What is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing technology that transforms metal sheets into specific shapes and functions through mechanical machining and forming processes. It is widely applied in industries such as automotive, aerospace, electronics, and construction. The core of this technology lies in utilizing the plastic deformation properties of metals, employing processes such as sheet metal cutting, bending, stamping, and welding to transform flat metal sheets into complex three-dimensional structures. Sheet metal fabrication typically involves the following key steps: First is blanking, which involves cutting metal sheets to design dimensions using methods such as laser cutting, plasma cutting, or punching; second is forming, where sheet metal is bent, stretched, or rolled using bending machines, rolling machines, or dies to achieve the desired geometric shapes; third is assembly, which involves joining multiple components into a complete product using methods such as welding, riveting, or bolting; Finally, surface treatment, such as painting, electroplating, or anodizing, is applied to enhance corrosion resistance and aesthetic appeal. The advantages of Sheet metal fabrication include high material utilization, fast production efficiency, relatively low costs, and the ability to achieve lightweight design. Modern Sheet metal fabrication also integrates computer-aided design (CAD) and computer numerical control (CNC) technology, significantly improving processing accuracy and automation levels to meet high-precision, small-batch, or large-scale customization requirements.

How the Sheet Metal Fabrication Process Works

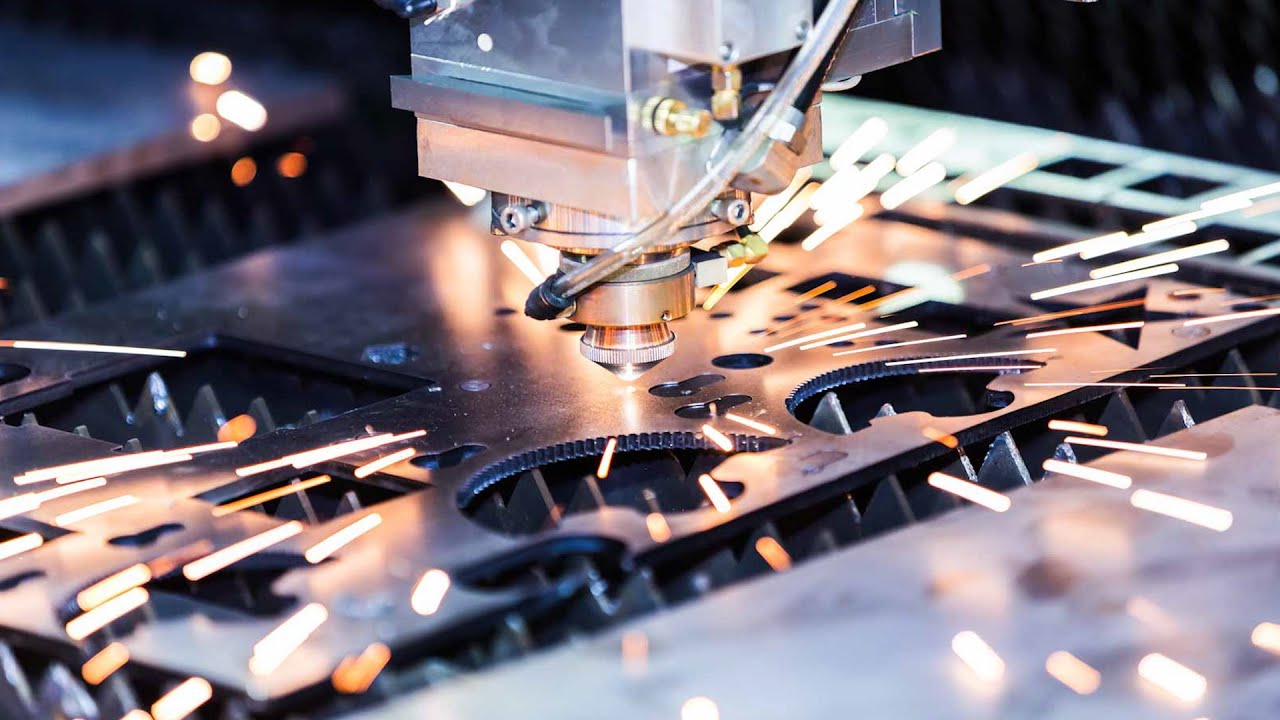

1. Sheet Metal Cutting (Shearing)

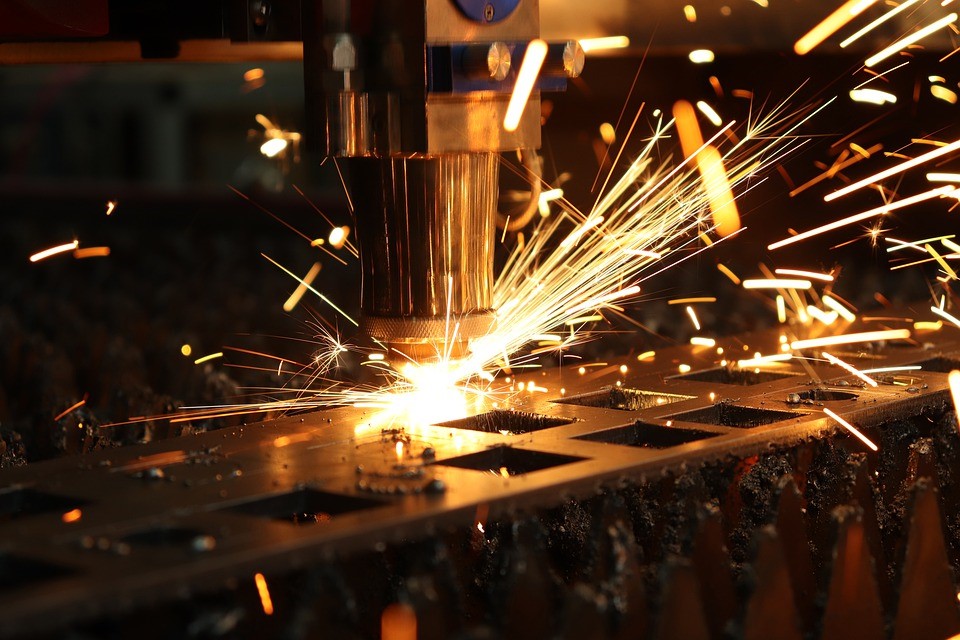

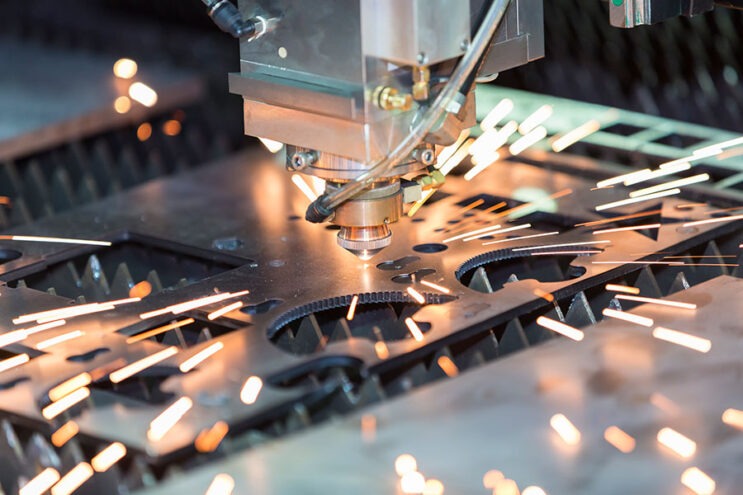

The core processes of Sheet metal fabrication involve multiple critical production stages, with the primary and foundational step being cutting (also known as the shearing process). During this phase, technicians must strictly adhere to the technical specifications outlined in engineering drawings to precisely divide raw metal sheets into specific shapes and exact dimensions required for subsequent processing. The following advanced cutting technologies are commonly used in modern manufacturing:

| Sheet Metal Laser Cutting Technology | This non-contact cutting method uses high-energy-density laser beams |

| Sheet Metal Plasma cutting technology | This method uses a high-temperature plasma arc to melt metal for cutting. |

| Sheet Metal Waterjet cutting technology | This method uses ultra-high-pressure water jets (which may include abrasives) for cold cutting, eliminating the formation of heat-affected zones. |

| Sheet Metal Punching Process | This method uses pre-made specialized dies and high-tonnage stamping equipment for rapid cutting. |

These Sheet metal cutting technologies each have their unique features. In actual production, the most suitable machining solution must be selected after comprehensively considering various factors such as material properties, thickness requirements, processing accuracy, and production costs. With the development of smart manufacturing, these cutting processes are increasingly being integrated with automated production lines and digital control systems to further enhance production efficiency and processing quality.

2. Sheet Metal Forming (bending, stretching, stamping)

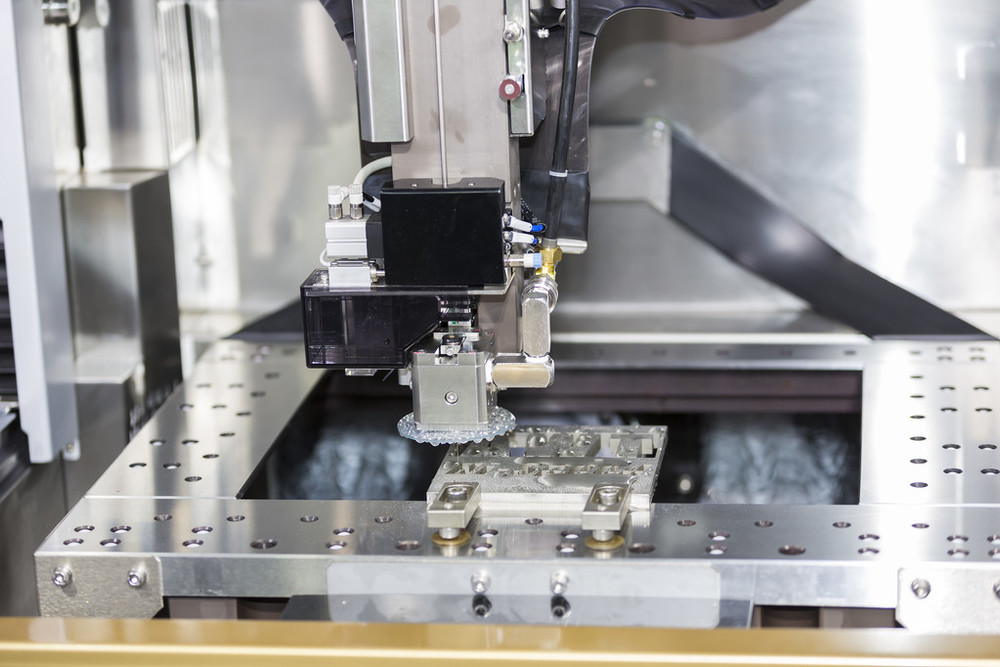

The Sheet metal forming process in Sheet metal fabrication is a critical step in the entire production process. It uses a series of precision processing techniques to transform flat sheet metal into three-dimensional structural components with specific functions. The forming process primarily includes the following key technologies:

- Sheet Metal Bending Forming Process:

This process uses a CNC bending machine in conjunction with specialized dies to perform precise bending operations on sheet metal. Modern bending equipment can achieve multi-axis control, enabling continuous bending of complex angles with a precision of ±0.1mm. The bending process is particularly suitable for manufacturing various types of boxes, brackets, and other structural components with regular geometric shapes.

