Did you know the world’s 3D printing market might be worth $168.93 billion by 2033? NOBLE helps you be part of this big change. You can make ideas into real things faster, taking advantage of the numerous 3D printing advantages. You can save money and create designs that were once too hard to achieve. 3D printing provides quick prototyping and allows you to produce items only when you need them, giving you more choices. Manufacturers are getting their stuff quicker, and there’s less waste, so their supply chains are stronger now. This helps you stay ahead, work better, and accomplish more.

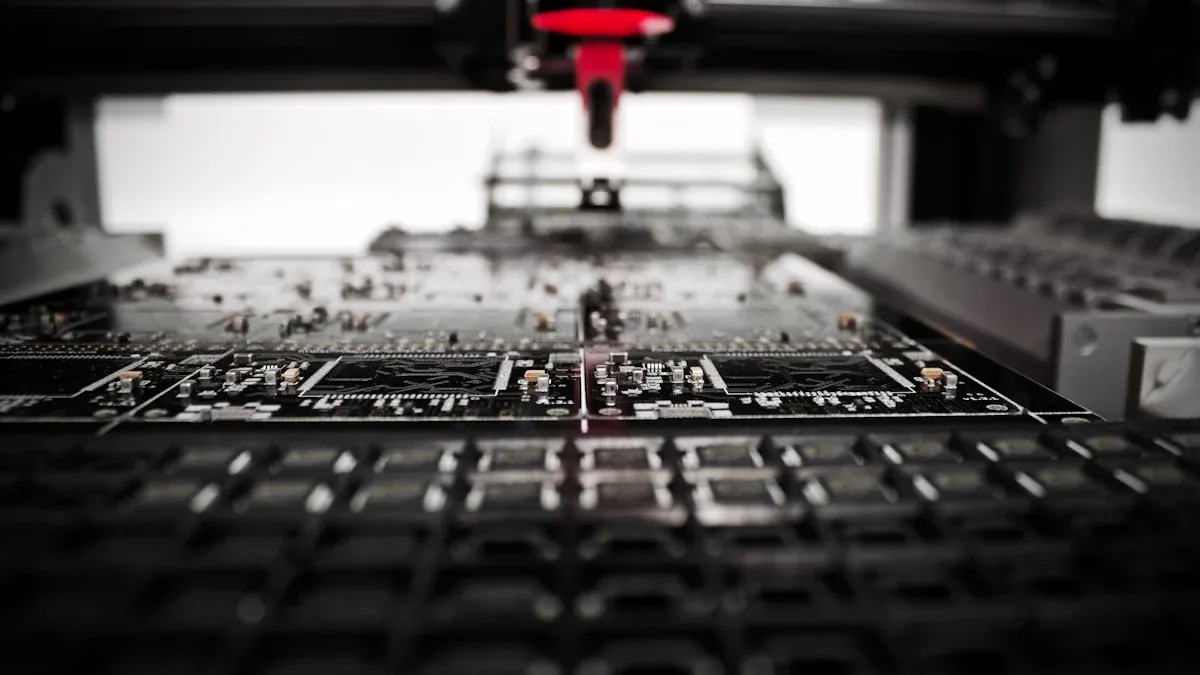

3D Printing Overview

Additive Manufacturing Basics

So, 3D printing—additive manufacturing—isn’t just another way to make a part. It’s a fundamentally different philosophy. The printer adds material only where it is needed. This is not like traditional manufacturing. Instead of starting with a block and cutting away what you don’t need, you start with nothing and add only what you do.

Let’s see how 3D printing is different from older ways:

| Aspect | 3D Printing | Traditional Manufacturing |

| Design Flexibility | Greater design flexibility for complex shapes | Limited by tooling design constraints |

| Time-to-Market | Faster production without molds | Longer lead times due to tooling requirements |

| Cost-Effectiveness | More cost-effective for low-volume production | Expensive for low-volume due to tooling costs |

| Waste | Produces less waste, using only the needed material | Generates waste through subtractive processes |

| Production Speed | Slower for large quantities | Faster for high-volume production |

| Material Availability | Compatible with a growing range of materials | Compatible with a wider range of materials |

You can make more complex shapes. You get dramatic time savings for prototypes and one-off parts. This allows for rapid iteration. You can test a design, find a flaw, tweak the model, and print a new version the same day.

How 3D Printing Works

Here is how the steps go:

- Design: You make a 3D model on your computer. This file is your plan.

- Slicing: Software cuts your model into thin layers.

- Printing: The printer reads each layer. It adds material one layer at a time. Your object slowly appears.

- Finishing: You may need to clean or polish the part. This gives it a nice look.

You do not need costly molds or tools. It trades the high upfront speed and material efficiency of mass production for unparalleled design freedom and agility in development.

You’re not just making a part differently; you’re thinking about design and problem-solving differently.

