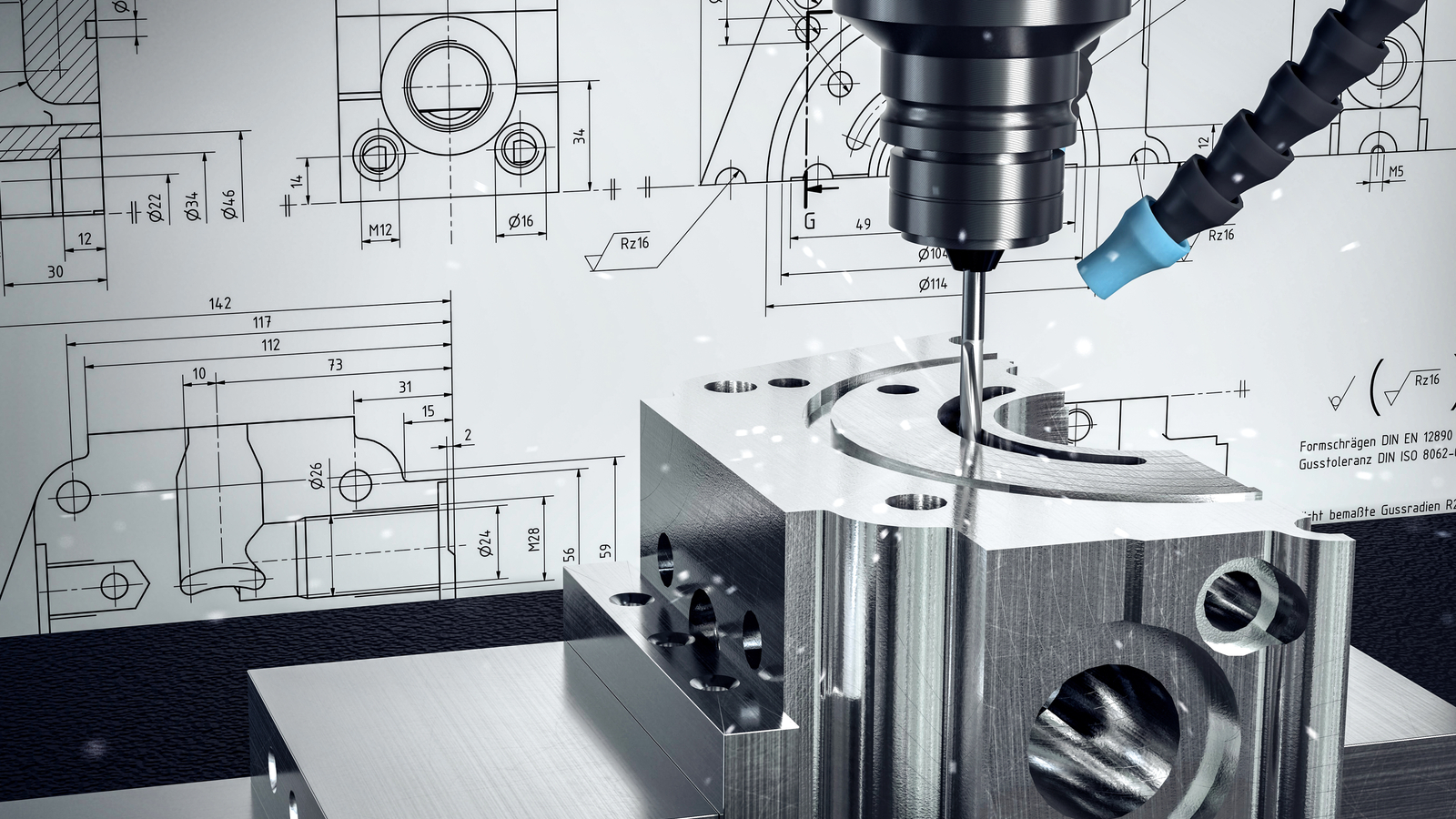

| CNC Machines | Cut and shape metal or plastic | Strong, precise parts |

| 3D Printers | Build parts layer by layer | Fast, flexible prototypes |

| Vacuum Casting Machines | Use a vacuum to fill molds | Small batches, flexible parts |

| Die Casting Machines | Inject metal into molds | Tough, detailed parts |

| RIM Machines | Mix and mold liquid materials | Large, lightweight parts |

A prototype factory in China, like NOBLE, uses advanced machines. You get high precision, often up to ±0.0003 inches. The prototype plant can handle many materials and finishes.

Workflow Steps

You want your prototype fast and easy. NOBLE makes the process simple. Here are the four steps you follow:

- Upload Your Design

You send your design files to the prototype provider. You can use CAD files or drawings. - Design Analysis and Quote

The team checks your design. You get feedback and a price quote. You can ask questions and make changes. - Manufacturing

The prototype manufacturer in China starts model production. They use the best method for your part, like a vac-casting mold or silicone rubber mold. - Delivery

You get your finished parts delivered to your door. The turnaround is fast, often within 7 days.

Tip: If you need help, NOBLE’s engineers are ready to support you 24/7. You get answers and advice at every step.

