I use copper CNC machining because it shapes copper into exact parts for many industries. Manufacturers pick copper because it carries electricity and heat very well. This helps control heat and power in important parts. Copper is soft, so I can make complex shapes easily. I need copper for electrical connectors, heat exchangers, and healthcare devices because it kills germs. Copper’s special features make it important where things must work well and last.

Key Takeaways

- Copper CNC machining makes very exact parts for many industries. It is important for electronics, cars, and medical uses. Copper has great electrical and heat conductivity. This makes it good for connectors and heat sinks. These parts help devices work well. CNC machining can make hard shapes with high accuracy. This is important for parts that need to fit very closely. Picking the right copper grade, like C110 or C101, changes how easy it is to machine and the price. Choose the grade that fits what the part needs. Using the right tools and keeping them in good shape is important. Carbide tools last longer and work better when cutting copper. Controlling heat and removing chips during machining helps stop tool damage. It also gives copper parts a smooth finish. Safety is important, so wear safety gear and keep the workspace clean. Checking designs and how you work often can save money and make copper CNC machining better.

The Economic Impact of Copper Machining

Why is Copper Machining Important in Modern Manufacturing?

Copper machining helps make strong parts for many industries. Using copper gives better results in high-tech fields. Copper moves electricity well, so it works great for connectors. It also spreads heat, which keeps devices cool. Copper lasts a long time and does not rust easily. This makes it good for tough places.

- Copper moves electricity well for connectors and terminals.

- It spreads heat, so heat sinks work better.

- Copper lasts a long time and does not rust in harsh environments.

CNC machining shapes copper into detailed designs. This helps make parts that work well in hard jobs. I can create heat sinks that move heat away fast. Careful cutting and finishing make copper parts last longer. CNC technology makes products look better and work better. Now, I can make exact parts for high-tech needs.

Alternatives to CNC Machining for Copper

Other ways to shape copper include stamping, casting, and manual milling. These methods work for simple shapes or big batches. But they are not as exact or flexible as CNC machining. Stamping is quick, but it cannot make hard shapes. Casting is good for lots of parts, but it needs extra steps. Manual milling lets me control the process, but it is slow and not as exact.

Tip: I pick copper cnc machining for high accuracy and making hard shapes. For simple parts or lots of pieces, old methods may save money.

Environmental and Health Considerations in Copper Machining

I think about health and the environment when machining copper. Cutting copper can put tiny bits in the air. To stay safe, I check air levels and follow safety rules.

| Health Risk | Mitigation Strategy |

|---|---|

| Breathing copper dust for a long time can be bad | Check air levels and set safety limits |

A study in Germany showed copper dust did not hurt workers’ lungs. Another study in rats showed some swelling, but it went away after rest. I use good airflow and safety gear to keep my shop safe. These steps help lower risks and keep everyone healthy.

What is Copper Machining?

Copper machining means making copper into exact parts. I use machines to cut, drill, and shape copper. This helps me make parts for electronics, plumbing, and medical tools. Copper is soft and carries electricity well. It does not rust easily. These things make copper a good pick for many jobs.

Key Aspects of Copper Machining

When I work with copper, I pay attention to important steps. Each step changes how good the part will be.

| Aspect | Description |

|---|---|

| Tool Selection | Picking the right cutting tools, like HSS or carbide, helps tools last and work well. |

| Cutting Techniques | Using special ways to cut copper makes the job better. |

| Feed Rates | Changing feed rates keeps the part cool and smooth. |

| Advanced Machining Methods | Using EDM and water jet cutting helps make very exact shapes. |

I always start by picking the best tool. High-speed steel or carbide tools cut copper well and last longer. I use sharp tools and keep them cool so copper does not smear. I watch my feed rate. If I go too fast, the copper gets hot and rough. I slow down to keep the part smooth and correct.

Sometimes, I need special methods. For hard shapes, I use EDM or water jet cutting. These ways help me make very exact and special parts.

Tip: I always check my tools and settings before I start a new copper cnc machining job. This helps me avoid problems and get good results.

Copper machining needs careful planning and focus. By following these steps, I can make parts that are high quality and work well.

How does Copper Machining work?

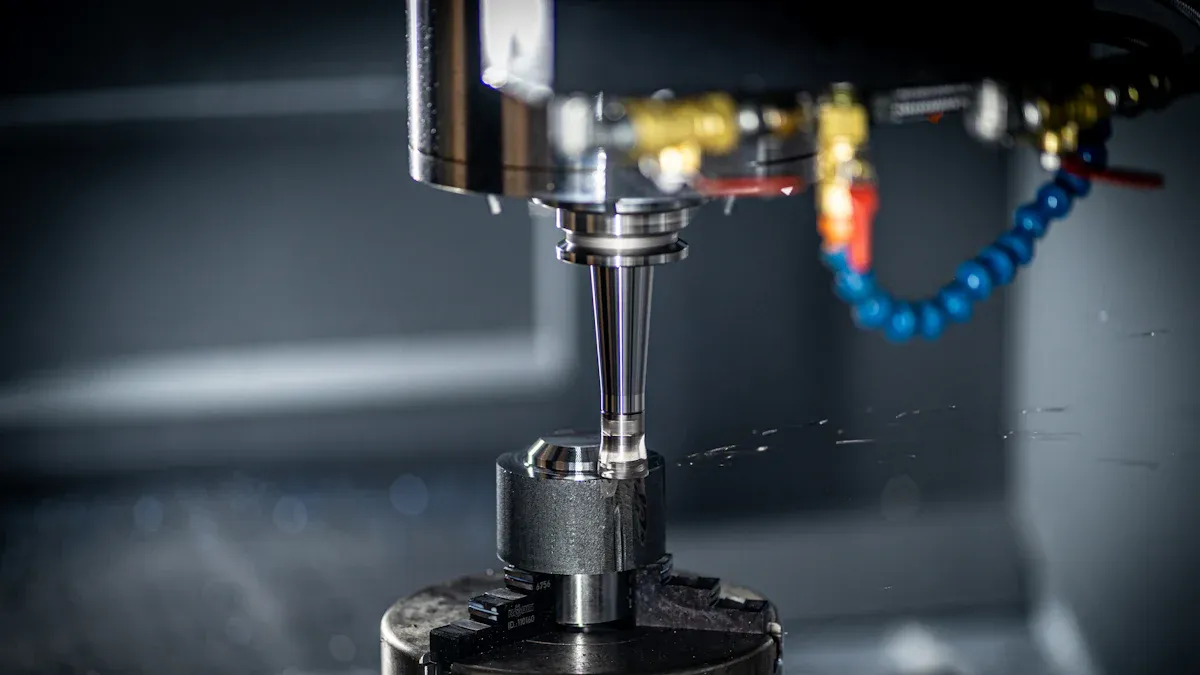

I use copper cnc machining to shape copper into exact parts. The process follows a series of steps. Each step helps me create strong and precise components for many industries.

