What is Low-Pressure Injection Molding?

Low-pressure injection molding is a plastic machining technology that utilizes a relatively low pressure to inject molten hot melt adhesive material into the mold, wrapping and protecting the internal components.

Compared with traditional injection molding, low-pressure injection molding has lower pressure and temperature, and is mainly suitable for the packaging of precision and sensitive electronic components or medical devices.

The advantages of low-pressure injection molding include reducing the risk of component damage, enhancing sealing performance and protective effects, as well as having a short machining cycle and lower energy consumption.

Material Used in Low-Pressure Injection Molding

PA

Polyamide (PA), particularly the PA12 series, is the most commonly used material for low-pressure injection molding. It is refined from bio-based castor oil.

This material has a key advantage: its melt viscosity is extremely low. When heated, it becomes as thin as water. This gives it excellent flowability.

As a result, it can fill the finest details of a mold with very little pressure. It also perfectly encapsulates delicate parts without moving them.

- Excellent mechanical strength

- Good heat resistance

- Outstanding resistance to chemical corrosion

TPU

The application of TPU in low-pressure injection molding mainly benefits from its outstanding elasticity, wear resistance, and low-temperature resistance.

Compared with polyamide, TPU can provide a more flexible encapsulation body and is often used in components that need to be frequently bent or subjected to mechanical stress, such as cable connectors and flexible circuits in wearable devices.

TPU has excellent impact resistance and shock absorption effects, and its surface feels more delicate with a certain degree of adhesion.

- Excellent waterproof sealing performance

- High coefficient of friction

- Good impact resistance effect

Polyolefin copolymers

Polyolefin copolymers are hot-melt adhesives modified from polyethylene or polypropylene. Their most notable features are high cost-effectiveness, as well as excellent electrical insulation performance and hydrolysis resistance.

Polyolefin materials have a wide range of hardness after curing, from semi-rigid to flexible, but their overall temperature resistance grade and bonding strength are usually not as good as those of polyamide and TPU.

- Good electrical insulation performance

- Good hydrolysis resistance

How does Low-Pressure Injection Molding Work?

Raw Material Pre-treatment

The special polyamide (PA) or hot melt granules used in low-pressure injection molding are highly sensitive to moisture and must undergo strict drying treatment before being put into production. Usually, the rubber granules are placed in a dehumidifying dryer and baked at a specific temperature for several hours to remove trace amounts of moisture.

Note:

- Strictly control the drying temperature and time

- Keep the raw materials in a closed storage bucket to prevent moisture absorption and recontamination

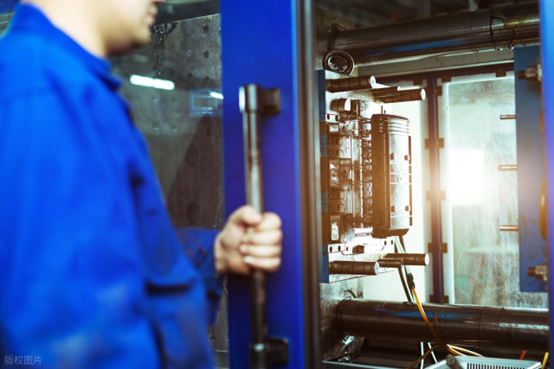

Insert Fixing

Inserts and mold preparation are key steps. First, delicate electronic parts like PCBs and sensors are placed and secured in the lower mold. Fixtures can be automated or manual. Then, the upper mold is closed and clamped shut. This strong clamping force keeps the mold sealed during injection, preventing material from leaking out.

Note:

- Ensure that the inserts are precisely and firmly positioned

- The surface of the mold must be clean and free of residues to ensure the adhesion effect.

