You may be surprised at how rapidly 3D printing in medical devices is transforming healthcare. Now, you can get an implant made just for you, tailored specifically to your needs. It does not have to be a standard size; surgeons fit devices to your body, making surgery quicker and safer. You can find this innovative technology in many medical products:

- Implants made for your body

- Prosthetics that fit your needs

- Models of your body parts

- Custom dental products

Manufacturers use special machines to create these items. Factories and medical machining companies now offer 3D printing in medical devices for a variety of applications. They can print forceps and dental crowns, and medical instrument makers can even produce items that were not possible before.

What Is 3D Printing?

Basic Principles

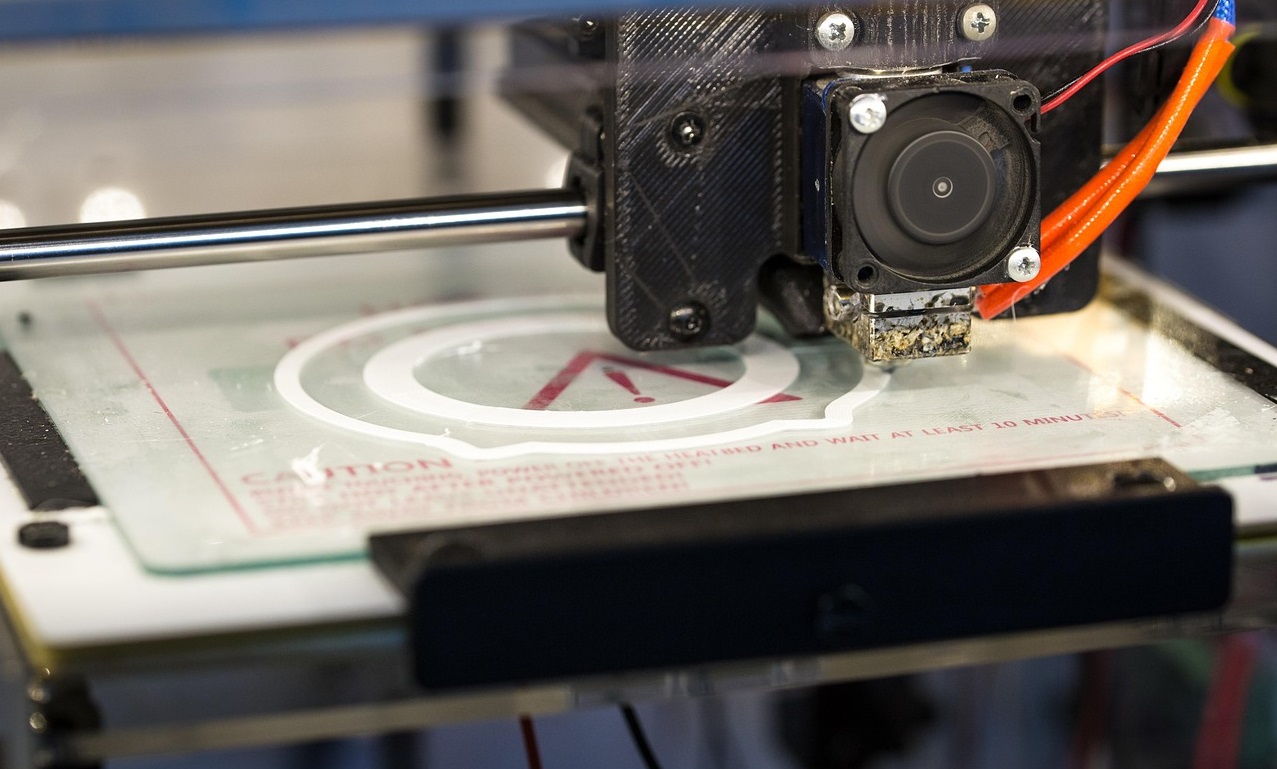

You might ask how 3D printing works. Think of building something by stacking thin layers. Each layer goes on top of the last one. This is called additive manufacturing. You begin with a digital design made in a CAD program. The printer software cuts this design into thin slices. The printer follows these slices and adds material only where it is needed.

Layering is the main idea behind 3D printing in medical devices. It helps make complex shapes that are hard or impossible to create with old methods.

Here’s what usually happens:

- You make a digital model.

- The printer software slices the model into layers.

- The printer puts down material layer by layer.

This way, you can make things with special shapes and details. Regular machines cannot do this. In 3D printing of medical devices, every detail is important for safety and comfort.

Differences from Traditional Manufacturing

You may think 3D printing is just another way to make things. But it is very different from older methods. Traditional manufacturing, like injection molding, starts with a big block of material. It cuts away what you do not need. This wastes material and limits the shapes you can make. Factories use these methods for large batches. It saves money when making thousands of the same item.

3D printing builds objects layer by layer. Each print has small differences. This is not like traditional methods, which make almost identical products. These differences make batch testing harder for 3D printed items. Also, traditional manufacturing uses many strong materials. 3D printing has trouble with some materials, like high-performance plastics and metal alloys. The strength of 3D printed parts can change in different directions. This makes them less reliable under stress than traditional parts.