- Drilling

I start by drilling holes in copper. This step lets me make round openings for bolts or fasteners. I use sharp drill bits to keep the holes clean and accurate. - Tapping

After drilling, I tap threads inside the holes. This step allows screws or bolts to fit tightly. I use special tools to cut threads without damaging the copper. - Grinding

I grind the copper surface to get a smooth finish. Grinding helps me reach the exact size needed for each part. I use an abrasive wheel to remove tiny bits and improve the look. - Electrical Discharge Machining (EDM)

For very detailed shapes, I use EDM. This method uses electrical sparks to cut copper with high precision. EDM works well when I need complex designs or tight tolerances. - Water Jet Cutting

Sometimes, I use water jet cutting. This technique uses high-pressure water to slice through copper. Water jet cutting does not heat the metal, so it keeps the copper strong and free from distortion.

Tip: I always check my machines and tools before starting. This helps me avoid mistakes and keeps the process safe.

I follow these steps to make sure each copper part meets strict standards. I choose the right method based on the part’s design and use. For example, I pick EDM for tiny features and water jet cutting for large shapes.

Here is a quick look at the main machining methods I use:

| Method | Purpose | Benefit |

|---|---|---|

| Drilling | Makes round holes | Accurate fastening |

| Tapping | Cuts threads in holes | Secure screw fit |

| Grinding | Smooths and sizes surfaces | Fine finish and precision |

| EDM | Shapes with electrical sparks | Extreme accuracy |

| Water Jet Cutting | Cuts with high-pressure water | No heat distortion |

I always plan each step carefully. This helps me deliver copper parts that work well and last long.

Best CNC Machines That Can Be Used For Copper Alloys

When I choose a CNC machine for copper alloys, I look for equipment that can handle copper’s softness and high thermal conductivity. Copper needs machines with stable frames and precise controls. I want machines that keep vibration low and maintain accuracy during cutting. I use these machines to make parts for electronics, plumbing, and medical devices.

Here are the main types of CNC machines I use for copper alloys:

- CNC Milling Machines

I use milling machines for most copper parts. These machines cut, drill, and shape copper with high precision. I pick models with rigid frames and advanced cooling systems. This helps prevent copper from overheating and keeps the part smooth. - CNC Turning Machines (Lathes)

I use CNC lathes to make round copper parts. These machines spin the copper and shape it with cutting tools. I choose lathes with high spindle speeds and strong tool holders. This setup gives me clean finishes and tight tolerances. - CNC EDM Machines

I use Electrical Discharge Machining (EDM) for complex copper shapes. EDM uses electrical sparks to cut copper without touching it. I pick EDM machines with fine wire controls. This lets me create tiny features and sharp corners. - CNC Router Machines

I use routers for thin copper sheets. Routers move fast and cut simple shapes. I select routers with vacuum tables to hold the copper flat. This keeps the sheet from moving and helps me get accurate cuts.

Tip: I always check the machine’s rigidity and cooling system before starting a copper job. Machines with weak frames or poor cooling can cause rough surfaces and tool wear.

What is the Best Tool to Machine Copper?

I find that tool choice matters as much as machine selection. Copper is soft, so I need sharp tools that resist wear. I use these tools most often:

| Tool Type | Why I Use It | Best For |

|---|---|---|

| Carbide End Mills | Stay sharp longer, cut cleanly | Milling and slotting |

| HSS Tools | Cost less, easy to sharpen | Drilling and turning |

| Diamond-Coated | Reduce friction, last longer | Fine finishing |

Carbide end mills work best for milling copper. They stay sharp and cut clean edges. High-speed steel (HSS) tools cost less and work well for drilling and turning. For the finest finishes, I use diamond-coated tools. These tools reduce friction and keep the copper surface smooth.

I always use sharp tools and replace them when they dull. Dull tools can smear copper and ruin the part. I set the right feed rate and speed for each tool. Fast speeds can heat copper and cause rough edges. Slow speeds keep the part cool and improve accuracy.

Note: I test new tools on scrap copper before using them on real parts. This helps me avoid mistakes and get the best results.

I match the right CNC machine and tool to each copper job. This approach helps me make strong, accurate, and smooth copper parts every time.

Properties Affecting the Machining of Copper

When I work with copper, I look at its features. These features tell me how easy copper is to machine. I always check the material before I start. Copper’s special traits help me pick the right tools and ways to work.

Copper is great because it carries electricity and heat well. This means I use copper for electrical parts and heat sinks. When I machine copper, heat moves away fast. My tools stay cool, and the part keeps its shape. I do not see much warping or overheating.

Copper is ductile. It bends and stretches without breaking. I can make complex shapes and thin walls. This makes copper good for detailed designs. I often make small connectors and tricky parts easily.

Impurities change how copper acts when I machine it. Pure copper can be sticky and hard to cut. If copper has a little lead, tellurium, or sulfur, it is easier to machine. These elements help chips break off. I get smoother surfaces and less tool wear. Other impurities can cause more tool wear and rough finishes.

Strength and hardness are important too. Copper is softer than steel or titanium. I use sharp tools and go slow. If I push too hard, copper can smear or change shape. I check my tool edges often. Dull tools make the job harder and can hurt the part.

Here is a table that shows how copper’s properties affect machinability:

| Property | Effect on Machinability |

|---|---|

| Conductivity | High conductivity can enhance machining processes |

| Ductility | High ductility allows for easier shaping |

| Impurities | Lead, tellurium, and sulfur improve machinability; other impurities can reduce it |

| Thermal Conductivity | High thermal conductivity aids in heat dissipation during machining |

| Strength and Hardness | Poor strength and hardness can affect tool wear and machining efficiency |

Tip: I always check the copper grade before I start. Alloys with tellurium or sulfur help me save time and money.

I changed my machining plan based on these features. For pure copper, I go slower and use sharper tools. For alloys, I can work faster and get smoother parts. I watch for tool wear and overheating. By knowing copper’s features, I make strong parts that last long.

Knowing these things helps me avoid mistakes. I get better results and keep my shop safe. Copper’s features guide every step I take.

Copper CNC Machining Benefits

Electrical and Thermal Conductivity

Copper is great for CNC machining. It carries electricity and heat better than most metals. I use copper to make electrical connectors and heat sinks. These parts need to move energy quickly. Copper helps electronics stay cool and work well. It also carries power without losing much energy. Copper parts work in power grids, circuit boards, and car batteries. I see fewer problems and longer-lasting products when I use copper.

