Solve acrylic CNC machining issues like melting, chipping, and rough edges with expert troubleshooting tips for better part quality and production efficiency.

You might notice that problems often happen during acrylic CNC machining. This is true when you need perfect parts for medical or car use. Fixing problems fast helps your factory work well. It also stops you from wasting materials. If you work with a good supplier like NOBLE, you get help for both new ideas and big orders. Here’s why acting quickly is important:

- If you spot tool wear early, you stop bad parts and delays.

- Doing regular checks and changing settings keeps your work accurate.

- Using the best machining plan saves time and stops expensive mistakes.

Key Takeaways

- Find problems like melting, chipping, and rough edges early. This helps keep your parts good and stops waste.

- Pick the right tools, speeds, and cooling to stop heat damage. This also helps your tools last longer when machining.

- Hold your acrylic parts tightly so they do not move or shake. Movement and vibration can mess up your work.

- Check your machines often and do regular care. This helps you find problems before they slow you down or cause bad parts.

- Work with trusted suppliers like NOBLE for expert help. They can give you special solutions to make your work better and faster.

Acrylic CNC Machining Issues

Melting

You may notice the acrylic starts to melt during CNC cutting. This usually happens when the material gets too hot. Melting is a frequent risk if you don’t set your machine parameters just right. The edges can look cloudy or sticky, and the part may lose its shape.

Tip: If you see melted chips or a rough, sticky edge, stop and check your settings.

Chipping

Chipping shows up as small cracks or missing pieces along the cut edge. It often happens when the feed rate or spindle speed is too high, or if the tool is dull. Chipping can make your parts look rough and may cause them to break more easily.

| Factor | What You Might See |

| High feed/speed | Cracks, chips, rough edges |

| Dull tool | Jagged cuts, more chipping |

| Poor cooling | Heat damage, small fractures |

Poor Edges

Poor edge quality means the cut looks rough, wavy, or uneven. You might see ripple marks or cloudy spots. This can happen if you use the wrong cutter, set the wrong speed, or use a worn tool in acrylic CNC machining. In precision manufacturing, clean edges are important for both looks and function.

Part Movement

Sometimes, the acrylic sheet moves or vibrates during cutting. This can mess up your part’s shape or size. Part movement often comes from weak clamping, machine vibrations, or loose parts. In a busy factory, this problem can slow down production and waste material.

Note: If you hear rattling or see the part shift, check your fixturing right away.

Bit Breakage

Bit breakage means your cutting tool snaps or wears out too fast. This can happen if the wrong tool is used during acrylic CNC machining, if the cut is too deep, or if the temperature of the bit is too high. Environmental factors like dust or humidity in your factory can also shorten tool life. Regular checks and good tool management help you avoid this issue.

NOBLE, as a trusted China-based supplier, helps you tackle these issues with expert support and advanced equipment. Whether you need a single prototype or mass production, you can count on our customized machining services to deliver reliable results.

Troubleshooting Steps in Acrylic CNC Machining

Identify Symptoms

When you run into trouble with acrylic CNC machining, you need to spot the signs fast. Here’s how you can identify what’s going wrong:

- Check your CNC machine’s indicator lights. If you see a steady or blinking light, grab your user guide to figure out what it means.

- Look at the wiring and connections. Loose or damaged wires can cause problems you might not expect.

- Use a multimeter to test the voltage at the machine’s indicator terminals. Make sure the numbers match what the manufacturer says.

- Inspect electrical parts like bulbs, LEDs, fuses, and relays. If you see burn marks or melted insulation, you’ve found a problem.

- Examine your cutting tools. Polished bands on the edge mean flank wear, while pits show crater wear. Chipping or built-up edges can also signal trouble.

- Watch for changes in your part’s surface. If you notice rough edges, cracks, or cloudy spots, your tool might be worn or your settings might be off.

- Listen for odd noises. Chatter or vibration often means something is wrong with your setup or tool.

Tip: Regular cleaning and inspection help you catch issues before they ruin your parts.