Key Technologies

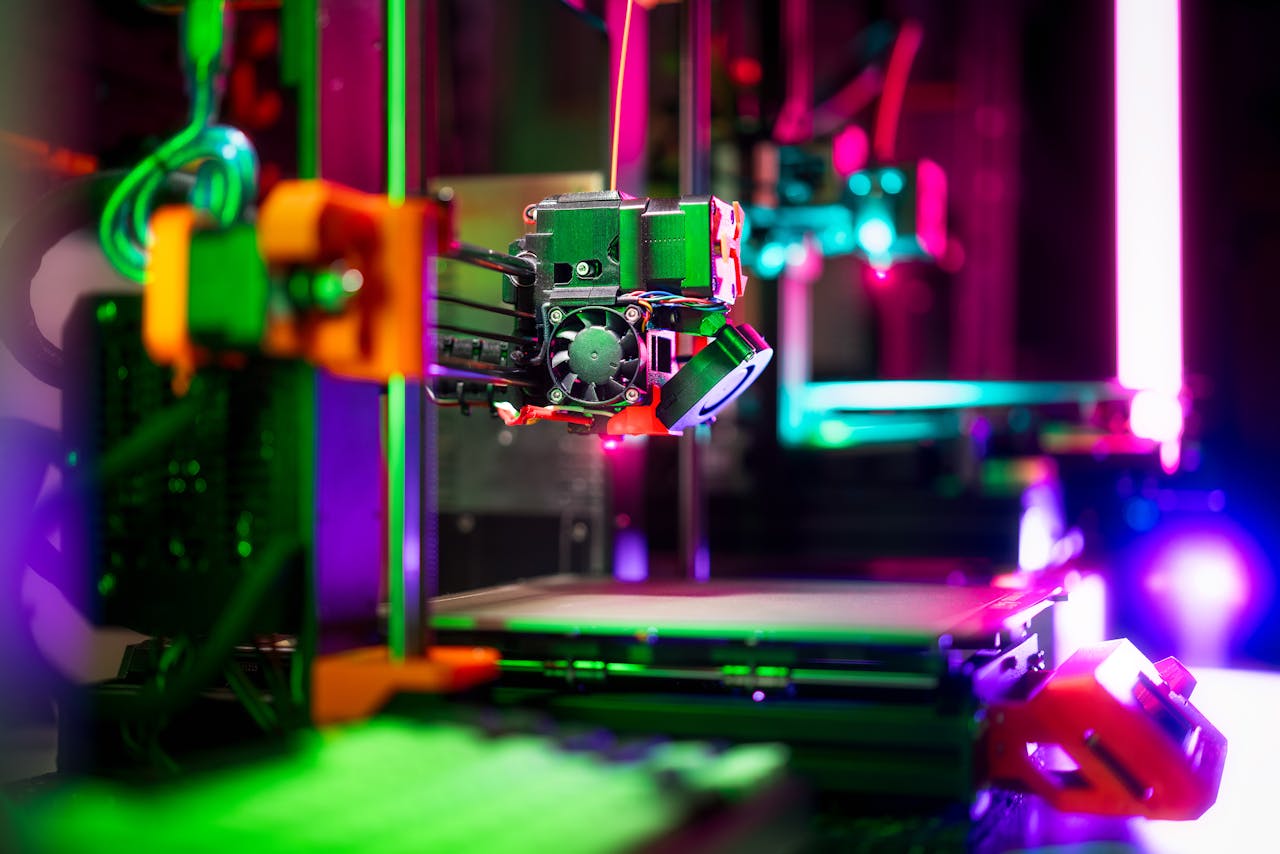

NOBLE is a leader in 3D printing. You can pick from many advanced technologies. Let’s break down why you’d pick one over another!

- Fused Deposition Modeling (FDM): It’s often the fastest and most cost-effective for conceptual prototypes and functional testing. It’s perfect for rapid iteration when surface finish isn’t the priority.

- Stereolithography (SLA): The results have excellent surface finish, fine feature resolution, and can achieve translucent or flexible properties.

- Selective Laser Sintering (SLS): It is for durability and complexity without supports.

- Multi Jet Fusion (MJF): It’s ideal for producing 50 to 500 functional parts that need to be durable and consistent.

NOBLE helps you choose the best technology for your needs. You’re not just getting a printed part. You’re getting the right printed part for the specific stage of your project—whether it’s a concept model, a functional test piece, or a short run of end-use components.

3D Printing Advantages in Manufacturing

Rapid Prototyping

You want your ideas to become real fast. Rapid prototyping helps with this. —It collapses the traditional development timeline. It fundamentally changes how you approach design and testing.

Here’s the comparison in real terms.

| Advantage | Description |

| Shorter lead times | You get models in hours or days, not weeks. |

| Cost efficiency | You do not need expensive tools or lots of workers. |

| Ease of use | Most 3D printers are easy to use. |

| Design flexibility | You can try new shapes and ideas easily. |

| Same-platform production | You can use one machine for both models and the final parts. |

NOBLE helps you make products faster. Engineered Profiles finished their work almost 90% quicker. They finished the design and approval before making any tools. Hemex Health is another classic case. In a field with tight regulatory deadlines and budget constraints, they used 3D printing to create functional test models. They met tight deadlines and budgets. The impact is profound.

In medical fields, it enables patient-specific models for surgical planning and custom implant design. A surgeon can hold an exact replica of a patient’s anatomy before an operation. This isn’t just faster; it’s safer.

Cost Efficiency

You want to spend less money. You do not need costly molds or tools. The cost efficiency of 3D printing isn’t just about a cheaper part. It’s about changing the entire cost structure of development and low-volume production. You’re avoiding the massive, upfront capital that traditional methods demand.

Here is how 3D printing saves you money:

| Mechanism | Description |

| Reducing Tooling Costs | You do not pay for molds and tools. |

| Lower Material Waste | You use material only where needed. |

| Faster Prototype Development | You improve products quickly, saving money. |

| Reduced Inventory and Storage Costs | You print parts when needed, so you do not pay for storage. |

Big 3D printers can work at speeds up to 400 mm/s, which directly translates to lower labor costs per part. The machine runs autonomously. NOBLE helps you get the best value, whether you need one part or many. Car makers use 3D printing for lightweight, complex brackets that would be multiple welded pieces otherwise. This lowers making and shipping costs. Medical applications, like patient-specific surgical guides or anatomical models, showcase the ultimate in custom, on-demand manufacturing. The alternative—traditional casting or machining a one-off—is prohibitively expensive and slow.

- Save on materials through near-net-shape additive processes.

- Eliminate payments for tooling, fixtures, and minimum order quantities.

- Get to market faster by collapsing the timeline from design to physical part, which means revenue starts sooner and development costs are lower.

Design Flexibility

You want to create what you imagine. The design is constrained only by your imagination and the physics of the material. Want a part with inside channels or a lattice? 3D printing makes it simple.

Let’s break down what this freedom actually enables.

- Software can now design a part based purely on the load paths it must carry. The result looks organic, like a bone structure. It uses the absolute minimum material to achieve maximum strength.

