Elderly Care parts manufacturing uses plastics, metals, liquid silicone rubber, and composites. Each material is selected to provide safe, comfortable, and durable products for the elderly. Companies like NOBLE are trusted medical device manufacturers with ISO9001 and ISO13485 certifications, and we also focus on providing customized solutions.

Customization brings many benefits:

| Benefit | Explanation |

| Precision & Personalization | Product design is tailored to meet the individual needs of each customer, ensuring that products are both comfortable and practical. |

| Quality Control | Strict control from design to assembly ensures high product quality. This is particularly important for elderly care equipment. |

| Cost Efficiency | Efficient use of resources and reduction of waste can lead to long-term cost savings, even if the initial investment is high. |

| Faster Lead Time | Streamlining processes accelerates production speed. This means even customized elderly care products can be delivered faster. |

| Tailored Solutions | Customized production enables companies to create tailored products for each user. This makes the products more comfortable and user-friendly. |

| Better Customer Satisfaction | Close collaboration with customers helps develop products that align with their needs. This enhances customer satisfaction and fosters loyalty. |

| Scalability | Companies can produce both small and large batches of products. This helps address the evolving demands of the elderly care sector. |

NOBLE has a team of highly skilled professionals who utilize advanced medical device component machining technology. As a leading CNC machining supplier, we stand out among many manufacturers thanks to our efficient machining speed and high-quality service. We help our customers achieve their business goals by providing safe and reliable services to manufacturers of elderly care products.

Overview

What Are Elderly Care Parts

Elderly care parts help seniors live safer and easier lives. These parts are found in many healthcare tools. People use them in beds, wheelchairs, and scooters. They are also in ramps, lift chairs, and grab bars. Other examples are stair lifts, patient lifts, and hospital beds. Oxygen concentrators are important too. Even small things like incontinence supplies and walking aids matter. Health monitoring aides are also very helpful.

Here’s a quick look at the main categories of elderly care parts:

- Beds (long-term care beds, adjustable beds, mattresses, home care beds, and accessories)

- Manual and power wheelchairs (including transport, standard, lightweight, bariatric, and accessories)

- Mobility scooters and wheelchair ramps

- Lift chairs, grab bars, and bathroom safety devices

- Stair lifts and patient lifts

- Hospital beds and oxygen concentrators

- Vehicle lifts and platform lifts

- Incontinence supplies and walking aids

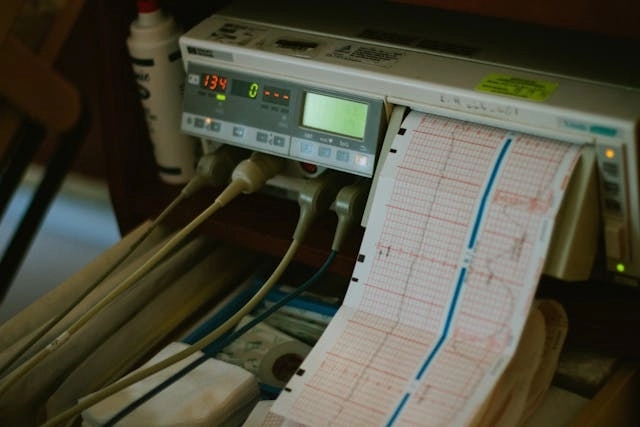

- Health monitoring aides (like blood pressure monitors and portable oxygen tanks)

- ADL (Activities of Daily Living) aides

Companies like NOBLE use advanced machines to make these parts. We team works hard to keep quality high. NOBLE makes sure every part is safe and works well.

Importance in Healthcare

Elderly care parts help seniors stay safe and do things on their own. These parts make daily life easier and help with care at home. Studies show that using the right equipment at home helps seniors as much as hospital care. Sometimes, it even helps them get better faster after leaving the hospital.

Elderly care parts are also used in special care plans. These plans bring together money, services, and medical care. They help seniors spend less time in the hospital and feel better at home. Seniors are happier when they have equipment that fits their needs.