Tip: Pick copper if you need a part that stays cool or carries lots of electricity.

Corrosion and Wear Resistance

Copper does not rust in air or water. It makes a thin layer that protects it from damage. I use copper for plumbing and outdoor gear. These parts last longer in tough places. Copper does not work well in strong acids or salty water. For most jobs, copper is strong and not too expensive.

Here is a table that shows how copper, aluminum, and stainless steel resist corrosion:

| Material | Corrosion Resistance Characteristics | Advantages | Limitations |

|---|---|---|---|

| Copper | Makes a protective layer; resists air and water; weak against acids | Great at carrying heat and electricity; bends easily | Not good for strong acids or salty water; costs more |

| Aluminum | Thin layer protects in normal places; rusts fast in acids | Light, cheap, easy to shape | Not good for strong acids, bases, or saltwater |

| Stainless Steel | Very strong against water, steam, chemicals, and salt | Lasts long; does not rust; very strong | Heavier than aluminum; costs more than aluminum |

I use copper when I need a part that will not rust in the air or water. For strong chemicals or saltwater, I pick stainless steel.

Flexibility and Toughness

Copper bends and stretches without breaking. This helps me make thin or tricky shapes. I can make tiny connectors and detailed heat exchangers. Brittle metals would crack, but copper does not. Copper is tough, so parts can bend and shape during machining and use.

Here is a table that shows how copper alloys work:

| Alloy | Purity | Ductility | Machinability | Corrosion Resistance |

|---|---|---|---|---|

| C101 | 99.99% | High | Excellent | Good |

| C110 | 99.9% | High | Good | Good |

C101 and C110 copper are easy to machine and do not break easily. These alloys help me make strong and flexible parts for electronics, plumbing, and medical tools.

Note: I always check the alloy before I start a copper cnc machining job. The right alloy gives me the best mix of bending, toughness, and easy machining.

Precision and Complex Shapes

I use copper CNC machining for very exact parts. Copper is soft, so I can cut tiny shapes easily. I do not need much force to make detailed features. I can make parts with tolerances as close as ±0.005mm. This is as accurate as aluminum. I need this accuracy for electronics and medical devices. It also helps with aerospace parts.

I watch how chips break off when I cut copper. I also check how coolant flows over the part. These steps help me get a smooth surface. They stop rough edges from forming. I use sharp tools and change my cutting speed. This keeps the copper cool. Copper bends well, so I can make thin walls and fine details. Other metals might crack or bend, but copper does not.

Here are reasons why copper CNC machining is good for tricky and exact parts:

- Copper is soft, so I use less force and make tiny features.

- I can reach high precision, just like with aluminum.

- Good chip breaking and coolant use help me get the finish I want.

- Copper bends easily, so I can shape thin sections and patterns.

Tip: I always check my machine settings and tool sharpness before I start. This helps me avoid mistakes and keeps the part exact.

Machinability and Tool Compatibility

Copper is easy to machine if I use the right tools. Most CNC tools work with copper, but I changed some settings. Copper alloys are soft and can bend if they get too hot. I set my machine speed lower and use bigger chiploads. This keeps the part cool. High-pressure coolant helps stop heat and tool sticking.

Sometimes, copper sticks to my cutting tools. I use strong coolant and make sure chips leave fast. This keeps my tools clean and helps them last longer. Copper bends easily, so I need a tight grip when I machine it. I use strong clamps to hold the part steady.

Here is how I handle copper’s machinability and tool use:

- I changed the machine speed and chip load to stop the heat.

- I use strong coolant to keep copper from sticking.

- I make sure chips leave fast to avoid problems.

- I use strong clamps to hold copper parts in place.

Note: I test my setup on scrap copper before I start. This helps me find the best settings and stops tool wear.

Limitations and Challenges

Copper CNC machining has many good points, but there are some problems. Copper can wear down my tools fast. I need good tools and must replace them often. Getting a perfect surface finish takes careful control. Copper can bend while I cut it, so parts may not be exact. Long chips can build up and hurt the finish or tool life.

I remember these problems and plan my jobs to avoid them. Here is a table that shows the main issues I see:

| Challenge | Explanation |

|---|---|

| Tool Wear | Copper wears down tools fast and can chip edges, which raises tooling costs. |

| Surface Finish | I need to optimize cutting parameters to reduce vibration and get a smooth finish. |

| Dimensional Accuracy | Copper can deform during cutting, so parts may not meet tight tolerances. |

| Chip Control | Long chips can build up and affect both surface finish and tool life. |

| Tool Life | Copper sticks to tools, which shortens tool life and means I need high-quality tooling. |

Tip: I always check for tool wear and chip buildup while I work. Regular checks help me keep quality high and avoid mistakes.

Copper CNC Machining Processes

CNC Milling Copper

Milling Operations

When I mill copper, I use a spinning tool to cut away material from a solid block. Milling lets me create flat surfaces, slots, pockets, and even complex 3D shapes. I often use this process for electrical parts, heat sinks, and custom connectors. Milling works well for copper because the metal is soft and easy to shape. I can reach tight tolerances and smooth finishes with the right setup.

Here are the main milling operations I use for copper:

- Face Milling: I remove the top layer to make a flat surface.

- Slot Milling: I cut grooves or slots for connectors or fasteners.

- Contour Milling: I follow a path to create curves or complex outlines.

- Pocket Milling: I remove material from inside a part to make cavities.

Tip: I always check the part drawing before I start. This helps me pick the best milling operation for each feature.

Tool Selection

Choosing the right tool is key when I mill copper. Copper is soft, so I use sharp tools to avoid smearing the metal. I prefer carbide end mills because they stay sharp longer and resist wear. For fine details, I use small-diameter tools. I also pick tools with a high helix angle. This helps remove chips quickly and keeps the cut smooth.

Here is a table that shows my favorite tools for milling copper:

| Tool Type | Best Use | Why I Choose It |

|---|---|---|

| Carbide End Mill | General milling | Stays sharp, cuts clean |

| HSS End Mill | Light cuts, prototypes | Easy to sharpen, low cost |

| Ball Nose Cutter | 3D shapes, contours | Smooth finish on curves |

I always use fresh, sharp tools for copper. Dull tools can cause rough edges and poor finishes. I also set the right spindle speed and feed rate to keep the tool cool and prevent copper from sticking.

CNC Turning Copper

Turning Techniques

Turning is a process where I spin a copper rod or bar and use a cutting tool to shape it. I use CNC lathes for this job. Turning works best for round parts like bushings, pins, and rings. I can make both simple and complex shapes by changing the tool path.