Find Causes

Once you spot a symptom, you need to dig deeper to find out why it’s happening. Use these tools and methods to track down the cause:

| Diagnostic Tool/Method | Purpose/Function | Impact on Acrylic CNC Machining Problems |

| In-machine measurement systems | Check part size during machining | Keeps your parts accurate and consistent |

| Calibration instruments | Make sure your machine is set up right | Cuts down errors, especially in big production runs |

| DLC-coated tools | Reduce tool wear and last longer | Let’s you run longer jobs without changing tools |

| Directed air blast (20-30 PSI) | Cool the cutting area | Stops acrylic from melting or warping |

| Compressed air or water-soluble lubricants | Keep things cool and clean | Prevents cracks and heat damage in acrylic |

| CMM and laser scanners | Check part quality and tight tolerances | Helps you meet strict specs for medical or automotive parts |

| Statistical Process Control (SPC) | Watch your process during production | Lowers scrap rates and keeps your factory running smoothly |

You can also use visual inspection under a magnifier to spot early tool wear. Tool sensors that track vibration or temperature can warn you before a tool fails. If you see surface roughness getting worse, it’s time to check your tool and settings.

Apply Solutions

Now that you know what’s wrong and why, you can fix the problem. Here’s what you should do for the most common acrylic CNC machining issues:

- Adjust spindle speed and feed rate. Keep spindle speeds between 8,000–15,000 rpm and match your feed rate so chips clear out fast. This stops the melting and rough edges.

- Pick the right cutter for acrylic cnc machining. Use single or double flute cutters with polished flutes. These tools cut clean and help chips move away, which keeps your acrylic cool.

- Use cooling methods. Blow air or use a mist coolant to keep the cutting area under 45°C. Avoid oil-based coolants, since they can damage acrylic.

- Break up deep cuts. If you need to drill deep, use pecking cycles. This clears chips and lets coolant reach the tool tip.

- Clamp your workpiece well. Use even pressure or try vacuum fixtures to stop the acrylic from moving or vibrating.

- Choose the right tool geometry before acrylic CNC machining. Tools with a higher rake angle and polished edges slice acrylic cleanly and reduce heat.

- Try climb milling for finishing passes. This technique shears the acrylic and leaves a smooth, clear edge.

- Ramp into your cuts. Instead of plunging straight down, ramping in helps prevent melting and tool walking.

- Make several shallow passes. Cutting in steps (about 0.02–0.06 inches each) keeps heat down and improves edge quality.

- Finish your parts. Flame polishing after acrylic CNC machining, vapor polishing, or mechanical polishing can make your edges shine and remove any last defects.

If you want to avoid these problems, keep a record of what works. Document your best settings and tool choices for each job. This helps you get repeatable results, whether your project is to create a single prototype for the medical industry or a high-volume product for an automotive customer.

NOBLE, as a leading supplier in China, offers expert support and advanced equipment for Acrylic CNC Machining. Our team help you with precision manufacturing and customized machining, so you can focus on quality and speed. Whether you need help with troubleshooting or want to improve your process, NOBLE stands ready to support your production goals.

Quick Reference in Acrylic CNC Machining

Diagnosis Table

If you have a problem in your shop, you want help fast. This table lets you find the cause and fix for each symptom. Keep it close when you work on medical or car parts.

| Symptom | Likely Cause | Quick Fix |

| Melting edges | High spindle speed, slow feed, poor cooling | Lower speed, increase feed, add air blast |

| Chipping | Dull bit, wrong feed/speed, loose part | Change bit, adjust settings, secure part |

| Rough/Cloudy edges | Worn tool, wrong cutter, poor chip removal | Replace tool, use polished flute, clear chips |

| Part movement | Weak clamping, machine vibration | Tighten clamps, check for loose screws |

| Bit breakage | Too deep cut, wrong tool, overheating | Reduce depth, use the right bit, cool area |

Tip: If you see more than one issue, check your machine’s calibration and toolpath plan. NOBLE’s team can help you get better results for precision work.

Checklist

NOBLE’s precision manufacturing experts have prepared this checklist for you. Use it before you start any work. Many people skip these steps, but they help improve quality and speed.

- Add oil to ball screws, guides, and spindle bearings.

- Calibrate your machine and check all settings.

- Look for wear, loose bolts, and belt problems.

- Hold the workpiece tight with clamps or vacuum.

- Pick the right bit for acrylic and check if it’s dull.

- Set feed rate and spindle speed for clear chips.

- Tighten all bolts, belts, and rails.

- Check limit switches and clean them if dirty.

- Set software zero points and coordinate systems.

- Remove debris or wires that block movement.

- Use the right post-processor for your machine.

- Check your G-code for mistakes before starting.

- Plan toolpaths that help your tools last longer.

- Try to use less material and avoid waste.

- Plan regular maintenance to keep things running.

NOBLE is a trusted automotive and medical parts manufacturer with good equipment and advice. No matter what you want to produce, our custom machining services can help your project run well.

