Introduction to Automotive Injection Molding

Automotive injection molding is a common machining process that involves injecting heated, melted plastic pellets into a mold, which then cools to form the desired part shape. This method is suitable for mass production, ensuring consistent part dimensions, smooth surfaces, and reliable strength.

In the automotive industry, injection molding is commonly used to produce bumpers, dashboards, interior components, lamp housings, functional structural parts, and more. Its advantages include high production efficiency, relatively low costs, and the ability to machine complex-shaped parts. Additionally, plastic materials are lightweight, helping automobiles achieve a lightweight design and improve fuel efficiency.

Injection molding can also combine different materials and colors to meet the diverse aesthetic and functional requirements of automobiles, making it widely adopted in modern automotive manufacturing.

What is Automotive Injection Molding?

Automotive injection molding is a common process where heated plastic pellets are injected into a mold, cooled, and shaped into precise parts. It is ideal for mass production, providing consistent size, smooth finishes, and reliable strength.

In the automotive industry, it is used for bumpers, dashboards, interior panels, lamp housings, and other functional or structural parts. Its main advantages are high efficiency, low cost, and the ability to manufacture complex shapes. Lightweight plastics can also reduce the weight of vehicles and improve fuel efficiency.

Injection molding also allows for the combination of different materials and colors, while meeting both functional and visual requirements. This makes it a key technology in modern automobile manufacturing.

History of Automotive Injection Molding

In the early days of the automotive industry, cars were almost entirely made of metal and were very heavy. By the 1940s and 1950s, the rise of plastic prompted manufacturers to try using plastic components.

By the 1970s, cars began to use plastic trim strips and decorative parts. By the late 1980s, functional plastic components such as headlights, bumpers, and mudguards began to emerge.

By the early 21st century, structural plastic components had become very common due to their advantages, such as light weight, high fuel efficiency, and cost savings. Today, injection molding is the main method used to produce automotive plastic parts.

The Injection Molding Process for Bumpers

The production of automotive bumpers via injection molding involves the following steps:

Automobile Bumper Mold Design and Machining

The first key step in making injection-molded car bumpers is mold design and machining. The quality of the mold directly affects the accuracy and performance of the final bumper.

Engineers begin by analyzing 3D CAD design data. They check factors like material shrinkage, draft angles, and cooling layout.

Molds are usually made from strong steels such as P20 or H13. They are produced with precision CNC machining, EDM, and other processes. A full bumper mold is complex and includes cavities, cores, ejection systems, and cooling channels. It normally takes about 4 to 8 weeks to complete.

For mass production, mold surfaces are coated with chrome or treated with nitriding to increase wear resistance. In recent years, advanced molds have also used conformal cooling technology. With 3D printing, mold cores can be made with complex cooling channels, which improves cooling efficiency and shortens production cycles.

Automotive Injection Molding Material Feeding

Raw material machining is an important step before bumper injection molding. Plastic pellets, usually PP or ABS, must be carefully checked and treated. First, they are dried to keep moisture below 0.02%. This prevents bubbles or surface defects during molding.

Modern factories often use central feeding systems. Dried pellets are sent through pipelines directly to each injection machine.

The whole process is usually controlled by PLC systems, which keep feeding steady and track process data.

