What is Automotive Injection Molding?

Automobile injection molding is an efficient manufacturing process, mainly used for the mass production of plastic components required for automobiles. This process involves heating and melting thermoplastic or thermosetting plastic materials and then injecting them under high pressure into precisely designed mold cavities. After cooling and solidification, it is formed into parts of specific shapes and finally demolded and taken out.

In the automotive field, injection molding technology is of vital importance as it can produce components that are lightweight, high-strength, have complex geometries and good appearances.

Common Automotive Components Made with Injection Molding

| Interior parts | Exterior trim parts | Engine intake manifold |

| Dashboard | Air intake grille | Engine hood |

| Seat components | Wheel eyebrow | Cooling fan |

| Air conditioning system components | Lampshade | Air filter housing |

| Inner door panel | Rearview mirror housing | Electronic and electrical components |

Instrument Panel

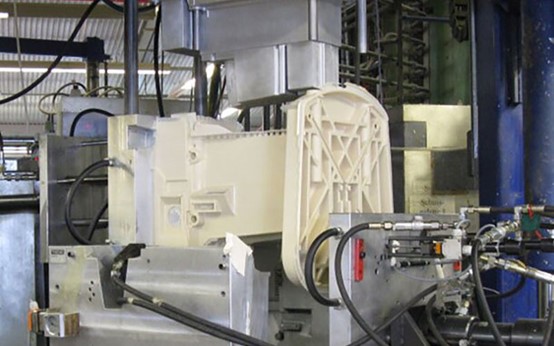

The instrument panel is the core component of a car’s interior and is directly related to the driving experience and safety. The instrument panel is usually formed in one piece by a large injection molding machine from materials such as modified polypropylene. Injection molding can produce large parts with complex structures and high integration, with precise installation points reserved inside.

Air Intake Grille

The air intake grille is an important appearance and functional component of the vehicle’s front face. Air intake grilles are usually injection molded from engineering plastics with good weather resistance, such as ABS or ASA. These materials can resist ultraviolet rays, temperature, and humidity changes for a long time without aging or fading easily.

Door Inner Panel

The inner panel of the car door is the main structural component that constitutes the interior of the car door. The inner panels of car doors are mostly injection molded from materials such as long glass fiber reinforced polypropylene to maintain lightweight. This material can provide sufficient strength and rigidity to support components such as handrails, switch boards, audio systems, and even side airbags.

Automotive Lamp Housing

Automobile lampshades have extremely high requirements for optical performance and weather resistance. They are usually made of highly transparent and heat-resistant polycarbonate (PC) material through precision injection molding.

Injection molding can directly form fine structures inside the lampshade and precisely adhere to components such as the reflector bowl inside the car lamp, effectively preventing water and dust.

Engine Intake Manifold

The intake manifold of an engine is one of the key components of an engine. Modern automobiles widely use glass fiber reinforced nylon (PA+GF) for manufacturing through injection molding processes.

Compared with traditional metal manifolds, plastic manifolds are lighter in weight, have smoother inner walls, which helps improve intake efficiency, and offer higher design freedom.

Center Console

The central console is an important interior component that integrates functionality and decoration. Its main frame and storage box are often injection molded from polypropylene (PP) or ABS.

Injection molding can efficiently manufacture structures with complex internal partitions, cup holder shapes, hinge mounting positions, and cable management channels.

The Injection Molding Process for Automotive Manufacturing

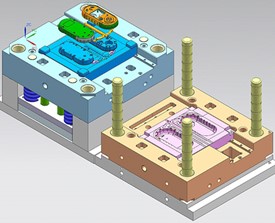

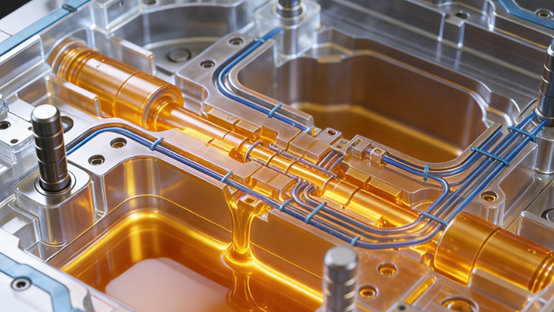

Mold Design

Engineers design a precision steel mold composed of a cavity and a core based on the 3D digital model of the part. The interior of the mold contains cooling water channels, ejection systems and complex runner systems. The quality of the mold directly determines the precision and appearance of the final product.

