What is Titanium CNC Machining?

Titanium metal CNC machining is a manufacturing process that uses computer numerical control machine tools to precisely cut and form titanium metal. In simple terms, titanium CNC machining is to control the cutting tools of large machine tools through pre-programmed computer software to gradually remove material from a solid titanium metal block, and ultimately manufacture high-precision complex parts.

The process of machining titanium is particularly challenging because titanium is renowned for its high strength, light weight, and excellent corrosion resistance, but titanium is also very hard and has poor thermal conductivity, which can easily lead to rapid tool wear and excessive heat generation during machining. Therefore, successfully conducting CNC machining of titanium metal requires professional equipment, specific tool knowledge, optimized cutting parameters, and rich experience.

How Does Titanium CNC Machining Work?

Titanium CNC machining is a highly automated and precise subtractive manufacturing process. Essentially, CNC machine is a computer-controlled machine that gradually processes a solid piece of titanium metal raw material into a designed three-dimensional shape part through cutting.

The workflow of titanium CNC machining can be summarized into the following core steps:

- Digital design: The entire process begins with a three-dimensional digital model of a part created using CAD software.

- Program programming: Engineers use CAM software to convert this 3D model into a machining program that the CNC machine can understand. This program precisely plans all parameters such as tool path, spindle speed, feed rate, and cutting depth, which is crucial for machining hard titanium metal.

- Preparatory work: On the machine tool, the operator needs to firmly clamp the titanium metal blank and install the appropriate special cutting tool. Because titanium is flammable and sensitive to heat, a high-pressure coolant system must be prepared.

- Precision machining: After starting the program, the CNC machine tool will operate automatically according to the instructions. While rotating at high speed, the cutting tool moves along the preset path, constantly removing tiny metal chips from the titanium billet. The entire process may involve the use of various cutting tools for rough machining, semi-finishing, and finishing to achieve the final dimensions and surface finish.

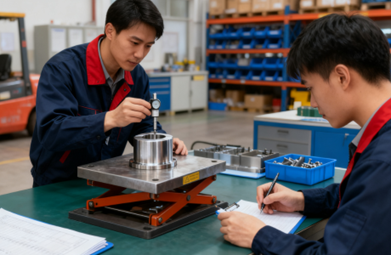

- Post-processing and inspection: After machining is completed, the parts will be removed and undergo necessary post-processing, such as deburring, polishing, heat treatment or cleaning. Finally, the parts are strictly inspected using precision measuring tools to ensure that they fully comply with the specification requirements of the design drawings.

Why is Titanium So Difficult to Machine?

The difficulty in machining titanium metal mainly stems from the combined effect of several of its own outstanding physical and chemical properties. These characteristics of titanium are advantages in the final parts, but they bring huge challenges during machining.

The following are several core reasons:

Low Thermal Conductivity

Titanium has a very poor thermal conductivity. The heat generated during the cutting process is difficult to quickly conduct away through the titanium parts themselves or the chips. As a result, the vast majority of the heat is concentrated at the tip of the cutting tool. This leads to extremely high localised temperatures at the tool tip, accelerating wear and dulling.

Work Hardening Tendency

Titanium maintains high strength at high temperatures. But during cutting, its surface undergoes “work hardening.” In this process, the area being cut hardens dramatically due to plastic deformation. This hardened area is far tougher than the base material. As a result, the tool is forced to cut an ever-hardening surface. This generates massive cutting resistance and accelerates tool wear.

Chemical Reactivity

Due to its high chemical reactivity at elevated temperatures, titanium tends to adhere to many cutting tool materials. This adhesion results in the formation of a built-up edge on the tool. Consequently, these unstable deposits periodically break away. When they do, they not only mar the machined surface finish but also tear away fragments of the tool material itself, leading to premature tool failure.

Low Elastic Modulus

Titanium has relatively low rigidity, which means it is prone to “elastic deformation” or giving way under the action of cutting force. This will cause vibration, flutter marks, and make it difficult to maintain a tight tolerance. This problem is particularly prominent when machining thin-walled structures.

Different Types of Titanium Used for CNC Machining

Grade 1 Titanium

- Features: The softest, most malleable, and easiest to process.

- Advantages: Strong corrosion resistance and good formability.

Grade 2 Titanium

- Features: Slightly harder than Grade 1, with higher mechanical strength.

- Advantages: Excellent balance between strength and processability.

Grade 3 Titanium

- Features: Medium strength, harder than Grades 1 and 2.

- Advantages: Excellent corrosion resistance and mechanical properties.

