Ever think 3D printing is just pressing a button for pizza? That would be awesome, but it’s more complex. It is still really cool! Here are the main types we used:

- FDMmelts plastic and stacks it to make things.

- SLA uses a laser to turn liquid resin into shapes.

- SLS joins powder together with a laser.

- DLP uses light to harden resin very fast.

- MJFsprays and joins powder for strong, detailed parts.

- PolyJetsprays liquid layers that harden right away.

- DMLS uses lasers to turn metal powder into solid pieces.

- EBMmelts metal powder with an electron beam.

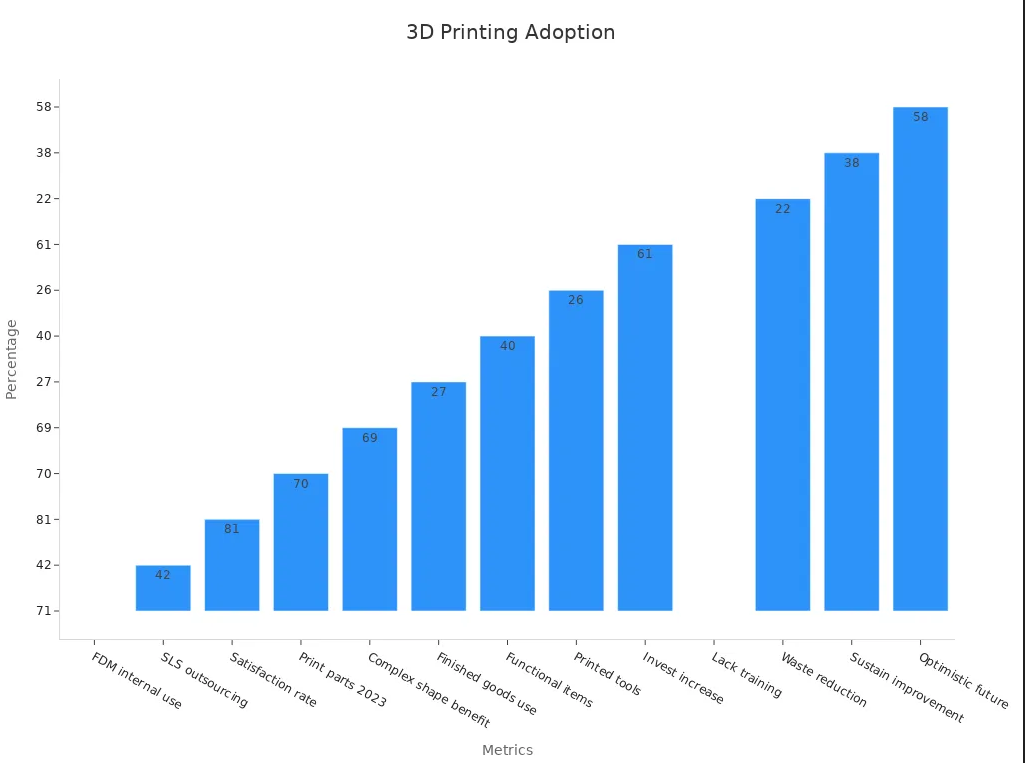

See how these technologies compare in the market:

| Technology Type | Market Share / Revenue Percentage (2024) |

| Stereolithography (SLA) | Over 11% of total revenues |

| Fused Deposition Modeling (FDM) | Sizable market share (2023) |

| Metal 3D Printing | About 53% of global revenue |

| Polymer 3D Printing | Fastest growing; $11.7 billion revenue (2024) |

So, if someone asks, “What are the different types of 3D printing?”—now you know we have choices for every project and budget!

3D Printing Technologies

Let’s step into the world of 3D printing technology! NOBLE uses several different methods, each with its own advantages. I’ll start by taking you through the three most common methods.