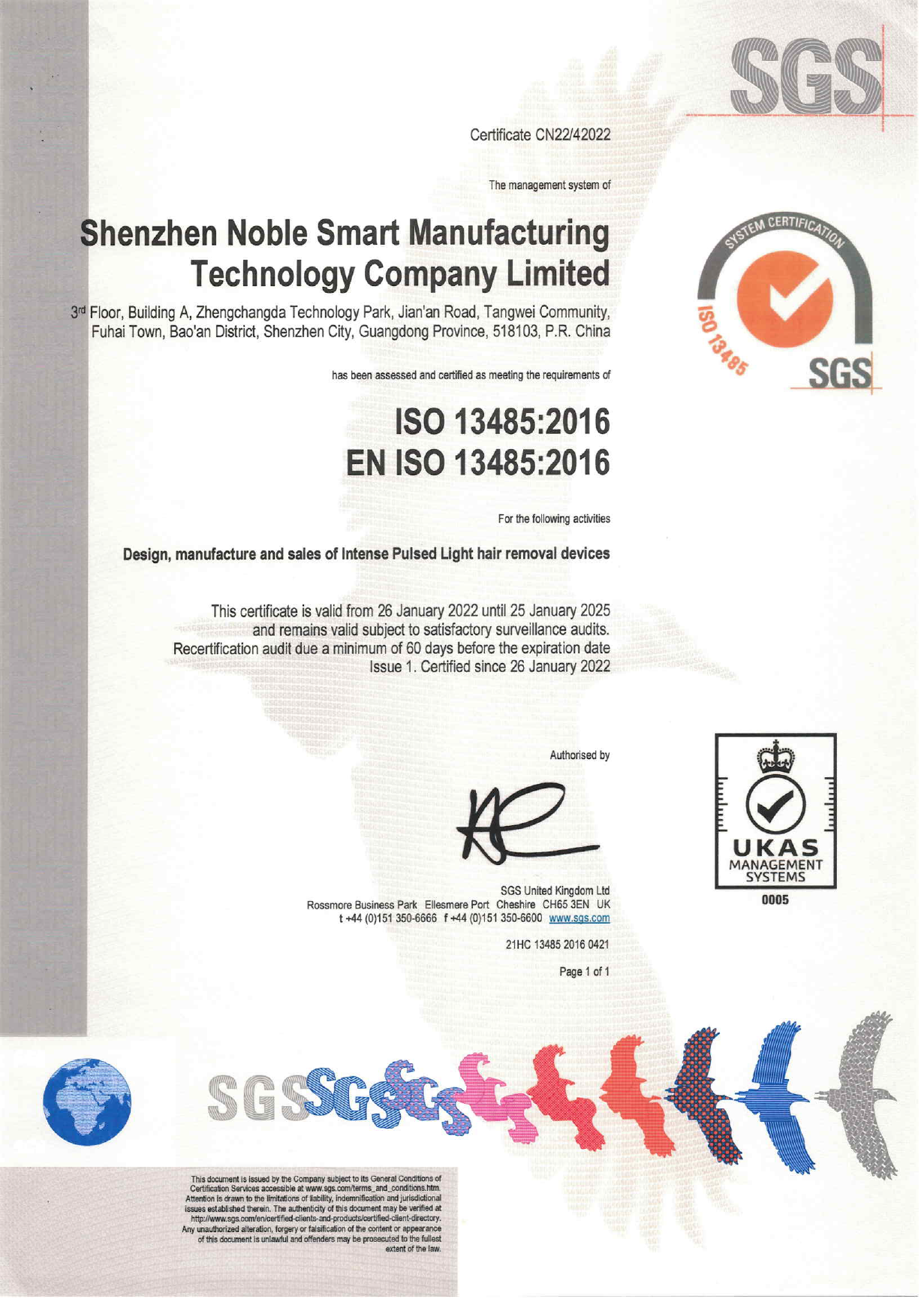

NOBLE is a trusted medical device manufacturing company with ISO9001 and ISO13485 certifications. NOBLE is a leader in the research, development, and manufacturing of elderly care equipment and products. Its high-quality services and efficient operations help other companies provide safe and reliable products. With its medical device processing technology, NOBLE is an industry leader in this field.

Materials Used in Elderly Care Parts Manufacturing

Elderly Care parts manufacturing uses different advanced materials. These materials help make products safe, strong, and comfortable for seniors. Each material has special benefits for healthcare equipment machining. Let’s see the main materials and why they are picked.

