Design plays a key role in achieving high-quality aluminum die casting results. Working with experts and applying design for manufacturing (DFM) early can improve quality, reduce costs, and accelerate production. NOBLE offers a strong advantage in this area. Their team provides a free DFM analysis. Use these insights to enhance your next project.

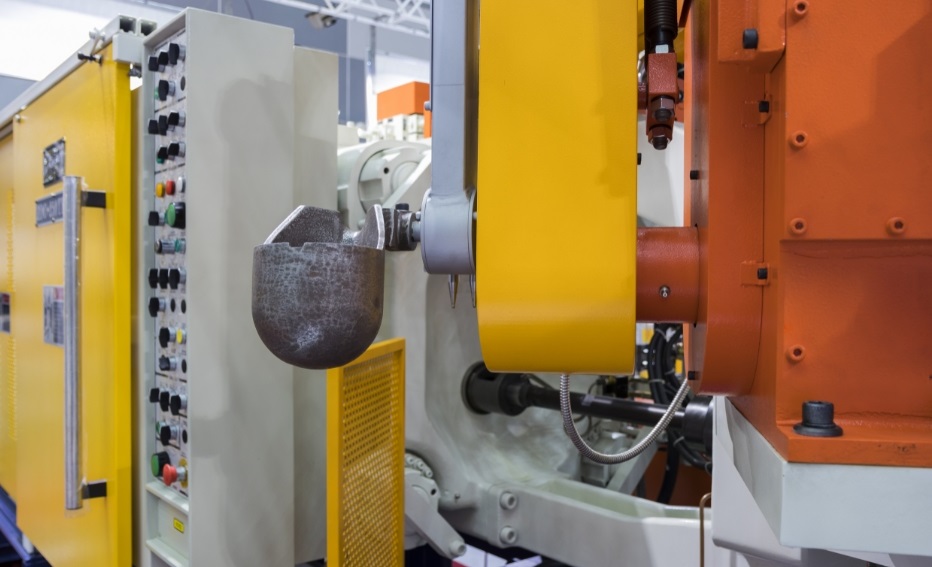

What is Aluminum Die Casting

Aluminum die casting is a manufacturing process used to produce metal parts by forcing molten aluminum into a mold (called a die) under high pressure. The die is typically made of steel and is designed to create parts with intricate shapes and fine details. This process is widely used to create high-volume, precise, and complex components for various industries, such as automotive, aerospace, electronics, and consumer goods.

Aluminum Die Casting Design Basics

When starting an aluminum die casting project, getting the basics right is crucial. Good design decisions help prevent problems later. Let’s review the key points you need to understand.

Alloy Selection

The first step is choosing the right raw material, as each one has its advantages. A380 is the most commonly used because it offers a balanced combination of strength, weight, and casting ability. A383 excels in corrosion resistance. A413 is ideal for parts requiring good sealing performance, like those in medical equipment or automotive components.

In industries like medical and automotive, precision is essential. The right alloy ensures you meet safety and performance standards.

NOBLE, a leading die casting manufacturer based in China, can assist you in selecting the best alloy. Our professional engineering team has extensive experience and can accurately select alloy materials based on customer requirements. Whether it is for manufacturing sturdy automotive parts or precision medical equipment.

Wall Thickness

Uniform wall thickness is key in aluminum die casting. If you keep the walls even, molten metal flows better inside the die casting mold. This reduces the risk of weak spots or defects. Most parts work best with walls between 0.020 and 0.787 inches thick.

- Thin-wall designs make parts lighter, which is advantageous for certain automotive and electronic products.

- Thick-wall designs increase strength but may slow heat dissipation and increase processing time.

It is important to note that mixing thick and thin walls may cause warping or shrinkage. Smooth transitions between different wall thicknesses must be ensured.

Draft Angles

A reasonable draft angle helps you remove aluminum die castings from the mold without damaging them. During production, you need to add a slight angle (usually 1 to 2 degrees) to the sides of the parts. This makes it easier to remove the parts after die casting.

An insufficient draft angle may cause the parts to stick or break. Excessive draft angle may change the shape of the parts. NOBLE’s experts can help you find the right balance.

Fillets & Radii

Sharp corners are a problem in aluminum die casting. They make it hard for metal to flow and can cause cracks. Fillets (rounded corners inside) and radii (rounded edges outside) fix this.