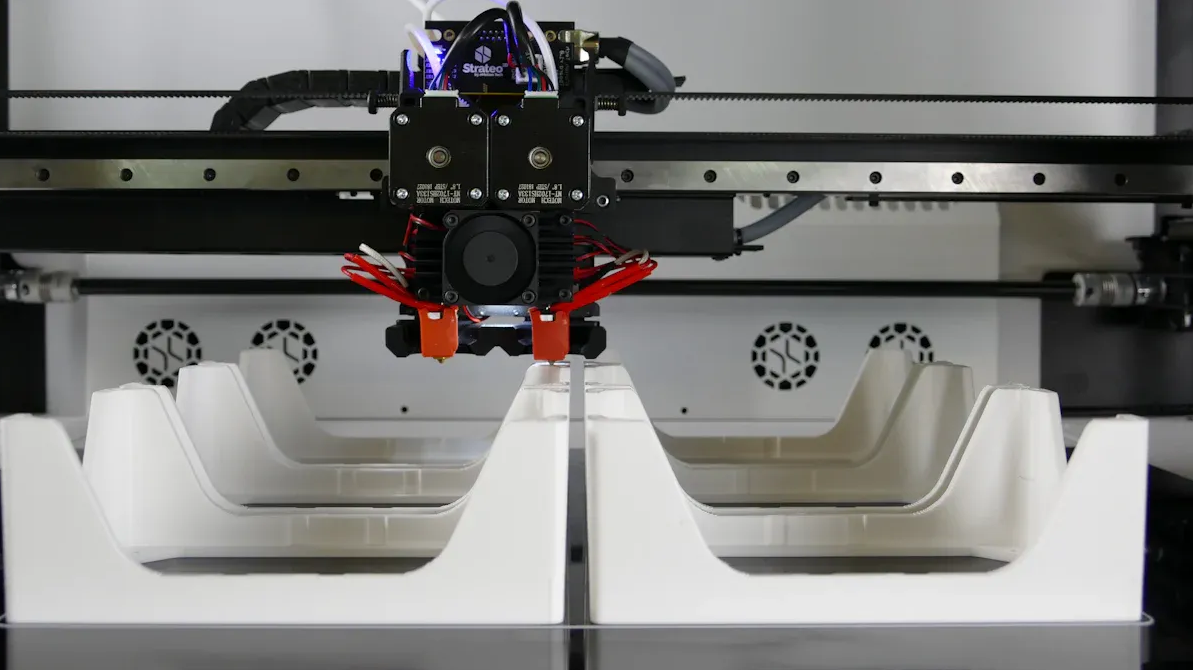

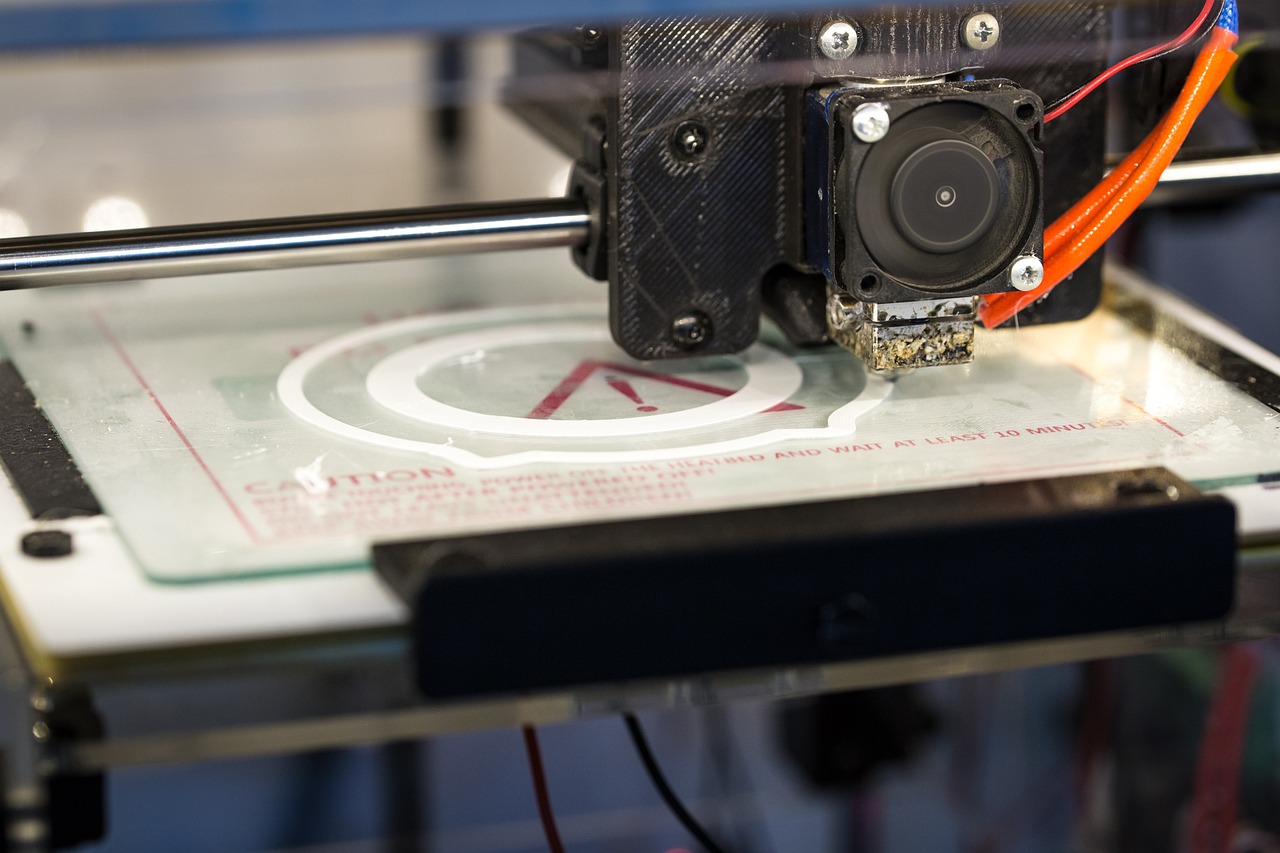

Fused Deposition Modeling (FDM)

When using FDM 3D printing, a roll of plastic filament is first added to the 3D printer, which heats the filament until it melts. The printer then pushes the melted plastic into a small nozzle. The nozzle moves from side to side, printing out the design layer by layer. I watched my design slowly take shape, layer by layer, and it felt a bit like building blocks with Legos, but the printer did all the stacking for me.

How It Works

The color or type of plastic can be changed simply by changing the filament. This makes FDM great for quick projects or colorful models. It is often used at work for prototyping or fixing things around the house.

I would recommend an FDM printer if you want something quick and practical. FDM is everywhere; it’s used in schools, homes, and businesses.

- About 71% of businesses use FDM printers for their projects.

- Over 4.5 million 3D printers are expected to be sold worldwide in 2024.

- Most companies use 3D printing for prototyping and pre-series manufacturing.

FDM is perfect for making prototypes, gadgets, and even replacement parts for things around the house.

Here’s a table that shows how FDM performs in real tests:

| Metric | What It Means | Typical Result / Accuracy |

| Ultimate Tensile Strength | How much force the part can handle | 33.3 MPa (with 93% prediction accuracy) |

| Elastic Modulus | How stiff the part is | 1381 MPa (with 87% prediction accuracy) |