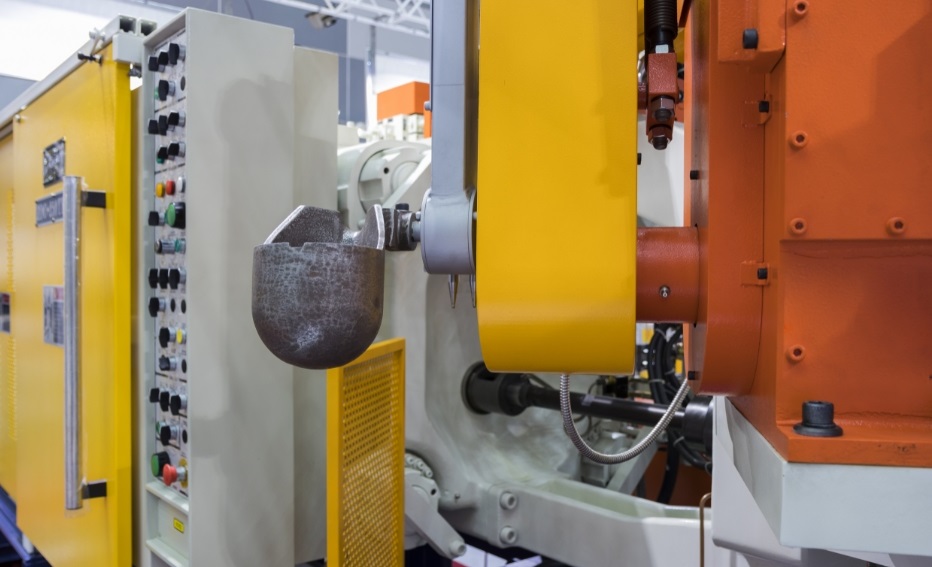

- Sheet Metal Stamping Process:

Utilizing high-tonnage stamping equipment and precision dies to apply instantaneous high pressure to sheet metal, causing it to undergo plastic deformation within the die cavity. This process can complete multiple operations such as stretching, flanging, and punching in a single step, offering extremely high production efficiency. It is particularly suitable for the mass production of automotive body panels, electrical appliance housings, and other products.

- Stretching Forming Process:

Using a hydraulic press in conjunction with specialized stretching dies, sheet metal undergoes deep deformation under controlled tensile force. This process can produce complex curved surfaces and deep cavity structural components, such as various metal containers and automotive fuel tanks.

- Roll forming process:

Multiple sets of rollers are used to continuously and progressively bend metal sheets, making it suitable for producing long-length, constant-section profiles such as architectural metal studs and pipes.

These forming processes require precise control of deformation volume, deformation speed, and material springback. Modern forming equipment is generally equipped with computer control systems that can store and retrieve hundreds of processing programs, enabling rapid die changes and parameter optimization. Additionally, advanced technologies such as finite element analysis can simulate the forming process before processing, effectively predicting and preventing quality defects such as cracking and wrinkling. The selection of forming processes must comprehensively consider factors such as product structural characteristics, material properties, production batch size, and cost-effectiveness.

3. Sheet Metal joining (welding, riveting, bolting)

In Sheet metal fabrication processes, the joining process is a critical stage in assembling multiple independently formed sheet metal components into a complete functional structure. This stage directly determines the structural strength, assembly accuracy, and service life of the final product, making it of paramount importance in the production process. Currently, the industry primarily employs three mainstream joining technologies, each with its unique advantages and application scenarios.

Sheet metal welding technology, as the most traditional connection method, achieves permanent connections by melting metal at high temperatures. It includes various forms such as arc welding, laser welding, and spot welding. Arc welding is suitable for connecting large structural components, featuring simple equipment and low costs; laser welding, with its advantages of concentrated energy and minimal heat-affected zones, is widely applied in precision electronics and automotive manufacturing; spot welding, due to its high efficiency and speed, has become the standard process for automotive body manufacturing. With technological advancements, modern welding equipment now widely adopts digital control systems, enabling precise adjustment of welding parameters to ensure weld quality and consistency.