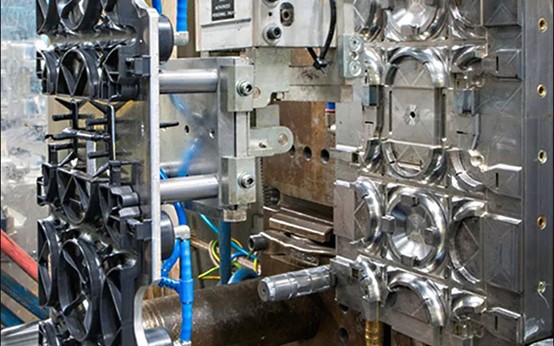

Mold Clamping

At the beginning of the molding cycle, the clamping mechanism of the injection molding machine tightly closes the two halves of the mold and applies high pressure to lock them in place, resisting the huge internal pressure generated during subsequent injection, preventing plastic from spilling out, and ensuring the dimensional stability of the parts.

Injection

Plastic pellets are heated to a molten state in the barrel. The screw or plunger of an injection molding machine injects precisely measured molten plastic into the closed mold cavity at high speed and high pressure.

After the injection is completed, the screw maintains a certain pressure. It continues to supply material into the cavity to counteract the effect of plastic cooling and shrinkage, preventing the parts from having shrinkage marks or insufficient dimensions.

Cooling and Solidification

The molten plastic begins to cool in the mold and gradually solidifies to take shape. The cooling time depends on the wall thickness of the part, the type of material, and the efficiency of the cooling system. Efficient cooling water channel design is crucial for shortening cycle time, enhancing production efficiency, and controlling part deformation.

Ejection

After the cooling is completed, the mold closing mechanism opens the mold. The built-in ejection system of the mold operates to smoothly push the formed plastic parts out of the mold cavity, causing them to detach from the mold.

Quality Inspection

The parts that have been injection molded may require subsequent machining, such as trimming off the excess material heads of the gate and runner system, deburring treatment, or surface decoration such as spraying and electroplating.

The parts also need strict quality inspections, including dimension measurement, appearance inspection and functional testing, to ensure compliance with the stringent standards of the automotive industry.

Benefits of Injection Molding for Automotive Parts

Exceptional Production Efficiency

Injection molding technology features a high degree of automation and a short production cycle for a single part, ranging from tens of seconds to several minutes. It is particularly suitable for the large-scale and high-volume production demands of the automotive industry. Once the mold development is completed, the production cost per unit part is significantly reduced.

Design Freedom

Injection molding technology can produce parts with extremely complex shapes and fine structures, which is difficult to achieve by many other processes. It can integrate functional components that originally require multiple parts to assemble into a single integral part through “insert forming” or complex mold design. This reduces assembly processes, lowering weight and enhancing the overall structural reliability.

Outstanding Dimensional Accuracy

Precise molds and machining parameters precisely controlled by computers ensure that the tens of thousands of parts produced have highly consistent dimensions and geometries. This stability and repeatability accuracy are crucial for demanding automotive assembly lines that require precise coordination, ensuring assembly quality and interchangeability.

Superior Material Performance

There is a wide variety of engineering plastics and composite materials available for injection molding, which can meet the diverse performance requirements of automotive parts. For instance, the use of glass fiber reinforced materials can achieve high strength and high rigidity.

High-temperature resistant materials can be applied to the engine compartment. Soft-touch components can be manufactured by using elastomer materials. The material formula can be flexibly adjusted to meet specific requirements.

Excellent Surface Quality

Injection-molded parts usually have excellent surface finish, which can directly achieve a smooth surface or complex texture effect, reducing subsequent machining. Meanwhile, the density of plastic parts is much lower than that of metals, which is one of the key means to achieve automotive lightweighting to reduce energy consumption and increase driving range. It also helps to improve handling and fuel consumption.

Post-Processing

After the parts are formed, usually only simple trimming of the gate is required, and many components do not need secondary machining. Waste materials generated during the production process can be conveniently recycled, crushed, and reused, which improves the material utilization rate and conforms to the sustainable development concept of modern manufacturing.