- An assembly of 10 separate components—fasteners, brackets, housings—can be printed as a single, integrated piece.

- Conformal cooling channels that follow the exact contour of a mold or engine part dramatically improve thermal management.

- The cost of making one unique part is the same as making one of a thousand identical parts.

A surgeon can now implant a titanium spinal cage that perfectly mirrors a patient’s own bone geometry. Car engineers design light parts with internal structures for better results. NOBLE helps you pick the best materials and technology for your project, so you get great results every time.

You can see, it changes everything. It provides speed (by eliminating tooling), savings (through material efficiency and consolidation), and unprecedented creative freedom. NOBLE is ready to help you use these benefits, whether you are making models or starting big production.

Waste Reduction

Traditional subtractive manufacturing is inherently wasteful. You start with a solid block, bar, or sheet. You then remove everything that isn’t your part. For complex parts, the “buy-to-fly” ratio—the amount of material you purchase versus what flies on the final product—can be abysmal. You only use the material your design needs. Old ways cut away extra material and leave lots of scraps. 80% waste isn’t an exaggeration for many machined aerospace components. 3D printing can cut waste by 70-90%.

Here’s how 3D printing helps you waste less:

- You purchase fewer raw materials.

- You have far less (and often less hazardous) scrap to manage.

- Less raw stock inventory, less space dedicated to scrap handling.

- For companies facing environmental regulations or consumer pressure, this is a tangible, data-driven advantage.

A study from the European Commission says additive manufacturing could save up to 90% of raw materials by 2050.

| Evidence Description | Details |

| Waste Plastic Production | 380 million tonnes are made each year, but only 9% gets recycled |

| Waste Biomass Generation | 140 billion metric tonnes from farms and forests, plus 2.01 billion tonnes from city trash |

| Mechanical Properties | 3D printed parts from recycled plastic work as well as new ones, and get even better with biomass fillers |

Tip: You can use recycled materials in 3D printing. The part remains strong—sometimes enhanced—while directly reducing the environmental burden.

Customization

3D printing erases that trade-off. It makes mass customization not just possible, but practical. The digital file is modified, not the factory line. The cost to print one unique item is essentially the same as printing one of a thousand identical ones. This changes the relationship between producer and customer.

Let’s see some real examples:

| Industry | Example | Description |

| Healthcare | Custom-fitted products | A custom prosthetic limb or patient-specific surgical guide isn’t a luxury; it’s a medical best practice. |

| Footwear | New Balance | Footwear, like New Balance’s work, uses 3D printing to create lattice-structured midsoles. |

| Art and Jewelry | Intricate designs | Designers can create intricate, interlocking pieces or lightweight, complex geometries that were previously unimaginable or prohibitively expensive to produce. |

NOBLE’s role in this is as an enabler. We provide the technical bridge. They help a medical device startup navigate biocompatible materials and sterilization requirements for a custom implant.