Applications of CNC Acrylic Machining

Acrylic, known for its clarity, durability, and versatility, is a preferred material in many sectors that require high-performance parts with superior finish quality. Below are some of the key industries benefiting from CNC acrylic machining:

1. Medical and Healthcare Industry

Acrylic’s perfect for making medical parts that need to be precise, clear, and tough. CNC machining is used to make parts for medical devices, diagnostic tools, and surgical instruments. This process ensures that things like protective covers or clear parts for imaging systems are up to standard.

- Medical display cases

- Surgical tool handles

- Medical device housings

- Diagnostic imaging components

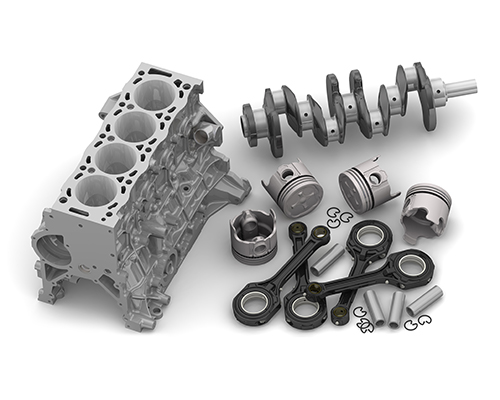

2. Acrylic Machining for the Automotive Industry

When it comes to automotive manufacturing, CNC acrylic machining helps create parts that look good and work well. Thanks to acrylic’s transparency, strength, and ability to be shaped easily, it’s perfect for things like headlamp covers, dashboards, and custom car accessories.

- Headlamp and tail light covers

- Instrument panels

- Window and mirror components

- Custom car accessories

3. Acrylic Machining for the Aerospace Industry

Acrylic’s low weight and exceptional impact resistance position it as an ideal material for the aerospace industry. CNC acrylic machining is employed to produce transparent components—such as aircraft windows and cockpit panels—that must meet rigorous standards for both strength and clarity.