| Strain at Maximum Stress | How much does it stretch before breaking | Optimized at 0.29 mm layer thickness |

| Predictive Model Accuracy | How well can we predict results | Up to 93% (very reliable) |

Tip: You can adjust settings such as layer thickness to get the best combination of intensity and detail. Tests have shown that the right settings make a big difference!

Pros and Cons

There are many reasons why NOBLE uses FDM 3D printing technology, but it also has its drawbacks. Here’s what I’ve noticed the most:

Pros:

- Easy to set up and use

- Works with many types of plastic

- Good for quick prototypes and repairs

- Affordable for home and school projects

- Reliable results with the right settings

Cons:

- Sometimes, I see visible lines between layers

- Not the best for super tiny details

- Some shapes need extra support during printing

FDM is great for learning to 3D print and making something useful quickly. If a customer wants a super smooth or detailed model, we may try another method.

Stereolithography (SLA)

How It Works

First, the liquid resin is poured into the tank. The laser draws shapes in the resin, layer by layer, turning it into a solid. And the result? A super smooth and detailed model. We use SLA when we want to make something that looks professional, like a model or jewelry for a client.

One thing I like about SLS is that we don’t need to add support structures. The loose powder holds everything in place, so we can print shapes that we wouldn’t be able to print otherwise. It’s even possible to print a lot of parts at once by stacking them together in a build box.