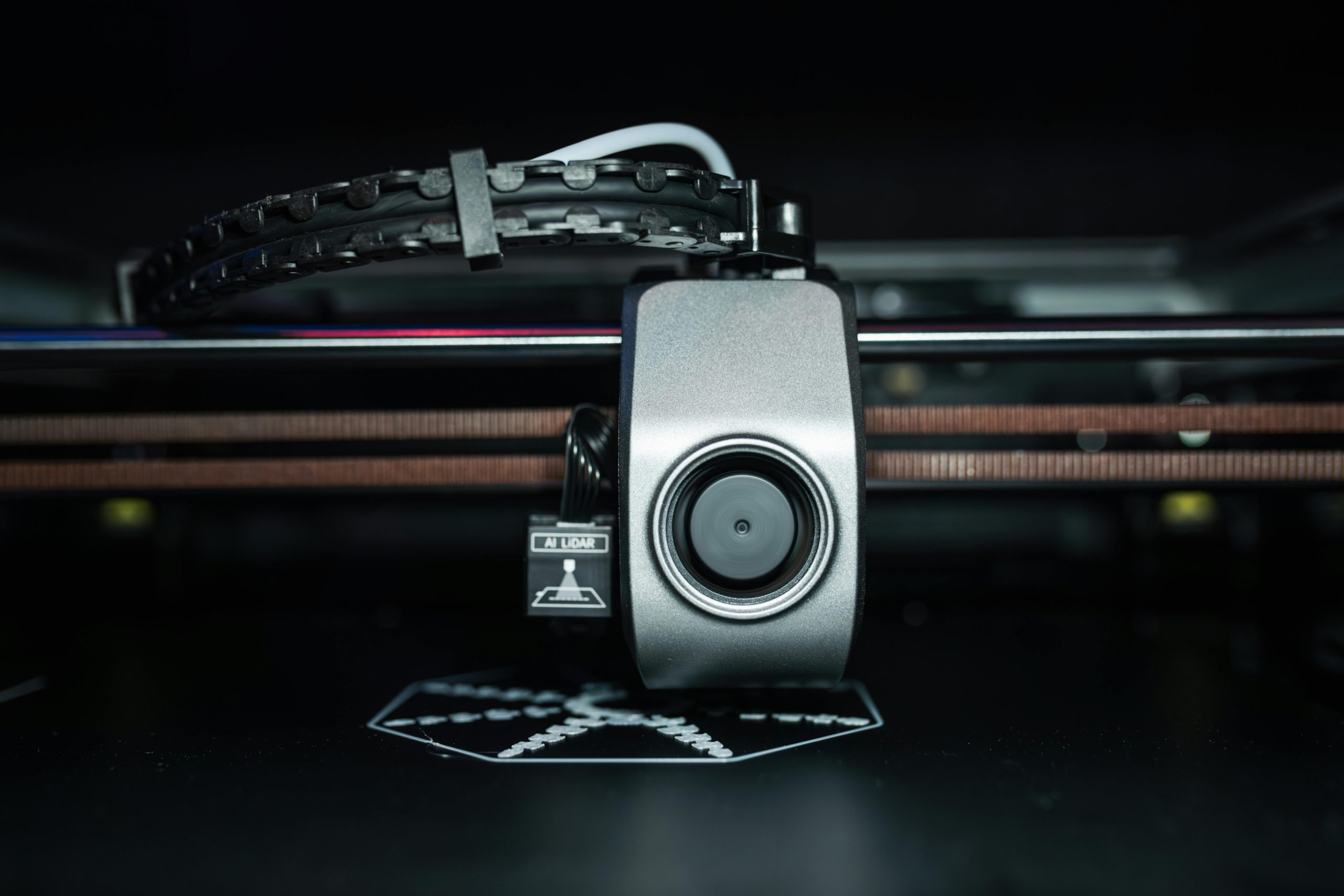

Quality Improvement

Quality in 3D printing isn’t an accident. It’s a deliberate outcome of controlling a chain of variables that traditional methods often can’t touch. You’re not just checking the final part; you’re engineering the environment it’s born in.

Let’s break down how this control translates to better quality:

- Maintaining a dry environment (30-50% RH) ensures the material behaves predictably.

- Controlling ambient temperature and eliminating vibrations from other factory equipment prevents warping, layer shifting, and dimensional inaccuracies.

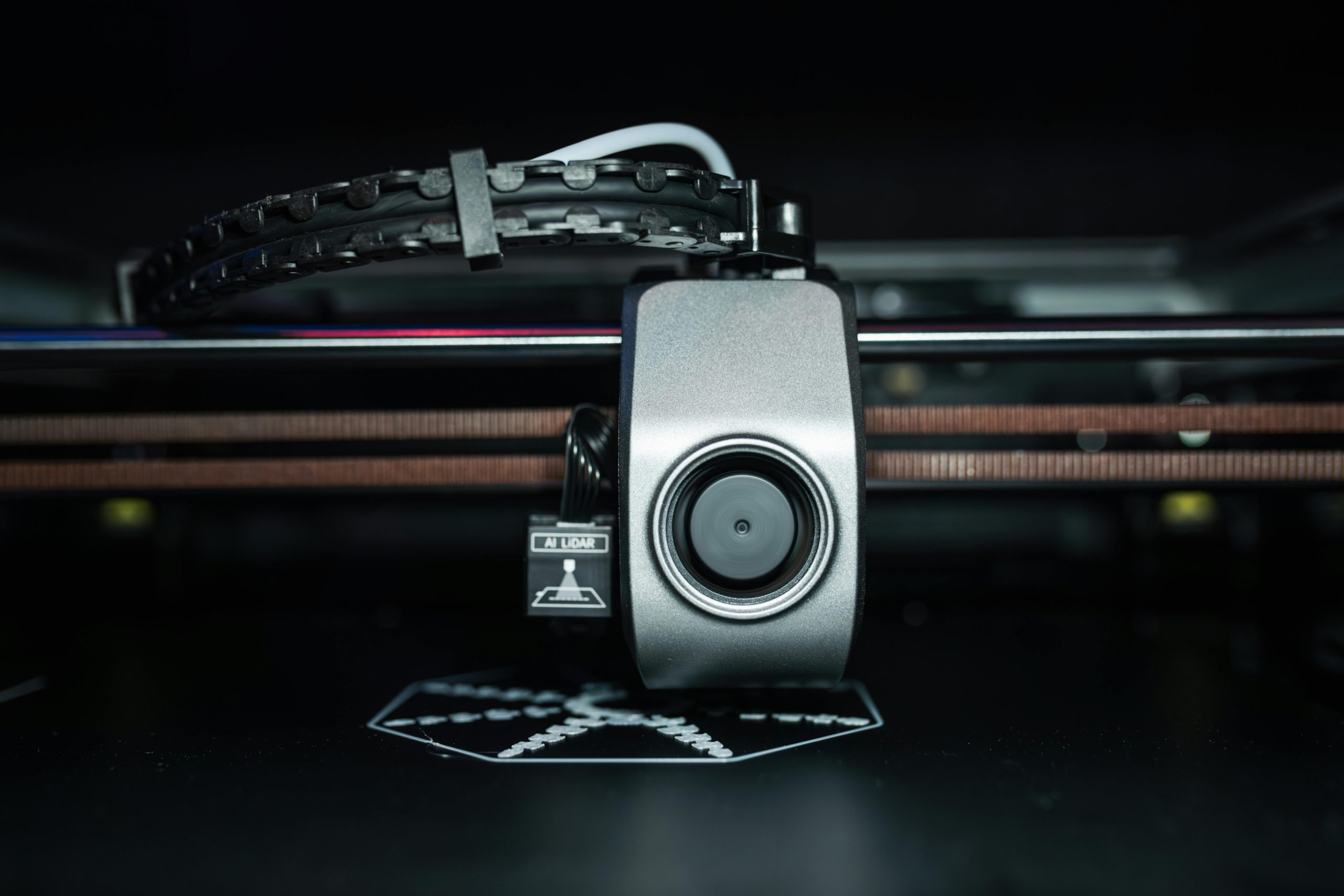

- Using sensors and cameras to watch the print in real time, detecting anomalies.

- Not just a visual check. Using coordinate measuring machines (CMM) or 3D scanners to verify critical dimensions against the original CAD model.

- Each part can be linked to its specific build job, machine, material batch, and operator.

- Design Iteration for Quality is a powerful feedback loop. Because you can print and test so rapidly, you don’t just fix flaws—you optimize for performance.

NOBLE uses advanced quality checks. Our advanced quality checks represent this systematized approach. It means they have moved beyond a craft and into a controlled manufacturing process. Our systems include:

- First Article Inspection (FAI) for new designs.

- Statistical Process Control (SPC) for production runs.

- Material certification for incoming feedstock.

- Regular machine calibration and maintenance logs.

The result is why we choose it: predictable, high-quality outcomes. You get more than a part that looks right. You get a part with verified dimensional accuracy, known mechanical properties, and a complete digital history.