Ti-6Al-4V (Grade 5)

- Features:It accounts for over 50% of the titanium alloy market and has excellent mechanical properties.

- Advantages: High strength, light weight, high temperature resistance, and weldability.

Ti-6Al-4V ELI (Grade 23)

- Features: Low impurities, higher toughness.

- Advantages: Excellent biocompatibility, suitable for the medical industry.

Selecting the Right Cutting Tools for Machining Titanium Alloys

Tool Material

Titanium alloys are strong and prone to work hardening. This demands a tool base with high toughness and impact strength. The goal is to avoid tool chipping.

We must apply a PVD coating. Good choices are titanium, aluminum nitride, or chromium aluminum nitride. This coating serves two key functions. First, it reduces chemical reactions. This stops the titanium from sticking to the tool. Second, it has low thermal conductivity. So, it works as an insulator. More heat is taken away by the chips. This protection keeps the tool base cool and hard, preventing it from softening..

Tool Geometry

The geometry of the cutting tool must facilitate chip removal and reduce cutting resistance. A large helix Angle can ensure that the cutting edge smoothly and gradually cuts into and out of the material, making the cutting process lighter and reducing the squeezing on the machined surface.

A sharp rake Angle can significantly reduce the generation of cutting force and cutting heat. However, in order to balance strength and prevent chipping, the cutting edge itself needs to undergo appropriate micro-rounding or honing treatment, that is, to keep the rake Angle sharp while giving the cutting edge a tiny arc, thereby achieving the best balance between sharpness and durability.

Tool Type

General-purpose channel-type cutting tools are not competent for titanium alloy machining. Priority should be given to series specially designed by tool manufacturers for titanium alloys or superalloys. These cutting tools usually combine optimized geometries and special chip groove types.

The wide and smooth open chip grooves ensure that long and coiled titanium alloy chips can be discharged smoothly and unobstructed.

Effective Cooling

The low thermal conductivity of titanium alloys causes the cutting heat to be highly concentrated at the cutting edge of the tool, so cooling is of vital importance. The machine tool must be equipped with a high-pressure internal cooling system, and the coolant pressure is preferably above 7MPa.

High-pressure coolant can penetrate the cutting zone, effectively reducing the temperature. More importantly, it can break the chips off the cutting edge and carry them away with its powerful impact force, preventing secondary friction between the chips and the tool and workpiece.

Rigorous Process

Titanium alloy machining is extremely sensitive to vibration. Any slight flutter will accelerate tool failure. Therefore, it is necessary to select machine tools with extremely high rigidity and use short and thick tool holders to minimize the tool overhang, so as to maximize the rigidity of the entire system.

At the same time, it is necessary to establish a preventive tool change strategy, changing tools regularly based on time or the quantity of machining, rather than waiting until the tools are completely worn out.

Essential Post-Processing for CNC-Machined Titanium Parts

Deburring

After CNC machining of titanium alloy, tiny, sharp burrs will occur at the edges, holes, and cross-holes of the parts. It must be carefully removed using professional tools.

If burrs remain, they will not only affect the assembly and usage safety of parts, but also, in high-stress aerospace or medical applications, may become metal debris after burrs fall off, causing system failures or inflammation of the tissues around the implant. Therefore, they must be thoroughly cleaned.

Annealing Treatment

CNC machining is a material removal process that disrupts the internal stress balance of the material, resulting in residual stress within the parts. This internal stress will cause the parts to gradually deform after machining or during subsequent use.

Through stress annealing treatment, titanium parts are held at a specific temperature for a sufficient period of time, allowing the internal atoms to rearrange and recover. This can effectively and significantly reduce or eliminate these harmful internal stresses, thereby significantly improving the dimensional stability and long-term reliability of the parts. This is particularly crucial for parts with high-precision requirements.

Sandblasting

Sandblasting treatment uses fine abrasive particles sprayed at high speed to impact the surface of parts. Its main purposes are three:

- To remove tool marks, scratches, and other minor surface defects left during the machining, making the appearance more uniform.

- To obtain a uniform matte or non-glossy surface texture, improving the aesthetic appeal and touch.

- It can provide a cleaner substrate with specific activity and roughness before subsequent anodizing or coating treatment, thereby enhancing the adhesion of the coating. This is an important process that bridges the previous and subsequent steps.

Polishing

For parts with high surface finish requirements, such as medical implants or components in contact with fluids, mechanical polishing or grinding is necessary.

Polishing uses gradually refined grinding paste or polishing wheels to eliminate micron-level surface unevenness through physical friction, ultimately achieving a mirror-like smooth surface.