The Role of Injection Molding in Electric Vehicle Production

Lightweighting Goals

- Reduce the overall weight of the vehicle: Injection-molded plastic and composite material components can significantly replace heavier metal parts and are one of the main means to achieve lightweighting.

- Innovative application of materials: In addition to traditional engineering plastics, high-performance composite materials such as carbon fiber reinforced plastics can be used through injection molding to produce key components that not only meet structural strength requirements but also achieve extreme lightweight.

Electric Component Production

- Battery system components: This is one of the fastest-growing applications of injection molding in the EV field. It is used to manufacture:

- Battery module housing and frame: Provide insulation, protection,n and structural support.

- The upper cover and lower shell of the battery pack: They are required to have high rigidity, lightweight, flame retardancy (V0 grade) and good sealing performance.

- Motor and electronic control components: These are used to produce motor end covers, connectors, and the shells and insulating parts of power electronic units. These components often require the use of special engineering plastics with high temperature resistance and high insulation properties.

- Charging system components: Manufacturing charging gun handles, socket shells, etc., which are required to have excellent electrical safety and durability.

Interior Design

- Intelligent interior integration: The interiors of electric vehicles are trending towards simplicity, intelligence, and integration. Large seamless injection-molded interior parts have become mainstream.

- New functional components: To meet users’ pursuit of a sense of technology, the application of light-transmitting decorative parts and smart surfaces is also becoming increasingly widespread.

Thermal Management Optimization

- Cooling system piping: Complex-shaped coolant pipes can be integrally manufactured through injection molding, reducing the risk of leakage and enhancing system reliability.

- Aerodynamic components: To reduce wind resistance and increase driving range, electric vehicles pay more attention to aerodynamic design. Injection molding can economically produce various lightweight exterior parts.

Cost Efficiency Boost

- Highly integrated components: Through technologies such as “multi-component injection molding”, multiple functions or materials are integrated in one production step, reducing the number of parts, simplifying the supply chain, and assembly process.

- Scale and consistency: Other components of electric vehicles still need to be produced on a large scale, with high quality and low cost. The inherent advantages of high efficiency and high consistency of injection molding can continue to be brought into play.

Cost Considerations for Automotive Injection Molding

Mold Cost

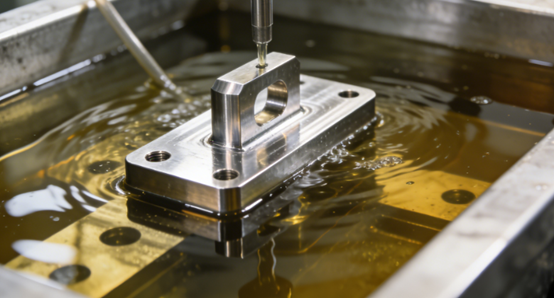

Automotive parts molds are typically made of high-strength die steel through precise CNC machining, electrical discharge machining, and polishing. They have a complex structure and include sliders, cooling systems, and exhaust systems.

The cost of a set of medium-sized interior parts molds can reach hundreds of thousands to millions of yuan. The lifespan of the mold and its ability to produce qualified parts directly determine the return on this investment. Optimization in design can save huge costs in long-term production.

Material Cost

Materials are the main cost for sustainability. Automotive parts extensively use engineering plastics such as PP, ABS, and PA, as well as their modified materials. When choosing materials, a balance should be struck between performance and cost. In addition, the material utilization rate is crucial.

By optimizing the flow channel design and reducing the wall thickness, the material consumption of each part can be decreased. Moreover, whether the sprue material in production can be recycled and reused directly affects the material cost.

Production Cost

The shorter the cycle time, the higher the output per unit time, and the lower the allocated machine and labor costs. The cycle time is restricted by factors such as the wall thickness of the part, the cooling efficiency of the mold, and the injection speed.

Using higher-performance mold steel to improve cooling and adopting multi-cavity molds to produce multiple parts simultaneously are both key measures to enhance production efficiency and reduce the cost per piece.

Part complexity

The design of the parts directly drives all the aforementioned costs. Designs that are overly complex in structure, uneven in wall thickness, insufficient in draft Angle or require special surface textures will increase the difficulty and cost of mold manufacturing, prolong the production cycle, and may raise the rate of defective products.

Post-Processing

The cost is generated after the parts are demolded. This includes trimming the gate, removing burrs, spraying, electroplating, or assembling with other parts such as metal inserts. Each additional process will increase the costs of labor, equipment, space, and quality control.