- Fillets help the metal fill every part of the mold.

- Radii make the part stronger and easier to finish.

If you add generous fillets and radii, you get smoother parts with fewer defects. This is important for industries like automotive die casting, where every detail counts.

Parting Lines

The parting line is the point where the two halves of a die-casting mold meet. When designing, you need to carefully plan this parting line. A well-designed parting line makes it easier to remove the part from the mold and reduces the need for subsequent processing.

- Place the parting line in a location that does not affect the appearance or function of the part.

- Avoid placing it on surfaces that require smoothness or precision.

The NOBLE team, with its extensive experience in precision manufacturing, can assist you in designing a reasonable parting line. This will save you time and costs in subsequent processing.

If you need to switch to zinc alloy die casting for specific features, the same design principles apply. Good design ensures optimal finished product results regardless of the material used.

When you collaborate with a professional die casting manufacturer like NOBLE, you receive more than just parts. From alloy selection to mold design, every step is supported by expert advice. This is how a good idea is transformed into an exceptional finished product.

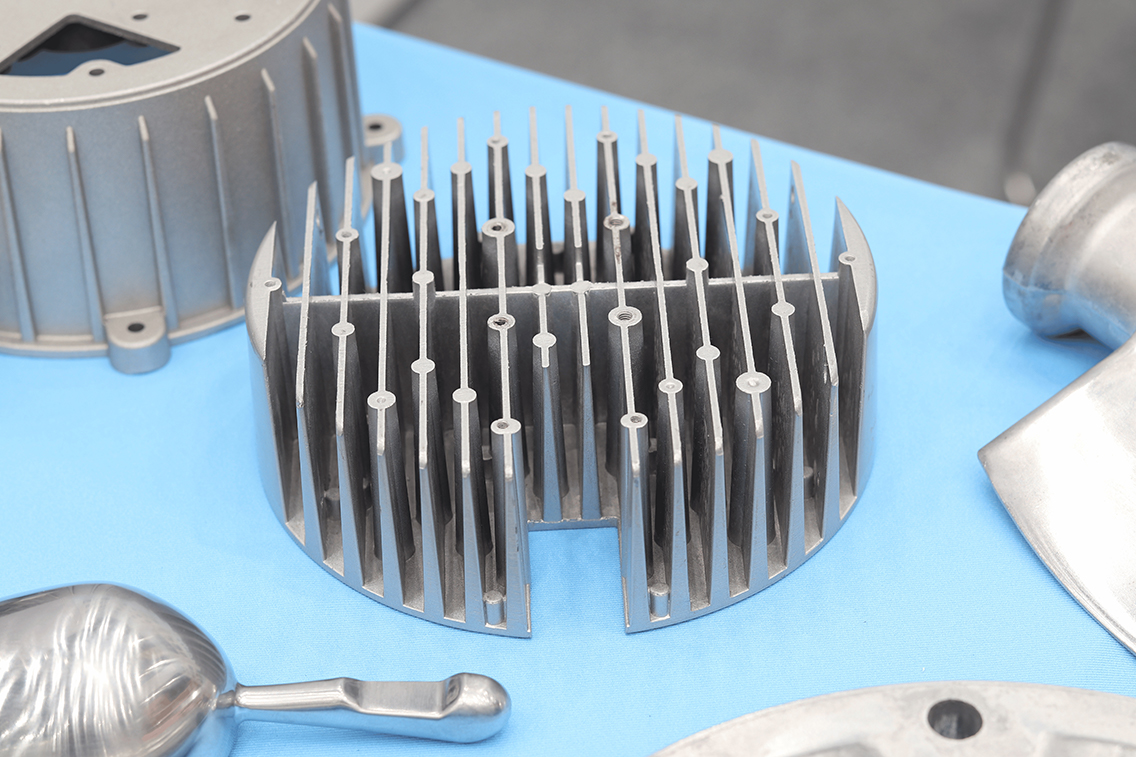

Optimizing Geometry

When designing aluminum alloy die castings, you need to keep the design simple and the structure sturdy. Choosing the right geometry can help save costs, reduce defects, and make parts easier to produce. Let’s take a look at how to optimize the shape of parts.