Some turning techniques I use include:

- Facing: I cut the end of the copper bar to make it flat.

- Straight Turning: I reduce the diameter along the length of the part.

- Grooving: I cut narrow channels for retaining rings or seals.

- Threading: I create screw threads for fasteners.

I always check the part’s design before I start. This helps me pick the right turning technique for each feature.

Surface Finish

Getting a smooth surface on copper takes careful control. Copper can be sticky, so I use sharp tools and the right cutting fluid. I set the spindle speed lower than I would for harder metals. This helps prevent heat buildup and keeps the finish clean.

Here are my tips for a better surface finish:

- Use sharp carbide inserts.

- Apply plenty of coolant to reduce heat.

- Take light cuts to avoid smearing.

- Check the tool edge often for wear.

Note: A smooth surface is important for electrical parts. It helps with conductivity and makes assembly easier.

CNC Drilling Copper

Drill Bit Choice

Drilling holes in copper is common in many projects. I use special drill bits to get clean, accurate holes. High-speed steel (HSS) bits work well for most jobs. For deeper holes or high-volume work, I switch to carbide-tipped bits. These last longer and stay sharper.

Here is a quick guide to my drill bit choices:

| Drill Bit Type | Best For | Why I Use It |

|---|---|---|

| HSS Drill Bit | General drilling | Easy to find, low cost |

| Carbide Drill Bit | Deep or precise holes | Stays sharp, less wear |

| Split Point Bit | Thin copper sheets | Reduces wandering |

I always use a center punch to mark the hole location. This keeps the drill bit from slipping.

Chip Removal

Copper makes long, stringy chips when I drill. If I do not clear these chips, they can clog the hole or damage the bit. I use peck drilling, which means I lift the bit out every few seconds to clear chips. I also use plenty of cutting fluid to help flush chips away.

Here are my steps for good chip removal:

- Drill a short distance, then lift the bit to clear chips.

- Use cutting fluid to keep the hole cool and clean.

- Check the hole often for chip buildup.

- Use compressed air to blow out chips if needed.

Tip: Good chip removal keeps the hole clean and helps my drill bits last longer.

Copper cnc machining uses these processes to make precise, high-quality parts. Each method has its own strengths, and I choose the best one based on the part’s design and function.

EDM for Copper

When to Use EDM

I use Electrical Discharge Machining (EDM) when I need to make very precise and complex copper parts. EDM works best for shapes that are hard to cut with regular tools. I choose EDM for thin walls, sharp corners, and tiny holes. EDM does not touch the copper directly. It uses electrical sparks to remove material. This method helps me avoid tool wear and keeps the part clean.

I pick EDM for these jobs:

- Making sharp internal corners with small radii.

- Cutting delicate or thin copper sections.

- Machining parts with tight tolerances.

- Working with expensive materials where I want minimal waste.

EDM includes three main methods:

Wire EDM uses a spool of wire to cut through copper. EDM hole drilling uses a tubular electrode for making small holes. Sinker EDM shapes copper with a custom electrode. Each method fits different needs, especially when I work with conductive materials.

EDM Pros and Cons

EDM gives me many benefits, but I also see some limits. I always weigh these before I choose EDM for copper cnc machining.

Pros:

- Non-contact process lets me machine fragile and complex shapes.

- No burrs form, so I get a clean finish.

- I can reach sharp internal corners and fine details.

- Minimal material loss, which saves money on costly copper alloys.

- Tool wear is low because the electrode does not touch the part.

Cons:

- EDM works only with conductive materials like copper.

- The process is slower than milling or turning.

- EDM machines cost more to run and maintain.

- Surface finish may need extra polishing for some jobs.

Tip: I use EDM when I need high accuracy and complex shapes that other methods cannot achieve.

Process Comparison

I often compare copper cnc machining processes to pick the best one for each job. Each method has strengths and weaknesses. I look at the part design, required accuracy, and cost.

Here is a table that shows the key differences:

| Process | Description | Key Differences |

|---|---|---|

| CNC Turning | I rotate the workpiece and remove material from the outside. | Best for round parts and exterior shaping. |

| CNC Milling | I use a spinning tool to cut a fixed workpiece. | Good for flat surfaces and complex shapes; the tool moves, not the part. |

| CNC Drilling | I make round holes with a drill bit. | Focused on hole-making; needs careful setup for precision. |

| EDM | I use electrical sparks to remove material without touching the copper. | Makes intricate shapes; no tool wear; best for delicate features. |

I choose turning for round parts, milling for flat or complex shapes, drilling for holes, and EDM for fine details or hard-to-reach areas.

How to Ensure Quality in Copper Machining Processes?

I always aim for high quality in every copper part I make. I follow strict steps to keep accuracy and finish at the top level.

- Check Material Grade

I start by checking the copper grade. Pure copper and alloys behave differently. I pick the right grade for each job. - Set Up Machines Carefully

I set up my CNC machines with tight controls. I use fresh, sharp tools and check spindle speeds. I make sure the clamps hold the copper steady. - Monitor Tolerances

I measure parts during and after machining. Copper cnc machining can reach tolerances as close as ±0.05 mm (±50 microns). I use calipers and micrometers to check every detail. - Control Chips and Heat

I use coolant and chip removal methods to keep the part cool and clean. This helps me avoid warping and keeps the surface smooth. - Inspect Surface Finish

I look for burrs, rough spots, or tool marks. I polish or deburr parts if needed. Clean surfaces help with conductivity and assembly. - Document Each Step

I keep records of settings, tool changes, and inspections. This helps me repeat good results and fix problems fast.

Note: Careful planning and regular checks help me deliver copper parts that meet strict standards every time.

Copper Grades and Alloys

When I choose copper for CNC machining, I look at many grades and alloys. Each type has unique properties that affect how I machine and use it. I want to share the most common options and how I decide which one fits each job.

Pure Copper Types

Pure copper gives me the best electrical and thermal conductivity. I often use two main types: C110 and C101. These grades work well for electrical parts, but they have different machinability and cost.

C110, C101 Properties

I compare C110 and C101 before I start a project. Here is a table that helps me see the differences:

| Copper Type | Purity Level | Machinability | Conductivity | Cost-Effectiveness |

|---|---|---|---|---|

| C110 | 99.90% Cu | Easier to machine | Moderate | More cost-effective |

| C101 | 99.99% Cu | More challenging | High | Less cost-effective |

C110 is my top pick for most jobs. It machines more easily and costs less. C101 gives the highest conductivity, so I use it for sensitive electronics. I always check if the job needs top conductivity or if I can save money with C110.