You can trust a prototype supplier like NOBLE for quick service and high quality. You save time and money. You get parts that match your needs.

Benefits of Prototype Machining

Precision and Speed

You want your parts to be exact and finished quickly. Prototype machining gives you both things. If you use a CNC machine or a 3D printer, your parts are very accurate. A prototype factory in China, like NOBLE, can make parts with precision up to ±0.0003 inches. This keeps your model manufacturing process on track. You do not need to wait a long time for your parts. You can finish your model production in just 7 days. This speed helps you test ideas fast and keep your project moving.

Tip: Getting parts quickly helps you find design problems early. You can fix them before making lots of products.

Cost-Effectiveness

Saving money is important for every project. Prototype machining helps you spend less in many ways. You do not have to buy expensive tools or molds for small batches. With a vacuum casting mold, a vacuum casting mold, and rapid mold, you can make a few parts without spending too much. NOBLE helps clients save up to 30% compared to old methods. You can test your design, change it, and avoid big mistakes later. This way, you keep your budget safe and your project on time.

Material Options

You have lots of choices for materials. Prototype machining works with plastics, metals, and flexible materials. If you need a clear or soft part, you can use a silicone rubber mold. For strong and detailed parts, you can pick metal or hard plastic. NOBLE offers many finishes, too. You can see how your product looks and feels before making many copies. This flexibility helps you choose the best final product.

Here’s a quick look at some material options:

| Material Type | Best For | Example Method |

| Plastics | Lightweight, flexible parts | 3D Printing, Vacuum Casting Mold |

| Metals | Strong, durable parts | CNC Machining, Die Casting |

| Silicone Rubber | Soft, flexible, clear parts | Silicone Rubber Mold |

NOBLE’s Expertise

When you pick NOBLE, you get more than a prototype supplier. You get a partner with over 12 years of experience in model manufacturing and model production. NOBLE is a top prototype manufacturer in China. The team uses advanced equipment in their prototype plant for high-quality results.

You can count on NOBLE for:

- 24/7 engineering support, so you always get help.

- A strong supply chain that keeps your project moving.

- Special skills in vacuum casting mold, rapid mold, and silicone rubber mold.

- The ability to do both prototype manufacturing and mass production well.

NOBLE is a reliable prototype provider and prototype company. You get expert advice, fast service, and parts that fit your needs.

Benefits of Prototype Machining

Let’s sum up why prototype machining is a smart choice for your project:

- Accuracy: Your parts match your design, so you can trust your tests.

- Fast Turnaround: You go from idea to part in days, not weeks.

- Cost Savings: You avoid big costs and save up to 30% on your project.

- Material Flexibility: You can try different materials and finishes to find what works best.

- Support: You get expert help and a strong supply chain at every step.

Prototype machining lets you check your design, test how it works, and find problems early. You can make changes before starting mass production. This process helps you avoid big mistakes and get your product to market faster.

Note: Working with a trusted prototype supplier like NOBLE gives you peace of mind. You know your parts will be right every time.

Applications of Prototype Machining

Medical Devices

There are many new ideas in medicine. Doctors and engineers want safe tools. Prototype machining helps test designs quickly. You can use a vacuum casting mold or silicone rubber mold for small batches. These parts help check if a device works before making thousands. NOBLE is a prototype supplier and provider for medical companies. You get models for testing, like surgical tools or device housings. A prototype factory in China, like NOBLE, follows strict quality rules. You can trust the parts for model manufacturing and model production.

Tip: Fast prototypes help you find problems early. You can fix them before spending more money.

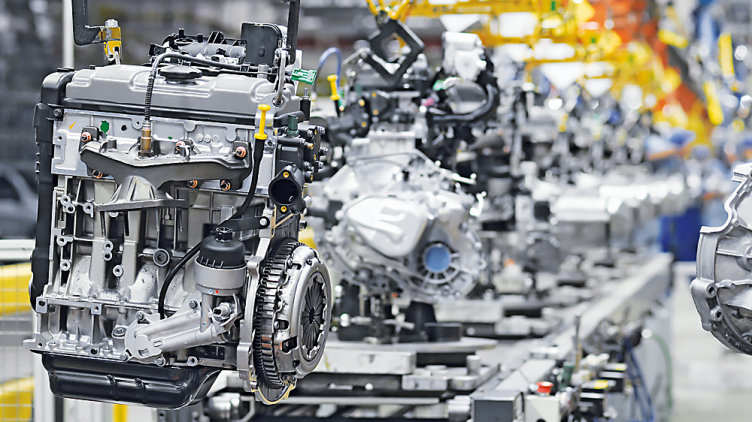

Automotive

Cars need to be safe and look nice. Prototype machining lets you try new shapes and features. You can use a rapid mold or vacuum casting mold to make car parts for testing. NOBLE is a top prototype manufacturer in China. They help make dashboards, handles, or engine covers. You can use strong materials with CNC machines. You can also test flexible parts with a silicone rubber mold. The prototype plant can make a few parts or a small batch. This way, you see how your design works in real life. You save time and money before big model production starts.