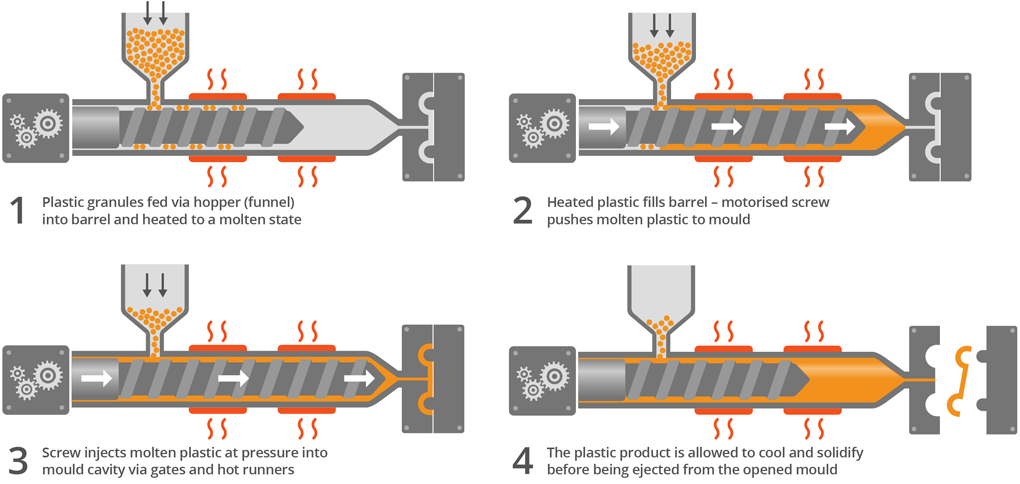

Injection and Cooling

Injection molding is the main process in making car bumpers. First, dried plastic pellets are melted in the barrel of the machine by heat, usually between 180 and 280°C, and by the screw’s shear action. The melted plastic is then injected into the mold cavity under high pressure, usually 800 to 1500 bar.

After filling, the holding pressure stage begins. This step offsets shrinkage and keeps the product dimensionally stable. Cooling comes next. Water between 20 and 80°C flows through mold channels to solidify the part. Cooling takes the most time—about 60–70% of the whole cycle.

Ejection and Finishing

After molding, the bumper goes through post-finishing steps. When the mold opens, the ejection system pushes the part out, and a robot arm moves it to a conveyor.

If it passes inspection, the bumper moves on to painting. A primer coat is applied first to cover small defects, then a topcoat and clear coat are added. Some models use special finishes like pearlescent or metallic paint. The painted bumper is then cured under controlled conditions.

Advantages of Injection Molding for Automotive Bumpers

High Precision

In the automotive industry, bumpers are very important parts. They are not just exterior parts. Their size accuracy directly affects assembly quality and vehicle performance.

Injection molding is a process that can achieve very high precision. With careful mold design and strict molding control, it can reach an accuracy of about ±0.1 mm. This allows each bumper to fit smoothly with the body panels of the car.

Durability

The car bumper is one of the main parts on the outside of a vehicle. It faces sun, rain, heat, and many other conditions for a long time. So it needs to resist weather, impacts, and aging. Injection molding is a process that can meet these needs.

Injection molding makes the bumper strong and impact-resistant, effectively resisting stone strikes or minor collisions. It can return to its original state after absorbing the impact, thus protecting the vehicle body.

Lightweight

Injection molding makes it possible to design lightweight bumpers. The process allows thin walls, usually 2.5 to 3.5 mm.

Cost-effectiveness

Injection molding is especially suitable for large-scale production, such as car bumpers. A single precision mold can usually run 500,000 to 1 million cycles.

The main advantage is cost. As production increases, the cost of molds, machines, and labor spreads over more parts. This creates economies of scale, reducing the unit cost of bumpers by 30–40% compared with older methods.

Material use is also very efficient. Almost all thermoplastic pellets become part of the final product. Scrap is usually below 5%, and leftover material can be recycled.

Materials Used in Injection-Molded Bumpers

The material chosen directly affects a bumper’s strength, flexibility, and damage resistance. Common materials include:

Polypropylene (PP)

Polypropylene, or PP, is the most widely used plastic for car bumpers today. PP material is widely popular because it combines strength, toughness and easy processability. Its key feature is excellent impact resistance. It can maintain toughness even at low temperatures and effectively absorb collision energy.

It is also very light, with a density of about 0.9 g/cm³, which is much lower than metal. This makes it a good choice for lightweight car designs. PP material is resistant to chemical corrosion and easy to form and produce. Additives can also enhance its UV resistance and extend the service life of the bumper in outdoor environments.

Acrylonitrile Butadiene Styrene (ABS)

| Excellent surface quality | It has a high surface finish and is convenient for secondary machining |

| Lightweight | Low density helps to reduce vehicle weight and lower energy consumption |

| Recyclable | Recyclable and reusable materials conform to the trend of environmental protection and sustainable development. |

ABS is another important material used in bumper machining. The main advantage of ABS is its strong weather resistance. It can handle long-term exposure to sunlight and temperature changes without losing performance.