Copper Alloys

Sometimes, I need more than pure copper. Alloys give me better machinability, strength, or corrosion resistance. Here are the main copper alloys I use:

Brass

Brass mixes copper and zinc. I use brass when I want easy machining and a gold-like look. Brass resists corrosion and works well for fittings, valves, and decorative parts. Grades like C260 and C360 are popular in my shop.

Bronze

Bronze blends copper with tin and sometimes other metals. I pick bronze for its toughness and wear resistance. It works well for bushings, bearings, and gears. Phosphor bronze (like C510 and C544) gives extra strength and springiness.

Beryllium Copper

Beryllium copper stands out for its high strength and hardness. I use it for springs, tools, and parts that need to resist fatigue. It also keeps good conductivity. I handle it with care because beryllium dust can be hazardous.

Tip: Tellurium copper (C145) machines almost as easily as aluminum. I use it for parts that need both conductivity and easy cutting. It does wear out tools faster at high speeds, so I watch my settings.

Here are some of the most widely used copper grades and alloys in CNC machining:

- 100 Series (Coppers): C101, C102, C110, C145, C147, C122

- 200 Series (Brasses): C210, C220, C230, C260, C272, C274

- 300 Series (Leaded Brasses): C314, C330, C335, C353, C360, C385

- 400 Series (Tin Brasses): C443, C464, C485

- 500 Series (Phosphor Bronzes): C510, C544

- 600 Series (Bronzes): C623, C630, C642, C655, C693

Material Selection Tips

I always match the copper grade or alloy to the job’s needs. Here is how I decide:

Application Needs

I look at what the part must do. For high conductivity, I pick pure copper like C101 or C110. For strength or wear, I choose bronze or beryllium copper. If I need easy machining, I go with brass or tellurium copper.

Cost and Availability

I check the price and how easy it is to get the material. C110 is usually cheaper and easier to find than C101. Alloys like C145 or C360 may cost more, but they save me time in machining. I balance material cost with how much time and effort I will spend making the part.

Note: I always talk with my supplier before I start. This helps me avoid delays and keeps my project on budget.

Precision and Tolerance in Copper Machining

Getting precision right is very important when I machine copper. Even a tiny mistake can make a part not work. I always try to keep tight tolerances. This means copper parts fit and work as they should. Tight tolerances matter most in electronics, aerospace, and medical devices.

I follow industry rules for tolerances when I machine copper. Most metal parts, including copper, use a standard tolerance of ±0.005 inches. I see this number in drawings and customer orders. CNC milling, turning, engraving, and screw machining use this standard. Plastics have a wider tolerance, usually ±0.010 inches.

Here are the tolerances I use for copper CNC machining:

- Milling: ±0.13 mm (±0.005 inches)

- Turning: ±0.13 mm (±0.005 inches)

- Engraving: ±0.13 mm (±0.005 inches)

- Screw machining: ±0.13 mm (±0.005 inches)

I always check what each part needs before I start. Some jobs need even tighter tolerances. Connectors for electronics or medical parts may need tolerances down to ±0.001 inches. I use special CNC machines and measuring tools for these jobs.

To get these tolerances, I follow a careful process:

- I pick the right copper grade for the job.

- I use sharp, good tools to stop burrs and bending.

- I set the machine speed and feed rate carefully.

- I watch the temperature so copper does not change shape.

- I check each part with micrometers and calipers while I work.

Tip: I measure parts at room temperature. This stops mistakes from heat making copper bigger.

Copper is soft, so holding tight tolerances can be hard. The metal can bend if I use too much force or dull tools. I keep my tools sharp and clamp parts gently so they do not change shape.

Here is a table that shows how copper compares to other materials for CNC tolerances:

| Material | Standard Tolerance (inches) | Notes |

|---|---|---|

| Copper | ±0.005 | High precision possible |

| Aluminum | ±0.005 | Similar to copper |

| Plastics | ±0.010 | Less precise than metals |

I always try for the best accuracy. By following these steps, I make copper parts that meet strict standards and work well.

Common Copper Machining Surface Treatments

When I finish making copper parts, I think about how to treat the surface. These treatments help protect the part and make it look better. They also help the part work well. I pick the right treatment for where the part will be used.

Here are the main surface treatments I use for copper CNC-machined parts:

- Nickel Plating

I use nickel plating to stop copper from rusting. Nickel makes a strong layer that keeps the part safe. It helps the part last longer and look shiny. Nickel plating is good for connectors and parts that face tough jobs. - Chrome Plating

Chrome plating makes copper parts harder. This treatment stops the part from getting dull. Chrome keeps the part shiny and strong. It also stops scratches. I use chrome for parts that need to look nice and stay tough. - Tin Plating

Tin plating helps copper parts fight rust. Tin is safe and not harmful. It makes the part easy to solder. This is important for electrical parts. I pick tin plating when the part needs to join with wires. - Silver Plating / Gold Plating

Silver and gold plating help copper parts carry electricity best. These treatments also stop rust. I use silver or gold for important electronic parts. These are used in special connectors and medical devices.

Tip: I match the surface treatment to the job. For electrical parts, I use silver or gold plating. For strong parts, I pick nickel or chrome plating.

Here is a table that shows what each surface treatment does for copper parts:

| Surface Treatment | Main Benefit | Best Use Case | Extra Feature |

|---|---|---|---|

| Nickel Plating | Stops rust | Connectors, strong parts | Shiny look |

| Chrome Plating | Makes the part hard | Fancy, moving parts | Stops dullness |

| Tin Plating | Easy to solder | Electrical parts | Safe to use |

| Silver Plating | Best electricity | Top electronics | Bright look |

| Gold Plating | Best electricity, stops rust | Medical, special electronics | Lasts a long time |

I always check what the part will do before I pick a treatment. Nickel and chrome make parts strong and last longer. Tin helps with soldering and safety. Silver and gold are best for electronic parts.

Surface treatments help copper parts work better and last longer. I use these treatments to make sure every part is strong and looks good.

Design and Machining Tips

Copper CNC Machining Design

Wall Thickness

I always pay close attention to wall thickness when I design copper parts. Thin walls can bend or break during machining. I keep the wall thickness above 0.8 mm for most copper components. This thickness gives enough strength and helps avoid warping. For parts that need extra durability, I increase the wall thickness to 1.5 mm or more. I check the part’s use before I decide on the final thickness.

Tip: I avoid making walls thinner than 0.8 mm unless the design demands it. Thin walls can cause problems with accuracy and strength.