Sheet Metal Riveting technology, as a mechanical connection method, is particularly suitable for joining materials of different types or those that cannot be welded. Traditional riveting requires pre-drilling holes, followed by deforming and securing the rivets using a rivet gun; modern self-piercing riveting technology, however, achieves both drilling and riveting in a single step, significantly improving production efficiency.

Bolted connections, as the most flexible assembly method, offer significant advantages such as disassemblability and ease of maintenance. This connection method is particularly suitable for products requiring regular maintenance or potential component replacement, such as large machinery or building steel structures. Modern bolted connections have developed various anti-loosening technologies, such as nylon lock nuts and thread adhesives, effectively addressing loosening issues in vibrating environments.

4. Surface Treatment (Rust Prevention and Aesthetics)

In the Sheet metal fabrication process, surface treatment is a critical step in ensuring product quality and extending service life. This process not only enhances the product’s aesthetic appeal but, more importantly, through specialized treatment techniques, forms a protective layer on the metal surface, significantly improving the product’s corrosion resistance, wear resistance, and environmental adaptability. Common surface treatment technologies in modern manufacturing each have unique characteristics, capable of meeting the diverse needs of various application scenarios.

Spray coating is one of the most widely adopted surface treatment methods, involving the application of liquid or powder coatings to metal surfaces using high-pressure spray guns. Anti-rust paint spraying forms a dense protective film that blocks air and moisture, making it particularly suitable for steel structures used outdoors; powder coatings, on the other hand, utilize electrostatic adhesion principles to form a robust protective layer after high-temperature curing, featuring rich colors and strong weather resistance, and are widely applied in appliance housings and architectural decoration fields.

Electroplating processes deposit protective layers of other metals on metal surfaces through electrolysis, making it one of the most effective corrosion prevention methods. Zinc plating forms a sacrificial anode protection, making it particularly suitable for corrosion prevention of iron-based materials, and is widely used in automotive components and building hardware; chrome plating provides both excellent corrosion resistance and a mirror-like finish, commonly used in high-end bathroom fixtures and automotive decorative parts.

Anodizing is the ideal surface treatment method for aluminum alloy products, forming a dense aluminum oxide protective layer on the surface of aluminum through electrolytic oxidation. This process not only significantly improves the surface hardness and wear resistance of aluminum alloys but also enables diverse aesthetic effects through dyeing processes. Anodizing has become a standard process in fields such as electronic product casings and aerospace components. Additionally, new surface treatment technologies like micro-arc oxidation are emerging, capable of forming thicker and harder ceramic protective layers to provide stronger protection for metal components in special operating conditions.

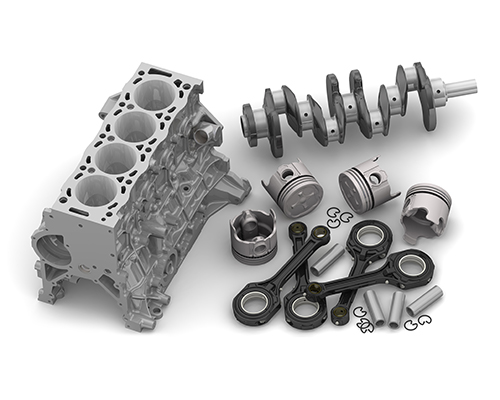

Materials for Sheet Metal Fabrication

The primary base materials commonly used in Sheet metal fabrication include the following types, each with unique properties and typical application scenarios:

1. Aluminum Alloy

Aluminum alloy is one of the most popular materials in sheet metal processing, renowned for its excellent strength-to-weight ratio and superior electrical conductivity, making it widely adopted across various industries. In the automotive industry, aluminum alloy sheet metal components are extensively used in body panels, engine hoods, and other parts, effectively reducing the overall vehicle weight; in the electrical equipment sector, aluminum alloy’s superior conductivity makes it an ideal choice for distribution boxes, heat sinks, and similar products; additionally, in the kitchenware industry, aluminum alloy is frequently used to manufacture various cooking containers and utensils due to its excellent thermal conductivity and corrosion resistance. Modern aluminum alloy materials further enhance their mechanical properties and processing characteristics by adding alloy elements such as magnesium and silicon.

