According to QYR (Hangzhou Bozhi) statistics and forecasts, the global prototype injection molding services market sales reached $3,562 million in 2023 and is expected to reach $4,700 million by 2030, at a compound annual growth rate (CAGR) of 4.1% (2024-2030).

How to choose the right injection molding material? How can design flaws lead to production failures? When it comes to your project, what are the most suitable materials?

Dive into this all-encompassing guide, where you’ll learn everything from insights into the injection molding process to material choices, cost savings, and real-world applications, all of which will help you master this essential manufacturing technique.

What is Injection Molding?

Injection molding—called injection moulding in the UK— is a precision-driven manufacturing process that involves injecting molten material into a mold under high pressure. This method is widely adopted for large-scale plastic component production due to its exceptional efficiency and adaptability to various design specifications.

Basic Definition and Historical Background

The year 1846 saw British inventor Charles Hancock—who was related to Thomas Hancock—patenting the first injection molding machine. A quarter of a century later, in 1872, American inventors John Wesley Hyatt and his brother Isaiah made their mark by patenting one of the first injection moulding machines in the United States.

Over the years, injection molding has evolved into one of the most widely adopted manufacturing techniques. This process entails melting plastic pellets, followed by the injection of the molten material into a mold cavity, where it then cools and solidifies, forming the desired shape.

How Injection Molding Works?

