What is CNC Grinding?

CNC grinding is a precision machining method of CNC. It precisely controls the movement and operation of the grinding machine through a pre-programmed computer system and is mainly used for high-precision surface machining of workpieces.

CNC grinding is suitable for machining various hard materials, such as quenched steel, cemented carbide, and ceramics etc., and can achieve the machining of complex shapes, such as threads, gears, and mold cavities.

How Does CNC Grinding Work?

Program Programming

Engineers must programme using specialised computer-aided manufacturing software based on the drawings and technical specifications of the workpiece.

The program contains all the key information during the grinding process, such as the movement trajectory of the grinding wheel relative to the workpiece, the rotational speed of the spindle, the feed rate, the cutting depth, and the timing for activating and deactivating the coolant.

The written program is typically referred to as G-code, which is then input into the CNC grinding machine’s control system through the data transmission interface or network, providing precise instructions for the entire machining procedure.

Workpiece Clamping

Before the program runs, the workpiece must be securely mounted on the machine tool’s worktable. Precision fixtures such as vices or specialised jigs are typically employed to ensure accurate positioning.

Subsequently, the critical tool setting operation is performed. The operator uses a dedicated probe or tool to determine the precise relative position between the grinding wheel and the workpiece reference point, and sets this position data as the origin of the machine coordinate system.

Grinding Operation

Once preparations are complete, the operator initiates the machining programme on the CNC system. The machine tool’s control unit then interprets the G-code instructions line by line, precisely controlling multiple axes of motion via the servo drive system. These typically comprise the X, Y, and Z linear axes, occasionally supplemented by rotary axes.

The grinding wheel rotates at high speed along a predefined path to grind the workpiece surface, while the worktable moves the workpiece with precise positioning and feed. The entire process, including wheel dressing and coolant spraying, operates fully automatically without manual intervention.

In-Process Inspection

On high-end CNC grinding centres, online measurement systems such as probes or laser gauges are typically integrated. During machining or at machining intervals, these measuring devices automatically perform real-time inspections of the workpiece’s critical dimensions.

If there is a slight deviation between the test result and the theoretical value, the control system will immediately automatically calculate and issue a compensation instruction based on the deviation value, fine-tuning the feed rate of the grinding wheel, thereby correcting this error in the subsequent processing steps.

Part Unloading

When the program has executed all the instructions, the machine tool spindle and coolant will automatically stop. The workbench is usually moved to a position that is convenient for operation, and the operator removes the processed parts from the fixture.

For modern production lines equipped with automatic loading and unloading systems, the processes of unloading and feeding new materials are also fully accomplished by mechanical arms or automated systems, achieving highly efficient continuous production. Finally, it may also be necessary to conduct a final cleaning and offline precise inspection of the parts to confirm that they fully meet all quality requirements.

Types of CNC Grinding Processes

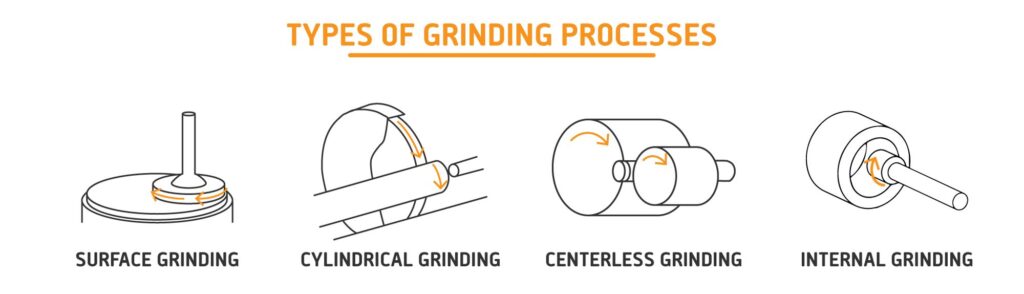

Surface Grinding

Surface grinding is primarily employed for machining flat surfaces. The workpiece is typically secured to a magnetic or mechanical fixture mounted on a worktable, which performs reciprocating or rotary transverse motion. Depending on the machine type, the grinding wheel spindle may undertake vertical feed motion.

Surface grinding is highly suitable for machining the precision planes of plate and block parts, capable of achieving extremely high flatness and surface finish. It is widely used in the precision plane machining of mold base plates, friction plates, and various mechanical parts.

Cylindrical Grinding

Cylindrical grinding is a process used for machining the outer surfaces of cylindrical or conical shapes. The workpiece is usually clamped by the headstock and tailstock and rotates. The grinding wheel rotates at high speed and moves radially and axially along the workpiece to grind out precise diameters and shapes.