An extremely smooth surface can greatly reduce the risk of bacterial adhesion and proliferation, enhance the biocompatibility of medical implants, and also significantly lower fluid flow resistance, thereby improving the efficiency of hydraulic or pneumatic systems.

Anodizing

Anodizing is an electrochemical surface treatment technology that artificially generates a thick and dense oxide film on the surface of titanium parts. This oxide film can greatly enhance the corrosion resistance and surface wear resistance of the parts.

By controlling the thickness of the oxide film, various bright colors can be produced by taking advantage of the interference effect of light. These colors are not only used for product brand identification and aesthetic distinction, but more importantly, the color differences can facilitate rapid quality control and batch management during production.

Cleaning and Packaging

After all the above treatments, abrasive materials, grease or chemical reagents may remain on the surface of the parts. High-purity solvents, deionized water and thorough cleaning must be carried out in an ultra-clean environment to ensure absolute cleanliness.

After cleaning is completed, vacuum packaging or inert gas-protected packaging should be adopted immediately to prevent titanium parts from being contaminated and oxidized by fingerprints, dust, or moisture during transportation and storage, ensuring that the products are delivered to customers in perfect condition.

Common Challenges of Machining Titanium

Tool Wear

Titanium alloys have high strength and can maintain it at high temperatures, which leads to huge cutting resistance. Meanwhile, its extremely poor thermal conductivity means that the large amount of heat generated during the cutting process cannot be quickly conducted away through the workpiece or chips, but is highly concentrated in a very small area of the cutting edge. This high-temperature and high-pressure environment will accelerate the abrasive wear and diffusion wear of the cutting tool, and due to the chemical affinity between titanium and the cutting tool material, it will cause adhesive wear.

Work Hardening

When titanium alloys are mechanically processed, the surface layer material becomes extremely hard due to plastic deformation. This phenomenon is called work hardening.

If, during the cutting process, the tool does not “cut” with a sharp edge but “squeezes” the material, or if the feed rate is too low, causing the tool tip to repeatedly rub against the hardened layer, this phenomenon will be exacerbated. The formed hardened layer will cause great difficulties for subsequent cutting, just like cutting a hard shell, further accelerating tool wear and seriously affecting the integrity and fatigue strength of the machined surface.

Chip Control

Titanium alloy chips are thin, discontinuous, and extremely hot. If not removed quickly, they accumulate near the cutting edge. This leads to secondary friction, generating more heat and creating a vicious cycle. This damages the tool and workpiece, and in extreme cases, the accumulated heat can ignite the titanium, creating a fire hazard—especially with oil-based coolants.

Low Stiffness

Titanium’s low elastic modulus gives it poor rigidity. It easily deforms and vibrates under cutting forces. This is a major issue when machining thin-walled or slender parts. The vibration harms accuracy, creates chatter marks, and causes the workpiece to spring back after cutting. This makes it very hard to hold tight tolerances consistently, placing high demands on both the operator’s skill and the machine tool’s stability.

Material Adhesion

Titanium will undergo chemical reactions and adhere to many tool materials at high temperatures. This will cause the titanium material to “cold weld” onto the cutting edge, forming a built-up edge.

Built-up edge is usually unstable and will fall off periodically. When it exists, it will change the actual geometric Angle of the tool and affect the cutting process. When it falls off, it often takes away the coating on the surface of the cutting tool and even the base material, causing the tool to break and leaving defects on the machined surface, which seriously affects the surface quality.

How to Reduce the Cost of Your Titanium CNC Machining Project

Optimize Design

Use rounded corners instead of sharp ones to maintain cutting speed and reduce machining time. Avoid deep cavities, as they require weak, long tools that lead to vibration and necessitate multiple slow passes. Also, relax tolerances on non-critical features, since tighter specs demand more expensive processes and exponentially increase cost. A simple design change can save significant time and money.

Select Materials Wisely

Under the premise of meeting the performance requirements, select the most economical titanium alloy grade. For instance, if it is not a load-bearing structural component, industrial pure titanium with a lower price can be considered for use.

At the same time, try to select the blank material that is closest in shape and size to the final part to minimize the amount of allowance that needs to be removed.

Maximize Machining Efficiency

Using advanced CAM software and adopting efficient tool path strategies, such as dynamic milling, it allows for greater cutting depth and higher feed rates by maintaining a constant tool load and continuous feed, thereby significantly reducing machining time.