- Aircraft windows and windshields

- Cockpit panel components

- Interior cabin elements

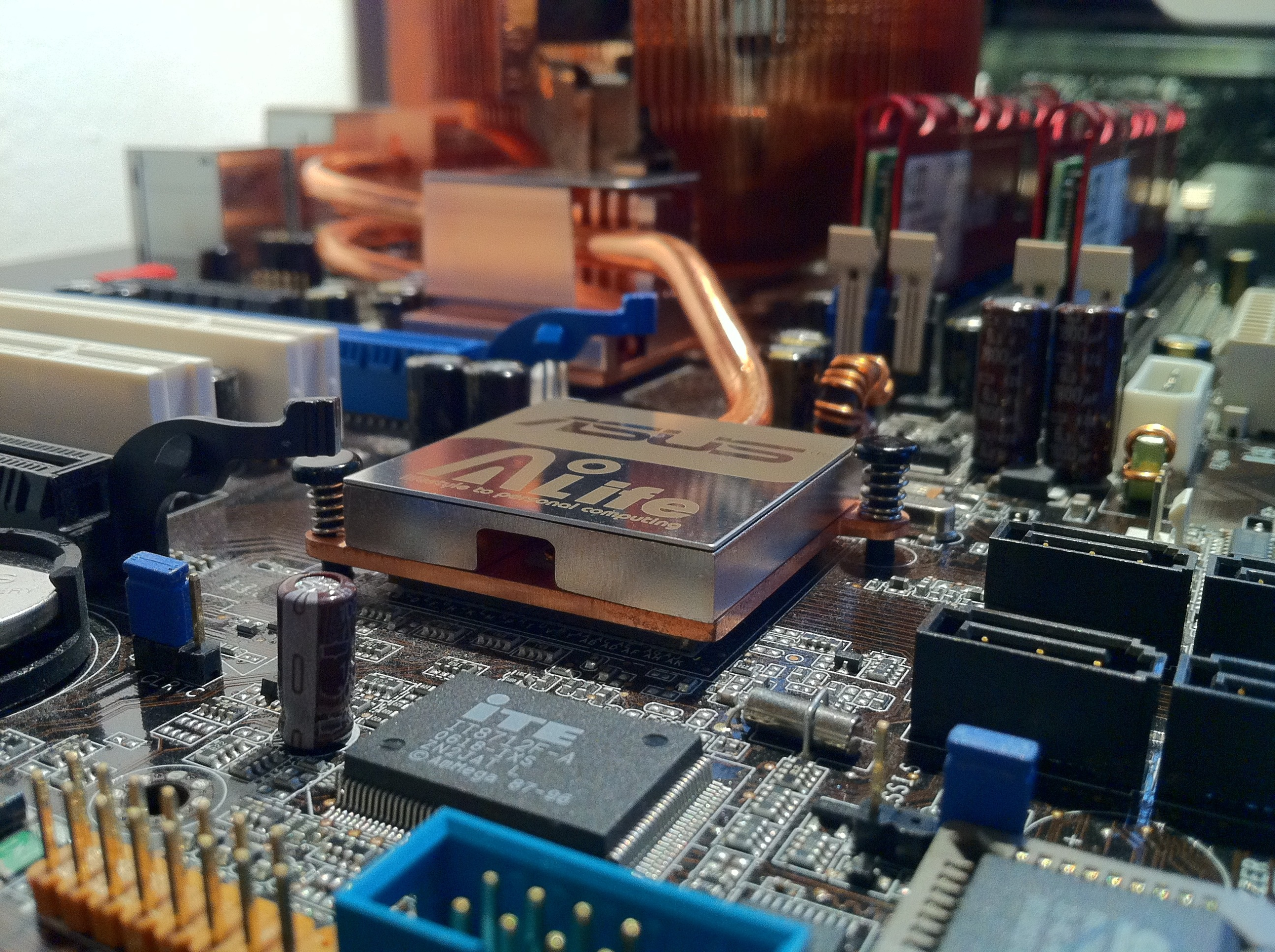

Acrylic Machining for the Electronics and Electrical Industry

Acrylic’s a go-to material for making casings and enclosures for electronics. With CNC machining, manufacturers can create precise, sturdy enclosures that protect the delicate parts inside and give a clear look at the electronics.

- Electronic enclosures

- Control panels

- Display screens

Prevention Tips

Best Practices

You want your acrylic CNC machining process to run smoothly every time. Here are some best practices that industry experts recommend:

- Always use sharp single-flute or O-flute end mills made for plastics. These tools help you avoid tool marks and keep heat low.

- Adjust spindle speeds and feed rates for each type of acrylic. High spindle speeds with lower feed rates work well to prevent melting.

- Use air blasts or mist coolant to keep the material cool and protect its properties.

- Clamp your acrylic parts tightly. This stops vibrations and keeps your parts accurate.

- Make sure chips clear out fast. Good chip evacuation prevents tool clogging and recutting.

- For finishing, try hand sanding with finer grits, buffing, or even flame polishing to get that clear, smooth edge.

Tip: Following these steps helps you get better results, saves time, and keeps your tools in good shape.

Tooling and Settings

Choosing the right tools and settings makes a big difference in your results. Here’s what you should keep in mind:

- Pick cutters with razor-sharp, smooth edges. Avoid using cutters that have touched metal before.

- Carbide bits work well for most jobs. If you want the best finish, diamond cutters are an option, but they cost more.

- Use a rake angle of about 5 degrees and a clearance angle of 2 degrees for acrylic.

- Set spindle speeds between 15,000 and 18,000 RPM for most acrylic jobs. Keep feed rates stable and aggressive to avoid heat buildup.

- Always keep your tools sharp. Dull tools cause friction, heat, and poor cuts.

- Try ramping into your cuts and use shallow passes to reduce stress and heat.

NOBLE, as a trusted supplier, uses advanced tooling and settings for both prototypes and mass production in the medical and automotive industries. Their precision manufacturing ensures you get consistent, high-quality parts.

Material Handling

How you handle your acrylic sheets matters a lot. Good material handling keeps defects away and helps your factory run better.

- Use the right equipment to move and store acrylic sheets. This reduces warping and scratches.

- Inspect your material before machining. Look for cracks, voids, or warping.

- Manage chips and swarf. Plastic chips can clog your machine and cause heat buildup, so clear them out often.

- Use anti-static sprays or grounding to stop chips from sticking everywhere.

- Clamp your parts evenly to avoid stress and warping during cutting.

- Keep your work area clean and organized for better results.

NOBLE’s team uses strict quality control and smart material handling to deliver top-notch customized machining for every order.

Why choose NOBLE as an acrylic CNC machining manufacturer?