Cylindrical grinding can efficiently process shaft and pin parts. It not only ensures extremely high dimensional accuracy and roundness but also grinds complex contour shapes, such as multi-step shafts and arc surfaces, through numerical control interpolation functions.

Internal Grinding

Unlike cylindrical grinding, internal grinding is specifically designed for machining cylindrical or conical holes on workpieces. Because the diameter of the grinding wheel must be smaller than the hole diameter, its spindle speed is usually very high. The grinding wheel is installed on a slender grinding wheel rod that extends into the interior of the workpiece, performing high-speed rotation and radial feed, while the workpiece or the grinding wheel moves back and forth axially.

Internal cylindrical grinding is highly suitable for machining the precise inner holes of parts such as bearing rings, gear holes, and hydraulic valve bodies, which is crucial for ensuring the roundness, cylindricity, and positional accuracy of the holes.

Centerless Grinding

Centerless grinding is a unique grinding method. During machining, the workpiece is not positioned by any center or chuck, but is freely supported between a support plate and a guide wheel. The guide wheel is responsible for driving the workpiece to rotate and controlling its feed rate, while the grinding wheel grinds the outer circle of the workpiece.

Centerless grinding is particularly suitable for mass production of small and simple rotary parts, such as bearing rollers and pins, as it does not require clamping, has extremely high production efficiency, and is easy to achieve fully automated continuous production.

Materials that Can be Used for CNC Grinding

Aluminium

- Pros: Aluminium is soft and readily machinable, but grinding is required when extremely high flatness, parallelism, or ultra-smooth surfaces are demanded.

- Cons: It clogs grinding wheels extremely readily; specialised grinding wheels and well-lubricating coolants must be used.

Stainless steel

- Pros: Martensitic stainless steel, after hardening or wear-resistant austenitic stainless steels, often achieve high precision and corrosion-resistant surfaces through grinding.

- Cons: Strong work hardening tendency, improper grinding force, and thermal control can affect surface quality and part life.

Copper

- Pros: Copper, with its excellent electrical and thermal conductivity, is often used in electrical components, heat sinks, etc.

- Cons: The high ductility of copper can cause the grinding wheel to be quickly clogged by chips, which is called “adhesive wear”. This will lead to an increase in grinding force and a decline in the surface quality of the workpiece.

Titanium

- Pros: Titanium alloys are renowned for their outstanding strength-to-weight ratio and excellent biocompatibility and corrosion resistance, and are widely used in aerospace and medical implant fields.

- Cons: Titanium has poor thermal conductivity, and grinding heat can easily concentrate on the surface of the workpiece, leading to work hardening, surface burning and the generation of harmful residual stress.

Acrylic

- Pros: The purpose of acrylic grinding is usually to obtain precise dimensions and smooth, transparent edges.

- Cons: The difficulty in grinding acrylic lies in its low melting point. The grinding heat can easily cause it to melt and adhere to the grinding wheel, resulting in surface scratches and fogging. Acrylic requires a sharp grinding wheel, a small feed rate, and good cooling to achieve a transparent effect.

Glass and Stone

- Pros: Glass can be used in optical components, semiconductor manufacturing equipment, laboratory vessels, and Windows etc.

- Cons: As typical hard and brittle materials, the grinding process of glass and stone is essentially brittle fracture removal. Diamond grinding wheels are needed. The precision requirement is extremely high.

Carbon Fiber Composites

- Pros: Grinding is an effective method for machining carbon fiber materials, especially for mixed materials involving fibers and resins, which can avoid burrs and delamination caused by conventional cutting.

- Cons: The challenge of CNC grinding carbon fiber lies in the anisotropy and uneven hardness of the material, which is prone to defects such as tearing and stringing. Extremely sharp abrasive grains and optimized parameters are required to remove material while minimizing damage to the fiber and matrix structure.

Advantages of CNC Grinding

Superior Precision Repeatability

The entire CNC grinding process is precisely controlled by computer programmes, eliminating the instability and errors inherent in manual operation. CNC grinding can stably achieve micron-level dimensional tolerances, extremely high geometric accuracy, and consistent surface finish.

Once the program is verified, CNC grinding can be repeated an unlimited number of times, ensuring that every part in mass production has the same precise dimensions. This is crucial for highly demanding fields such as aerospace and automotive engines.