Tolerances

Tolerances matter a lot in copper CNC machining. I set tight tolerances for parts that need to fit together or carry electricity. I use a standard tolerance of ±0.13 mm (±0.005 inches) for most jobs. For high-precision parts, I go down to ±0.025 mm (±0.001 inches). I always check the drawing and talk with the customer before I start. Tight tolerances help parts work well and last longer.

| Part Type | Typical Tolerance |

|---|---|

| General Parts | ±0.13 mm (±0.005 in) |

| Precision Parts | ±0.025 mm (±0.001 in) |

Note: I measure parts often during machining. This helps me catch mistakes early and keep tolerances tight.

Tooling and Parameters

Tool Materials

I choose tool materials based on copper’s softness and stickiness. Carbide tools work best for most copper jobs. They stay sharp and resist wear. High-speed steel (HSS) tools cost less and work for simple cuts. For fine finishes, I use diamond-coated tools. These tools help me get smooth surfaces and reduce friction.

- Carbide: Best for long runs and tough jobs.

- HSS: Good for prototypes and low-cost projects.

- Diamond-coated: Ideal for fine details and smooth finishes.

Feed Rates and Speeds

I set feed rates and spindle speeds to match copper’s properties. I use lower speeds to keep copper cool and avoid smearing. For carbide tools, I set spindle speeds between 2,000 and 6,000 RPM. I use higher feed rates to help chips break off and leave the cutting area. I adjust these settings based on the tool size and part design.

| Tool Type | Spindle Speed (RPM) | Feed Rate (mm/min) |

|---|---|---|

| Carbide End Mill | 2,000–6,000 | 100–500 |

| HSS Drill Bit | 1,000–3,000 | 50–200 |

Tip: I test my settings on scrap copper before I start the real job. This helps me find the best speed and feed for each tool.

Overcoming Challenges

Work Hardening

Copper can harden as I cut it. This makes machining harder and can damage tools. I use sharp tools and take light cuts to avoid work hardening. I keep the cutting area cool with plenty of fluid. I also avoid stopping and starting the cut too often.

- Use sharp tools.

- Take light cuts.

- Keep the part cool.

Heat Management

Heat builds up fast when I machine copper. Too much heat can warp the part or dull the tool. I use high-pressure coolant to keep the part and tool cool. I also use lower spindle speeds and higher feed rates. I check the part often for signs of overheating.

| Challenge | Solution |

|---|---|

| Work Hardening | Sharp tools, light cuts |

| Heat | Coolant, lower speeds |

Note: Good heat management helps me get better finishes and longer tool life.

Quality Control

Quality control is very important in copper CNC machining. I check every part to make sure it is good. I follow the steps to find mistakes early. This helps me make parts that work well.

Inspection Steps

I look at the raw copper first. I check for cracks or dents. I also look for things that should not be there. Clean copper helps me avoid problems later. Before I start, I measure the copper with calipers. I make sure the size is right for the job.

While I machine, I stop and check the part often. I use tools like micrometers and calipers. Gauges help me measure thickness and length. I compare these numbers to the drawing. If something is wrong, I fix it right away.

After machining, I check the finished part again. I look for burrs and scratches. I also check for rough spots. I make sure holes and threads are clean. They must fit the right fasteners. For very exact parts, I use a CMM. This machine checks every detail.

Here is a checklist I use for copper CNC parts:

- Check raw copper for damage.

- Measure size before machining.

- Check size during each step.

- Look at the surface and edges after machining.

- Test holes and threads to see if they fit.

- Use a CMM for very exact parts.

Tip: I write down my inspection results. This helps me keep track of quality and fix problems fast.

Post-Processing

Post-processing makes copper parts look and work better. First, I remove sharp edges and burrs. I use files or pads for this. This step keeps parts safe and helps them fit together.

Next, I clean the parts. I get rid of oil, chips, and dust. I use an ultrasonic cleaner or wash with soap and water. Clean parts do not rust and look nicer.

If the part needs a special finish, I add plating or polishing. Nickel, tin, or silver plating protects copper. It also helps copper carry electricity. I pick the finish based on what the part will do.

Last, I checked the part one more time. I look at the finish and measure key spots again. I pack the parts carefully. I put a label with the job number and date.

| Post-Processing Step | Purpose | Tools/Methods Used |

|---|---|---|

| Deburring | Remove sharp edges | Files, abrasive pads |

| Cleaning | Remove oil and dust | Ultrasonic cleaner, soap |

| Surface Treatment | Protect and improve | Plating, polishing |

| Final Inspection | Check before shipping | Calipers, visual check |

Note: Careful post-processing helps copper parts last longer and work better in their final use.

Applications of Copper CNC Machining

Copper cnc machining is used in many fields. This process helps make parts that need to be exact and strong. Copper is chosen because it conducts electricity and heat better than most metals. It also does not rust easily and can be shaped into tricky forms.

Here are the main ways copper cnc machining is used:

- Electronics

Copper is used for circuit boards, connectors, and heat sinks. These parts need to be shaped very carefully. Copper helps devices stay cool and work well. CNC milling helps make these parts very exact. - Automotive

Copper is used for engine parts and cooling system pieces. It is also used for electrical connectors in cars. Cars need parts that last and work under stress. Copper gives the strength and accuracy needed. Hybrid and electric cars use copper because it conducts electricity well. - Aerospace

Copper is used for parts that face high heat and tough places. Aerospace parts must not rust and must work in hard conditions. Copper helps meet these needs. It is used for fuel systems, avionics, and heat exchangers. - Medical Devices

Copper is used for surgical tools and medical machines. It is also used for connectors in medical equipment. Copper kills germs, so it is a smart choice. CNC machining helps make parts that fit well and meet health rules. - Plumbing and HVAC

Copper is used for fittings, valves, and heat exchangers. These parts go in plumbing and heating systems. Copper does not rust and can handle temperature changes. CNC machining helps make custom parts for each system.

Tip: I always pick the right copper grade and process for each job. This helps make parts that last and work well.

Here is a table that shows how copper cnc machining helps different fields:

| Industry | Common Copper Parts | Main Benefit |

|---|---|---|

| Electronics | Circuit boards, connectors | High conductivity, precision |

| Automotive | Engine parts, connectors | Durability, accuracy |

| Aerospace | Fuel systems, avionics | Corrosion resistance |

| Medical | Surgical tools, connectors | Antimicrobial, precision |

| Plumbing/HVAC | Fittings, heat exchangers | Rust resistance, custom fit |

Copper cnc machining is important for making modern products. It helps meet the needs of industries that want quality and strong performance.

Design Considerations for Effective Copper Machining

When I design copper parts for CNC machining, I always start by thinking about the metal’s unique properties. Copper is soft and ductile. It bends and stretches more than steel or aluminum. I must plan my designs to take advantage of these traits and avoid problems.