2. Aluminum-coated steel

Aluminum-coated steel is a composite sheet metal material that cleverly combines the mechanical strength of carbon steel with the corrosion resistance of aluminum. This material is produced by hot-dip coating a layer of aluminum onto a carbon steel substrate, retaining the high strength of steel while gaining the oxidation resistance of aluminum. Aluminum-coated steel sheets are particularly suitable for high-temperature applications, such as oven liners, barbecue grills, and other kitchen equipment, as they can withstand repeated high-temperature heating without oxidizing. Additionally, in industrial chimneys, heat exchangers, and other applications requiring high-temperature corrosion resistance, aluminum-coated steel is one of the preferred materials.

3. Carbon steel

As the most traditional sheet metal material, carbon steel plays a significant role in industrial and consumer goods applications. This material, primarily composed of iron-carbon alloy, can achieve different mechanical properties by adjusting its carbon content. Low-carbon steel offers excellent ductility and weldability, making it commonly used for manufacturing enclosures, cabinets, and similar products; medium-carbon steel, after appropriate heat treatment, exhibits significantly enhanced strength and is suitable for manufacturing tools and mechanical components; high-carbon steel, with its outstanding hardness and wear resistance, is widely used in cutting tools and mold manufacturing. Carbon steel materials have relatively low costs and mature processing techniques, making them one of the most economical and practical choices in sheet metal processing.

4. Copper and its alloys

Copper and its alloys demonstrate unique value in sheet metal applications. Pure copper has the best electrical and thermal conductivity among all metallic materials, making it indispensable in the production of electrical components and heat exchangers. In the construction industry, copper sheets are commonly used to make high-end sinks, roofs, rain gutters, and decorative doors and windows, not only due to their excellent corrosion resistance but also because they develop a unique copper patina over time, adding special aesthetic value. Although copper materials are relatively expensive, their long service life and high recyclability make them economically advantageous in the long term. Copper alloys such as brass and bronze achieve improved mechanical properties and machinability by adding elements like zinc and tin, while retaining the inherent characteristics of copper.