Check out these numbers:

| Metric / Statistic | Value / Description |

| SLA market projected CAGR | 19.27% (to reach $6.746 billion by 2028) |

| Satisfaction rate with the 3D printing strategy | 81% |

| Percentage of companies using 3D printing for prototyping/pre-series manufacturing | More than 68% |

SLA is NOBLE’s go-to for high-detail work. The finish is so smooth, it almost looks like glass.

Key Features

SLA stands out for its amazing detail and finish. Here’s what we notice every time we print:

- With SLA, we get a super smooth surface that looks like glass.

- The printer can handle complex shapes and tiny features.

- Many types of resins are available: clear, gray, tough, flexible, and even high-temperature resins.

- Printed parts have very tight tolerances, usually within 0.127 mm for the first inch.

- Post-processing is quick. Just cleaning, curing, and sometimes polishing is required.

- Large objects (up to 50 x 50 x 60 cm³) can be printed without loss of detail.

- The UV laser does not heat the resin like other methods, so there are very few errors.

NOBLE uses special resins according to the different needs of our customers. Flexible resins can make sturdy parts. Flexible resins can make curved models. High-temperature resins are for items that need to withstand high temperatures. Even metal plating can be added to make parts stronger and more durable.

Pros and Cons

SLA 3D printing has its own set of strengths and quirks. Here’s how I see it:

| Pros | Cons |

| Incredible detail and smooth finish | Parts can be brittle |

| Great for complex, intricate designs | Not ideal for high-impact uses |

| Wide range of resin choices | Some resins may yellow over time |

| Fast post-processing | Limited thermal performance |

| Large build volume is possible | Printing can take longer for big jobs |

We choose SLA when our customers want models that look realistic or have tiny details. It’s perfect for jewelry, dental molds, or display prototypes. It always impresses our customers with its surface finish. If I need something that can withstand a lot of pressure or heat, I might try another 3D printing method. But for visual models and fine features, SLA is hard to beat.

SLS 3D Printing

How It Works

SLS is where things get really high-tech. Start with a bed of powder—usually nylon or another plastic. A laser zaps the powder, fusing it to form each layer. Because no support structure is required, complex shapes can be printed that cannot be printed by other methods.

Here’s a quick look at how SLS fits into the bigger picture:

- SLS outsourcing rate is 42%.

- SLS is popular for making strong, functional parts.

- Many companies use SLS for both prototypes and finished products.

We use SLS when our customers need parts that are robust and can be used in real-world environments, and it’s amazing how many shapes can be created with just powder and a laser.

Key Features

SLS stands out for several reasons:

- Ultra-fast print speeds produce strong, usable parts. The high-speed laser allows customers to complete projects quickly.

- We can nest tightly in the build chamber and print multiple parts at once. This saves time and maximizes space.

- No support structure is required. Powder can support a variety of angles and curves.

- Multiple materials to choose from. Nylon is often used in our orders, but metal powders such as stainless steel or titanium, carbon fiber blends, biodegradable plastics, and even special sands or ceramics for casting are also available.

- The process is very efficient. The remaining powder can be filtered and reused, which means less waste and lower costs.

- You can freely design complex shapes that are difficult to produce by other methods.

Tip: If you want to make a bunch of parts quickly, SLS is a great choice. I often use it when I need strong, detailed pieces for real-world use.

Pros and Cons

Here’s how I see the main advantages and a few things to keep in mind with SLS:

| Pros | Cons |

| Fastest way to print functional parts | Parts can feel a bit grainy |

| No supports needed for complex shapes | Equipment is usually large |

| High productivity and throughput | Requires careful powder handling |

| Wide range of materials to choose from | Post-processing can get messy |

| Low waste—unused powder gets recycled |

SLS is used when we want to make hard, detailed parts without wasting time and materials, and its ability to reuse powder and print multiple parts at once makes it one of our most popular methods for prototyping and finished 3D printing.