1. Choose the Right Wall Thickness

Thin walls in copper parts can bend or vibrate during machining. I keep the wall thickness above 0.8 mm for most designs. For parts that need extra strength, I use 1.5 mm or more. This helps the part stay strong and keeps it from warping.

Tip: If you need thin walls, support them with ribs or add fillets at corners. This makes the part stronger without adding much weight.

2. Use Generous Radii and Fillets

Sharp corners in copper parts can cause stress and make machining harder. I add fillets or rounded edges wherever possible. A radius of at least 0.5 mm works well for most features. This helps tools move smoothly and reduces the risk of cracks.

3. Plan for Tolerances and Fits

Copper expands when it gets hot. I always check the working temperature of the part. For tight fits, I use standard tolerances of ±0.13 mm (±0.005 in). For high-precision parts, I go down to ±0.025 mm (±0.001 in). I measure parts at room temperature to avoid mistakes.

| Feature Type | Recommended Tolerance |

|---|---|

| General Features | ±0.13 mm (±0.005 in) |

| Precision Areas | ±0.025 mm (±0.001 in) |

4. Avoid Deep or Narrow Slots

Deep or narrow slots can cause tools to chatter or break. I keep the slot depth less than four times the width. For example, if a slot is 2 mm wide, I keep the depth under 8 mm. This keeps the cut stable and the finish smooth.

5. Design for Good Chip Removal

Copper makes long, stringy chips. I design open features and avoid blind holes when possible. This helps chips escape and keeps the tool from clogging.

Note: I add access holes or slots to help with chip removal in tricky areas.

6. Consider Surface Finish Needs

If the part needs a smooth or shiny finish, I plan for extra machining or polishing steps. I avoid tiny features that are hard to polish. I also choose surface treatments that match the part’s use, like nickel or tin plating for protection.

7. Keep Assembly in Mind

I design features that make assembly easy. I use chamfers on holes and edges to guide fasteners. I avoid sharp edges that can cut wires or hands.

By following these design rules, I make copper parts that machine well, last longer, and work better in their final use. Good design saves time and money in the shop.

Key Safety Tips for Copper Machining

Safety always comes first in my shop. When I machine copper, I follow strict rules to keep myself and my team safe. Copper is soft, but the process can create sharp chips, dust, and heat. I want to share the safety steps I use every day.

1. Wear Proper Protective Equipment

I always put on safety glasses before I start. Chips can fly from the machine and hurt my eyes. I use gloves to protect my hands from sharp edges and hot surfaces. I wear ear protection because CNC machines make loud noises. I choose a dust mask when I cut or grind copper to avoid breathing in fine particles.

2. Keep the Work Area Clean

I sweep up chips and dust after each job. Copper dust can build up and cause breathing problems. I use a vacuum with a HEPA filter to remove fine particles. I keep tools and materials organized to prevent trips and falls.

3. Check Machines Before Use

I inspect my CNC machines before I turn them on. I look for loose wires, damaged guards, or worn-out parts. I test emergency stops to make sure they work. I check coolant levels and make sure the ventilation system runs well.

4. Control Copper Dust and Fumes

Copper machining creates dust and fumes. I use local exhaust ventilation to pull dust away from my face. I open windows or use fans to keep fresh air moving. I avoid eating or drinking near the machines to prevent copper dust from getting into my food.

Tip: I always wash my hands after handling copper parts. This simple step keeps copper dust out of my mouth and eyes.

5. Prevent Fire Hazards

Copper chips and dust can catch fire if mixed with oil or sparks. I keep flammable liquids away from the machining area. I store oily rags in metal containers with tight lids. I keep a fire extinguisher nearby and know how to use it.

6. Handle Chemicals Safely

I use coolants and cleaning agents when I machine copper. I read the labels and follow instructions. I wear gloves and goggles when I handle chemicals. I store chemicals in marked containers and keep them away from heat.

7. Know Emergency Procedures

I train my team on what to do in an emergency. I post emergency numbers and first aid instructions on the wall. I keep a first aid kit stocked and easy to reach. I practice fire drills and machine shutdowns.

Here is a quick table of my top safety tips:

| Safety Tip | Why It Matters |

|---|---|

| Wear PPE | Protects eyes, hands, and ears |

| Clean work area | Prevents slips, breathing issues |

| Inspect machines | Avoids accidents |

| Control dust/fumes | Keeps the air safe |

| Prevent fire hazards | Stops fires before they start |

| Handle chemicals safely | Prevents burns, poisoning |

| Know emergency steps | Responds quickly to danger |

I follow these safety tips every time I machine copper. Staying safe helps me work better and keeps my shop running smoothly. 🦺

Common Problems and Solutions in Copper Machining

When I machine copper, I often run into a few common problems. Copper’s softness and high conductivity make it unique, but these same features can cause trouble. Over time, I have learned how to spot these issues and fix them fast. Here are the main problems I see in my shop and how I solve them.

1. Tool Wear and Dulling

Copper wears down cutting tools quickly. Dull tools leave rough surfaces and can ruin a part.

How I solve it:

- I use carbide or diamond-coated tools. These last longer than regular steel.

- I check tool edges often. When I see wear, I replace the tool right away.

- I keep my tools sharp by using proper grinding methods.

2. Poor Surface Finish

Copper can smear or leave burrs. This makes the part look bad and can hurt its function.

How I solve it:

- I use sharp tools and high-quality coolants.

- I set the right feed rate and spindle speed. Lower speeds help prevent smearing.

- I deburr parts after machining with files or abrasive pads.

3. Chip Control Issues

Copper makes long, stringy chips. These chips can clog the tool or damage the part.

How I solve it:

- I use chip breakers on my cutting tools.

- I apply plenty of coolant to help move chips away.

- I stop the machine to clear chips if I see a buildup.

4. Workpiece Deformation

Copper bends easily. Thin parts can warp or lose shape during machining.

How I solve it:

- I design parts with thicker walls when possible.

- I use strong clamps to hold the part steady.

- I take light cuts to reduce force on the part.

5. Overheating

Copper moves heat fast, but tools can still get hot. Too much heat can cause tool wear and part distortion.

How I solve it:

- I use high-pressure coolant to keep the part and tool cool.

- I lower spindle speeds and increase feed rates to reduce heat.

- I pause between cuts to let the part cool down.

Tip: I always test my setup on scrap copper before starting a new job. This helps me catch problems early and adjust my process.