Applications of Sheet Metal Fabrication

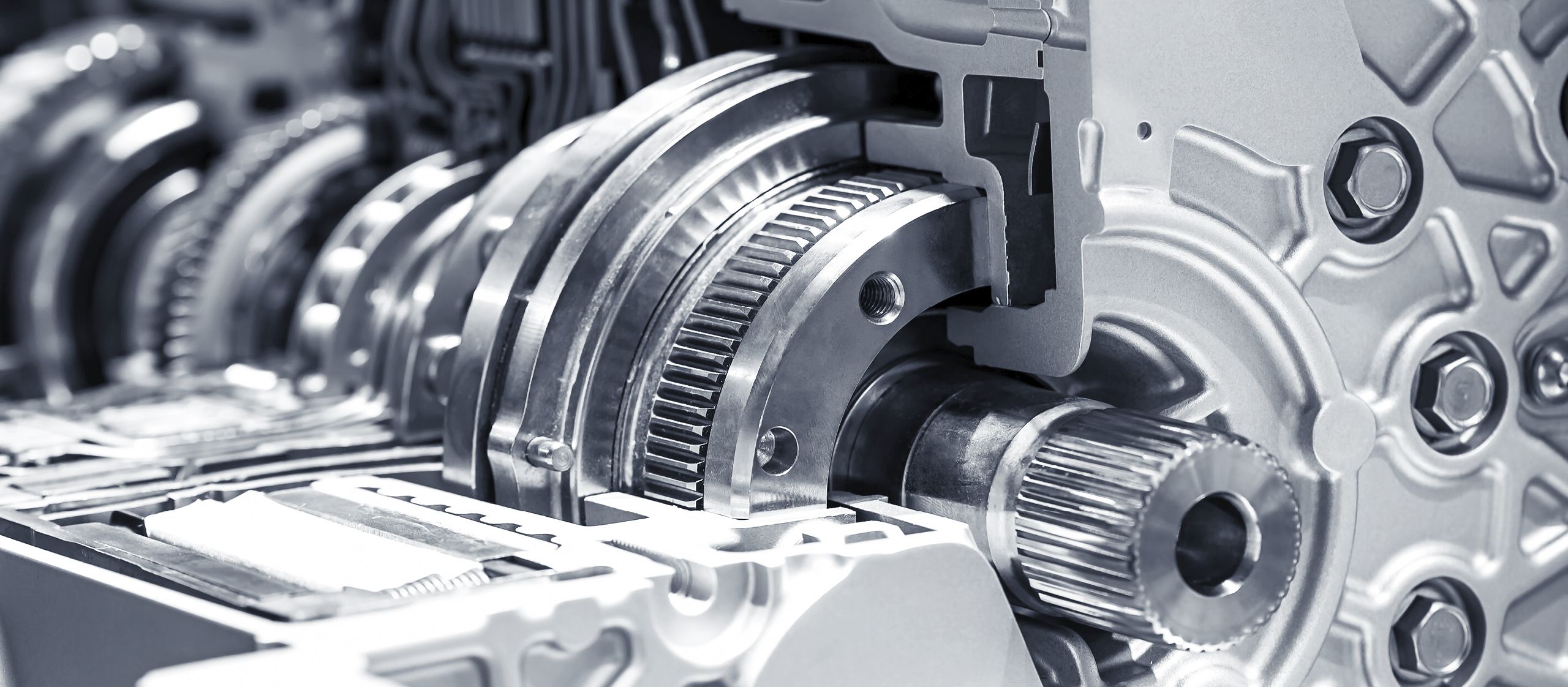

1. Sheet Metal Fabrication for the Automotive Industry

In the automotive manufacturing industry, sheet metal machining technology plays a critical role. Over 70% of a vehicle’s body components are manufactured using sheet metal processes, including large body panels such as doors, hoods, and roofs, as well as various structural components like brackets and chassis parts. In modern automotive manufacturing, high-strength galvanized steel sheets and aluminum alloy sheets are processed through precise stamping and welding techniques, ensuring both structural strength and lightweight design. Key components of new energy vehicles, such as battery housings and motor casings, also extensively utilize Sheet metal fabrication processes.

2. Sheet Metal Fabrication for the Electronics and Electrical Industry

The electronics and electrical industry is another major application area for Sheet metal fabrication. Products such as computer cases, server cabinets, and switch housings that we use daily all require precise sheet metal processing. These products not only demand precise dimensional tolerances but also must consider functional requirements such as electromagnetic shielding and heat dissipation. Metal frames and back panels in consumer electronics products like smartphones and tablets also utilize high-precision sheet metal processing technology.

3. Sheet Metal Fabrication for the Architectural Decoration Industry

In the architectural decoration industry, sheet metal products also play a significant role. Common decorative components in modern buildings, such as metal curtain walls, ceilings, doors, and windows, all rely on sheet metal processing. Materials like stainless steel and aluminum alloy are processed into aesthetically pleasing architectural components through sheet metal techniques, meeting both architectural aesthetic requirements and excellent weather resistance. Building auxiliary equipment such as elevator cabins and escalator housings is also a typical application of sheet metal.

4. Sheet Metal Fabrication for the Aerospace Industry

The aerospace industry imposes even higher demands on Sheet metal fabrication. Critical components such as aircraft skins and rocket fuel tanks require high-strength aluminum alloy or titanium alloy sheets, which are manufactured through precision sheet metal forming processes. These components must withstand extreme environmental conditions while ensuring absolute structural reliability. In modern aerospace manufacturing, advanced sheet metal processes such as superplastic forming and creep forming are increasingly being adopted.