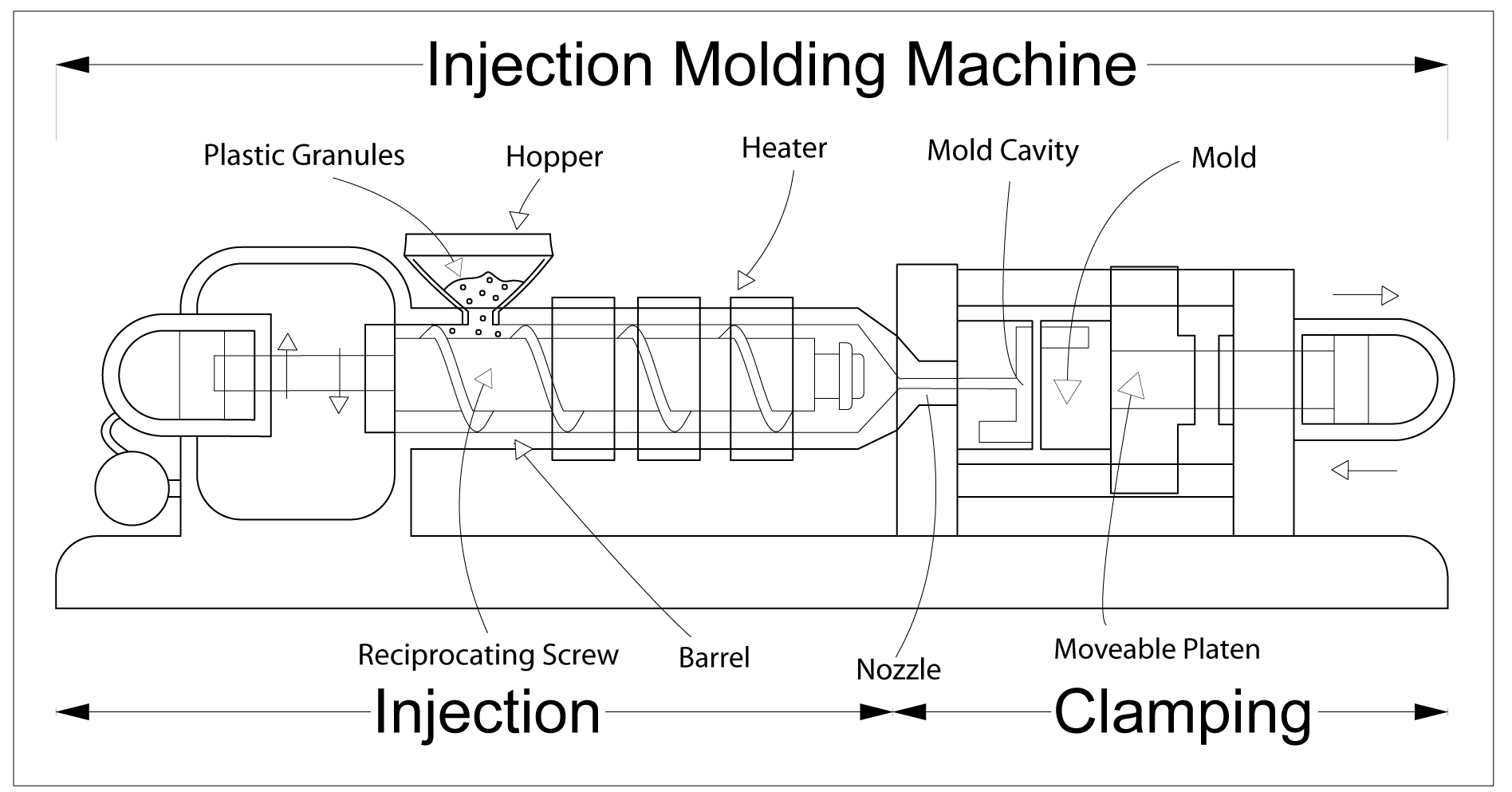

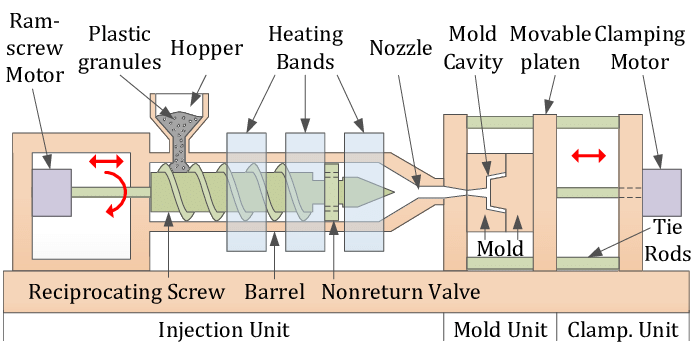

The injection molding machine consists of several key components: a hopper, an injection unit, and a mold. Initially, plastic pellets are introduced into the hopper, where they are subjected to heat and transformed into a molten state. The molten plastic is then injected into the mold cavity under high pressure. Once the plastic has cooled and solidified, the mold is opened, and the part is ejected.

Step-by-Step Injection Molding Process

Injection molding is a cyclic manufacturing process with several key stages, all aimed at transforming raw plastic into a finished product. Here’s a step-by-step look at how it works:

1. Product Design and Mold Flow Analysis

Before production kicks off, engineers take a close look at the design and do a mold flow analysis to predict how the molten plastic will fill the mold. This helps catch potential problems, like air bubbles or uneven cooling, that could cause defects later.

2. Material Preparation

The plastic pellets are dried, then fed into the hopper. Once inside, the pellets are heated until they melt, turning into a thick liquid ready to be injected.

3. Injection Phase

The molten plastic is injected into the mold under high pressure. A screw in the injection unit pushes the melted material through a nozzle and into the mold.

4. Cooling and Solidification

After the mold is filled, the plastic cools and hardens. The cooling time depends on the material and thickness of the part. It’s important to get this right to avoid issues like warping.

5. Mold Opening and Ejection

Once the plastic is solid, the mold opens, and ejector pins push the part out. Then the mold closes, and the whole process starts again.

6. Surface Finishes for Injection Molding

Sometimes, products need a little extra work on the surface, like polishing, powder coating, or adding texture. This is super important because it makes the product look better, perform better, and last longer—plus, it helps reduce waste in the process.

7. Quality Inspection

Once the manufacturing process is concluded, the final, essential step is quality inspection. This process is designed to confirm that the part adheres to the required specifications.

Common Defects and How to Fix Them:

- Sink Marks: These occur when the cooling process isn’t uniform. To fix this, you can optimize both the cooling time and the mold’s temperature to ensure even cooling throughout.

- Flash: This defect is caused by excess material escaping from the mold. By increasing the clamping force or adjusting the mold alignment, you can prevent this from happening.

- Bubbles: Trapped air in the mold results in bubbles. You can improve the mold’s venting system or adjust the injection speed to solve this problem.

Thermoplastic vs. Thermoset Plastic Processing Differences

| Aspect | Thermoplastic | Thermoset |

| Melting Behavior | Can be melted and reshaped | Cannot be remelted |

| Applications | Packaging, consumer goods | Electrical components, adhesives |

| Recyclability | Recyclable | Not recyclable |

Materials Guide for Injection Molding

Picking the right material is key to making sure your injection molding project goes smoothly. Here’s a quick look at the most common materials used:

Tooling Materials

- Tool Steel: Known for its durability and exceptional wear resistance, tool steel is ideal for applications requiring high-volume production.

- Stainless Steel: Renowned for its excellent corrosion resistance, stainless steel is widely used in medical and food-grade applications.

- Aluminum: Lightweight and cost-effective, aluminum is commonly employed in the prototyping phase of production.

Plastic Materials

- General-Purpose Plastics:

- PP (Polypropylene): Super light and resistant to chemicals, often used for packaging and car parts.

- ABS (Acrylonitrile Butadiene Styrene): Tough and impact-resistant, it’s found in everything from electronics to toys.