Risk Reduction

You want to avoid surprises in your manufacturing process. That’s the strategic advantage. 3D printing isn’t just a production method; it’s a powerful tool for de-risking the entire product lifecycle, from concept to supply chain. It turns unknowns into knowns faster and cheaper than any traditional approach.

Take a look at how much time you save:

| Process Type | Traditional Lead Time | 3D Printing Lead Time | Reduction (%) |

| Prototyping | Months | 7 to 10 days | 50 to 80 |

| Pilot Production (Injection Molding) | Months | 7 to 10 days | 50 to 80 |

The core of the risk is the unknown. Will the design work? Will the parts fit? Will the market want it? Traditional manufacturing forces you to answer these questions with a massive financial commitment—molds, fixtures, minimum order quantities. You’re betting big before you have any real data.

With 3D printing, your initial investment is minimal. You can produce a small batch, test the market, and then scale seamlessly by running printers longer or adding more machines. This means less risk of wasted money and materials.

3D printing also helps you react to changes in demand. The control you gain is the real source of peace of mind. Your production capability isn’t locked in a foreign factory or a single mold. It’s portable, digital, and adaptable.

Sustainability

You care about the planet and want your business to do its part. 3D printing supports your sustainability goals in several ways. Traditional manufacturing is often linear: you extract the raw materials, process them, manufacture the product (with high waste), ship the finished product, use it, and then (often) discard it. 3D printing makes for a more circular, localised model.

Let’s break down the sustainability claims into concrete engineering and logistical facts.

- You purchase and process only the grams of material that end up in the final part. Powder-based systems can achieve over 95% material reuse.

- Energy use is more complicated. A 3D printer might use the same amount of energy as a dedicated injection moulding machine when making lots of products. But often, the total energy use is lower.

- You eliminate overproduction and the associated waste of unsold goods. You make one when you need one.

- Many 3D printing materials, like PLA, ABS, Nylon (PA), and TPU, are thermoplastics. They can be remelted and reformed.

When you print parts as needed, you do not have to keep large inventories. Many companies now see 3D printing as a way to meet both business and environmental goals. NOBLE supports you with eco-friendly materials and smart production methods, so you can feel good about your choices.

The outcome is clear. You’re no longer choosing between what’s best for your product and what’s best for the planet. The most efficient, innovative, and resilient way to manufacture—especially for complex, customized, or low-to-medium volume parts—is also the cleanest.

Speed and On-Demand Production

Shorter Lead Times

You want your products quickly. You can go from design to finished part in just days. Waiting weeks or months for a mold, die, or custom fixture is standard in traditional manufacturing. That entire wait—and its cost—vanishes. You print what you need, when you need it. Your timeline shifts from procurement and fabrication to upload and print.

Manufacturers are facing some major changes in their operations:

- Speeding up by 20-50% isn’t just about moving faster; it’s about making more informed decisions per unit of time.

- You can print at your facility, at a partner’s hub near your customer, or even at the point of use. This cuts logistics lead time from weeks to hours.

- You don’t need to forecast demand months in advance and build stock. When an order comes in, you start printing.

- Superior customer service through rapid fulfillment and customization.

Unilever made prototype parts 40% faster after using 3D printing. Audi prints tail light covers, showing how quickly you can change in real factories. You can join them and see these results in your own work.