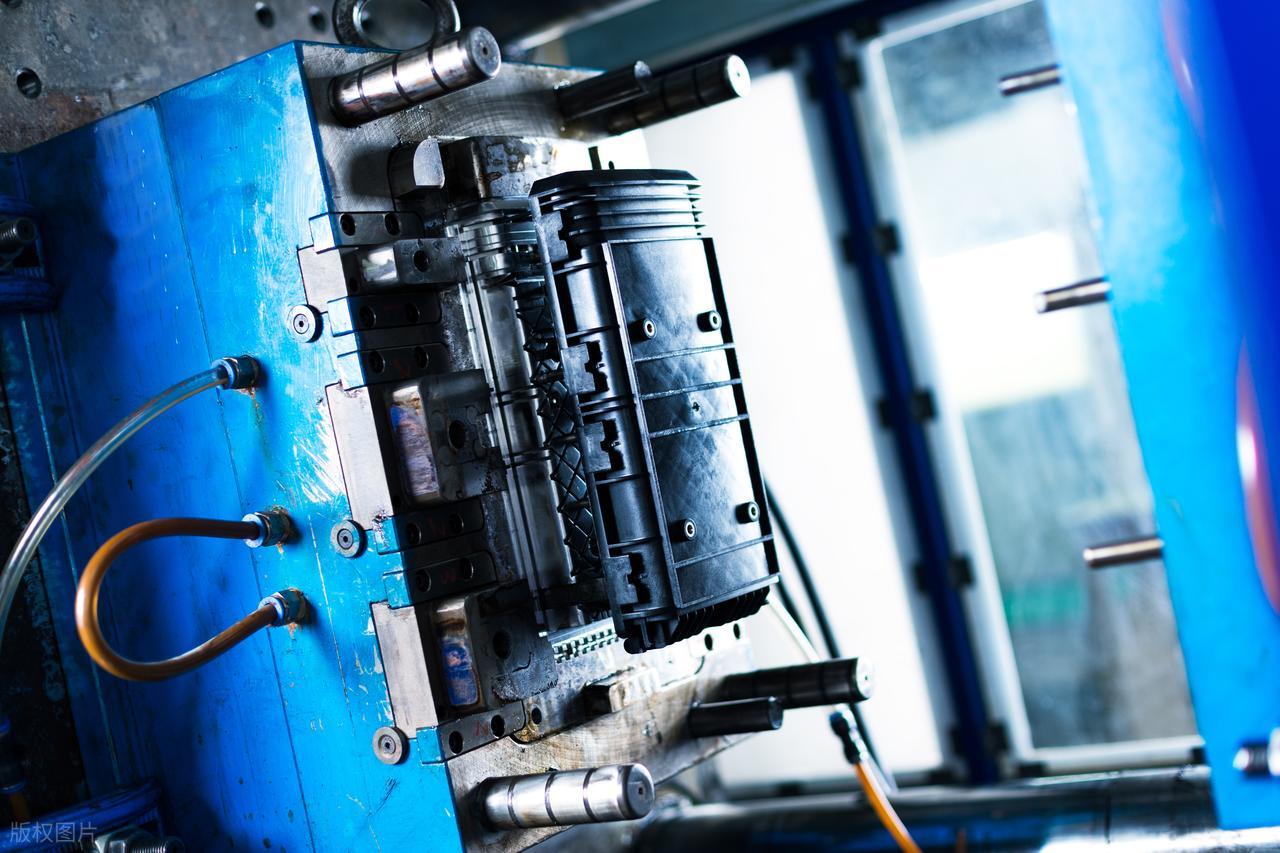

Melt Injection

While the mold is being prepared, the dried plastic pellets are sent into the barrel of the injection molding machine. The barrel heats the material above its melting point through a precisely controlled heater, transforming it into a molten state with extremely low viscosity.

The injection molding machine slowly and steadily injects this molten rubber compound into the closed mold cavity at a very low pressure through a screw or piston.

Note:

- Control the injection temperature and speed

- Ensure the smooth flow path

Holding Pressure

After the mold cavity is filled, the system enters the pressure-holding stage. A lower pressure is continuously applied. This pressure pushes more material in to compensate for shrinkage as the plastic cools. This ensures the final part has accurate dimensions, a smooth surface, and is tightly bonded to any internal components.

Next, the part cools inside the mold. It can cool naturally or be cooled faster by water channels in the mold itself. Cooling continues until the part is solid and strong enough to be ejected without damage.

Note:

- The pressure-holding time should be moderate

- Uniform cooling rate

- Precisely adjust the local temperature

Ejection

Once it is confirmed that the part has cooled and solidified, the injection molding machine will move the template to open the mold. Immediately after, the built-in ejection system of the mold, such as the ejector pin or the top plate, will act and smoothly push the already formed package out of the mold cavity.

Note:

- Maintain a certain mold opening speed

- Balance the force on the ejection device

- Check in time whether there is any sticking to the mold or poor demolding

Inspection

The protruding parts may also have a small amount of auxiliary structures, such as gates or tiny spouts, which usually need to be removed by hand or with simple fixtures.

Afterwards, a comprehensive inspection of the finished products is required to check if their appearance is intact, if the packaging is complete, and if there are any defects, such as missing materials or bubbles, to ensure that the quality of each product meets the requirements.