Other Industries

Many other fields use prototype machining. Aerospace needs light and strong parts. Robotics needs custom shapes and quick changes. Consumer electronics companies want to see how a new gadget feels. NOBLE is a trusted prototype company with advanced tools in its factory in China. You can pick from many materials and finishes. The team uses vacuum casting molds, rapid molds, and more. You get support from design to delivery. This makes model manufacturing smooth and fast.

Note: NOBLE’s experience as a prototype supplier covers many industries. You get expert help for every project.

Challenges and Comparisons in Prototype Machining

Common Challenges

You may run into some problems with prototype machining. Sometimes, you want a special material, but not every method works for it. For example, a vacuum casting mold or silicone rubber mold is best for some plastics or rubbers. If you need metal, you might need CNC machining or a rapid mold instead. Cost can be a problem if you need lots of changes or many parts. Some projects get bigger fast, so you need to plan for more model production. A prototype factory in China, like NOBLE, can help you solve these problems. You get advice on the best method, whether you use a vac-casting mold or something else.

Tip: Talk to your prototype supplier early. This helps you avoid problems and pick the best way for model manufacturing.

Limitations

Prototype machining is quick and flexible, but it has limits. Some shapes are hard to make with some tools. For example, a silicone rubber mold may not show tiny details as well as a CNC machine. Big parts may need special equipment at the prototype plant. You also need to think about how many parts you want. Small batches work well, but making lots may need another way. Your prototype provider can help you choose what works best for your project.

Comparison with Other Methods

You have different ways to make prototypes. Here’s a simple table to show how prototype machining compares to 3D printing and injection molding:

| Method | Best For | Speed | Cost | Material Options |

| Prototype Machining | Precise, strong parts | Fast | Moderate | Many |

| 3D Printing | Complex shapes | Very Fast | Low | Limited |

| Injection Molding | Mass production | Slow setup | High | Many |

A prototype company like NOBLE helps you pick the right method. If you want a few strong parts, prototype machining is a good choice. For quick samples, 3D printing is great. If you need thousands, injection molding is best. Always ask your prototype manufacturer in China for advice. The right prototype supplier or prototype provider makes model manufacturing and model production easy.

Note: Choosing a trusted prototype factory in China saves you time and money. You get expert help at every step.

Choose NOBLE for The Best Prototype Machining

If you want great results, you need a partner you trust. NOBLE is a top prototype supplier and prototype provider. You get more than parts. The team wants you to succeed.

NOBLE has worked as a prototype manufacturer in China for over 12 years. You can trust their skills in model manufacturing and model production. Their prototype plant uses advanced equipment. You always get high-quality parts.

Here are reasons to pick NOBLE:

- Fast Turnaround: You get prototypes quickly. The team often delivers in 7 days.

- Precision: Your parts have tight tolerances, up to ±0.0003 inches.

- Material Choices: You can choose many materials and finishes. Try a vacuum casting mold, vac-casting mold, or silicone rubber mold for your needs.

- Expert Support: You get help from engineers at any time. They know rapid mold and other methods.

- Cost Savings: You save up to 30% compared to other choices.

Tip: NOBLE’s strong supply chain keeps your project moving. You avoid delays and surprises.

You can trust a prototype company like NOBLE for every step. The team helps you pick the right method. You get advice on using a prototype factory in China for your project.

Here is a table showing what NOBLE gives you:

| Feature | What You Get |

| Experience | 12+ years in the industry |

| Services | CNC, vacuum casting, 3D printing, sheet metal |

| Support | 24/7 engineering help |

| Quality | ISO 9001 & ISO 13485 certified |

Are you ready to make your ideas real? Pick NOBLE as your prototype supplier and see the difference!

You want your ideas to turn into real products quickly. Prototype machining lets you test your designs and save money. You can also pick the best materials for your parts. NOBLE is a trusted prototype supplier and manufacturer in China. Their team helps you from design to delivery at their advanced plant. If you need a vacuum casting mold, a rapid mold, or a silicone rubber mold, NOBLE can help. Contact them today to see how easy model manufacturing and model production can be with a top prototype company.

Prototype Machining of FAQs

What is the difference between a vacuum casting mold and a silicone rubber mold?

A vacuum casting mold uses vacuum pressure to fill the mold. This helps make parts with lots of details. A silicone rubber mold is soft and bends easily. It is good for making soft or see-through parts. Both types help you make models and test your ideas.

How fast can I get my prototype from a prototype factory in China?

You can get your prototype in about 7 days. A prototype supplier like NOBLE works fast. You can test your ideas and keep your project moving.

Can I use different materials for my prototype?

Yes! You can choose plastics, metals, or silicone rubber. A prototype provider or company gives you many choices. You can try what works best for your model.

Why should I choose a prototype manufacturer in China?

You get good parts, fast service, and fair prices. A prototype manufacturer in China, like NOBLE, uses new machines in their plant. You also get help from design to delivery.

What is a rapid mold, and when should I use it?

A rapid mold helps you make parts fast for testing. Use it when you need a few samples before making many. It saves time and money when making models.

Tip: Always ask your prototype supplier which way is best for your project!