Excellent Surface Quality

CNC grinding not only focuses on shape and size, but also can achieve excellent surface quality. By precisely controlling the rotational speed and feed rate of the grinding wheel and using grinding wheels with fine grit, it can achieve extremely low surface roughness values.

Reasonable grinding parameters and adequate cooling can prevent surface burns, microcracks, and other damage to the workpiece, thereby improving the surface integrity of the parts, significantly enhancing their wear resistance, fatigue strength, and corrosion resistance, and prolonging their service life.

Complex Shape Machining

Unlike traditional grinding machines that can only process simple planes and cylindrical surfaces, multi-axis linkage CNC grinding machines can generate complex relative movements between the grinding wheel and the workpiece through programming.

CNC grinding can easily process complex contour curves, non-circular cross-sections, conical shapes, and various formed surfaces, such as the tenon teeth at the root of engine turbine blades, precise mold cavities, and complex tool edge shapes, all of which are difficult or impossible to achieve by conventional grinding methods.

High Productivity Automation

CNC grinding integrates multiple machining steps on a single machine, reducing the turnover, clamping, and adjustment time of workpieces between different machine tools. Its automated process, including automatic measurement, automatic compensation, automatic tool changing, etc., significantly reduces the machining time of individual products and the reliance on the operator’s skills.

The combination of CNC grinding and an automatic loading and unloading system can achieve long-term “unmanned” production, which is particularly suitable for large-scale production and significantly improves overall production efficiency.

Hard Material Machining

CNC grinding is the preferred, and often the only effective, finishing method for ultra-hard materials such as hardened steel, cemented carbide, ceramics, and superalloys. The hardness of these materials typically exceeds the capabilities of conventional turning and milling tools.

Grinding, however, employs abrasive grains of even greater hardness to achieve effective material removal, ultimately producing high-precision components. This process is indispensable in modern tooling, mould manufacturing, and high-end equipment production.

Factors Influencing the Cost of CNC Grinding

Tooling Costs

Grinding wheels serve as the primary ‘cutting tools’ in CNC grinding operations, and their cost should not be overlooked. Different materials necessitate wheels of varying compositions; for instance, machining cemented carbide requires the use of costly diamond wheels, while machining high-temperature alloys demands CBN wheels with specific ceramic bonds.

Grinding wheels require periodic dressing and replacement due to blunting and wear. Their service life, dressing frequency, and unit purchase price collectively constitute ongoing tool consumption costs, which are particularly pronounced when machining high-hardness materials.

Material Costs

The cost of the workpiece material constitutes the direct raw material expense. More significantly, the material’s ‘machinability’ profoundly influences the overall cost.

Difficult-to-machine materials such as cemented carbide, ceramics, and high-temperature alloys lead to accelerated grinding wheel wear, reduced grinding efficiency, increased power consumption, and necessitate more frequent wheel dressing and coolant replacement.

Programming

Before the start of mass production, process planning, computer programming, and a large amount of machine tool preparation work are required, including the installation and calibration of tooling fixtures, the installation and precise dressing of grinding wheels, the machining and inspection of the first product, etc. These non-productive times need to be accomplished by skilled engineers or technicians, and the labor cost is very high.

For the production mode of small batch and multiple varieties, the proportion of this part of the preparation cost in the unit cost will be very high, directly affecting the economic benefits.

Labor Costs

CNC grinding machines require highly skilled operators. The salary level of senior technicians is relatively high, but their ability to optimize processes, predict, and handle problems can effectively reduce the scrap rate, increase equipment utilization, and production efficiency. In the long run, it is actually helpful to control the overall cost. Inexperienced operators may lead to costly processing errors.

Quality Requirements

The precision and surface quality requirements of parts are the key factors determining the cost. When the tolerance requirement is raised from ±0.01 mm to ±0.001 m,m and the surface roughness requirement is increased from Ra0.8 microns to Ra0.1 microns, the cost will increase exponentially.

Using more precise machine tools, grinding wheels with finer grit, conducting more fine grinding passes, adopting online measurement and compensation systems, the machining time will be significantly prolonged, and the requirements for environmental stability and operational skills will also be more stringent.

Auxiliary Costs

The coolant used in the grinding process is a continuous consumable cost. In addition, the management of coolant, including filtration, purification, prevention of deterioration, and final environmental protection treatment, all require specialized equipment and costs.

Metal chips produced during grinding, along with discarded grinding wheels and coolant mixtures, all fall under industrial waste. Their collection, classification, and harmless treatment must also comply with environmental protection regulations, incurring corresponding waste treatment costs.