Plastics and Polymers

Plastics and polymers are used a lot in elderly care equipment. They cost less than metals and can be shaped exactly with injection molding. These materials are light, so seniors can use the products more easily. Plastics are good for single-use, pre-sterilized parts that lower infection risks. Medical-grade plastics are safe, resist chemicals, and can be recycled. Their flexibility lets Elderly care product manufacturers make complex shapes for comfort and use. Many healthcare equipment manufacturers like plastics because they save money and can be cleaned many times.

Metals

Metals like aluminum and stainless steel are used in Elderly Care products. They are strong and last a long time. This is important for parts that hold weight, like wheelchair frames or hospital bed rails. Metals do not wear out fast and can last for years, even with daily use. Health care equipment manufacturers use metals for parts that must be sturdy and dependable. CNC machining suppliers like NOBLE use special machines to shape metals very carefully. This makes sure every part meets high-quality standards.

Liquid Silicone Rubber (LSR)

Liquid silicone rubber (LSR) is great for parts that touch skin or need to stay clean. LSR is safe for sensitive skin and does not cause allergies. It does not let water, chemicals, or heat damage it, so it is good for things that need cleaning or sterilizing often. LSR stays soft and keeps its shape even when pressed. Elderly Care equipment developing uses LSR for seals, gaskets, and soft grips. NOBLE, a healthcare manufacturing company with ISO9001 and ISO13485 certifications, uses LSR to make safe and comfy parts for seniors.

Tip: LSR parts do not let mold or bacteria grow, so they are great for hygiene-focused Elderly Care products.

Composites

Composites mix two or more materials to get the best features. For example, carbon fiber composites are light and very strong. Elderly Care parts machining uses composites for parts that must be tough and easy to move. These materials help Elderly Care products manufacturers make items that are strong, light, and comfortable for daily use.

NOBLE is a top health care equipment manufacturer. Our team uses advanced healthcare parts machining and smart processing to make high-quality parts. With great service and skill, NOBLE helps Elderly Care products from start to finish.

Manufacturing Process in Elderly Care Parts Manufacturing

Making Elderly Care parts starts with an idea and ends with a finished product. Each step uses new technology and follows strict rules. This makes sure every part is safe, works well, and feels good for seniors. Let’s look at each step.

Design and Prototyping

Design and prototyping are the first steps. Teams include designers, engineers, doctors, and patients. They work together to share ideas and fix problems. This teamwork helps make parts that help seniors.

- Teams have experts and people who use the parts.

- They talk about what the part should do.

- Designers make early models called prototypes.

- People try these models and say what they think.

- The team changes the design to make it better.

- They test the new model again and again.

- The last prototype is ready for real-life testing.

Prototyping lets everyone see and touch the design. It helps people test ideas before making the real thing. This step saves time and money by finding problems early.

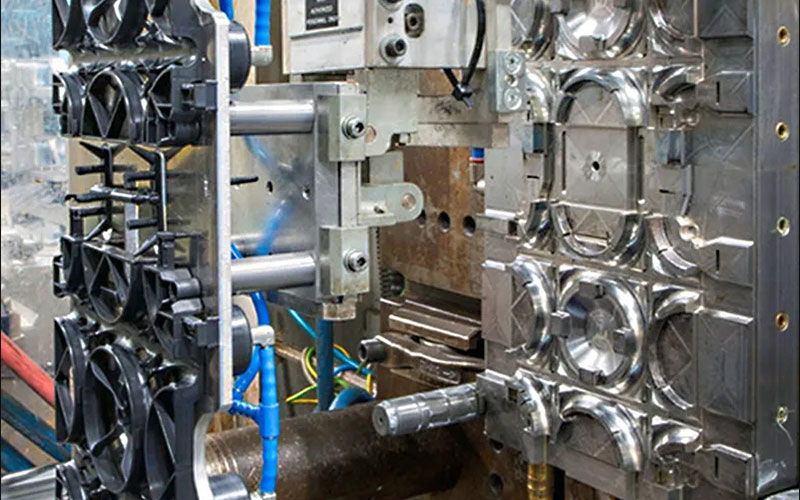

Injection Molding

Injection molding shapes many plastic parts for elderly care. Melted plastic goes into a mold and cools to make the part. This method is good for making lots of the same part. Injection molding makes smooth, strong, and light pieces. These parts are easy to clean and safe for seniors. Companies like NOBLE use this for handles, buttons, and covers.