Note:

- Remove the residual material or flash in the flow channel

- Check the appearance and functions of the product

- Conduct waterproof, dustproof, or electrical performance tests on packaged products

Benefits of Low-Pressure Injection Molding

Superior Component Protection

The core feature of low-pressure injection molding is the use of extremely low injection pressure, which ensures that when packaging fragile components such as printed circuit boards, sensors, and precision connectors, the components will not shift, deform or be damaged due to the impact of high pressure.

The materials used in low-pressure injection molding can form a tough shell after curing, endowing the product with excellent water resistance, dust resistance, and chemical corrosion resistance, and comprehensively enhancing the reliability and service life of the product in harsh environments.

High Process Efficiency

The low-pressure injection molding process is extremely rapid. The entire cycle from mold closing, injection molding, to cooling and demolding usually only takes a few dozen seconds, which is much faster than the traditional potting or shell assembly methods.

The high efficiency of low-pressure injection molding is highly suitable for large-scale continuous production, which can greatly increase production capacity and meet the strict requirements of modern manufacturing for production efficiency, thereby helping enterprises reduce production costs per unit of time.

High Structural Integration

Low-pressure injection molding can combine multiple separate parts—like circuit boards, connectors, and cables—into one solid piece in a single step. This replaces the traditional, more complex method of first making a housing and then assembling and sealing it.

Low-pressure injection molding reduces both production steps and the number of parts needed. It also avoids potential assembly errors and simplifies supply chain and inventory management..

Excellent Encapsulation Quality

The formed package has excellent sealing and insulation properties, which can effectively prevent the intrusion of moisture and harmful gases, ensuring the long-term stable operation of electronic components.

The material itself possesses high and low temperature resistance, excellent electrical insulation performance, and impact resistance, which enables the final product to easily meet the complex working conditions in fields such as automobiles and industrial equipment.

Outstanding Cost Efficiency

The cost per kilogram of the special rubber compound for low-pressure injection molding may be higher than that of ordinary plastics. However, considering the advantages such as reduced assembly time, lower labor costs, decreased defect rates, and reduced scrap rates brought about by its simplified process, the comprehensive manufacturing cost of the product is often effectively controlled.

Challenges of Low-Pressure Injection Molding

Strict Material Requirements

Hot melt adhesives for low-pressure molding easily absorb moisture from the air. This absorbed moisture causes hydrolysis during processing, which breaks down the material’s molecules.

This leads to changes in viscosity and defects like bubbles, silver streaks, or burns in the final product. More seriously, it damages the part’s sealing ability, strength, and electrical insulation.

Therefore, strict storage and drying procedures are essential. Material must be thoroughly dried before use and kept dry during production to prevent moisture reabsorption.

Challenging Mold Design

The melt viscosity and fluidity of low-pressure injection molding are low, and the injection pressure is also low.

- Precision Fit: The mold must be precisely machined and tightly sealed. This prevents the fluid material from leaking and creating flash on the part.

- Efficient Venting: The mold needs a well-designed exhaust system. Otherwise, trapped air can cause short shots (unfilled areas) or burnt material.

- Optimized Flow: The runner and gate must guide the melt to fill the cavity evenly and calmly. This avoids damaging delicate internal components.

Precise Insert Positioning

During the injection molding process, the flow of the melt exerts a certain force on the insert. If the inserts are not precisely positioned or firmly fixed in the mold, they may float, shift, or deform under pressure, resulting in substandard final products. This requires that the mold must be designed with precise positioning mechanisms and reliable fixing devices, and ensure that the inserts are placed correctly in each production cycle.

High Initial Cost

Stable low-pressure injection molding demands a dedicated setup, including specialized machines, high-precision molds, and auxiliary drying equipment, leading to a higher initial cost than traditional processes.

Furthermore, suitable materials are limited to specific polyamides and TPU that offer low viscosity and rapid curing. These materials are more costly and less diverse than conventional plastics, somewhat restricting the technology’s application scope.

Low-Pressure Injection Molding and High-Pressure Injection Molding

| Item | Low-Pressure Injection Molding | High-Pressure Injection Molding |

| Injection Pressure | Low pressure (approx. 2–5 MPa) | High pressure (typically 50–150 MPa) |

| Main Materials | Hot-melt polyamide (PA), EVA, polyolefin, TPU, etc. | Various thermoplastics such as ABS, PC, PP, PE, PA, POM, etc. |

| Mold Structure | Simple structure; aluminum or soft molds can be used | Complex steel molds with long service life |

| Mold Cost | Low cost and short fabrication cycle | High cost and long fabrication cycle |

| Pressure Impact on Inserts | Gentle on inserts and internal components | High pressure may deform or stress inserts |

Applications of Low-Pressure Injection Molding

Automotive Electronics

- Engine Control Units

- Wheel Speed Sensors in Anti-lock Braking Systems

- Airbag Sensors

In the automotive field, low-pressure injection molding is widely used for packaging various electronic control units and sensors. These components of a car need to maintain high reliability in extreme environments such as vibration, oil stains, high temperature and humidity, and chemical corrosion.