Tips for CNC Grinding Machining

Process Planning Optimization

Before programming, it is essential to conduct a thorough analysis of the material properties of the workpiece, the heat treatment status, and the final precision requirements. Based on this information, rationally plan the allowance distribution and process parameters for rough grinding, semi-fine grinding, and fine grinding, and avoid the “one-size-fits-all” processing strategy. This can effectively balance efficiency and accuracy, and prevent deformation and burning.

Wheel Dressing Techniques

The condition of the grinding wheel directly determines the grinding effect. Grinding wheels must be dressed regularly and in accordance with processing requirements.

The optimization of dressing parameters is of vital importance. A sharp and well-shaped grinding wheel can significantly enhance grinding efficiency, improve surface quality, and reduce grinding force.

Simulation and Verification

Before formal machining, especially for complex or high-value parts, it is strongly recommended to use the simulation software of the machine tool to simulate and verify the machining program. This can effectively prevent serious accidents such as collisions and over-cutting caused by program errors, saving expensive trial-and-error costs and time.

Preventive Maintenance Implementation

CNC grinding machines are precision equipment and must strictly follow regular preventive maintenance plans. This includes the cleaning, lubrication, and precision inspection of key moving parts such as guide rails, lead screws, and bearings to ensure that the machine tool is always in the best working condition, thereby guaranteeing the long-term stability of machining accuracy.

Precision Tooling Investment

The stable clamping of workpieces is the foundation of precision grinding. High-precision fixtures, magnetic tables, or special jigs should be invested in and used, and it is necessary to ensure that they are clean and in good condition.

Each time the workpiece is clamped, the workpiece reference must be carefully corrected. This is the first and most crucial step to avoid cumulative errors and ensure positional accuracy.

In-Process Monitoring Control

Actively utilise the online measurement systems fitted to machine tools to conduct real-time inspection of critical dimensions during machining operations or at machining intervals. Based on measurement results, the system automatically performs compensatory adjustments, establishing a closed-loop control system of ‘inspection-feedback-compensation’. This significantly enhances consistency in batch production while reducing scrap rates.

Coolant Management System

Coolant not only affects cooling and lubrication performance but also impacts grinding wheel longevity and workpiece surface quality. Regular checks of coolant concentration, pH level and cleanliness are required, with timely replacement and system cleaning.

Proper coolant management is essential for preventing thermal damage to workpieces and maintaining internal machine tool cleanliness.

The Application Industries of CNC Grinding

Aerospace

CNC grinding is employed to machine critical engine components such as turbine blade teeth, rotor journal shafts, and aircraft landing gear actuator cylinders. These parts are typically fabricated from tough, difficult-to-machine high-temperature alloys or titanium alloys, with extremely stringent dimensional tolerances.

CNC grinding can not only precisely guarantee its complex contour shape, but also obtain a surface with high integrity, ensuring that the parts have excellent fatigue strength and a long service life under extremely high temperature and high-pressure environments.

Automotive Industry

From high-performance engines to precision transmission systems, the application of CNC grinding is ubiquitous. CNC grinding is responsible for the finishing of engine crankshafts, camshafts, piston rings, as well as gears and drive shafts within gearboxes.

Through grinding, these critical moving components achieve micrometre-level dimensional accuracy and exceptionally low surface roughness. This significantly reduces friction, wear, and operational noise, enhancing the engine’s power density and transmission efficiency. Ultimately, this delivers improved fuel economy, extended service life, and enhanced reliability for the vehicle.

Tool and Mold Making

CNC grinding is used to manufacture cavities and cores for various precision stamping dies, injection molds, and die-casting molds.

CNC grinding, especially CNC forming grinding, can efficiently and precisely process the complex contours, fine textures, and extremely high surface finish of molds. This directly ensures the long service life of the mold itself as well as the precise dimensions and high-quality appearance of the products produced. It is a fundamental manufacturing link in industries such as consumer electronics, home appliances, and automotive parts.

Precision Instrument Hydraulics

CNC grinding is widely used in machining the valve cores and valve sleeves of hydraulic servo valves, the spindles and guide rails of precision measuring instruments, and the distribution plates of high-end hydraulic pumps.

The parts of precision instruments usually require micron-level tolerances and mirror-like surface quality to ensure extremely low internal leakage, sensitive response and ultra-high motion smoothness. CNC grinding is the ultimate machining method to achieve these performance indicators.