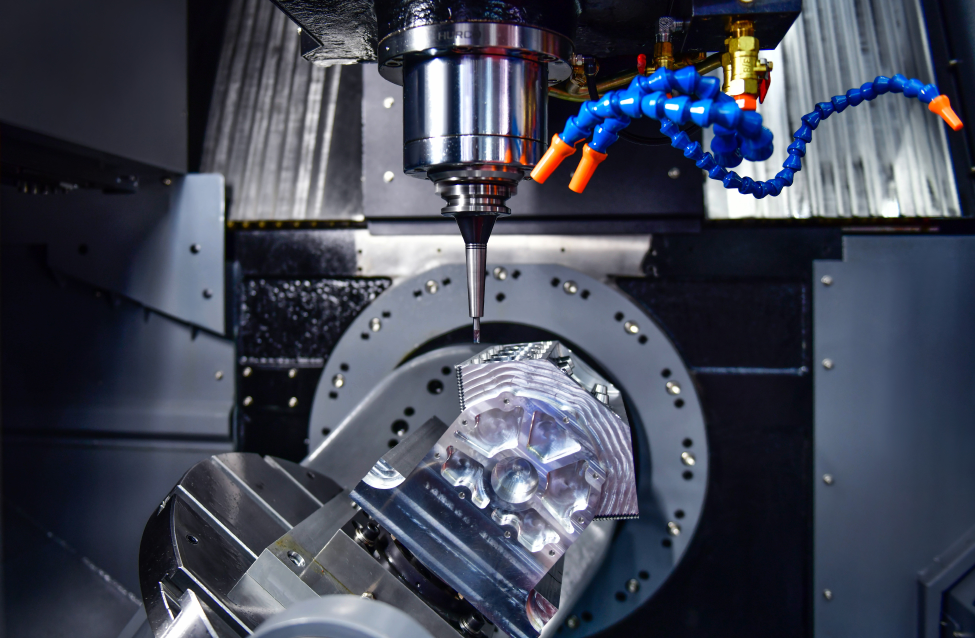

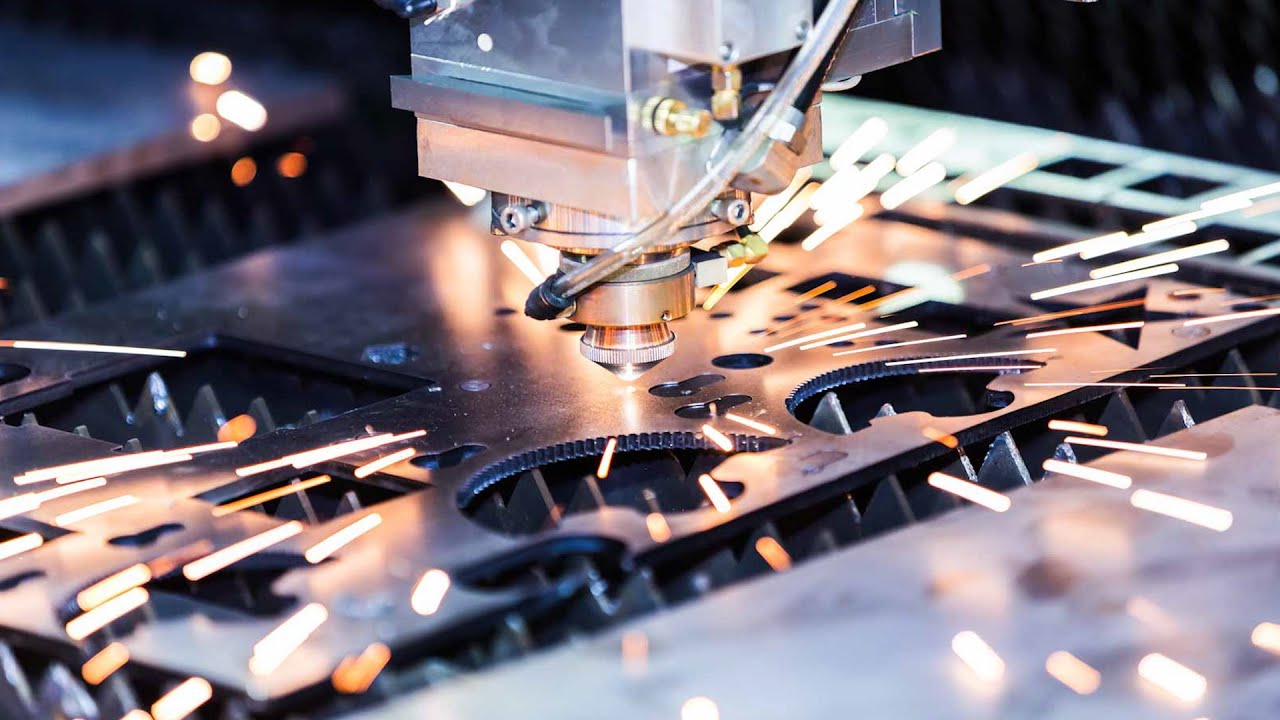

CNC Machining

CNC machining uses computers to cut and shape metal and plastic. This step is important for making very exact parts. CNC machines can cut very small details. Every part is the same, which keeps things safe.

- CNC machining works with metals and special plastics.

- It makes shapes that other machines cannot make.

- The process is fast and can make many parts quickly.

- Quality checks happen at every step to keep standards high.

NOBLE is a top cnc machining supplier. Their health care parts machining makes strong, exact parts for Elderly Care products. Their ISO9001 and ISO13485 certifications show they care about quality.

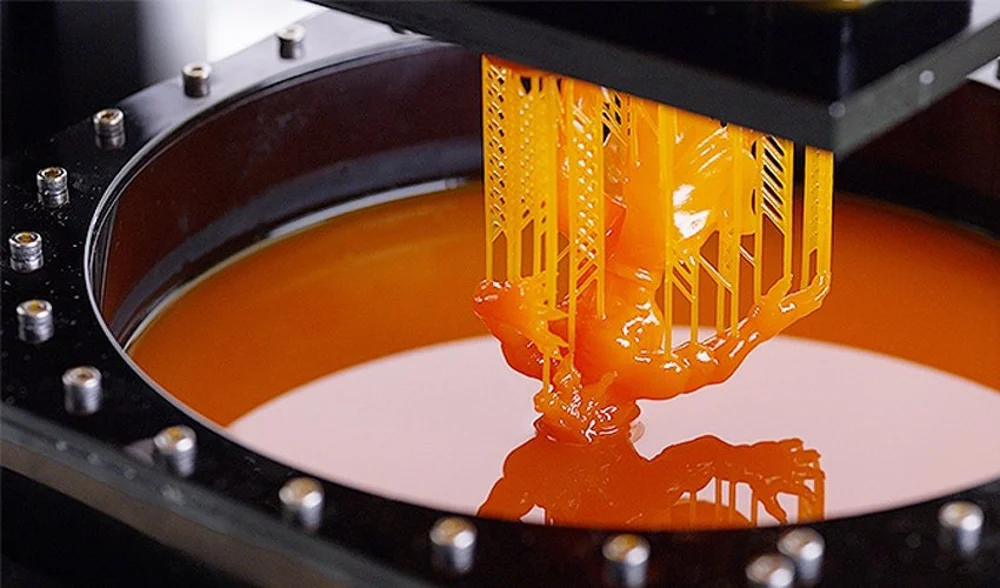

3D Printing

3D printing builds parts one layer at a time from digital plans. This helps the Elderly Care parts manufacturing move quickly. Designers can test new shapes in just days.

3D printing lets companies:

- Make special shapes for each user.

- Test ideas fast and fix problems before making molds.

- Use less material and make less waste.

- Make small numbers or one-of-a-kind parts for special needs.

Hospitals and Elderly care product makers use 3D printing for custom grips, braces, and wheelchair parts. This method helps meet the special needs of seniors.

Sheet Metal Fabrication and Welding

Sheet metal fabrication shapes metal sheets into strong parts. Welding joins these pieces together. This step is needed for frames, rails, and supports in elderly care equipment.

- Custom sheet metal work makes tough, long-lasting parts.

- Special tools cut and bend metal to the right size.

- Welding makes parts strong and safe for daily use.

- Finishing steps, like polishing, make surfaces smooth and easy to clean.

NOBLE uses new machines and skilled workers for sheet metal work. Our work meets high safety and cleanliness standards. This makes them a trusted healthcare equipment maker.

Assembly and Finishing

The last steps put all the parts together. Workers or machines build the final product. They check each part for safety and quality. Finishing touches, like painting or coating, protect the parts and make them look nice.

Non-reactive surfaces are important in elderly care equipment. They stop germs and make cleaning easy. NOBLE always uses safe materials and follows strict rules.

