Introduction

Injection molding is a key part of modern manufacturing. It allows mass production of complex plastic parts with high accuracy. Mold design is at the center of this process. It affects the quality of the product, how fast it can be made, and how much it costs. Getting the design right from the start is very important. Even small mistakes can cause serious defects, higher costs, and delays in production.

Common Mold Design Problems

1. Shrinkage, Venting, and Ejection Issues

Shrinkage: Shrinkage occurs during mold design when the molded part cools and gets smaller. This can cause size and shape errors. Shrinkage is especially common in thermoplastic materials during mold design because different areas cool at different speeds. To reduce shrinkage in mold design, parts should have even wall thickness. It also helps to choose materials that shrink less during the mold design process.

Venting Problems: Venting problems often happen in mold design when air gets trapped in the mold. This can lead to burn marks or parts that do not fill completely. Good venting in mold design lets air and gas escape during injection. To avoid venting issues in mold design, place vents in the right spots and make sure they are large enough.

Ejection Issues: Ejection problems can also arise during mold design. They happen when parts are hard to remove or get damaged. In mold design, wrong draft angles or poor ejection systems often cause these problems. Draft angles in mold design help parts slide out by lowering friction. A draft angle between 1° and 2° is usually enough to make removal easier and prevent damage in the mold design process.

2. Troubleshooting Flow Marks and Weld Lines

Flow Marks: Flow marks are lines or patterns on the part surface. They appear when material flows unevenly during mold design. These marks are usually caused by uneven cooling or changes in material thickness or viscosity. To reduce flow marks in mold design, use uniform wall thickness and adjust gate placement to keep material flow steady.

Weld Lines: Weld lines form in mold design when two flow fronts meet, but don’t fuse well. These lines create weak areas and can reduce the part’s strength. Low injection pressure or bad gate placement often causes them. To prevent weld lines in mold design, increase the injection pressure and place gates correctly.

3. Warping and Dimensional Inaccuracies

Warping: Warping in mold design is the bending or twisting of a part caused by uneven cooling or built-up stress. It happens when different areas of the part cool at different speeds. This can lead to size or shape errors. To avoid warping in mold design, use uniform wall thickness and apply even cooling throughout the mold.

Dimensional Inaccuracies: Dimensional inaccuracies in mold design are differences between the actual part and its intended size. These errors can affect how the part fits or functions. They often come from uneven cooling, shrinkage, or wear on the mold over time.

4. Flash, Short Shots, and Voids

Flash: Dimensional inaccuracies in mold design are differences between the actual part and its intended size. These errors can affect how the part fits or functions. They often come from uneven cooling, shrinkage, or wear on the mold over time.

Short Shots: Short shots in mold design occur when the mold cavity doesn’t fill, leaving gaps or missing sections. Short shots can be caused by low injection pressure, poor gate design, or material thickness problems. To prevent short shots in mold design, increase injection pressure, and improve the gate design.

Voids: Voids in mold design are hollow areas in the part caused by trapped air or non-material. Voids can weaken the part and affect its appearance. In mold design, using proper venting and ensuring full mold filling can help reduce voids.

5. Ejection Problems: Design and Tolerance

Ejection Marks: Ejection marks in mold design are visible marks left on the part surface due to improper ejection. These marks can happen when ejector pins are misaligned or the draft angles are insufficient. To reduce ejection marks in mold design, align the ejector pins properly and use adequate draft angles.

Tolerance Issues: Tolerance issues in mold design occur when parts don’t meet the required tolerances, which affects assembly and function. Tolerance stack-up in mold design happens when small dimensional errors add up across different features. Conducting tolerance analysis during the mold design phase helps ensure parts meet the specifications.

6. When to Redesign vs. When to Rework

Redesign: Redesign in the mold design may be necessary if recurring defects can’t be solved by simple adjustments. This redesign might involve changing part geometry, adjusting gate locations, or modifying the cooling system to fix ongoing issues.

Rework: Rework in mold design is useful for minor problems that don’t need a full redesign. Rework can include adjusting processing settings, changing venting, or replacing worn mold components.

Key Considerations for Engineers on Mold Design

1. Material Properties and Their Influence on Mold Design

The choice of material significantly impacts mold design decisions. Materials with high shrinkage rates, such as certain thermoplastics, require careful consideration of wall thickness and cooling rates to prevent defects like sink marks and warping. Additionally, materials with varying flow characteristics necessitate adjustments in gate placement and runner design to ensure uniform filling and minimize flow marks. Understanding the specific properties of the chosen material allows engineers to tailor the mold design to achieve optimal part quality and performance.

2. Wall Thickness and Rib Design

In the process of mold design, maintaining uniform wall thickness is essential to prevent issues such as uneven cooling, sink marks, and warping. When incorporating ribs for added strength, it’s important to design them with a thickness between 40% and 60% of the main wall thickness to avoid sink marks. Rib height should be limited to three times the wall thickness, and spacing between ribs should be at least twice the wall thickness to ensure proper cooling and structural integrity.