Let’s look at the differences:

| Feature | 3D Printing Stuff | Traditional Manufacturing |

| Customization | Excellent | Limited |

| Batch Size | Small batches, unique items | Large batches, identical items |

| Material Waste | Minimal | Often high |

| Speed | Fast for prototypes | Fast for mass production |

| Cost | Higher for big batches | Lower for big batches |

You get more choices with a 3D printing service. It helps with customized machining and precision manufacturing. Medical machining manufacturers and manufacturers of medical instruments use these differences to make special devices for patients.

Why It Matters in Healthcare

Why does this technology matter to you? 3D printing in medical devices fixes problems that old methods cannot. You get implants and tools made for your body. This means less pain and better results. Doctors use 3D printed models to plan surgeries. This makes surgeries safer and faster. New ideas are tested quickly with rapid prototyping.

- Addressing Core Challenges: Custom devices fit your body and reduce problems.

- Enhancing Patient Outcomes: Special devices help you feel better and make treatments work.

- Accelerating Innovation: Rapid prototyping lets people design and test new devices faster.

- Improving Surgical and Medical Education: 3D printed models help doctors train and teach patients.

- Supporting Sustainability and Accessibility: Printing on demand cuts waste and helps people in hard-to-reach places.

- Preparing for Future Healthcare Needs: 3D printing helps with aging and emergencies.

You get quick access to custom dental crowns, surgical guides, and prosthetics. Medical machining manufacturers and factories can help with rare conditions. With 3D printing service, you get faster care and better results. Healthcare will keep changing as technology grows. You will see more treatments made just for you.

3D Printing Technologies in Medical Devices

Fused Deposition Modeling (FDM)

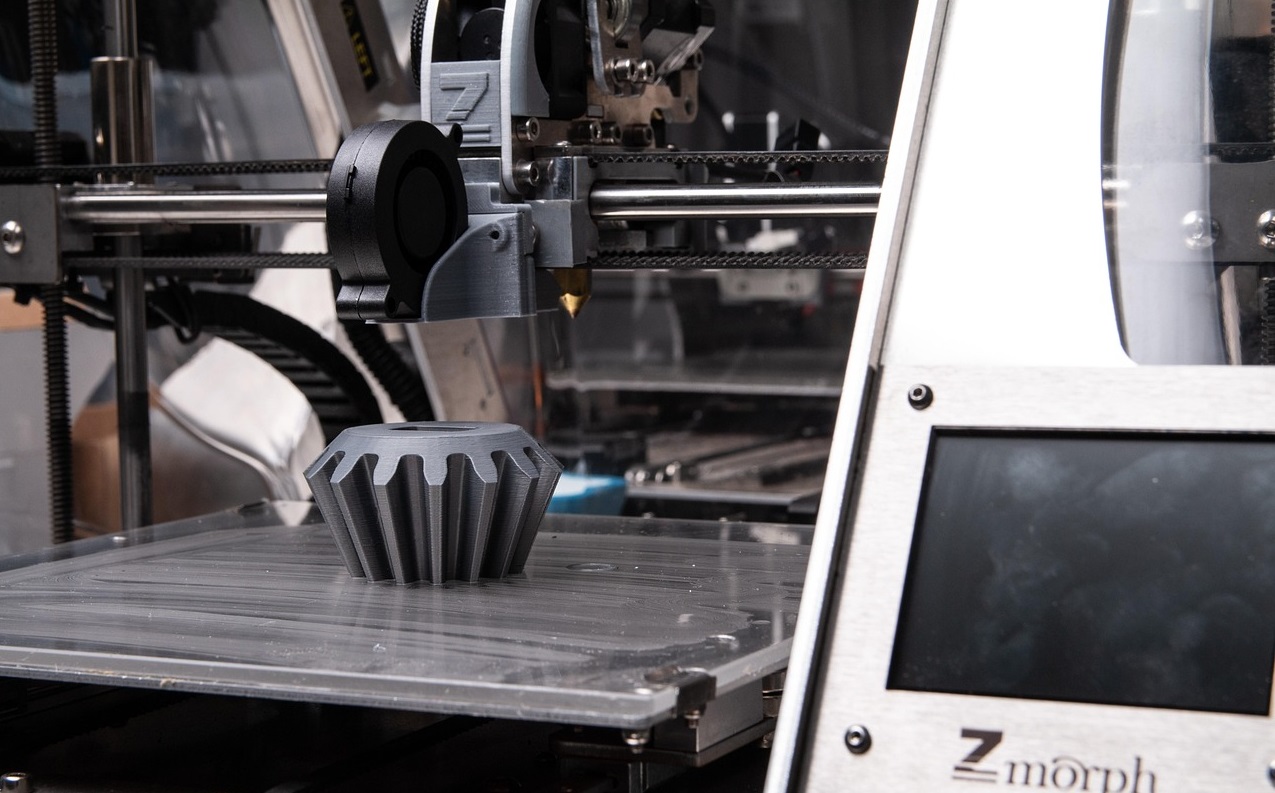

Maybe you have seen a 3D printer at school or work. Fused Deposition Modeling, called FDM, is very common. You start with a roll of plastic. The printer heats the plastic and pushes it out. The nozzle moves and puts down melted plastic in layers. You can watch your design appear as it prints.