- PE (Polyethylene): Flexible and strong, great for bottles and containers.

- Engineering Plastics:

- PC (Polycarbonate): Strong and transparent, you’ll find it in eyewear and medical devices.

- Nylon: Known for its wear resistance, it’s commonly used in gears and bearings.

- POM (Polyoxymethylene): Low friction and super stiff, used for precision parts.

- High-Performance Plastics:

- PEEK (Polyether Ether Ketone): Super resistant to heat and chemicals, it’s a go-to for aerospace and medical fields.

- LCP (Liquid Crystal Polymer): Stable in shape, it’s mainly used in electronics.

Additives and Fibers

- UV Stabilizers: Help protect the material from UV damage.

- Flame Retardants: Make the material more fire-resistant.

- Glass Fibers: Strengthen the material and make it stiffer.

- Colorants: Give the material a vibrant, appealing look.

Pros and Cons of Injection Molding

Advantages:

- High Efficiency: The process is optimized for mass production, ensuring fast cycle times and high output, making it an excellent choice for large volumes.

- Precision: Capable of creating highly detailed parts with very tight tolerances, often within ±0.1mm, ensuring accuracy in every component.

- Material Efficiency: Injection molding generates minimal waste, as any excess material can be recycled back into the process, helping reduce environmental impact.

Limitations:

- High Initial Costs: The upfront investment in mold tooling is significant, making it less economical for small-scale production.

- Design Constraints: For optimal performance, parts must be designed with uniform wall thickness to avoid potential defects like warping or uneven cooling.

Injection Molding vs. 3D Printing vs. Blow Molding

| Aspect | Injection Molding | 3D Printing | Blow Molding |

| Cost | High initial cost, low per-unit cost | Low initial cost, high per-unit cost | Moderate initial and per-unit cost |

| Speed | Fast for mass production | Slow, suitable for prototyping | Moderate |

| Applications | Complex, high-volume parts | Prototypes, custom parts | Hollow parts (bottles, containers) |

Industry Applications of Injection Molding

Thanks to its remarkable efficiency and adaptability, injection molding is a go-to solution for many industries. Let’s take a look at some of the key areas where it’s applied:

- Automotive: Injection molding is used to create vital components like dashboards, light covers, and connectors, ensuring durability and precision.

- Consumer Electronics: From sleek phone cases to tactile buttons and protective charger housings, injection molding plays a key role in consumer electronics.

- Medical Devices: The medical field relies on injection molding for producing sterilized devices such as syringes and surgical tools, ensuring safety and compliance with stringent sterility requirements.

Cost Analysis and Optimization Strategies

Cost Breakdown:

- Mold Costs: While steel molds are an investment upfront, their durability makes them ideal for long-term, high-volume runs. Aluminum molds, though more affordable initially, may need replacing sooner due to wear and tear.

- Material Costs: The costs for materials fluctuate depending on the specific plastic chosen and the quantity required for production runs.

- Labor and Energy: Labor and energy costs factor in the operation of machinery as well as any necessary post-processing steps to ensure the final product meets specifications.

Cost Optimization Tips:

- Design Simplification: Streamlining the design by reducing undercuts and ensuring uniform wall thickness can lead to significant cost savings by reducing complexity in the molding process.

- Bulk Production Discounts: When placing large orders, negotiating for bulk production discounts can reduce the cost per unit, making large-scale production more affordable.

- Simulation Software: Leveraging simulation software like Moldflow can help you detect potential defects early, allowing for corrections before actual production begins, thus preventing costly reworks.

How to Choose an Injection Molding Service Provider

Evaluation Criteria:

- Equipment Precision: Ensure that the injection molding machines are of sufficient tonnage and clamping force to meet your required tolerances and production volume.

- Industry Certifications: Confirm that the provider has the appropriate certifications, such as ISO 9001, or medical-specific certifications if required for your product.

- Sample Quality and Lead Time: Request prototypes or sample parts and assess both their dimensional accuracy and the provider’s ability to meet deadlines.

Red Flags:

- Low Prices: Unusually low pricing may be a signal that substandard materials or outdated molds are being used, potentially jeopardizing part quality.

- Lack of Transparency: A provider who isn’t open about their processes and materials might be hiding corners they’ve cut. Avoid such companies to ensure a smooth production experience.

Conclusion

Injection molding stands out as one of the most efficient and versatile manufacturing processes, used across industries from automotive to medical devices. By fully understanding the intricacies of the process, selecting the right materials, and considering the cost factors, you can achieve optimal production efficiency and exceptional product quality.

Call to Action: Get in touch with our team today and let’s create a tailored injection molding solution for your project!