Machine Tool Manufacturing

CNC grinding can be used for the fine machining of the basic core components of the machine tool itself, such as the bed guide rails, spindles, and lead screw support seats.

The high straightness, high flatness, and high surface hardness obtained through grinding are the foundation for ensuring the overall geometric accuracy, long-term stability, and retention of machine tools. Without precise grinding processes, it is impossible to manufacture high-precision machine tools.

New Energy Industry

In the energy field, CNC grinding is used to process key components such as gas turbine blades and sealing surfaces of nuclear power plant pumps. In the medical field, it is used to manufacture surgical robots, precise articulated arms, and implants such as artificial knee and hip joints.

Medical Industry

Parts in the medical field typically use special biocompatible materials or high-strength materials, and have strict requirements for surface cleanliness, non-damaging layers, and complex biological shapes. CNC grinding is a reliable choice to meet these stringent standards.

NOBLE’s CNC Grinding Service

NOBLE possesses a variety of state-of-the-art CNC machines and exacting testing equipment. Under the direction of a skilled group of professionals, we maintain uncompromising quality standards from beginning to end as an ISO 9001-certified business.

For aircraft parts and other components used in a variety of industries, NOBLE has been a top provider of precision grinding services. We carry out extremely specialized, small cylindrical grinding operations with diameters ranging from 0.2 to 20 mm, complex shapes and forms, and extremely tight tolerances and surface polish requirements.

Quality is our top priority. We implement rigorous testing and quality control measures throughout the manufacturing process to ensure that every prototype meets your expectations.

FAQs

What is CNC grinding?

CNC grinding is a precision machining process that uses a computer-controlled machine to remove material from a workpiece with a high-speed abrasive grinding wheel. It is widely used for achieving tight tolerances, fine surface finishes, and complex geometries on hard or delicate materials.

What materials can be processed with CNC grinding?

CNC grinding is suitable for a wide range of materials, including:

- Hardened steels and tool steels

- Stainless steel, aluminum, and titanium alloys

- Tungsten carbide and ceramics

- Plastics and composites (for specific applications)

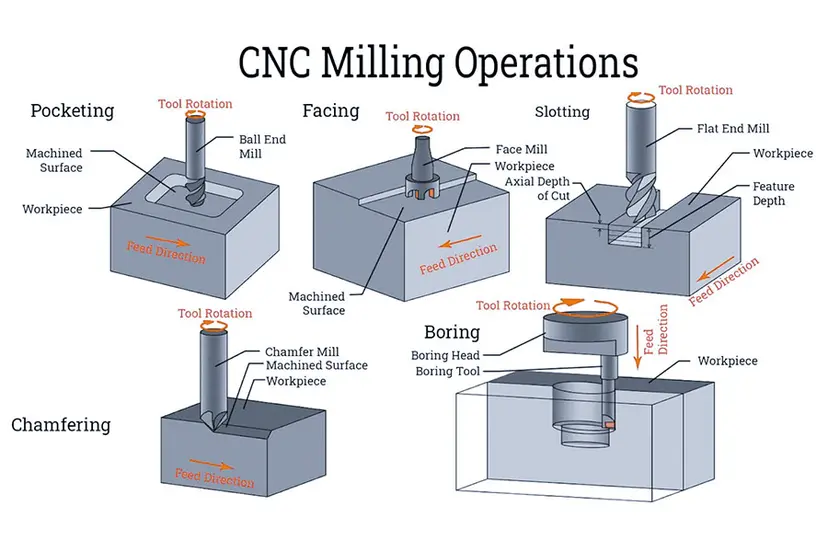

What is the difference between CNC grinding and CNC milling?

While both are subtractive machining processes, CNC grinding uses an abrasive wheel to remove material through friction, making it ideal for finishing hard materials with high precision. CNC milling uses rotating cutting tools to shear away material, better suited for faster material removal and softer materials.

What are the common types of CNC grinding processes?

Common types include:

- Surface grinding for flat surfaces

- Cylindrical grinding for external/internal round shapes

- Centerless grinding for cylindrical parts without fixing centers

- Tool and cutter grinding for sharpening cutting tools

- Creep-feed grinding for deep cuts in a single pass

What are the key components of a CNC grinding machine?

A typical CNC grinding machine consists of several critical components: the machine bed for stability, a high-precision spindle that rotates the grinding wheel, axes drives (like linear motors or ball screws) for movement control, a CNC controller as the brain, a coolant system to manage heat and remove debris, and often an automatic wheel dressing unit to maintain the wheel’s shape and sharpness.