FDM is popular with medical machining manufacturers because it is fast and cheap. You get new models quickly, so changes are easy. If you need a custom splint or guide, FDM can make it. You can pick from many materials, even strong plastics. This makes FDM good for customized machining and precision manufacturing.

Let’s check the good and bad sides:

| Advantages of FDM | Limitations of FDM |

| It is fast, so you get models quickly. | The surface can look rough and may need extra work. |

| It is cheap because the materials do not cost much. | The parts may not be as strong as those made another way. |

| You can use many types of plastic. | The layers can make weak spots in the part. |

| You can change designs easily. | Extra supports are needed, which use more material. |

Tip: FDM is great if you want a quick model or a custom device. You might need to smooth the surface after printing.

You see FDM used for braces, splints, and some tools. A manufacturer of medical instruments uses FDM for first designs. You get fast, low-cost results, but the surface may feel rough. That is normal with this 3D printing stuff.

Stereolithography (SLA)

Stereolithography, or SLA, works differently. You start with a tub of liquid resin. A laser draws each layer and hardens the resin. You get parts with lots of detail and smooth surfaces. If you need a dental crown or a small tool, SLA can make it.

SLA is used when you need high detail. Medical machining manufacturers use it for dental work and models. You get very accurate parts, which is good for patient-specific devices. SLA can use biocompatible materials, so it is safe for medical use.

Here is what makes SLA special:

- You get prosthetics and orthotics made just for you.

- Doctors use SLA models to plan surgeries.

- Researchers use SLA to print living cells and tissues.

- SLA helps make tiny devices for testing new drugs.

- You see fine details and smooth surfaces.

- Some materials are safe for the body.

- You can test new ideas quickly.

Note: SLA is best for detailed, patient-specific devices. You get smooth parts, but it can cost more than FDM.

Selective Laser Melting (SLM) and Selective Laser Sintering (SLS)

You may wonder how 3D printing makes strong metal parts. SLM and SLS do this job. Both use lasers and powder, but they work in different ways.

SLM melts the powder all the way, making solid parts. SLS heats the powder so it sticks together, but does not melt fully. You get different results with each method. Factories use SLM for implants and tools that must be strong. SLS is good for testing and making tricky shapes.

Here is a quick look:

| Category | Selective Laser Sintering (SLS) | Selective Laser Melting (SLM) |

| Material State During Process | Powder is heated and sticks together. | Powder is melted to make a solid part. |

| End-Product Characteristics | Parts can be a bit porous and less strong. | Parts are dense and strong, like regular metal parts. |

| Applications | Good for testing and tricky shapes. | Used for strong metal parts in important jobs. |

| Support Structures | No extra supports needed; loose powder holds the part. | Needs support to stop the part from bending. |

| Surface Finish | The finish is rougher because of the powder. | The finish is smoother, but it may need extra work. |

You see SLM used for hip implants, dental frames, and bone plates. Manufacturer of medical instruments trusts SLM for strong parts. SLS is used for testing and new designs. Both help with precision manufacturing and customized machining, so you get what you need.

If you want strong, custom metal parts, SLM is the best choice. SLS is good for testing ideas and making tricky shapes.

You now have more options with the 3D printing service. Medical machining manufacturers and factories can make what you need, from models to finished implants.

Digital Light Processing (DLP)

Have you ever wondered why some medical devices look so smooth? Digital Light Processing, or DLP, is a 3D printing technology that uses light to harden liquid resin, one layer at a time. DLP is used for dental crowns, hearing aids, and tiny surgical tools. This process is quick and very accurate, so medical machining manufacturers can make custom products fast.

DLP is special because it can print many items at once. All the parts come out with great detail and strength. If you need a custom implant or dental restoration, DLP can help. Factories and manufacturers of medical instruments like DLP because it is fast and makes high-quality parts.

Here’s how DLP helps make medical devices:

| Application Area | Description |

| Custom Implants | DLP makes custom zirconia implants with the right size and good bending strength. |

| Bioprinting | PEGDA and GelMA are popular inks for bioprinting because they are safe for the body and work well. |

| Functionalized Constructs | Adding nanoparticles gives printed products special features like piezoelectricity and electroconductivity. |

| FDA Approvals | Since 2015, at least 85 3D printed medical devices have been approved by the FDA, including custom implants and models. |

With DLP, you have more options. You can get implants that match your bones or dental crowns that fit just right. DLP also helps with bioprinting, where special inks make living tissues. If you want a device with extra features, DLP can add nanoparticles. Medical machining manufacturers use DLP for precision manufacturing and customized machining, so every part fits your needs.

Tip: DLP is good for printing lots of small, detailed parts at once. You get smooth finishes and fast results, so you do not have to wait long for your device.