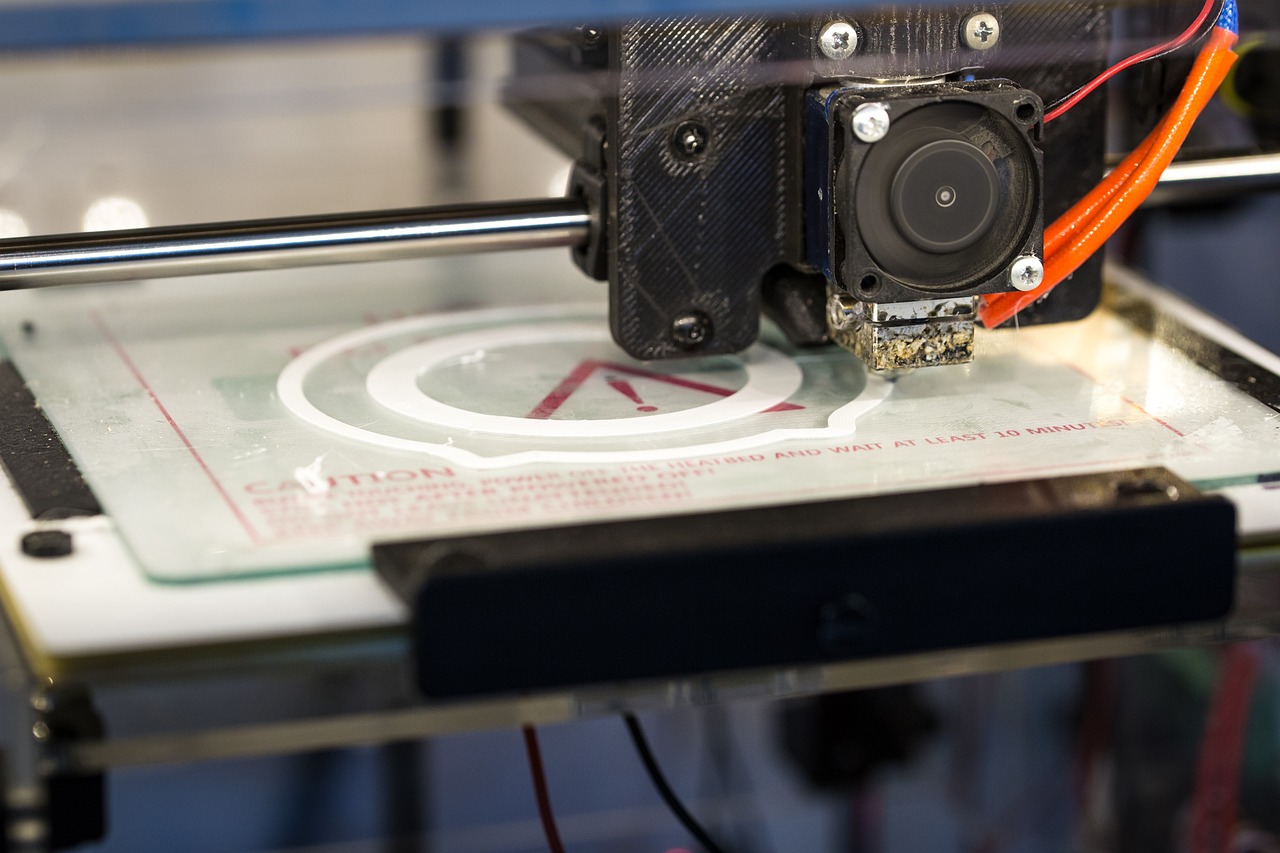

Print-on-Demand Benefits

Print-on-demand isn’t just a production method; it’s a different business model. It shifts you from push manufacturing (make, then sell) to pull manufacturing (sell, then make). This reverses the traditional logic and its associated risks and costs.

Let’s break down what this reversal means in practical terms.

- Sunk cost is zero. Your startup cost is the digital design file and the machine time for the first unit.

- With the usual approach to forecasting, it’s a bit of a gamble. If you guess wrong and make 10,000 units but only sell 4,000, you’re left with dead inventory. You’ve already paid for all the material, labour, and overheads to make 6,000 items, so now you’ve got to store them, discount them heavily, or destroy them. Print-on-demand makes this impossible.

- Print-on-demand collapses this into a single step: digital file to finished product. You don’t need a warehouse full of parts.

- With a digital inventory, you update the design file immediately. The next order prints the new, improved version. You’re never stuck with obsolete stock.

You’re not just saving on molds and warehouses – you’re saving on so much more! You’re building an incredible system that is, by its very nature, anti-fragile. In other words, it gets stronger (more efficient, more tailored) when faced with market volatility and specific customer demands.

Inventory Reduction

You want your workspace to be neat and your costs to be low. 3D printing changes the nature of that bet. You move from physical inventory to digital inventory. You spend less on storage and avoid having too much stock.

The Costs You Stop Paying:

- Warehousing & Storage: The square footage, rent, utilities, and insurance for storing thousands of parts disappear.

- Inventory Management: The labor for counting, handling, rotating, and securing physical stock is drastically reduced.

- Obsolescence & Shrinkage: The financial loss from products going out of date, being damaged in storage, or simply being pilfered drops to near zero. If a design is updated, the old digital file is simply archived.

- Financing Costs: The capital tied up in that unsold stock is freed up for other uses.

Over 40% of 1300 people using 3D printing say shorter wait times are a top benefit, according to a 2019 survey.

So, the workspace gets neater, yes. But more importantly, the balance sheet gets stronger, and the operation becomes more resilient. You do not worry about unsold products piling up.

Table: How 3D Printing Transforms Production Speed

| Benefit | Traditional Manufacturing | 3D Printing |

| Lead Time | Weeks to Months | Days to Weeks |

| Inventory Needs | Large Warehouses | Minimal, On-Demand |

| Customization | Limited | Easy and Fast |

| Response to Demand | Slow | Immediate |

NOBLE’s 3D printing services help you deliver products faster and smarter.

Complex Geometries and Integration

Intricate Structures

Traditional manufacturing methods have a basic rule: a cutting tool must be able to physically reach the surface it’s machining, or a part must be able to be ejected from a mold. This imposes huge limits. 3D printing erases that rule. The only tool is a focused energy source—a laser, an extruder nozzle, a UV light—moving in a pre-planned path.

- Software takes a basic design space and the load paths it must handle, then algorithmically removes material where it’s not needed. The result is an organic, often beautiful, skeletal structure that uses minimal material for maximum strength.

- You achieve the same—or greater—stiffness and strength with a fraction of the weight and material.

- The challenge shifts from “can we make this?” to “what is the optimal structure to fulfill this function?”

You do not need to stick to simple shapes. If you can imagine it, you can print it.

Multi-Part Integration

Building things with many pieces takes a long time. This is one of the most powerful and practical advantages. It’s called part consolidation or assembly integration. This saves time and lowers mistakes.

3D printing lets you re-imagine that as a single, monolithic part. That housing, bracket, spacer, and integrated fastener bosses are now one continuous piece of material. You’ve just eliminated:

- Multiple design files and drawings.

- Multiple manufacturing setups.

- The entire assembly step and its labor.

- All the fasteners (screws, bolts, pins).

- The potential for assembly error.

The benefits are direct:

Increased Reliability: A monolithic part has no joints to loosen, rattle, or leak. The stress is distributed through a continuous material, not concentrated at fastener holes or welds. Fewer parts mean fewer things that can break.

Weight Reduction: Fasteners and the flanges needed to accommodate them add significant weight. By designing the functions directly into the geometry, you use only the material needed for the function itself, leading to a lighter final product.

Just think about a car engine! Instead of making each part, you print one piece with everything inside, which is so much easier! Cooling channels? No problem. Complex supports? Easy.

Performance Enhancement

The end goal isn’t the print itself. It’s the performance of the final product. You can use special plastics and polymers. 3D printing is the tool that lets you unlock material and geometric capabilities that were previously off the table, directly translating to better function.

See how different materials help performance:

| Material | Performance Enhancements | Applications |

| Rilsan® PA11 | Flexible, resists chemicals and fatigue | Consumer products, electronics |

| Kynar® PVDF | Absorbs little water, does not burn easily, resists fatigue | Industrial parts |

| Kepstan® PEKK | Works well for tough jobs | Bearing cages, pico turbines |

| Rilsan® Polyamide 11 | Resists impact and chemicals, easy to clean | Medical devices, orthotics |

| High-performance polymers | Light, strong, good for complex shapes | Sports equipment, automotive |

That’s what keeps customers happy: a product that simply works better, for longer.