The surface of ABS material is hard and smooth, making it very suitable for high-end cars that pay attention to appearance. By adjusting the proportion of its three components, the performance of ABS can be flexibly changed, thereby providing more diverse options for bumper design.

PC

For bumpers that need higher performance, polycarbonate (PC) blends are often the best choice. PC has a very high impact strength and strong heat resistance.

PC blends also provide an excellent surface finish, which allows more complex and stylish bumper designs. These materials are mainly used in high-end cars or bumpers needing special performance. They cost more but last longer and keep a good appearance over time.

Applications of Automotive Injection Molding

| Interior Components | dashboard assemblies, console parts, door handles, and seat components |

| Exterior Body Parts | bumpers, grilles, and body panels |

| Under-the-Hood Components | engine covers, air intakes, and various housings |

Interior Components

Instrument panels, door panels, center consoles, air vents, glove compartments, seat elements, and various storage boxes are predominantly produced through injection molding. These parts are often large, highly complex in shape, and require excellent surface aesthetics.

Injection molding can produce complex structures in one step and integrate multiple functions into a single component.

Finishing, such as coating, electroplating, and in-mold decoration (IMD), significantly enhances the decorative effect of the products. This improves the cabin’s look and comfort while meeting the automotive industry’s needs for lightweight and cost-efficient designs.

Exterior Trim Components

Modern automotive headlamps have developed into more than just lighting devices—they are now key elements of vehicle exterior design. Its internal structure is very complex, usually including a rearview mirror, a lampshade, and multiple installation brackets.

Injection molding, especially the application of transparent materials, can precisely manufacture these optical-grade parts while ensuring their functionality and appearance quality.

Functional Structural Components

Over the past two decades, many manufacturers have replaced metal parts under the bonnet with plastic alternatives.

Nowadays, injection molding technology has been used to manufacture components such as cylinder head covers and oil pans. Compared with metal parts, this type of plastic parts significantly reduces weight and production costs.

Challenges in Injection Molding of Automotive Bumpers

Cooling efficiency and deformation control.

The cooling stage usually takes more than 60% of the injection molding cycle. The quality of its design is directly related to production efficiency and the quality of the final product.

If the cooling system layout is unreasonable or the cooling rate control is improper, it not only significantly reduces production efficiency but also easily leads to defects such as warping deformation and uneven shrinkage in the plastic parts, severely affecting the assembly accuracy and surface quality of the bumper.

Requirements for mass production

To achieve the economic viability and stability of mass production, the mold must have a long service life and excellent mechanical stability to withstand the wear and stress caused by high-frequency repetitive use.

The production line must also reach a high level of automation. If automation or process control is lacking, it can quickly cause more product defects, higher production costs, and lower overall efficiency.

Quality Control in Bumper Injection Molding

To ensure safety and performance, manufacturers conduct rigorous inspections:

1. Dimensional accuracy inspection

Dimensional accuracy is the primary indicator of bumper quality control. Manufacturers use high-precision coordinate measuring machines (CMMs) to perform full-dimensional inspections of key mounting points and mating surfaces on bumpers, with a measurement accuracy of ±0.02 mm. The inspection covers key dimensions such as length, width, thickness, and hole positions, as well as the matching gaps with other body components. To ensure consistency in mass production, sampling inspections are conducted for each production batch, and a complete dimensional data archive is established. For complex curved surfaces, laser scanning technology is also used to obtain complete 3D point cloud data for comparison and analysis with the original CAD design. Modern smart factories have begun to introduce online automatic inspection systems, using visual measurement technology to achieve 100% critical dimensional inspection, significantly improving quality control efficiency.