Electron Beam Melting (EBM)

If you need a strong metal implant, Electron Beam Melting, or EBM, is the technology that makes it. EBM uses a beam of electrons to melt metal powder in a vacuum. The parts made are dense, strong, and safe for your body. Factories and manufacturers of medical instruments use EBM for hip replacements, bone plates, and facial repairs.

EBM is used when you need special shapes and features. The vacuum keeps the metal clean, which is important for titanium implants. Medical machining manufacturers trust EBM because it can make macro-porous structures that help bone grow into the implant.

Here’s what makes EBM different:

- You get complex 3D shapes and porous parts that help bone grow.

- The vacuum stops contamination, which is important for titanium and its alloys.

- EBM is used for simple cups and also for tricky face reconstructions.

- You can order custom prostheses and implants with special shapes and strengths.

- Titanium and its alloys are used in EBM because they are safe and strong.

- Factories like EBM because it is efficient and meets tough implant rules.

If you want a device that matches your body and lasts a long time, EBM is a great choice. Medical machining manufacturers use EBM for precision manufacturing and customized machining, so your implant fits well and works right.

Note: EBM is best for metal implants that must be strong, pure, and custom-shaped. You get good results and advanced features that help your body heal.

Bio-Printing

Imagine getting a new organ printed just for you. Bio-printing is making this dream closer to real life. This 3D printing stuff uses living cells and special bioinks to make tissues like skin, blood vessels, and even organs. Medical machining manufacturers and 3D printing in medical devices service providers use bio-printing to make medical devices that match your body.

Bio-printing lowers the risk of rejection because the printed tissues act like your own. You get implants and prosthetics faster, so you do not have to wait long. Factories and manufacturers of medical instruments are trying bio-printing for things like stents and skin grafts.

Bio-printing is changing medical care. You get hope for new treatments and faster healing. Medical machining manufacturers and factories are working to solve problems and bring bio-printed devices to more people.

Callout: Bio-printing is the future of personalized medicine. You may see printed organs and tissues in hospitals soon, thanks to new 3D printing stuff and precision manufacturing.

Applications of 3D Printing in Medical Devices

Custom Implants

Doctors can now get implants that fit your body perfectly. With 3D printing in medical devices, implants are made just for you. Medical machining manufacturers use this technology to match your body’s shape. You get a better fit and heal faster with fewer problems.

Orthopedic and Cranial

If you break a bone or need part of your skull fixed, you want a perfect fit. Old implants often needed more surgeries to fit right. Now, 3D printing stuff uses your CT or MRI scans to make exact implants. Factories use biocompatible materials, so your body accepts the implant.

- Custom orthopedic implants fix hips, knees, and small hand bones.

- Cranial plates from a 3D printing service fit your skull’s curves and protect your brain.

- Doctors plan surgeries better because the implant fits the first time.

3D printing technology makes complex shapes that help the body accept implants. These patient-specific implants make surgery easier and help you heal faster.

You get an implant that feels like it belongs in your body. This means less pain, and you can get back to your normal life sooner.

Dental Restorations

If you need a crown or denture, 3D printing in medical devices helps a lot. The dentist scans your mouth. Then, the manufacturer of medical instruments or dental lab prints a crown, bridge, or denture that fits you.

- Crowns and bridges are ready in just a few hours.

- Dentures fit better, so eating and talking are easier.

- Dental implants match your jawbone and feel strong.

You do not have to wait long or come back many times. Customized machining and precision manufacturing make sure your dental device fits well.

The best thing about 3D printers in medicine is making custom products and equipment.

Surgical Tools

Doctors need special tools for every surgery. With a 3D printing service, tools are made for each patient and surgery. Medical machining manufacturers can design and print forceps, clamps, and hemostats that fit the surgeon’s hand or the patient’s body.

Guides and Instruments

Surgical guides help doctors cut or drill in the right spot. These guides are made from scans of your body, so they fit perfectly. Surgeries are safer, and results are better.

Here are some common 3D-printed surgical tools:

- Scalpel handles: Easy to hold, so surgeons stay steady.

- Forceps: Custom grips help doctors handle tissues gently.

- Clamps: Light and shaped for your body.

- Retractors: Hold skin or organs out of the way.

- Hemostats: Stop bleeding by closing blood vessels.

3D-printed implants fit better than regular ones. They work better with your body and help you heal. Customization means fewer extra surgeries.

You see these tools in hospitals and clinics. Factories can print them fast, so doctors always have what they need. The manufacturer of medical instruments can even make disposable tools for safer surgeries.

Anatomical Models

Imagine holding a model of your own heart or brain before surgery. 3D printing stuff makes this possible. Doctors and students use these models to learn, plan, and practice.

- You can see and touch a copy of your organ to understand your treatment.

- Surgeons use models to plan hard operations, making them safer and faster.

- Medical students learn anatomy by studying real-size, accurate models.

3D-printed models help people understand the body by giving real organ copies to look at and touch. They help surgeons do better and help students learn faster.