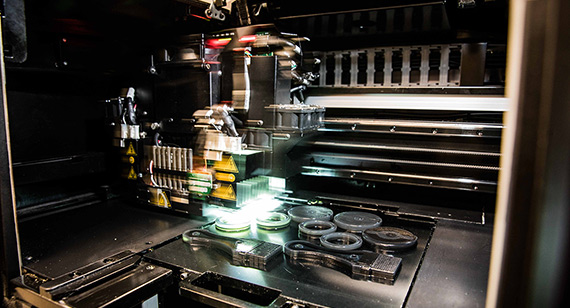

Digital Light Processing (DLP)

We prefer DLP when our customers want small parts with crisp detail, and the resulting surfaces are so smooth that they almost look like glass.DLP technology can be used to make dental molds, jewelry, or small toys. The printers work best with special resins, so we always check the materials needed before we start.

How It Works

DLP is one of the methods for creating detailed models quickly. We use a special projector that shines light onto a tray of liquid resin. The light hardens the resin in the shape I want, one layer at a time. Each flash of light creates a whole layer in seconds. This makes DLP much faster than some other methods.

Key Features

DLP stands out for its speed and detail. Here’s what we notice every time I use it:

- Fast printing for small, detailed models

- Smooth surfaces that look almost polished

- Great for making lots of tiny parts at once

- Works best with special liquid resins

- Sharp edges and crisp details

We also have a choice of different types of resin. Some are hard, some are flexible, and some are even clear. This gives customers a lot of options for different projects.

Pros and Cons

| Pros | Cons |

| Very fast for small prints | Limited to resin materials |

| High detail and smooth finish | Parts may need post-cleaning |

| Can print many parts at once | Build size is usually small |

| Sharp, crisp features | Some resins can be brittle |

Multi Jet Fusion (MJF)

If you need sturdy, functional parts, NOBLE recommends MJF. The finished product is strong, durable, and uniformly colored. It can be used to make gears, brackets, and even cell phone cases. By the way, MJF is also suitable for making a large number of parts at the same time.

Key Features

The Multi Jet Fusion stands out for its speed, detail, and strength. This prints parts with smooth surfaces and sharp edges. The printer runs fast, so customers don’t have to wait long for their projects. The MJF can be used with different materials such as PA12, PA11, TPU, and PP. The printed parts are strong and resilient, which makes them perfect for items such as gears, brackets, or cell phone housings.

Here’s a table that shows how Multi Jet Fusion compares to another fast 3D printing method:

| Metric | Multi Jet Fusion (MJF) | High Speed Sintering (HSS) |

| Build Volume | Up to 380 x 294 x 380 mm | Up to 1,000 x 540 x 400 mm |

| Printing Speed | Up to 5,058 cm³/h | Up to 6,500 cm³/h |

| Resolution | 1200 dpi | 360 dpi |

| Materials | PA12, PA11, TPA, TPU, PP | PA12, TPU, PP, PEBA, EVA |

| Accuracy | ±0.3% (±0.3 mm lower limit) | ±0.3% (±0.3 mm lower limit) |

| Layer Thickness | 80 µm | 80 µm |

| Mechanical Strength | E-modulus: 1700-1800 MPa | 1716-1725 MPa |

| Tensile Strength | 48 MPa | 46-52 MPa |

| Elongation at Break | 15-20% | 5-10% |

| Cooling Times | Fast cooling available | Not available |

I like the high resolution that Multi Jet Fusion offers, up to 1200 dpi. This means that parts look crisp and professional. The process also has a fast cooling option, so NOBLE can finish projects faster.

PolyJet Printing

PolyJet fabrication is great when you need to display prototypes with different textures or colors! It can even make soft parts and hard parts at once. This method is great for making medical models, product samples, or artwork.

I use these 3D printing methods when we have short man-hours and need detail or lots of color options. Each method helps me bring my ideas to life in a different way.

How It Works

PolyJet printing is like using an ultra-precision inkjet printer, but with a special liquid material. The printer sprays tiny droplets onto a build tray. UV light hits the droplets and they immediately harden. Multiple colors and materials can be used in a single print, which is great for making realistic-looking models.

Key Features

The PolyJet stood out to me because it offers so many options for the customer. We can print different colors, clear or solid, and even choose how soft or hard each part is. This is very important when a customer wants to create a model that looks and feels realistic. We can print toys with both soft rubber grips and hard plastic parts.