Reducing Undercuts

Chamfers are complex areas in parts that are difficult to demold from die-casting molds. If there are too many chamfers, you may need special tools or additional processes. This increases costs and delays production schedules. Therefore, designers should minimize chamfers during the design process. The NOBLE team can assist you in finding the optimal solution to ensure the project progresses as planned.

Ribs & Bosses

Ribs and bosses enhance strength without increasing part weight. Ribs are thin-walled structures that support larger surfaces. Bosses are raised areas often used for installing screws or fasteners. Ribs can prevent parts from bending or breaking. Bosses facilitate assembly and improve part usability. Ribs and bosses should be positioned where the part requires additional support. This is particularly important in the automotive die-casting field, where weight requirements are stringent but strength demands are even more critical.

Pockets & Weight Reduction

You can reduce the weight of parts by adding pockets or hollow sections. This reduces material usage and lowers costs. Lighter parts help cars save fuel and make electronic devices easier to operate. However, it is important to ensure that pockets do not weaken the part’s strength. NOBLE uses precision manufacturing technology to balance weight and strength, ensuring your parts remain reliable.

Assembly Features

Consider how the part will fit with other components. Add features such as holes, slots, or tabs during the initial design phase. Planning can speed up assembly and improve precision. If these features are planned from the start, it can avoid additional work later on. As a leading manufacturer in China, NOBLE can provide you with the best assembly solutions, whether it’s threading, welding, or zinc die-casting for special parts.

By focusing on smart geometric design, you can make aluminum alloy casting projects smoother and more cost-effective. You will also achieve better results from casting molds and manufacturers.

Minimizing Defects

You want your aluminum die castings to look great and perform well. Defects can ruin an entire project and result in wasted time and money. Let’s explore the most common issues and how to avoid them through proper design.

Porosity

Porosity refers to tiny holes or bubbles inside a part. These defects can cause insufficient strength or leaks. You can prevent porosity by maintaining uniform wall thickness and ensuring smooth metal flow in the die casting mold. A well-designed gate ensures that molten aluminum alloy fills all spaces without trapping air. If you collaborate with a professional die casting manufacturer like NOBLE, you can receive expert advice on gate and vent design. Their precision manufacturing processes can help you achieve strong and reliable parts.

Tip: If you need automotive die castings or electronic components, consult NOBLE about special techniques to reduce porosity. We know how to keep your parts strong and leak-free.

Shrinkage

Shrinkage occurs during the cooling and contraction of metal. This can lead to deformation or cracks. You can prevent shrinkage by designing uniform wall thicknesses and adding radii at sharp corners. Smooth transitions help the metal cool uniformly. NOBLE uses advanced simulation tools to predict shrinkage and adjust your design, ensuring parts fit perfectly every time before production.

Misruns & Cold Shuts

Misruns and cold shuts show up when the molten metal doesn’t fill the mold. You might see lines or gaps in your part. These problems often come from thin walls or slow metal flow. You can fix this by making sure your aluminum casting die has proper gating and by avoiding walls that are too thin. If you ever switch to zinc die casting for special features, the same rules apply. NOBLE’s team helps you spot these risks early and design parts that fit perfectly.

Cost Optimization

If you want to save money, it is best to start planning early. Smart design choices can help you reduce costs and material usage. At the same time, the amount of work will also be reduced accordingly. Based on my experience, I have listed the following methods to achieve this:

Material Efficiency

Use only the necessary materials. Maintain a moderate wall thickness while ensuring structural integrity. Enhance strength by adding reinforcing ribs and grooves, while avoiding additional weight. This will make the parts lighter and less expensive. This is crucial in the automotive die casting field. NOBLE helps you reduce material waste through precision manufacturing technology.

Tip: We recommend that you have your design reviewed by a die casting manufacturer. They can help you optimize material usage and ensure part strength. If you need it, NOBLE’s professional team of designers is always ready to serve you!

Reducing Secondary Operations

Additional processing steps, such as drilling or tapping, increase time and cost. You can add holes, slots, or threads to the die casting mold, eliminating these steps. Plan these features early on. The NOBLE team can assist you in adding these designs to avoid additional post-processing steps. The same principle applies to zinc alloy die casting—reduce post-processing steps by optimizing the design.

- Reducing additional processes means faster production.

- Your parts can be removed directly from the mold and used immediately.