Hospitals use anatomical models for heart surgery, bone repairs, and brain operations. Customized machining and precision manufacturing make each model special, just like you.

In summary:

- You get custom implants, dental restorations, and surgical tools made for you.

- Doctors use anatomical models to plan and practice, making your care safer.

- 3D printing in medical devices gives you better results, faster healing, and lower costs.

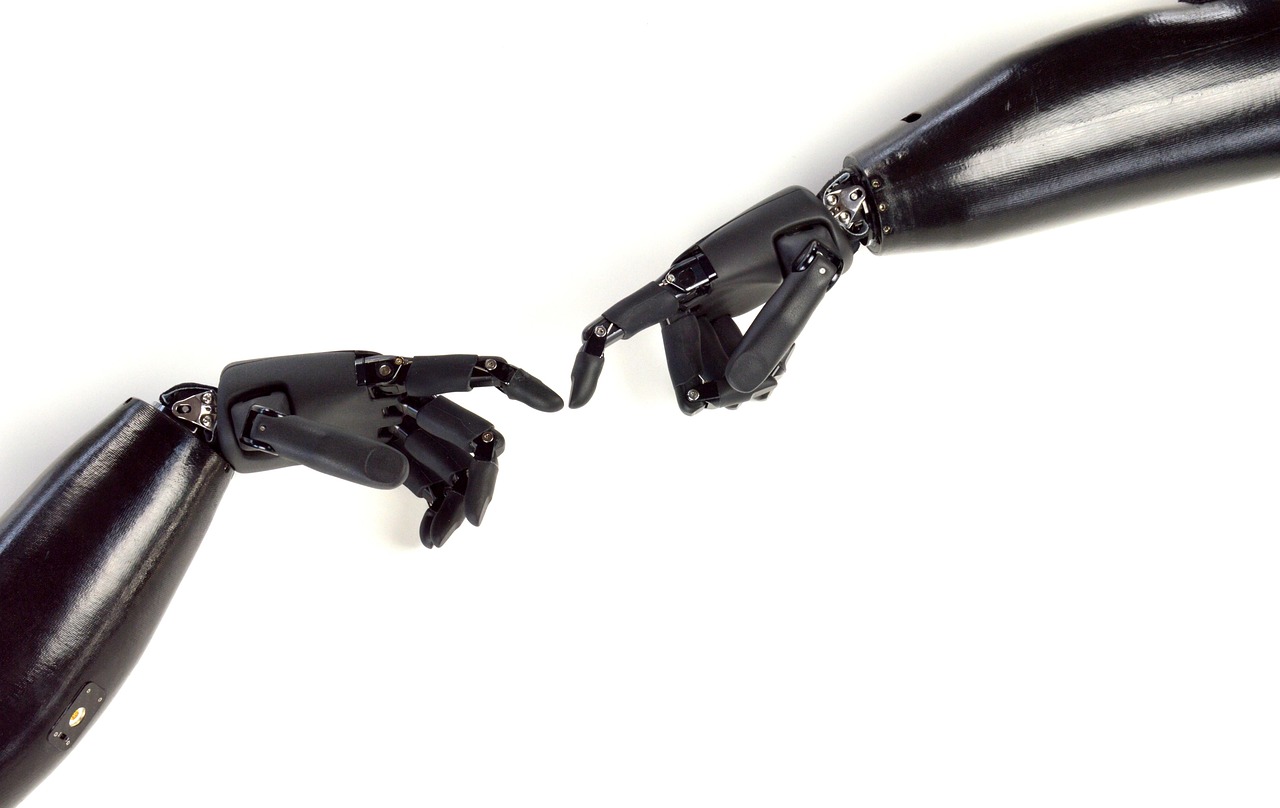

Prosthetics and Splints

Getting a prosthetic limb or splint used to be hard. It was expensive and took a long time. Years ago, people waited weeks or months for help. They paid thousands of dollars for a device. Now, 3D printing stuff is changing things fast. You can go to a clinic and get a new hand or leg quickly. The device fits your body perfectly. It feels almost like magic.

3D printing service helps make prosthetics and splints just for you. Medical machining manufacturers use scans of your limb or injury. They design a device that matches your shape and needs. You get a comfortable fit and better movement. The device looks and feels right for you.

Tip: With 3D printing, you can pick colors and shapes. You can add cool designs to your prosthetic. Kids like choosing their favorite superhero or sports team!

Here’s how 3D printing in medical devices makes prosthetics and splints better:

- You get a device that fits your body, not a one-size-fits-all.

- Factories can print hands, arms, legs, and splints in days.

- A manufacturer of medical instruments uses precision manufacturing for strong parts.

- Customized machining means your device matches your lifestyle.

Affordability and Accessibility

You do not have to worry about big bills now. 3D printing makes prosthetics and splints affordable for almost everyone. Here’s what is happening:

- Prosthetics that cost thousands now cost less than $100.

- Clinics in remote areas can print devices nearby, so you do not have to travel far.

- Open-source designs let you download and customize your own prosthetic for free.