Companies like NOBLE follow rules like 21 CFR Part 211. These rules cover quality checks, keeping records, and training workers. Here’s how companies follow the rules:

| Compliance Aspect | Description |

| Quality Assurance & Control | Checks every batch for safety and quality. |

| Documentation & Recordkeeping | Keeps records for tracking and recalls. |

| Facility & Equipment Standards | Keeps workspaces clean and safe. |

| Personnel Training | Teaches workers to avoid mistakes. |

| Raw Material & Supplier Control | Picks good suppliers and checks materials. |

| Process Validation | Test every step to make sure it works right. |

| Product Testing & Release | Test products before shipping. |

| Complaint Handling | Fixes problems and listens to feedback fast. |

NOBLE’s team uses health care equipment machining and new tools to make great parts. Our fast work helps Elderly Care product makers get good products on time. Their ISO9001 and ISO13485 certifications show we care about safety and quality.

Quality and Compliance

Regulatory Standards

Elderly Care parts manufacturing must follow many rules. These rules help keep products safe and reliable for seniors. The main rule is the FDA’s Quality System Regulation, called QSR. This rule is found in 21 CFR Part 820. It tells companies how to design, make, and label medical devices. It also covers how to store and fix them. Even if a company only makes parts, it should still use these rules as a guide. The QSR has many parts:

- Companies must keep buildings and equipment in good shape.

- They must check materials and watch automated machines.

- They need to test the software and each step in the process.

- Tools for checking parts must be set up correctly and kept working.

- Companies must check new parts and finished parts before using them.

- They must check and write down how good their suppliers are.

- Parts must be labeled and tracked to stop mixups.

- Companies must control how things are made, check the air, and train workers.

A new rule will soon match these rules with ISO 13485:2016. NOBLE already follows this rule. This helps NOBLE, a top healthcare equipment maker, give safe and high-quality parts.

Quality Control

Quality control is very important in health care equipment machining. NOBLE uses smart tools and skilled workers to check every step. They look at raw materials, watch the work, and test finished parts. Our team follows ISO9001 and ISO13485 rules. This means we keep records, teach workers, and fix problems fast. As a top CNC machining supplier, NOBLE makes sure every part meets strict rules. Elderly Care products manufacturer teams use these checks to stop mistakes and keep seniors safe.

Tip: Good quality control helps Elderly care product manufacturers find problems early. This saves time and money.

Patient Safety

Patient safety is the most important thing in Elderly Care parts machining. Teams check beds, rails, and wheelchairs often to find and fix dangers. Nurses, engineers, and helpers work together to keep equipment safe. They use forms and lists to track checks and repairs. Staff take away things not being used and put equipment in the right spot. Checks happen every few months to make sure everything stays safe.

Some safety features are:

- Fall mats help soften falls.

- Transfer belts help move people safely.

- Fall alarms tell staff if someone falls.

- Remote monitoring helps staff give quick help.

- Bathroom railings give support.

- Patient lifts help stop injuries.

NOBLE, a trusted healthcare manufacturing company, uses these safety steps in Elderly Care equipment. Our fast service and smart health care parts machining help Elderly Care products developing teams give safe products on time.

Innovations and Trends

Advanced Materials

Elderly Care parts manufacturing is always getting better with new materials. Many Elderly care product manufacturers now use smart wound dressings, hydrogels, and foams. These materials help wounds heal faster and lower infection risk. Some dressings have sensors that check pH or other signs in the wound. This helps doctors give better care and change treatment quickly. Microphysiological systems, called MPS, are also being made. They act like tiny organs and help researchers study aging and test new drugs. AI-driven social robots are starting to help with dementia care. This makes life easier for seniors and caregivers.

Note: Some of these advanced materials are still new. Manufacturing companies work hard to make them cheap and easy to use for developing Elderly Care products.

Additive Manufacturing

Additive manufacturing, or 3D printing, is changing how Elderly Care parts are machined. This technology lets healthcare equipment manufacturers make complex shapes and custom parts. These shapes were not possible before. For example, engineers can make custom hearing aids and tremor aids. They can even make special food for people who have trouble swallowing. Additive manufacturing allows for quick changes and fast production. It also uses medical-grade plastics that are safe and strong. CNC machining suppliers like NOBLE use these methods to make parts with high precision and speed. Their ISO9001 and ISO13485 certifications show they care about quality and safety.