Surface Treatment of Aluminum Die Casting

Proper surface finishing can enhance the appearance of your parts and extend their service life. Depending on your requirements, you can choose from anodizing, powder coating, or polishing etc. Each method offers distinct advantages. Anodizing effectively prevents corrosion of parts. Powder coating provides a durable and vibrant surface finish. NOBLE will recommend the most suitable surface treatment solution based on your specific requirements. With extensive experience in aluminum alloy casting molds and precision manufacturing, NOBLE ensures that every surface treatment delivers a smooth, high-quality finish.

Simulation & Prototyping

Designing an excellent part begins with careful planning. You want to confirm its functionality before manufacturing the part. This is where simulation and prototyping come into play. The following steps will help you identify problems early on and make better decisions.

Simulation Tools

Simulation tools allow you to visually see how the part fills the die casting mold. You can identify weak areas, bubbles, or regions with poor metal flow, enabling timely corrections. This helps resolve issues before incurring mold manufacturing costs. During the project, NOBLE uses advanced software to test your design. You will receive feedback on wall thickness, draft angles, and even the performance of aluminum alloy casting molds. This saves time and helps you avoid costly mistakes.

Rapid Prototyping

Rapid prototyping allows you to obtain physical components for testing. You can create samples using 3D printing or CNC machining. This enables you to check whether the components’ fit, dimensions, and shape meet expectations. If you need to understand how components function in an automotive die-casting project, prototyping can be highly beneficial. As a leading manufacturer in China, NOBLE can quickly produce samples for you. You can even compare aluminum alloy and zinc alloy die-casting solutions at this stage.

- Try out different designs fast.

- Test assembly with other parts.

- Show your team or customers a real model.

Iterative Improvement

It is important to note that it is normal for the first attempt to be less than perfect. We often use the experience gained from simulations and prototyping to make improvements. Testing and refining designs leads to better results and fewer surprises. Each new version is an improvement. This is called iterative improvement. Precision manufacturing means you can adjust the details to achieve significant results. NOBLE will work with you every step of the way to ensure that the final parts meet your needs.

Common Pitfalls

Even the best ideas can run into problems if common design mistakes are overlooked. Let’s take a look at a few pitfalls to watch out for when working with die casting manufacturers like NOBLE.

Overly Complex Designs

You may want everything to be perfect and add a lot of features to your parts. However, sometimes too many details can make things more complicated rather than better. Complex shapes increase the cost of die casting molds. They can also slow down production and make surface treatment more difficult.

- Try to keep your design simple.

- Avoid deep pockets, sharp corners, or tricky undercuts unless you really need them.

- If you need special features, talk to NOBLE early. Their team can help you find smart ways to use ribs, bosses, or even zinc die casting for certain parts.

Inadequate Draft or Fillets

Not enough draft angle or missing fillets can cause big problems. Parts may stick in the aluminum casting die or break during removal. Sharp corners can lead to cracks or weak spots.

- Always add draft angles (usually 1-2 degrees) to help with part ejection.

- Use fillets and radii to smooth out corners and improve metal flow.

NOBLE’s experts can review your design and suggest the right draft and fillet sizes. This helps you avoid costly mistakes and get a stronger part.

Tolerance Issues

Tight tolerances sound good, but they can make your part hard to produce. If you ask for very tight fits, you might need extra machining or special checks. This adds time and cost.

- Set realistic tolerances for each feature.

- Focus on critical areas, like those used in automotive die casting or assemblies.

If you’re not sure, ask your die casting manufacturer for advice. NOBLE, as a leading China-based fabrication manufacturer, uses precision manufacturing to help you meet your needs without extra hassle.

Remember: Good planning and clear communication with your manufacturer help you avoid these common pitfalls.

Expert Collaboration

Working with the right partner can make your project much easier. When you work with a team of experts like NOBLE, you get more than just parts. You get expert advice, technical support, and smart solutions at every stage. See how our expert collaboration can help you achieve the best results.

Early Supplier Involvement

Involve your die casting manufacturer in your project as early as possible. By sharing your ideas and drawings with NOBLE in the early stages of your project, you can save time and avoid mistakes. Our team has extensive expertise in aluminum alloy die casting molds and die casting mold design, enabling us to identify potential issues before they arise. You will also receive recommendations on how to leverage precision manufacturing technologies to enhance part strength and streamline production processes. If you require zinc die casting for special functions, NOBLE can assist you in selecting the appropriate process solution. Early involvement ensures a smoother transition from the prototype stage to mass production.