- Small clinics and people can buy 3D printers and make devices themselves.

- Functional prosthetic hands can be printed for under $50, helping more people.

Accessibility for All

More people get the help they need, even in small towns. Local production solves problems with shipping and waiting. Communities work together using 3D printing services and customized machining.

- You get your prosthetic or splint faster, sometimes in just hours.

- Local clinics use 3D printing to help kids and adults who could not afford devices before.

- Precision manufacturing makes every device strong and safe, even in small places.

Why It Matters

Think about a child who lost a hand. Before, the family could not afford a prosthetic. Now, with 3D printing, the child gets a new hand for the price of shoes. The device fits, works, and looks cool. The child goes back to school and plays with friends. The child feels confident again.

Callout: 3D printing is not just about technology. It gives people their lives back. You get comfort, movement, and independence.

Medical machining manufacturers and manufacturers of medical instruments keep making these devices better. You see new materials and smarter designs every day. Production is faster now. The future looks bright, and more amazing changes are coming soon.

In summary:

- You get affordable, custom prosthetics and splints thanks to the 3D printing service.

- Clinics and factories use precision manufacturing and customized machining to help more people.

- 3D printing stuff brings hope and independence to those who need it most.

Recent Breakthroughs of 3D Printing in Medical Devices

New Materials

You might think only plastic and metal are used for medical devices. But now, new materials are making things better. There are flexible resins that act like real body tissues. These help make prosthetics and implants that move like your own parts. At the University of Texas at Austin, researchers developed a dual-light printing method. This lets one device have both soft and hard parts. Imagine a knee joint model with bendy ligaments and hard bones, all printed at once!

Here’s a quick look at how different materials compare:

| Material Type | Advantages | Challenges |

| Metallic Materials | Very strong, lasts long, safe for the body | Metal powders cost a lot, are hard to process, and can cause stress problems |

| Polymeric Materials | It can be used in many ways, is easy to shape, and is not expensive | Not strong enough for heavy loads |

| Bioactive Agents | Help tissues heal, and can release growth factors where needed | Not always strong, hard to keep cells alive during printing |

Titanium alloys are used for strong, light implants. Stainless steel is good for short-term devices. Cobalt-chromium alloys last a long time in joints. Polylactic acid (PLA) is used for body models. Polyether ether ketone (PEEK) is a tough plastic for spine cages. Medical machining manufacturers and factories now have more choices for making custom devices.

Tip: With new materials, your device fits better, lasts longer, and feels more natural.

Speed and Precision

You want your medical device fast and working well. 3D printing stuff helps with this. Factories and manufacturers of medical instruments can now make tiny, detailed parts. Better materials make devices safer and work better. You get custom devices quickly, even for rare needs.

See how speed and precision are better now:

| Evidence | Explanation |

| Miniaturization | 3D printing in medical devices makes very small parts with great detail, perfect for medical use. |

| Advanced materials | Safe and heat-resistant materials make devices work better and safer. |

| Customization | You can get single-use or small-batch devices, saving money and time. |

Medical machining manufacturers use 3D printing in medical device services to test ideas fast. Customized machining means your device matches your body. Precision manufacturing makes sure every part fits and works right.

Callout: Faster and more accurate production means you wait less and heal faster.

Digital Integration

Digital integration is making medical devices smarter and more personal. You see cool stories where 3D printing services and digital design work together. For example:

- A cancer patient got a custom 3D-printed titanium jaw implant. This helped them heal faster and use their jaw better.

- Doctors made models of heart defects with 3D printing. These models helped plan surgeries and made the results better.

- Researchers printed an ear prosthesis using PVDF. It was very sensitive to pressure, which could help in new medical ways.

Medical machining manufacturers and manufacturers of medical instruments use digital files to design and print devices that fit you. Factories use digital integration for customized machining, so every device matches your needs.

Note: Digital integration means you get devices made just for you, using your scans and data.

These breakthroughs show the future of healthcare. New materials, faster making, and digital design are changing your care. 3D printing stuff is making medical devices safer, smarter, and more personal every day.

Regulation and Safety of 3D Printing in Medical Devices

FDA Guidelines

You may wonder how 3D-printed medical devices get approved. The FDA has rules to keep you safe. Every step in making a device is important. The FDA checks the materials, design, and printing process. They want medical machining manufacturers and factories to follow strict rules.

Here’s a table showing what the FDA checks:

| Theme/Process | Description |

| Materials | Plastics, metals, ceramics (not biological AM materials) |

| Design, printing, and validation | Every step must be checked and proven |

| Printing characteristics | Printers must meet specific standards |

| Physical and mechanical assessment | Devices must be strong and reliable |

| Biological considerations | Cleaning, sterility, and biocompatibility are required |

| Common AM processes | FDM, SLS, SLA, LBE |

Every device needs careful testing to prove it works. The FDA wants records from start to finish. Biocompatibility tests must follow ISO-10993-1 rules. The FDA also asks people for feedback to make better rules. This helps keep 3D printing stuff safe for everyone.