2. Impact Resistance Testing

Impact resistance directly affects the safety protection function of the bumper. Manufacturers use various testing methods for comprehensive evaluation: room-temperature ball drop impact testing (using a 50mm-diameter, 500g steel ball dropped from a height of 1-2m), low-temperature impact testing (testing samples after exposure to a -30°C environment for 4 hours), and multi-angle collision testing. Bumpers for high-end vehicles must also pass dynamic impact tests, using a pendulum-type impact testing machine to simulate collisions at different speeds. All tested samples undergo rigorous inspection to assess for defects such as cracks or fractures, and the maximum impact energy absorbed is recorded. These tests ensure that bumpers can effectively absorb collision energy under various conditions, protecting the safety of pedestrians and vehicles.

3. Surface Quality and Paint Adhesion Testing

Surface quality inspection encompasses multiple aspects, including visual inspection, gloss measurement, and orange peel analysis. Professional inspectors examine the product surface under standard lighting conditions to identify defects such as shrink marks, flow marks, and bubbles. Coating performance testing includes: cross-hatch adhesion testing (by ISO 2409 standards), pencil hardness testing (to assess coating surface hardness), and stone impact testing (to simulate the impact of stones at high speeds). Color difference control is also a critical step, with a spectrophotometer used to measure ΔE values to ensure color consistency. Modern production lines are generally equipped with automatic optical inspection systems (AOI), which use high-definition cameras and AI algorithms to automatically identify and classify surface defects, significantly improving inspection efficiency and accuracy.

4. UV resistance and weatherability assessment

Weatherability testing primarily evaluates the performance retention capability of bumpers after long-term use. Accelerated aging tests are the most commonly used methods, including: UV aging tests (simulating sunlight exposure in a QUV aging test chamber for 500–1,000 hours), wet-heat cycle tests (cyclic testing under conditions of 40°C temperature and 95% humidity), and salt spray tests (assessing corrosion resistance). Although outdoor exposure tests have a longer cycle (typically 6–12 months), they provide the most realistic performance data. These tests assess whether materials exhibit fading, chalking, or brittleness, as well as the retention rate of mechanical properties. High-end vehicles also undergo real-road testing, with samples installed in different climatic regions for long-term monitoring. All test data is fed back into material formulation and process optimization to continuously improve product quality.

Trends in Automotive Bumper Injection Molding

The industry is moving toward lightweight designs, recycled materials, and integrated sensors for advanced driver-assistance systems (ADAS). Modern injection molding technology also enables multi-material molding, allowing different properties in specific bumper areas for optimized performance.

NOBLE Automotive Plastic Injection Molding Services

NOBLE has many years of experience in automotive parts manufacturing. We use advanced injection molding equipment and a strict quality control system that meets ISO9001 and ISO13485 standards.

With profound industry knowledge and modern technology, NOBLE can transform your design concepts into high-quality products. Our team is committed to ensuring reliable quality and providing each customer with smooth and satisfactory service.

For various automotive component needs, we offer highly customized solutions and state-of-the-art production facilities, providing a complete end-to-end service chain from prototype development to post-processing.

NOBLE adheres to a strict quality control system to ensure that every link from design to mass production meets the highest standards. NOBLE can efficiently and precisely support your automotive design projects from concept to mass production. As your reliable partner, NOBLE is committed to jointly promoting innovation and development in the automotive industry.

FAQs for Injection Molding

Can injection-molded bumpers be recycled?

Yes. Many, especially those made from polypropylene, can be recycled and reused to make new automotive parts, supporting sustainable manufacturing.

What factors affect the quality of injection-molded car bumpers?

Factors include mold design accuracy, material quality, injection molding machine settings, cooling time, and quality control testing during production.

Why Is Injection Molding Preferred in the Automotive Industry?

Injection molding is widely favored in the automotive industry for many reasons. It is able to produce a large volume of parts with high precision and stable quality. At the same time, it is cost-efficient and supports the use of a wide range of materials.

Are there sustainable practices in automotive injection molding?

Yes. They include using recycled materials and improving processes to reduce waste. Choosing materials with lower environmental impact also helps. These practices make the automotive industry more sustainable.

How does automotive injection molding contribute to vehicle safety?

Automobile injection molding can produce strong and reliable parts, and these components play a crucial role. Some of them are structural components that can effectively protect passengers in a collision. Others are precise engine or cabin functional components to ensure the normal operation of the vehicle.