Design Reviews

Design review is a critical checkpoint in the project. You and your supplier will review every detail together. At NOBLE, our experts will examine your drawings, focusing on chamfer angles, wall thickness, and the optimal use of die casting molds. They will help you find ways to save materials and reduce costs. If you are in the automotive die casting industry, these reviews ensure that your parts meet strict standards. You can also discuss surface treatment options and assembly characteristics. Through regular reviews, you can avoid unexpected situations and achieve better results.

Continuous Improvement

Great projects don’t stop at the first attempt. You can continuously optimize your part design. NOBLE uses feedback from each production batch to improve your design and process flow. Engineers use precision manufacturing tools to test new ideas and resolve minor issues. If you want to switch from aluminum die casting to zinc die casting or try new surface treatments, NOBLE can guide you. We will help you keep up with new trends and technologies. This way, your parts will remain strong, reliable, and ready to tackle any challenge.

Partnering with a company like NOBLE, which has professional manufacturing capabilities in China, means you always have a partner who cares about your success.

Why Choose NOBLE For Aluminum Die Casting

If you want your aluminum die casting project to achieve outstanding results, you need a partner who truly understands the process. NOBLE is a leading manufacturer in China. Our team will do everything we can to help your project succeed.

Here’s why NOBLE is the right choice:

- Expertise Across Industries: NOBLE has years of experience in the medical and automotive die casting fields. You can trust our team to handle stringent standards and complex tasks. We have manufactured precision parts for automotive engines and medical devices.

- Advanced Precision Manufacturing: NOBLE employs cutting-edge technology to ensure every part is flawless. Our precision manufacturing processes scrutinize every detail. You can always count on receiving durable, reliable parts.

- Full-Service Capabilities: NOBLE can manufacture both aluminum alloy die casting molds and zinc alloy die casting molds. Engineers are highly skilled at designing and producing the optimal die casting molds tailored to your needs. If you require assistance with assembly features or special surface treatments, they will provide full support throughout the process.

- Superior Support: The NOBLE team assists you at every stage. You will receive guidance on design recommendations, material selection, and surface treatment solutions. We offer free DFM analysis to help you identify issues before starting production.

To save time and avoid errors, involve NOBLE early in your project. The engineers’ expertise can make a significant difference.

As a leading die casting manufacturer, NOBLE is renowned for its commitment to quality and customer service. Choosing NOBLE means partnering with a company that will help you succeed at every stage of your aluminum die casting project.

You now understand the key steps to achieving high-quality aluminum die casting results. Focus on smart design, adopt DFM analysis early, and collaborate with experts. This helps avoid errors and save costs. As a top-tier die casting manufacturer, NOBLE offers free DFM analysis and support for your next project. If you need high-quality die casting parts or mold design assistance for automotive applications, please contact us! Trust in precision manufacturing and professional advice to achieve superior results.

Aluminum Die Casting of FAQS

What is an aluminum casting die?

An aluminum alloy die casting mold is a special type of mold. It shapes molten aluminum alloy into the desired parts. You can quickly obtain high-strength parts. NOBLE uses advanced precision manufacturing processes to produce these molds. They are suitable for automotive die casting and other industries.

How do I choose between aluminum and zinc die casting?

If you need lightweight and high-strength parts, aluminum alloy is the ideal choice. It also has excellent heat resistance. Zinc alloy die casting is more suitable for small, precision parts. As a leading die casting manufacturer, NOBLE can assist you in selecting the appropriate material. Our engineering team will provide professional advice based on your project requirements and budget.

Why does wall thickness matter in die casting molds?

Wall thickness affects how metal flows and cools within the mold. Proper wall thickness prevents issues and improves part quality. The NOBLE team will review your design according to precision manufacturing standards.

Can NOBLE help with automotive die casting projects?

Absolutely! NOBLE is a leading manufacturer in China. Their experts have extensive experience in automotive die casting. You can receive comprehensive support for design, material selection, and surface treatment solutions to create durable automotive components.

What finishing options can I use for my die-cast parts?

You can choose from anodizing, powder coating, polishing, or electroplating. Each treatment protects the component and enhances its appearance. NOBLE will recommend the optimal surface treatment solution based on your aluminum or zinc die-casting project requirements.