Studies have shown that PolyJet models are super accurate. Compared to other 3D printing methods, such as SLA or SLS, PolyJet printed models have fewer dimensional errors and better detail. For example, one study measured a dimensional error of only 0.18 microns, much smaller than other printers. I also like the ability to use matte or white resin, which makes it easy to scan the model without additional painting or coating. The details on the printout are very crisp, and the shape matches my design almost exactly.

Pros and Cons

I recommend PolyJet when my clients want my models to look and feel just right, and the table below summarizes my preferences and caveats:

| Pros | Cons |

| Amazing detail and smooth finish | Models can be less strong |

| Prints soft and hard parts together | Not ideal for outdoor use |

| Many colors and textures in one go | Material cost can be higher |

| No extra curing needed | Parts may need gentle handling |

| Great for realistic prototypes |

Direct Metal Laser Sintering & Electron Beam Melting (DMLS & EBM)

Direct Metal Laser Sintering (DMLS)

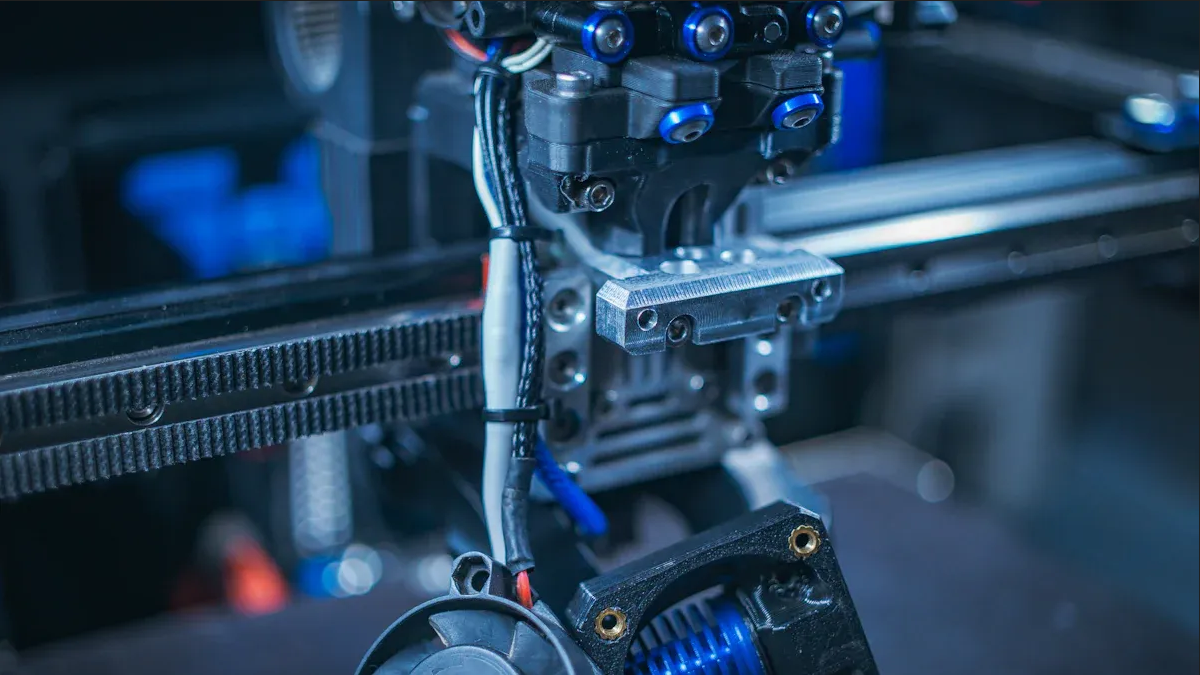

When I want to 3D print with metal, DMLS is our first choice. Starting with a bed of fine metal powder, the printer uses a laser to draw each layer of the object. The laser heats the powder and fuses it. The part grows layer by layer until you get a solid piece of metal.

NOBLE uses DMLS to create parts that need to be strong and precise. It’s great for engine parts, medical tools, or custom jewelry. This method is used when normal metalworking techniques won’t work. So, if you need a metal part that is both strong and detailed, DMLS is a great choice.