Here is a quick table that sums up the problems and solutions:

| Problem | Solution |

|---|---|

| Tool Wear | Use carbide tools, check and replace often |

| Poor Finish | Use sharp tools, adjust speed, and deburr |

| Chip Control | Use chip breakers, coolant, and clear chips |

| Deformation | Thicker walls, strong clamps, light cuts |

| Overheating | Coolant, lower speed, pause between cuts |

By watching for these issues and using the right fixes, I make sure my copper parts turn out strong, smooth, and accurate every time. 🛠️

Cost and Efficiency

Material and Machining Costs

When I plan a copper CNC machining job, I always look at material and machining costs first. Copper is more expensive than aluminum or steel. The price changes based on the grade and purity. Pure copper, like C101, costs more than alloys such as brass. I check the market price before I order. I also talk to my supplier to get the best deal.

Machining costs depend on the time and tools needed. Copper wears down tools faster than some other metals. I use carbide or diamond-coated tools to save money in the long run. Tool changes and setup time add to the cost. I keep my machines running smoothly to avoid delays.

Here is a table that shows how copper compares to other metals:

| Material | Average Cost per Pound | Tool Wear Rate | Machining Difficulty |

|---|---|---|---|

| Copper | High | High | Medium |

| Aluminum | Low | Low | Easy |

| Steel | Medium | Medium | Medium |

Tip: I always order a little extra copper. This covers mistakes and lets me test my setup without wasting the main material.

Design for Manufacturability

I design copper parts to make them easy and cheap to machine. I avoid thin walls and deep pockets because these features take more time and can cause errors. I use standard sizes for holes and threads. This lets me use off-the-shelf tools and saves money.

I keep the design simple. Fewer features mean less machining time. I add fillets to the corners. This helps tools move smoothly and reduces tool wear. I also plan for easy chip removal. Open shapes and wide slots help chips escape and keep the process safe.

Here are my main design tips for saving money:

- Use standard hole sizes and thread types.

- Avoid thin walls and deep cuts.

- Add fillets to sharp corners.

- Keep features simple and open.

Note: I always review my design with the machinist. This helps catch problems early and keeps costs down.

Batch Size Impact

Batch size changes the cost of copper CNC machining. Small batches cost more per part. Setup and programming take time, no matter how many parts I make. When I run a large batch, I spread these costs over more parts. This lowers the price for each piece.

For one-off or prototype parts, I expect to pay more. I use these runs to test the design and process. For production runs, I plan for bigger batches. This helps me save money and get better prices from suppliers.

Here is how batch size affects cost:

- Small batch (1-10 parts): High cost per part, good for testing.

- Medium batch (10-100 parts): Lower cost per part, good for small production.

- Large batch (100+ parts): Lowest cost per part, best for full production.

Tip: I always ask for a quote for different batch sizes. This helps me see where I can save the most money.

Reducing Costs

I always look for ways to lower costs in copper CNC machining. Saving money helps me stay competitive and deliver better value to my customers. Over time, I have found several strategies that work well in my shop.

1. Optimize Part Design

Simple designs cost less to machine. I avoid deep pockets, thin walls, and complex shapes unless the job requires them. Standard hole sizes and thread types let me use common tools. I add fillets to sharp corners. This reduces tool wear and speeds up machining.

2. Choose the Right Copper Grade

I select copper grades that match the part’s needs. Pure copper costs more and is harder to machine. Alloys like C110 or tellurium copper (C145) offer good machinability and lower price. I talk with my supplier to find the best balance between cost and performance.

3. Extend Tool Life

Copper wears down tools quickly. I use carbide or diamond-coated tools to get more cuts before replacement. I keep tools sharp and check them often. Proper coolant and chip removal help tools last longer.

4. Plan Efficient Machining Steps

I group similar parts together. This reduces setup time and tool changes. I use batch processing for large orders. I program my CNC machines to minimize tool movement and idle time.

5. Reduce Material Waste

I nest parts closely on the copper sheet. This saves material and lowers scrap. I order the right amount of copper for each job. I use leftover pieces for prototypes or test runs.

6. Maintain Equipment

Well-maintained machines run smoother and break down less often. I clean and inspect my CNC machines regularly. I replace worn parts before they cause problems.

Tip: I always review my process after each job. Small changes can lead to big savings over time.

Here is a table that shows my top cost-saving actions and their impact:

| Cost-Saving Action | Impact on Cost | How I Apply It |

|---|---|---|

| Simple Design | Lowers machining time | Use standard features |

| Right Copper Grade | Cuts material cost | Match grade to job |

| Tool Maintenance | Extends tool life | Sharpen and inspect tools |

| Efficient Setup | Reduces labor costs | Batch similar parts |

| Material Nesting | Lowers scrap | Plan part layout |

I use these steps every day to keep my copper CNC machining jobs affordable. Careful planning and smart choices help me deliver quality parts at a better price. 🛠️

I see copper cnc machining as a smart choice for making precise, durable parts. I focus on picking the right copper grade, designing for easy machining, and optimizing each process. These steps help me keep costs low and quality high. If you want strong results, use the tips I shared. You can reach out to experts or request a quote for your next copper cnc machining project.

Ready to improve your parts? Take action and start your copper cnc machining journey today!

FAQ

What is the best copper grade for CNC machining?

I use C110 copper for most jobs. It offers good machinability and high conductivity. For parts that need even better conductivity, I pick C101. If I want easier cutting, I choose tellurium copper (C145).

Can I machine pure copper with standard CNC tools?

Yes, I can machine pure copper with standard tools. I use sharp carbide or HSS tools. I keep speeds low and use plenty of coolant. This helps prevent tool wear and keeps the part cool.

How do I prevent copper from sticking to cutting tools?

I use high-pressure coolant and sharp tools. I set the right feed rate and spindle speed. This keeps copper chips moving and stops them from sticking. I also clean my tools often during the job.

What surface finish can I achieve on copper parts?

I can get a smooth, shiny finish on copper parts. I use sharp tools and the right cutting fluid. For extra shine, I polish or plate the surface after machining. Most parts look bright and clean.

Is copper safe to machine in my shop?

Yes, copper is safe to machine if I follow safety rules. I wear safety glasses, gloves, and a dust mask. I keep my work area clean and use good ventilation. I always wash my hands after handling copper.

Why does copper wear out my tools faster than aluminum?

Copper is softer but sticky. It causes more friction and heat. This makes tools dull faster than when I cut aluminum. I use carbide or diamond-coated tools to help them last longer.

Can I use CNC machining for small copper parts?

Yes, I use CNC machining for small copper parts. The process gives me high accuracy and tight tolerances. I make tiny connectors, pins, and custom shapes with ease.

What industries use copper CNC-machined parts the most?

I see copper parts in electronics, automotive, aerospace, medical, and plumbing industries. These fields need parts that conduct electricity, resist corrosion, and fit exact designs.