Low-pressure injection molding technology can provide a strong and sealed protective shell for automotive components, effectively preventing the intrusion of moisture, salt spray, and gasoline, ensuring the long-term stable operation of the vehicle’s key electronic systems, and greatly enhancing driving safety.

Consumer Electronics

Consumer electronics are one of the main application fields for low-pressure injection molding, especially for protecting core precision components.

The internal parts of electronic products are fragile and require a high level of cleanliness. Low-pressure injection molding allows these components to be safely sealed under very low pressure, avoiding any damage during the process. The protective layer formed can effectively resist sweat, dust, and small impacts during daily use.

Medical Devices

The medical industry has extremely high requirements for the reliability, sealing performance, and biocompatibility of equipment.

The encapsulation formed by this process provides complete sealing. It can resist repeated cleaning with chemical disinfectants and endure high-temperature and high-pressure sterilization. This helps prevent liquids and bacteria from entering the inside of the equipment.

The materials used must pass strict medical certifications to ensure they are safe and non-toxic to the human body.

- Circuit boards and sensors in endoscopes

- Hearing AIDS

- Portable diagnostic devices

Industrial Sensors

In the field of industrial automation, a large number of sensors, proximity switches, encoders, and PLC connectors need to operate in factory environments with high dust, humidity, corrosive gases, or strong mechanical vibrations.

Low-pressure injection molding can provide comprehensive protection for these industrial-grade components. Its robust packaging body can resist physical shock and vibration, and its excellent sealing performance prevents dust and moisture from damaging the internal precision circuits.

Smart Home Devices

- Smart door locks

- Environmental sensors

- Smart water meters/electricity meters

With the popularization of the Internet of Things, more and more smart devices have entered households and cities. These devices are often in unattended outdoor or semi-outdoor environments.

Low-pressure injection molding technology is used to protect its core control module and communication module, effectively coping with the influence of natural aging, such as temperature differences throughout the four seasons, rain, and ultraviolet rays.

This integrated packaging method not only enhances the environmental tolerance of the product but also makes its structure more compact and durable, making it highly suitable for large-scale deployment of Internet of Things terminal devices.

NOBLE: Professional Low-pressure Injection Molding Service Provider

At NOBLE, we specialize in Low Pressure Injection Molding (LPM) — a proven process for encapsulating and protecting delicate electronic components. With advanced equipment, professional engineering expertise, and strict quality control, we deliver reliable molding solutions that ensure both functional protection and aesthetic excellence.

Why Choose Us

- Over 10 years of experience in precision molding manufacturing

- Customized solutions for small or medium batch production

- Fast lead times and flexible project support

- Compliance with RoHS, REACH, and ISO 9001 quality standards

With our Low Pressure Injection Molding expertise, we help customers achieve superior protection, cleaner product designs, and longer service life for electronic components.

FAQs of Pressure Injection Molding

What is Low-Pressure Injection Molding?

Low-Pressure Injection Molding (LPM) is a process that uses low-pressure hot-melt materials to encapsulate and protect delicate electronic components. It provides excellent sealing, insulation, and mechanical protection without damaging sensitive parts.

What materials are used in Low-Pressure Injection Molding?

Common materials include hot-melt polyamides (PA), EVA, polyolefins, and TPU. These materials have low melting points, good adhesion, and excellent resistance to water, chemicals, and temperature changes.

What are the advantages of Low-Pressure Injection Molding?

LPM offers many benefits: gentle processing for sensitive components, superior sealing and waterproofing, simplified product design, and reduced overall manufacturing cost compared to potting or high-pressure molding.

What industries use Low-Pressure Injection Molding?

It is widely used in automotive electronics, consumer electronics, medical devices, industrial sensors, and smart home products, especially where durability and protection are critical.

How does Low-Pressure Injection Molding differ from High-Pressure Injection Molding?

LPM operates at much lower pressure (2–5 MPa) and temperature, focusing on protection and sealing rather than structural strength. High-pressure molding is used for producing rigid plastic parts with precise shapes in mass production.