Electron Beam Melting (EBM)

EBM is another way we print metal, but it uses an electron beam instead of a laser. A metal powder is loaded into the printer, the electron beam melts the metal powder, and then the part is created layer by layer.EBM works in a vacuum, which keeps the metal clean and strong.

NOBLE uses EBM when customers need parts for difficult jobs, such as airplanes or medical implants. This process creates parts that are very dense and free of cracks. I have found that EBM is particularly well-suited for machining titanium.

Other 3D Printing Methods

Binder Jetting

Spray binder feels a bit like building a sandcastle, but with a high-tech twist. Start with a bed of powder, which can be metal, sand or even ceramic. The printer moves over the powder and sprays a liquid binder, which acts like glue. The adhesive holds the powder together, layer by layer, until the part is complete. When the printing stops, I use a brush to remove the excess powder and see the customer’s item take shape.

I like binder jetting because it works with a wide variety of materials.NOBLE can use this to make metal parts, colored sand models, and even ceramic items. The process is quick, and there is no heat required during the printing process, so the parts won’t warp or crack. After printing, we sometimes bake the parts in a furnace to make them stronger.

NanoParticle Jetting (NPJ)

NanoParticle Jetting, or NPJ for short, feels like a scene out of a science fiction novel. We’ll use special inks filled with tiny particles, which can be metals, ceramics, or even polymers. The NPJ printer jets these inks onto the surface of the object, one thin layer at a time. Once the printing is complete, the part is then heated to remove the liquid and fuse the particles.

What makes the NPJ stand out? We can print objects with very fine details and smooth surfaces. Sometimes I can even mix materials to give the part special properties, such as extra strength or heat resistance.

Here’s what I find exciting about NPJ:

- It can make complex shapes that are difficult to make with other methods.

- The finished parts have high resolution and crisp detail.

- NPJ allows me to customize the material properties for each project.

- Researchers are working on using eco-friendly inks, which could help the environment.

Did you know? NPJ is opening doors for new medical devices and electronics because of its precision and material choices.

Drop-On-Demand (DOD)

DOD reminds me of an ultra-precision inkjet printer. The printer drops tiny bits of material only where I need them. It works layer by layer, gradually forming the client’s design. The DOD is great for making flat surfaces and sharp edges. I often use it to make jewelry molds or casting models.

The outstanding feature of the DOD is its precision. The printer can print very fine details, which is important for small, delicate parts. Also like

Here are some of the advantages of the DOD:

- High resolution for detailed work

- Smooth, flat surfaces

- Great for industries like jewelry and dental work

- New research is looking at using biodegradable resins, which could make DOD more sustainable

We love trying these new methods. They help us solve problems in ways I never imagined. Every year, I see new ideas that push the limits of what I can make. Who knows? Maybe the next big breakthrough will come from someone like you!

| Metric/Aspect | Data/Insight |

| Market Size (2024) | USD 3.44 billion |

| Market Size (2033) | USD 13.17 billion |

| CAGR (2025-2033) | 16.1% |

| Hospitals Using 3D Printing (2022) | ~400 |

| Cost Savings | Up to 70% reduction; $1.75 million saved in some cases |

| Customization Benefits | Patient-specific devices improve outcomes and reduce replacements |

3D Printing of Applications

Manufacturing & Prototyping

I use 3D printing a lot to make things and test ideas. It allows me to turn designs into physical objects very quickly. I can make a part on my computer, then print it out and try it out in a day.. 3D printing makes it easier to see our designs and share them with others. In jobs such as oil extraction and water storage, companies use 3D printing to make models and test new ideas. This technology saves time and helps people learn by doing, not just reading.

Healthcare & Medical Devices

3D printing in healthcare is pretty cool. Hospitals use it to make special devices for each patient. For example, they can print just the right amount of bone or dental implants. The number of hospitals using 3D printing technology has increased from 3 in 2015 to about 400 by 2022. This helps hospitals save money, reduce waste, and work faster. During the COVID-19 pandemic, 3D printing technology helped create parts when they were needed most. Now, doctors can customize implants and prosthetics, which means better results and fewer replacements.