Plan the machining sequence reasonably and reduce the number of clamping times, as each re-clamping will increase the time and error. Under the premise of ensuring quality, it is advisable to use tools with larger diameters for rough machining as much as possible to quickly remove the material.

Choose a Reliable Supplier

It is crucial to choose a partner specializing in titanium alloy machining. Although their unit price may not be the lowest, their professional craftsmanship, optimized parameters, suitable cutting tools, and rich experience can fundamentally avoid hidden costs such as frequent tool damage, workpiece scrapping, and machine tool shutdown.

As a professional partner, NOBLE can reduce your total cost of ownership through high success rates, high efficiency, and high-quality yield rates.

Plan Batches Smartly

The cost of producing a single part at one time is much higher than that of mass production. If possible, combining multiple identical parts for production or machining different small parts on a single sheet can significantly spread out fixed costs such as programming, clamping, and equipment preparation time.

Ensure Strict QC

Before the project commences, clarify the key features, testing methods, and acceptance criteria with the processor. This can prevent rework or disputes caused by misunderstandings in the later stage.

The loss of a titanium alloy part that is scrapped in the final stage of machining is not only the raw material, but also all the machining hours and equipment resources previously invested.

Applications of Titanium CNC Machining

Aerospace

Aerospace is the field where titanium CNC is most widely applied and has the highest requirements. Titanium alloys are used to manufacture key components of aircraft engines, such as fan blades, compressor discs and blades, as well as fuselage structural parts, such as landing gear struts and wing connectors. These parts must maintain extremely high reliability and service life under extreme temperatures, high stress, and corrosive environments.

Medical

Titanium has become the preferred material for surgical implants due to its excellent biocompatibility and resistance to body fluid corrosion.

CNC machining is used to manufacture artificial joints, bone plates, bone screws, dental implants, and surgical instruments. These parts have extremely high requirements for surface finish, precision, and sterility.

High-Performance Automotive

In racing cars and high-performance sports cars, weight reduction is the key to enhancing speed and efficiency.

Titanium CNC parts are used to manufacture engine connecting rods, valves, suspension components and exhaust systems. They can withstand extremely high rotational speeds and temperatures while significantly reducing unsprung mass and enhancing handling.

Defense

The application of titanium in this field is similar to that in aerospace, but it places more emphasis on its survivability and reliability in extreme environments.

Titanium CNC parts are used to manufacture armored vehicles, naval vessels, missiles, rockets, as well as lightweight equipment and weapon systems carried by soldiers.

Premium Consumer Goods

In pursuit of ultimate lightweight and performance, some high-end products also adopt titanium CNC machining. For instance, high-end bicycle frames and components, golf club heads, mountaineering equipment, high-end watch cases, and high-end spectacle frames etc.

NOBLE’s Titanium CNC Machining Service

When your project demands the exceptional properties of titanium, you need a machining partner with proven expertise. NOBLE delivers precisely that. Our titanium CNC machining services are built on a foundation of:

- Advanced Capabilities: We utilize state-of-the-art 5-axis CNC mills and lathes, capable of creating complex geometries with tight tolerances.

- Technical Excellence: Our proprietary machining parameters and specialized tooling strategies directly address titanium’s low thermal conductivity, preventing work hardening and ensuring superior tool life and part quality.

- Rigorous Quality Assurance: Every component is meticulously inspected to ensure it meets your exact specifications and the stringent demands of your industry.

Let us become your trusted source for reliable, high-performance titanium components.

FAQs

What are the biggest challenges of CNC machining titanium?

Titanium is known for being difficult to machine, primarily due to its low thermal conductivity, high chemical reactivity, and strength at high temperatures. These properties cause heat to concentrate on the cutting tool edge instead of being carried away by the chips.

What is the best CNC machine for machining titanium?

The “best” machine depends on the part, but ideal machines share key characteristics. A rigid, high-torque machining center is essential to handle titanium’s strength and resist vibration. For complex parts, a 5-axis CNC machine is highly recommended as it allows for better tool access and can reduce the need for multiple setups.

Which cutting tools are recommended for titanium alloys?

Carbide tools are the standard for titanium machining. Specifically, micro-grain or sub-micro-grain carbide provides an optimal balance of hardness and toughness.

What are the most common titanium alloys used in CNC machining?

The two most common grades are Grade 5 (Ti-6Al-4V) and Grade 2 (Commercially Pure Titanium).

How does the cost of machining titanium compare to aluminum or steel?

Machining titanium is significantly more expensive than machining aluminum or steel. The cost premium can be 3 to 10 times higher than aluminum and 2 to 5 times higher than steel.