3. Gate Location and Runner Design

When designing a mold, strategic placement of gates and runners is vital for achieving uniform material flow and minimizing defects. Gate location affects the filling pattern and can influence the occurrence of weld lines and flow marks. Designing runners with appropriate dimensions and minimizing their length can reduce material waste and cycle time. Additionally, optimizing runner design contributes to consistent part quality and efficient production processes.

4. Draft Angles and Part Ejection on Mold Design

Incorporating draft angles into mold design facilitates the easy removal of parts from the mold, reducing the risk of damage during ejection. A general guideline is to apply a draft angle of at least 1 degree per inch of cavity depth, with a minimum of 0.5 degrees on all vertical faces. Proper draft angles not only prevent part damage but also extend the lifespan of the mold by reducing wear and tear.

5. Tolerance Stack-Up and Dimensional Accuracy When Mold design

Ensuring dimensional accuracy is critical for parts that require precise fits and functions. Tolerance stack-up analysis helps identify potential issues arising from the accumulation of dimensional variations across multiple features. By carefully considering tolerances during the mold design phase, engineers can minimize the risk of assembly problems and ensure that parts meet functional requirements.

6. Design for Manufacturability (DFM)

Implementing Design for Manufacturability principles early in the mold design process can lead to cost savings and improved part quality. DFM involves designing parts that are easy to manufacture, assemble, and test, thereby reducing production costs and time to market. Utilizing DFM checklists ensures that common manufacturing challenges are addressed proactively, leading to more efficient and reliable production processes.

7. Design Tools and Standards for Mold Design

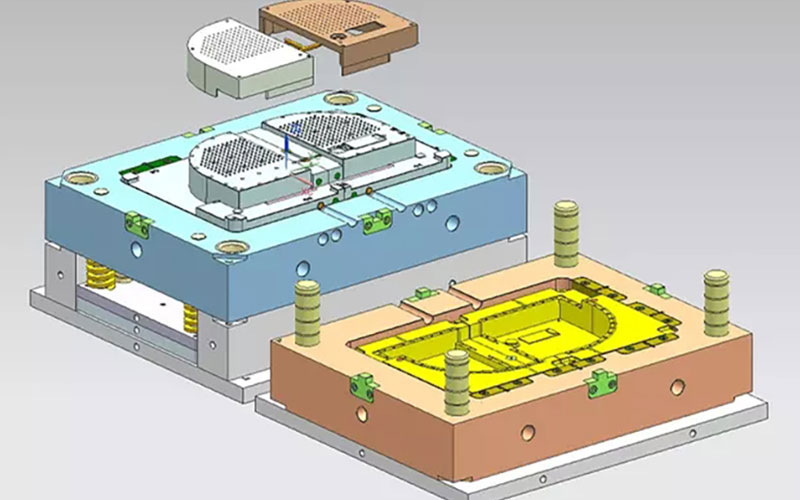

Adhering to established design standards, such as ISO and ASME guidelines, provides a framework for creating molds that meet industry best practices. These standards cover various aspects of mold design, including material selection, dimensional tolerances, and safety considerations, ensuring consistency and quality across different projects. Utilizing advanced design tools, such as CAD software and simulation programs, allows engineers to visualize and test mold designs before physical production, reducing the likelihood of errors and optimizing design efficiency.

Why choose NOBLE for Injection Molding Mold Design

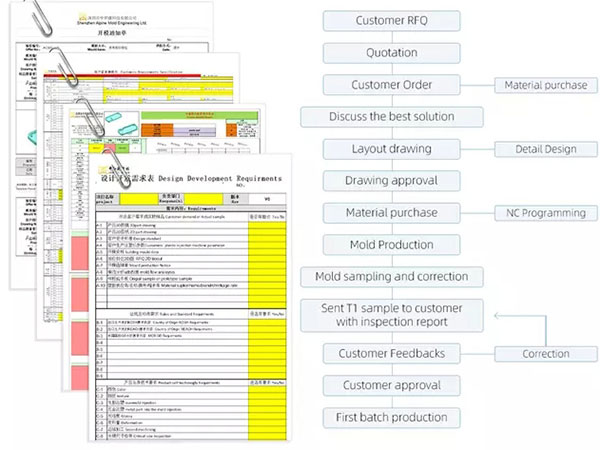

When selecting a partner for injection molding mold design, NOBLE stands out as a premier choice due to its comprehensive capabilities, commitment to quality, and customer-centric approach.

1. Comprehensive Services from Prototyping to Production

NOBLE offers end-to-end solutions, encompassing rapid prototyping, mold design, and full-scale production. Their advanced prototyping tools enable quick turnaround times, allowing clients to perform functional tests and verify market interest before committing to full-scale production. This approach minimizes project risks and ensures that designs are optimized for manufacturability.

2. Expertise in Material Selection and Mold Design

With over a decade of experience, NOBLE’s engineers possess in-depth knowledge of various materials and their properties. This expertise allows them to provide informed recommendations on material selection, ensuring that the chosen materials align with the part’s functional requirements and manufacturing constraints. Additionally, NOBLE’s design team employs advanced CAD tools to create precise mold designs that enhance part quality and reduce production costs.