Tip: If you use 3D printing in medical devices, check if they follow FDA rules. This keeps you safe and makes sure your device works well.

Quality and Standards

Quality is very important in healthcare. You want your device to work every time. Precision manufacturing and customized machining help with this. The FDA, MFDS, and ISO all have safety and performance rules. Manufacturers of medical instruments must follow these before selling devices.

Here’s a table of important quality rules:

| Quality Standard | Description |

| MFDS Guidelines | Devices must meet safety and performance standards |

| ISO 13485 | Requires a Quality Management System for manufacturing |

| GMP | Covers design, testing, and quality control |

| FDA Guidance | Focuses on design, manufacturing, and testing for 3D printed devices |

There are strict checks in place. Factories must keep records of everything. They check suppliers, report problems, and train workers. Risk management and design checks are done every day. Clinical tests are needed before you get a device.

- Document controls

- Manufacturing checks

- Transport and storage rules

- Supplier management

- Problem reporting

- CAPA (Corrective and Preventive Actions)

- Risk management

- Design controls

- Staff training

- Clinical evaluation

It is important to control and check the 3D printing in the medical device process. The ISO/ASTM 52900 series helps set up these checks. Medical machining manufacturers use these rules to make sure every device is safe and works well.

Approval Challenges

Getting approval for 3D printed medical devices is hard. New materials and printing methods bring new risks. Regulators sometimes cannot keep up with fast changes. 3D printing stuff is complex, so testing is tough.

Here are some common problems:

- New materials and ways can bring risks that are hard to predict.

- Complex shapes make safety tests harder.

- Rough surfaces and hidden defects need careful checks.

- Different countries have different rules, which can be confusing.

- The FDA has rules, but the European Union does not have clear rules for additive manufacturing.

Medical machining manufacturers and factories work hard to solve these problems. Manufacturer of medical instruments must show their devices are safe. Precision manufacturing and customized machining help lower risks, but approval still takes time.

Note: The approval process is hard, but it keeps you safe. Always pick devices from trusted 3D printing in medical devices service providers who follow the newest rules.

Future of 3D Printing in Medical Devices

Personalized Care

You may wonder how 3D printing in medical devices will change your doctor visits. Imagine going to a clinic and getting a device made just for you. This is not just a dream anymore. New technology lets you get implants, prosthetics, and even medicine made for your needs. Medical machining manufacturers use scans of your body to design devices that fit you. You could get a prosthetic limb that matches your shape. You might get a wound dressing that helps you heal faster.

Here’s what you can expect:

- You can get medicine with the exact dose you need, sometimes with more than one drug in a single pill.

- Doctors use customized machining to make implants and prostheses that fit your body.

- Special wound dressings and microneedles help treat your own condition.

This kind of precision manufacturing means fewer side effects and better results. You spend less time waiting and more time getting better. The manufacturer of medical instruments and factory teams work together to make sure every device fits your body and your life.

Tip: Personalized care means you get treatments made for you. They work better because they are made for your body.

On-Demand Manufacturing

Have you ever needed a medical device fast? On-demand manufacturing is changing how you get care. With 3D printing in medical device services, clinics and hospitals can print devices when needed. You do not have to wait for shipments from far away. Factories use 3D printing to make custom implants, splints, and tools right at the clinic.

Look at the good and bad sides:

| Benefits | Challenges |

| Customization | Hard to make many at once |

| Lower costs | Hard to copy exactly |

| Better access | Size and shape can be tricky |

| Not enough rules yet |

You get devices faster and pay less. Clinics in far places can help more people. But making lots of devices at once is still hard. Sometimes, it is tough to get the size or shape just right. Rules are catching up, so always check if your device is safe.

Callout: On-demand manufacturing means you get what you need, when you need it. It makes healthcare easier and helps more people.

Trends and Research

You live in a time when things change quickly. The future of 3D printing in medical devices looks bright. Multi-material printing lets factories use different materials at once. Devices can act more like real body parts. For example, 3D Systems got FDA clearance for dentures made with several materials. This gives patients better results.

Here’s what is happening:

- Customization is growing fast. Experts think it will grow by 21% each year by 2026, because of lower costs and better designs.

- Bioprinting may soon make working organs, so fewer people will need donors. Some labs have already printed pancreas models.

- Surgeons use 3D-printed models to plan surgeries. This helps them practice and lowers mistakes.

- Pharmaceutical printing lets you get medicine made just for you, with the right dose and lower costs.

- Remote 3D printing service centers help people in far places get what they need.

Research shows that better 3D scanning and modeling help doctors treat you more accurately. Additive manufacturing, like laser sintering, makes custom products faster. AI helps design safer devices with biocompatible materials. Tissue engineering is moving toward printing new organs for transplants.

Note: The future brings more choices, faster care, and better results. You will see new devices and treatments that fit your life.

Impact on Patients and Providers

You may wonder how 3D printing stuff changes things for you and your doctor. The answer is easy. It makes care more personal, quicker, and simpler to understand. When you go to the hospital, doctors use 3D printed models to show you your surgery. You can hold a copy of your heart or bone. This helps you feel calm and ready for treatment.