Customization and Personalization

Mass Customization

If you’re after products that fit into your life, rather than off-the-shelf items, 3D printing is the way to go. You can get items made just for you, and you won’t have to wait long. You don’t need to spend loads of money on moulds or tools, which is great. They can print each item to order. So, you can order a product with whatever colour, shape or even name you like on it.

- The “mold” is a digital file, and changing it has near-zero cost.

- 3D-printed products have a double value: they are useful, and they are personalised.

- You’ll see a real-time render or simulation. When you place the order, you’re not ordering from stock; you’re getting the product made for the first time.

The result is a fantastic market where products are adapted to people, not the other way around. It’s a great way to show off your style and get the most out of every piece. For businesses, it’s a big change from the days when everyone was trying to make the cheapest standard item to now, where it’s all about providing the most responsive, personalised, and meaningful solution. That’s the amazing power of mass customisation that 3D printing makes possible.

Unique Product Variations

You do not have to settle for “one size fits all.” The era of compromise is ending for many product categories. 3D printing removes that limitation, making unique variations the new standard.

Let’s look at what this means in practice.

- Products should adapt to users, not the other way around.

- You might start with a base model and then modify its texture (grip, pattern), add a monogram or graphic, or integrate a mount for a specific accessory.

- It’s more personalised and tailored to each user, which makes it work better and meet people’s needs.

- Competing on personalized value builds loyalty and commands a premium.

“Boring, standard options” create disengaged customers. Unique variations create products that feel owned, intentional, and special. They carry a story: “This was made for me.” This emotional connection is incredibly strong. It turns customers into advocates and makes products more than just utilitarian objects—they become extensions of personal identity and specific need. You get more choices, and they get happy customers.

Industry Applications

You might wonder where you can see this in real life. 3D printing is moving from personal prototyping to mainstream industry value creation. Here’s where it’s making a tangible difference:

| Industry | Application Description |

| Food | Chefs create custom chocolates and fancy dishes for special events. |

| Fashion | Designers make jewelry, shoes, and clothes that fit each person perfectly. |

| Healthcare | Doctors use 3D printing for prosthetics, dental models, and hearing aids made for each patient. |

| Consumer Goods | You can buy custom-fit earphones, ergonomic phone stands, and razors designed just for you. |

Yes, 3D printing has seamlessly integrated into our lives—from the shoes on our feet to the food we eat! In hospitals, patients can receive prosthetics that perfectly match their bodies; in the fashion world, you can wear one-of-a-kind jewellery; and if you wish, even your favourite snacks can be printed with your name. You get items made for you, not just for the crowd.

Cost Savings and Efficiency

Lower Production Costs

Let’s talk about money. You want to save money every step of the way. This technology uses only the material you need for each part. First, look at the material. Traditional machining is brutally inefficient. You start with a solid block. You end up with a part and a pile of chips. You paid for all of it. Additive manufacturing builds the part layer by layer, using only what the design calls for. The waste figure plummets.

Reduced Tooling

You know how expensive molds and tools can get. Traditional manufacturing needs a new mold for every design. With 3D printing, you change the digital file. That’s it.

- You don’t need to buy costly molds for each new part.

- The cost of a design iteration becomes trivial.

- Print that same geometry as one single, consolidated piece. You just eliminated the entire assembly line for that component.

- There is no physical tool. The barrier to production isn’t a mold; it’s a digital file and printer time.

- You can produce on demand. There’s no need for huge batch orders to amortize that mold cost.

For a new company, this is a real game-changer. It makes product development less of a high-stakes capital game and more of an agile, iterative process. You can test a concept, get feedback, modify it, and have a new version in days, not months. You also cut down on lead times, so you deliver faster.

Small Batch Production

Sometimes you don’t need thousands of parts. Sometimes, you just need a handful. This is where traditional manufacturing stumbles. It’s built for scale, not for agility.

| Advantage | Description |

| Cost Savings | You skip traditional tooling, so you save money—especially in early development. |

| Fast Turnaround Times | You go from digital model to real part in hours, not weeks. |

| Design Flexibility | You make complex shapes and intricate parts without worrying about mold limits. |

| Material Diversity | You pick from many materials, so you get the right fit for your industry. |

| Sustainability | You create less waste, which helps your business stay green. |

Now, 3D printing. The setup is digital. You load the file and the material. The cost to run the machine for one part or for ten parts scales almost linearly. There’s no massive upfront penalty for a small order. This makes low-volume production economically viable for the first time.

We’re all about small batches and strong possibilities. You’ll always be ready for anything the market throws at you.

Sustainability and Safety

Eco-Friendly Materials

The material choice is a direct lever for sustainability. But “eco-friendly” needs a closer look. It’s not just about the source; it’s about the entire life cycle—from where it comes from, to how it’s used, to where it ends up.

Here are the materials you can choose from:

| Material | Bio-based | Recyclable | Biodegradable | Processing energy | Post-processing impact |

| PLA | Yes | Limited | Yes (industrial) | Low | Moderate |

| Recycled PETG | No | Yes | No | Ledium | Low |

| Wood/hemp composite | Partial | Yes | Partial | Low / Medium | Moderate |

Take PLA (Polylactic Acid). It’s made from corn starch or sugarcane. That’s a renewable resource, which is good. Recycled PETG is a solid, practical choice. It takes post-consumer plastic bottles—a major waste problem—and turns them into a durable engineering material. This is a true circular economy.

Picking the “right” material means finding the point where environmental benefit and functional requirement intersect. You can’t have a biodegradable, algae-based hinge that snaps after ten uses. You need a durable product first. The goal is to meet that durability need with the most responsible material available. That’s how you build products that last and lighten the load on the planet.

Material Recycling

You can recycle old prints and scraps with 3D printing. This is a win-win: it saves money and helps nature. Using recycled materials is a great way to save new resources. You also help cut greenhouse gases. This is fantastic news for the environment and our climate goals.