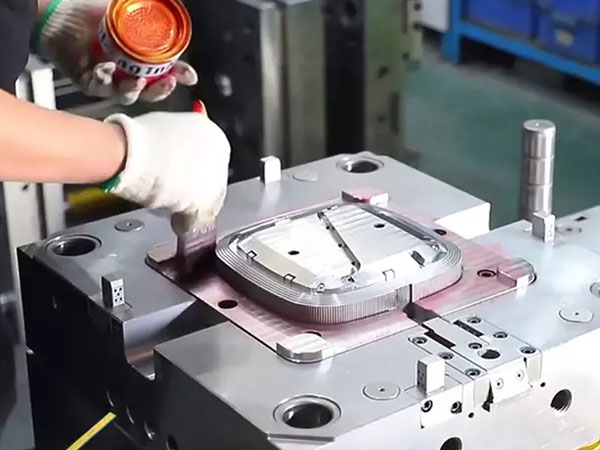

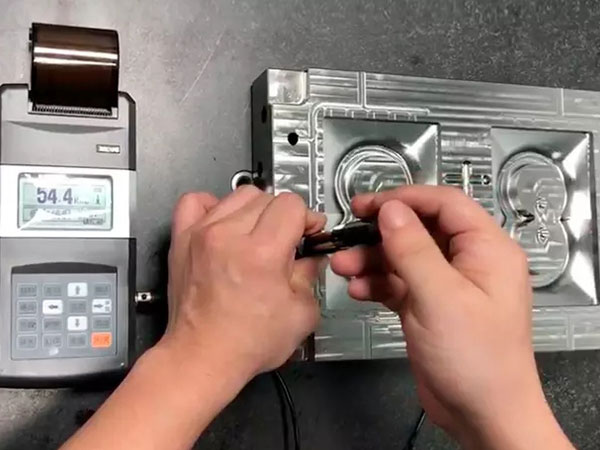

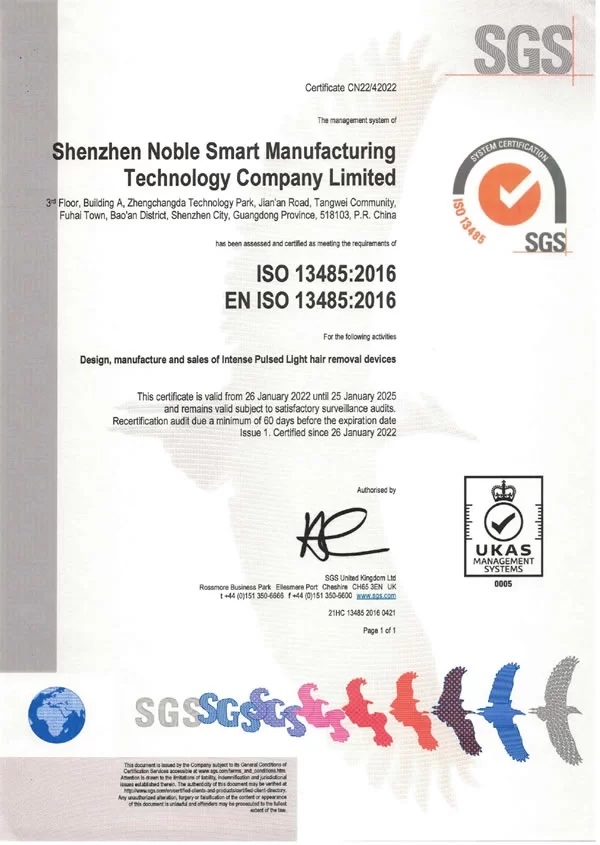

3. Commitment to Quality and Precision

NOBLE operates ISO 9001 and ISO 13485 certified facilities, adhering to stringent quality standards throughout the manufacturing process. Their commitment to quality is evident in their in-process inspections and dimensional verification procedures, ensuring that each molded part meets the specified tolerances and functional requirements. This dedication to precision results in consistent, high-quality parts that meet or exceed customer expectations.

4. Flexible Manufacturing Capabilities

Understanding the diverse needs of their clients, NOBLE offers flexible manufacturing options, including single-cavity, multi-cavity, and family molds. Their capabilities extend to producing parts of varying sizes and complexities, accommodating both low-volume and high-volume production runs. This versatility ensures that NOBLE can meet the specific demands of different industries and applications.

5. Customer-Centric Approach

NOBLE places a strong emphasis on customer satisfaction, offering personalized services tailored to each project’s unique requirements. Their team provides transparent communication, timely updates, and collaborative support throughout the design and manufacturing process. By fostering strong partnerships with clients, NOBLE ensures that each project is executed efficiently and successfully.

Conclusion

Selecting the right partner for injection molding mold design is crucial to the success of any manufacturing project. NOBLE’s comprehensive services, expertise in material selection and mold design, commitment to quality and precision, flexible manufacturing capabilities, and customer-centric approach make them an ideal choice for businesses seeking reliable and efficient injection molding solutions. By choosing NOBLE, companies can ensure that their products are designed and manufactured to the highest standards, meeting both functional and aesthetic requirements.