Medical machining manufacturers and manufacturers of medical instruments work with doctors now. They use customized machining and precision manufacturing to make devices that fit you. You get implants and tools made for your body. This means fewer problems after surgery and faster healing. If you need something in an emergency, a factory can use a 3D printing service to make it quickly. During COVID-19, hospitals printed face shields and ventilator parts overnight. You saw new solutions appear when you needed help.

Here’s how 3D printing stuff helps you and your care team:

- 3D printed surgical models help doctors see tricky anatomy.

- These models help surgeons talk with you about your surgery.

- Planning with 3D models saves time in the operating room.

- Custom tools and implants mean fewer mistakes and better results.

You notice your doctor feels more sure. Nurses and surgeons trust their tools and plans more. You spend less time in surgery and heal faster. The whole team works together better because they can see and touch what they need before surgery.

Check out this table to see some benefits:

| Benefit | Description |

| Increased Confidence | Doctors and nurses feel sure about their procedures with 3D printed models. |

| Shortened Procedure Times | Surgeries take less time, so you recover sooner. |

You get more than just a device. You get care that feels safe and personal. Your team uses 3D printing service and precision manufacturing to make sure every step fits you. You see, technology and teamwork help you feel better, faster.

Tip: If you ever need surgery, ask your doctor if they use 3D printed models or custom tools. You might be surprised at how much easier and safer your care can be.

Why Choose NOBLE for 3D Printing in Medical Devices

If you want your medical device to work well, you need a team that knows every step. NOBLE is a top company in China for making these devices. You get more than just a factory. You get a group that is great at precision manufacturing and customized machining. NOBLE helps you go from an idea to a finished device. You can order one prototype or thousands of products.

NOBLE is different from other companies. You do not have to pay for expensive molds or tools. We use advanced 3D printing stuff, so small orders cost much less. You get prototypes in just a few days, not months. This helps you test, fix, and sell your product faster.

Here’s a table that shows why NOBLE is a smart pick for 3D printing in medical devices:

| Advantage | What You Get |

| Cost Savings | No need for costly molds; small batches are affordable |

| Perfect Fit | Custom prosthetics, surgical guides, and dental implants tailored to you |

| Fast Prototyping | Prototypes and testing completed in days |

| Design Freedom | Complex shapes and easy modifications for unique patient needs |

| Mass Production Capability | Seamless transition from prototype to large-scale manufacturing |

| Expert Support | Skilled engineers guide you through every step |

NOBLE helps with hard designs. Our 3D printing service lets you make shapes that old ways cannot. You can change designs for each patient’s body. This is great for medical machining manufacturers and anyone who needs special devices.

NOBLE’s team works with you at every step. You get help from experts in customized machining and precision manufacturing. If you need a new tool, NOBLE’s engineers can print and test it fast. When you want to make many devices, the factory can do it quickly. The manufacturer of medical instruments trusts NOBLE for good quality and fast work.

Tip: With NOBLE, you get more than a product. You get a partner who wants you to succeed. Our service makes your job easier, whether you are a doctor, designer, or business owner.

You see better comfort and safety for patients. Devices fit well, work well, and help people heal faster. NOBLE cares about quality, so you can trust every part. If you want to make your ideas real, NOBLE is ready to help from start to finish.

You can see that 3D printing is making medical devices better. Now, you can get implants made just for you. Prosthetics are made faster, so you do not have to wait long. Tools for doctors are safer than before. Factories and medical machining manufacturers use special machines to help you heal. Manufacturers of medical instruments and 3D printing in medical devices service teams work hard to make new designs. New ideas and rules will change your care. Think about how healthcare might look for you soon!

- Customization makes things more comfortable.

- Faster speed helps you get better sooner.

- New inventions give people hope.

FAQs

What medical devices can you make with 3D printing stuff?

You can get implants, prosthetics, dental crowns, and splints. Factories use 3D printing services to make tools and models. Doctors and patients use these for care and treatment.

How does a 3D printing service help with customized machining?

3D printing service lets you design devices for your body. You get a perfect fit each time. The manufacturer of medical instruments makes sure your device matches your needs.

Is 3D printing safe for medical devices?

Yes, most devices follow strict safety rules. Precision manufacturing and checks keep you safe. The FDA and other groups test materials and designs before use.

Tip: Always ask your doctor if your device meets safety standards.

Can you get a device faster with 3D printing stuff?

Yes, you can get devices quickly. Factories and medical machining manufacturers print fast. You wait less for prosthetics, implants, or dental crowns. An on-demand 3D printing service means you get help when you need it.

Why do doctors choose precision manufacturing for medical devices?

Precision manufacturing gives better results for patients. Doctors trust manufacturers of medical instruments who use this method. You get devices that fit well and work right, so you heal faster.

How affordable is 3D printed medical equipment?

3D printing stuff lowers costs for custom devices. You pay less for prosthetics and dental crowns. Small clinics and factories use a 3D printing service to help more people.

Note: Open-source designs and local production make devices even more affordable.