Here’s how recycling works in 3D printing:

| Method | Description |

| Shredding and Extruding | Get rid of waste by shredding and melting it to make new things. This is perfect for shops that produce a lot of waste. |

| Local Recycling Programs | Sorted plastics can be sent to special recycling centres for processing. |

| Metal and Powder Recycling | When you’re done, collect the metal shavings and any unused powder to use in new prints. |

| Resin Recycling and Upcycling | Some resins can be recycled or upcycled, but you’ve got to handle them carefully. |

- And the best thing is, by reusing materials effectively, we can reduce waste generation!

- This is a great way to conserve resources and protect natural ecosystems.

- Using recycled filament or powder slashes the carbon footprint of your raw material.

Safer Manufacturing Environments

Saying it’s inherently “safe” is misleading. Any industrial process has hazards. The advantage is that the hazards are different—and often more manageable—than those in a traditional machine shop. You use less energy and make fewer emissions.

- You’ve removed the immediate, violent risks of amputation or crushing that define conventional machining.

- If 3D printing prevents 80% material waste, then the energy spent creating that wasted material is saved upstream. This is a major, indirect energy saving.

- Chemical and fume exposure is significantly reduced compared to processes like solvent-based painting, electroplating, or certain adhesive applications.

Khoshnevis says 3D printing can make construction safer by cutting waste. It’s a different, and often simpler, safety profile to manage. That’s working smarter.

NOBLE’s 3D Printing Services

Why Choose NOBLE

You want a partner who listens to you. NOBLE is a top machining company in China. You get advanced 3D printing and expert machining help. Their team helps you go from idea to finished product fast. Their engineers guide you through each step.

NOBLE’s experts help you solve tough problems. Our engineers will be able to help you choose the materials, make any design changes, and work out how to manufacture the product. It’ll save you time and money.

You need quick prototypes. NOBLE makes them really quickly, and they look real. If you need a lot of parts, NOBLE can make them for you. Their factory’s kitted out with some high-tech machines, and they’ve got solid quality checks in place. You get the same good results whether you order one or a thousand parts.

Service Highlights

NOBLE gives you many 3D printing choices. You’ve got options like FDM, SLA, SLS, and MJF. Each one is designed for different jobs. You can get strong, detailed, or bendable parts, depending on what you need.

Here’s what you get:

- Quick turnaround: You get samples in days, not weeks.

- Material Options: Choose plastics, metals, or mixes.

- Design Support: NOBLE’s team can help you with that.

- Quality Assurance: We make sure to check every part carefully.

- Scalable Production: Can be produced in any size. Just start with one sampl,e and then you can make more easily.

| Feature | Benefit for You |

| Advanced Machining | Makes tricky, exact parts |

| Rapid Prototyping | Checks designs quickly |

| Mass Production | Same quality for lots of parts |

| Expert Consultation | Help with hard problems |

NOBLE’s process keeps your project moving.

Customer Success

You want to know that NOBLE works well. Lots of companies trust NOBLE for big projects. A medical startup needed some special samples ASAP. NOBLE made great samples in less than a week. The team helped improve the design, saving time and money.

A big car company needed light brackets for a new car. NOBLE’s engineers picked strong plastics and made the part better. The company saved money and got better results.

You get more than just parts. NOBLE’s help lets you finish on time, impress others, and stay ahead.

So, are you ready to turn your ideas into reality? NOBLE’s 3D printing advantages give you the boost.

You see how NOBLE’s 3D printing advantages help you work smarter and faster. The advantages—speed, savings, freedom in design—aren’t separate items on a list. They feed into each other. Saving time lets you test more ideas. Testing ideas cheaply boosts creativity. Creative, optimized products help you stay ahead. Reach out to NOBLE and explore what you can build next.

- Save time and costs

- Boost creativity

- Stay ahead in your industry

Want to learn more? The next step is straightforward. Contact NOBLE today and unlock new possibilities.

FAQ

What is 3D printing?

It’s additive manufacturing. You build an object from the ground up, one layer at a time, following a digital blueprint. The key here is the word ‘additive’. You’re not carving away from a block, you know. You’re putting material exactly where it’s needed. This basic difference is what changes everything else.

How does 3D printing help me save money?

It eliminates tooling. No molds, no custom fixtures. That upfront capital cost drops to zero. You use only the material needed. It lets you produce products when you need them. You shouldn’t tie up cash in inventory or pay for warehouse space for parts you might not sell. Many companies save up to half their costs.

Can NOBLE use 3D printing for custom products?

Yes! This is precisely its advantage. Customization is no longer just for the high-end—if you want it, you can get it for a small price. Because the cost is only in the blueprint making and printing time, the cost of making one unique product is the same as making a thousand identical products. Surgical guides made based on patients’ CT scan data, shoe soles adjusted according to athletes’ pressure distribution maps—these are not fantasy.

What materials can NOBLE use with 3D printing?

When it comes to prototyping and lightweight parts, we’d highly recommend using plastics such as PLA, ABS, and ASA. When it comes to functional engineering applications, it’s so important to have materials that can handle high temperatures. Nylon (PA), composites (PA-CF, PA-GF), and PEEK are great examples of materials that can keep their cool when it’s really hot. And for end-use metal components, you can’t go wrong with stainless steel, aluminum, or titanium!

Is 3D printing good for the environment?

3D printing uses way less material and energy than the old ways, which is great news! You can recycle old prints and choose green materials, so you can feel good about your purchase. Lots of companies are doing their bit for the planet too.

How fast can I get a prototype with 3D printing?

Hey, don’t worry – you can get a model really quickly, it’ll only take a few days! Some projects finish in hours, which is really great when you’re in a rush! This is a really helpful way to test ideas and make changes quickly.

Does 3D printing work for large production runs?

You can use 3D printing for small or big batches. NOBLE’s machines make thousands of parts with the same quality.

What industries use 3D printing the most?

You see 3D printing in so many different things, like cars, planes, healthcare, fashion, and even the things people buy. Hey, just so you know, companies use it to make models, custom items, and tricky designs.