Integration of Medical Technology

Today’s Elderly Care equipment uses smart technology. Many Elderly Care product manufacturers add features like medication reminders and activity trackers. Some products have fall detection too. Wearable devices now check heart rate and alert caregivers if something is wrong. Smart home tools, like voice assistants and automated lights, help seniors stay safe at home. Telehealth lets seniors talk to doctors without leaving home. AI-powered systems can spot health problems early and help stop hospital visits. Robots and automation help with daily tasks. This gives seniors more independence. NOBLE, a top healthcare manufacturing company, uses these trends to make advanced, safe, and reliable Elderly Care products. They give great service and use efficient healthcare parts machining.

Why Choose NOBLE for Elderly Care Parts Manufacturing

Expertise

NOBLE is a top company in health care equipment machining. Their team has worked on many projects for years. Engineers, designers, and technicians work together to fix hard problems. They can make both easy and tricky parts. NOBLE uses new machines for the Elderly Care parts machining. They always try to find better ways to help seniors. Their experts know what Elderly Care product manufacturer teams need. They help from the first idea to the final delivery. NOBLE’s staff keeps learning about new tools and trends. This helps them stay ahead of others in the industry.

Quality Commitment

NOBLE places a high priority on quality. We adhere to strict standards and use intelligent systems to inspect each component. Here are some specific ways in which NOBLE delivers on its commitment:

- We use Six Sigma methods to improve product quality and ensure product excellence.

- Data collection software inspects each stage of production to ensure that every component meets standards.

- Our laboratory conducts strength, safety, and cleanliness tests on materials.

- NOBLE holds certifications for multiple medical device components, demonstrating compliance with stringent standards.

- We assist partners in complying with EU medical device regulations, supporting global compliance.

- NOBLE recycles materials and adopts environmentally friendly practices to help protect the planet.

- Its Code of Conduct ensures a safe and fair workplace for all employees.

NOBLE’s commitment to quality gives manufacturers of elderly care products confidence in their products. As a medical device manufacturer, its work ensures that the elderly have access to safe and reliable equipment.

Custom Solutions

Every senior needs something different. NOBLE understands this and offers custom solutions for Elderly Care products. Our team listens to what clients want. We use healthcare parts machining and cnc machining supplier skills to make special parts. NOBLE can make small or large orders. We work fast and deliver on time. Our service team answers questions and fixes problems quickly. NOBLE’s flexible way helps Elderly Care equipment developing teams get the right fit for every project. As a healthcare manufacturing company, NOBLE makes sure each product is comfortable, safe, and easy to use.

Elderly Care parts manufacturing uses new materials and smart ways to make safe products. Companies like NOBLE use health care equipment machining, CNC machining, and 3D printing. These methods help make parts that are strong and feel good to use. Safety and following rules are very important. Picking a healthcare equipment manufacturer with ISO9001 and ISO13485 means you get better quality and can trust them.

| Why Choose NOBLE? | What You Get |

| Certified (ISO9001/13485) | Proven safety and quality |

| Fast, efficient service | Quick delivery and expert support |

| Custom solutions | Parts made for your needs |

NOBLE helps elderly care product development teams perform at their best. Contact us now to learn more!

Elderly Care Components of FAQs

What materials do Elderly Care parts manufacturers use most often?

Elderly Care parts manufacturers use plastics, metals, liquid silicone rubber, and composites. These materials help make products safe, strong, and comfortable for seniors. NOBLE, a top healthcare equipment manufacturer, chooses each material for safety and long-lasting use.

How does NOBLE ensure quality in health care equipment machining?

NOBLE follows ISO9001 and ISO13485 rules. Our team checks every step, from design to finish. NOBLE uses advanced health care parts machining and tests each part for safety. This helps Elderly Care products developing teams trust the final product.

Why do Elderly Care product manufacturers choose CNC machining suppliers?

CNC machining suppliers like NOBLE work fast and make exact parts. We can create custom parts for Elderly Care equipment. This helps Elderly Care products manufacturers get strong, precise parts that fit each user’s needs.

What makes NOBLE different from other manufacturing companies?

NOBLE is different because they have skilled workers, great service, and fast processing. Our team helps with the Elderly Care parts machining from start to finish. They have ISO9001 and ISO13485 certifications, showing they care about quality and safety.