Here’s a quick look at some numbers:

| Metric/Aspect | Data/Insight |

| Market Size (2024) | USD 3.44 billion |

| Market Size (2033) | USD 13.17 billion |

| CAGR (2025-2033) | 16.1% |

| Hospitals Using 3D Printing (2022) | ~400 |

| Cost Savings | Up to 70% reduction; $1.75 million saved in some cases |

| Customization Benefits | Patient-specific devices improve outcomes and reduce replacements |

Automotive & Aerospace

In the automotive field, 3D printing allows for customization of car parts, tools, and even entire vehicle panels.NOBLE prints prototypes of new engine parts and tests them the same day. This helps us solve problems and try out new ideas quickly without having to wait weeks.

In aerospace, things get even cooler. 3D printing prints lightweight parts for airplanes and rockets. These parts need to be strong but not heavy. 3D printing can design shapes that can’t be made with normal tools. For example, 3D printing can create a small model of a jet engine to show how a real jet engine works. Engineers use this technology to save fuel and make flying safer.

Architecture & Construction

When NOBLE receives an architectural project, 3D printing technology helps us turn the blueprint into a real model. 3D printing allows us to print a miniature of the entire building and then show it to the client. This makes it easier for everyone to see what the project will look like when it’s finished. It is also possible to test how the sunlight hits the building or how the rooms fit together.

In construction, I’ve seen giant printers build walls and even small houses. This saves time and reduces waste. I once witnessed a team print a concrete bridge in just a few days. It was amazing to see something so large come together so quickly.

Here’s a quick table showing what I can print in architecture and construction:

| What NOBLE Print | Why It’s Useful |

| Scale models | Show designs to clients |

| Building parts | Speed up construction |

| Custom decorations | Make each project unique |

Why Choose Us for Custom 3D Printing Services

Bring your concept to life with exceptional on-demand manufacturing services. NOBLE’s custom 3D printing services can quickly turn your designs and prototyping into production printed parts. All of our products meet strict tolerance standards and quality standards, making us a leading on-demand manufacturing company in China.

Economical Price

Our price is 20% lower than in Europe and the United States, providing you with the best price on the market.

Strong Capabilities

Advanced materials, cutting-edge technology, and exacting quality assurance procedures. This commitment results in quality product durability and precision, minimizing rework and enhancing your project’s success.

High Precision Parts

NOBLE specializes in custom manufacturing industrial equipment parts to precise requirements. Our manufacturing capabilities allow us to produce 3D-printed parts with tolerances as tight as +/- 0.01mm.

Quality Assurance

We are ISO 9001:2015, ISO 13485:2016, and MDML Class 2 certified. For each 3D printing order, we will strictly control the quality according to your requirements to ensure that 3D printing meets your application needs.

FAQs of 3D Printing

What is the easiest 3D printing method for beginners?

I always suggest starting with FDM. The printers are affordable and simple to use. You can find lots of tutorials online. I learned by printing small toys and fixing things around my house.

Can I print food or clothes with 3D printers?

Yes, I can print food with special printers that use chocolate or dough. Some designers use 3D printers to make clothes or shoes. These printers work differently from regular ones, but the idea is the same—layer by layer!

How strong are 3D printed parts?

Strength depends on the material and method. We often use SLS or MJF for hard parts. Metal printers such as DMLS and EBM print parts that are as strong as real metal. For everyday use, FDM parts work well enough.

Do I need special software to design 3D prints?

Yes. Some popular programs include Tinkercad, Fusion 360, and Blender. Some popular programs include Tinkercad, Fusion 360, and Blender. Many are free and easy to learn. I started with Tinkercad because it felt like I was playing with digital blocks. Or, our engineers can help design parts to bring your ideas to life!

How long does it take to print something?

Print time depends on the size and method. Small objects can finish in under an hour. Big or detailed prints might take several hours or even a day.

Can I recycle leftover 3D printing material?

Plastic waste from FDM prints can be recycled. Some companies will also offer machines that convert old prints into new filament. Leftover powder from SLS and MJF printers can also be recycled. Recycling saves money and reduces waste.

Is 3D printing safe to use at home?

We always use the printer in a well-ventilated room. Some materials produce fumes. It is a good idea to wear gloves when handling resins or powders. Also, I highly recommend that you keep your work area clean and follow the safety tips in your printer manual.