5. Sheet Metal Fabrication for the Medical Device Industry

Medical device manufacturing is another important application area for sheet metal technology. Medical devices such as surgical instruments, medical carts, and CT scanner housings have extremely high requirements for material safety and processing precision. Stainless steel and titanium alloy materials, processed through precision sheet metal fabrication, can meet the strict hygiene standards and functional requirements of medical devices.

Advantages and Disadvantages of Sheet Metal Fabrication

Advantages of Sheet Metal Fabrication

- High production efficiency

Sheet metal fabrication employs molded and mechanized production methods, making it particularly suitable for the mass production of standardized products. A mature mold can continuously produce tens of thousands, or even hundreds of thousands, of identical parts. This high-precision, repetitive production process is unmatched by other processing methods. Modern CNC sheet metal equipment, such as laser cutters and sheet metal bending machines, combined with automated production lines, enables 24/7 uninterrupted production, significantly enhancing manufacturing efficiency. Take the automotive industry as an example: a large stamping machine can produce dozens of body sheet metal parts per minute, and this high efficiency is the foundation of modern large-scale industrial production. Additionally, the manufacturing process for sheet metal is relatively standardized, and operators can quickly become proficient after standardized training, further ensuring production efficiency.

- High material utilization rate

Sheet metal fabrication uses sheet metal as raw material, and through optimized layout design, it can minimize the generation of scrap material. Modern CAD/CAM software features intelligent layout functions that can automatically calculate the most optimized cutting paths, minimizing material waste. Compared to machining processes that require the removal of large amounts of material, sheet metal processing typically keeps raw material loss below 5%. For valuable metals such as stainless steel and copper, this high material utilization rate offers significant cost advantages. Additionally, the scrap generated during production is easy to recycle and reuse, aligning with the green and environmentally friendly development philosophy of modern manufacturing.

Disadvantages of Sheet Metal Machining

- High mold costs

Although Sheet metal fabrication has cost advantages in mass production, the high mold costs become a significant drawback in small-batch production. The manufacturing cost of a precision stamping mold can reach hundreds of thousands of dollars, making such upfront investments difficult to bear for small-batch prototyping during product development or for personalized customization needs. Even with relatively simple bending molds, they must be specifically designed and manufactured according to the product’s shape, resulting in high unit costs for small-batch production. This is why rapid prototyping technologies, such as 3D printing, have emerged as competitors to traditional Sheet metal fabrication in the small-batch production sector.

- Design limitations

Sheet metal fabrication fundamentally involves deforming sheet metal to achieve the desired shape. This process characteristic imposes certain structural limitations on the product. Complex curved surfaces, enclosed cavities, and other designs are often difficult to achieve using conventional sheet metal processes. While modern sheet metal technology can produce fairly complex parts, it still lags behind casting and 3D printing in terms of structural freedom. Additionally, the strength of sheet metal parts primarily relies on structural design. In applications requiring isotropic strength, sheet metal parts may not be as advantageous as forged or cast parts. These process characteristics determine that Sheet metal fabrication may not be the optimal choice in certain specialized application scenarios.

Your Trusted Sheet Metal Fabrication Manufacturer

If you are looking for a reliable partner in sheet metal fabrication, NOBLE is here to provide high-quality, cost-effective solutions tailored to your needs. With advanced equipment, experienced engineers, and strict quality control, we ensure every project meets international standards. Contact us today to discuss your requirements and let us help you bring your designs to life with precision and efficiency.

FAQs of Sheet Metal Fabrication

How do I choose a reliable sheet metal fabrication company?

Look for a company with advanced machinery, experienced engineers, strong quality control systems, and the ability to handle custom projects efficiently.

Can sheet metal fabrication be customized for unique designs?

Yes, sheet metal fabrication allows for fully customized parts and components according to specific drawings, prototypes, and functional requirements.