When you work with NOBLE, you get more than just a supplier. You get a partner who understands acrylic CNC machining and precision manufacturing. NOBLE helps you:

- Advanced Equipment & Cost-Effective Price

- 10+ years of CNC Machining Parts

- ISO 9001 & ISO13485 Certified Factory

- Machining Parts As Fast As 2 Days

- Instant CNC Machining Quotes

- 24/7 Engineering Support

If you want reliable, high-quality acrylic parts, NOBLE’s customized machining services and expert support make your work easier and your results better.

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, with huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

FAQs

What is the best tool for acrylic CNC machining?

You should pick a sharp single-flute or O-flute end mill. These tools cut acrylic cleanly and help stop melting. NOBLE always chooses the right tool for your job. They do this for both medical and car projects.

How do I stop acrylic from melting during cutting?

Lower your spindle speed and raise your feed rate. Use air blasts to keep the acrylic cool. NOBLE’s experts use these tips in their factory. This helps them make perfect parts every time.

Can I use acrylic CNC machining for medical parts?

Yes, you can use acrylic CNC machining for medical parts. It gives you clear and strong pieces with tight sizes. NOBLE’s custom machining meets strict medical rules. This keeps your factory running well.

Why do my acrylic parts chip or crack?

Chipping happens if your tool is dull or your settings are wrong. Check your bit and change your speed if needed. NOBLE’s team can help you fix these problems fast. They do this even for big car jobs.

Does NOBLE offer support for prototypes and big orders?

Yes, NOBLE helps with both small and big jobs. Their factory uses advanced acrylic CNC machining. You get reliable and custom machining for any project.

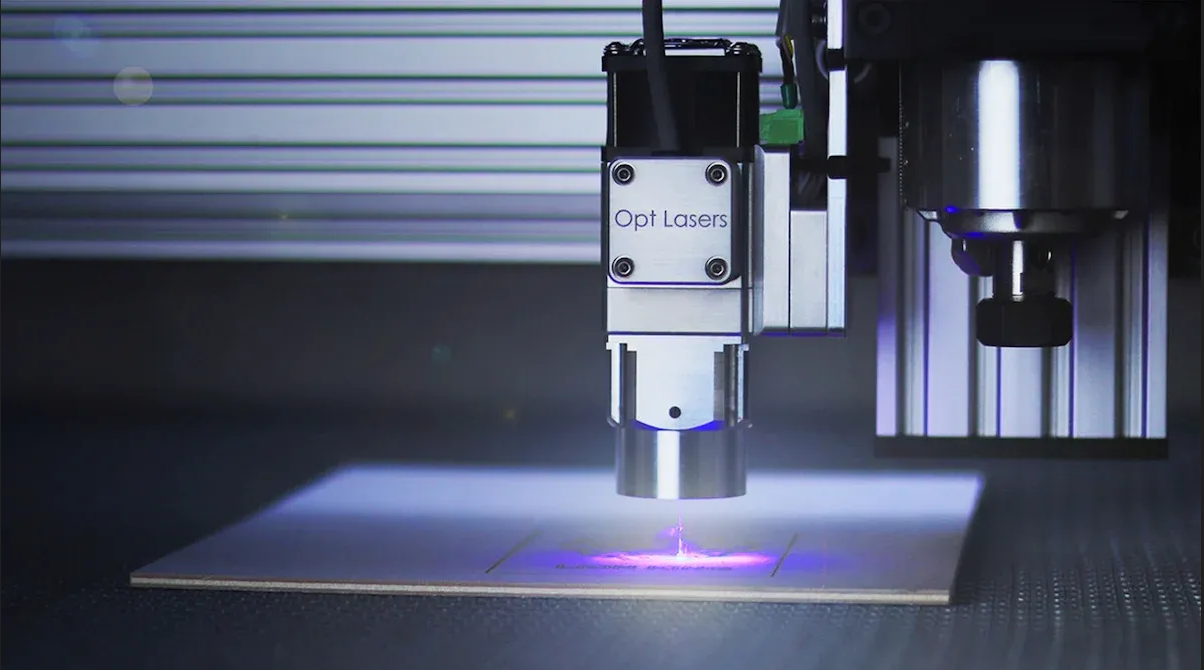

What materials cannot be CNC machined?

Some materials are not suitable for CNC machining due to their physical properties. These include brittle materials (glass, ceramics), hard substances (diamonds), soft or elastic materials (rubber, foam), and hazardous materials (magnesium alloys, asbestos). Composites like carbon fiber and fiberglass can cause tool wear and harmful dust, while materials with high moisture content, foils, and biological tissues present their own challenges. Special tools, like lasers, waterjets, or EDM machines, are often required for these materials.