Quality Assurance

To ensure that the parts meet the strict safety and performance standards of the automotive industry, considerable testing costs must be invested.

The testing comprises initial mould prototyping and debugging, in-process inspection during production, periodic third-party material performance testing, and necessary full-scale coordinate measuring machine inspections.

Design Tips for Automotive Injection Molded Parts

Uniform Wall Thickness

The wall thickness of the parts should be kept as uniform as possible to avoid situations where some parts are too thick or too thin.

Uneven wall thickness can lead to different cooling rates, causing shrinkage marks and depressions in thick-walled areas, and internal stress concentration at the junction of thin and thick walls, resulting in warping, deformation, or even cracking of parts.

Proper Draft Angles

To facilitate the smooth ejection of parts from the mold after cooling, all sides perpendicular to the parting surface must be designed with sufficient draft angles. Generally, it is recommended that the smooth surfaces of interior and exterior parts have a slope of 1.5° to 2° on each side.

For etched surfaces, to prevent the texture from being scratched during demolding, the slope should be increased according to the depth of the texture.

Optimized Rib Design

Reinforcing ribs are used to enhance the rigidity and strength of parts without significantly increasing the overall wall thickness. The thickness of the ribs should be 50% to 60% of the main wall thickness to avoid shrinkage marks on the back.

The height of the ribs should not be too high, usually not exceeding three times the thickness of the main wall. The root of the rib must be designed with a fillet transition to disperse stress, and the top also needs to have a fillet.

Radius Transitions

Both the inner and outer corners should be smoothly transitioned with rounded corners. Fillets can significantly reduce stress concentration, enhance the structural strength and impact resistance of parts, and at the same time improve the flow state of molten plastic in the mold cavity, making filling smoother.

Rounded corners are also beneficial for the mechanical machining and heat treatment of molds, thereby extending their service life.

NOBLE’s Automotive Parts Injection Molding

Plastic injection molding is a cost-effective method for obtaining both small and large quantities of plastic parts. NOBLE is a world-class plastic injection molding company that can provide complete manufacturing solutions for your project. We are committed to customer satisfaction, and our custom plastic injection molding services involve on-demand prototyping and production. You can expect the highest quality injection-molded parts regardless of size and complexity.

NOBLE’s custom injection molding services are ideal for making competitively priced and high-quality molded parts in fast lead times, from plastic prototyping to production molding. Significant manufacturing facilities with powerful, precision machines ensure that the same mold tools are used to create compatible parts. Even better, we provide free expert consultation with every injection molding order, including mold design advice, material and finish selection for end-use applications, and shipping methods.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Plastic Parts Injection Molding

- ISO 9001 & ISO13485 Certified Factory

- Instant Plastic Injection Molding Quotes

- Plastic Injection Molding as fast as 2 weeks

- Provide a Free DFM Report within 12 Hours

FAQ

What is automotive injection molding?

Automotive injection molding is a specialized manufacturing process where thermoplastic or thermoset materials are melted and injected under high pressure into a precision mold to produce plastic parts for vehicles. This process is used to create a wide range of components, from small interior buttons and connectors to large exterior parts like bumpers and dashboard panels.

What types of plastic materials are commonly used in automotive injection molding?

Common materials include polypropylene (PP), acrylonitrile butadiene styrene (ABS), polyamide (nylon, PA), polycarbonate (PC), and polyethylene (PE). Engineering plastics and composites, such as glass-filled nylons, are also widely used for parts requiring extra strength, heat resistance, or dimensional stability.

What are the key advantages of injection molding for automotive parts?

The key advantages are high production efficiency, excellent repeatability and part consistency, the ability to produce complex geometries with tight tolerances, and a strong cost-per-part ratio for high-volume runs.

What are some examples of automotive parts made with injection molding?

Examples are numerous and include interior components like instrument panels, door panels, cup holders, and vents. Exterior parts include bumpers, grilles, light housings, and wheel covers. Under-the-hood and functional parts also use this process, such as fluid reservoirs, air intake manifolds, connector housings, and various brackets.

How does injection molding contribute to lightweighting in vehicles?

Injection molding enables the design and production of thin-walled, strong plastic parts that replace heavier metal components. This directly reduces vehicle weight, which improves fuel efficiency and battery range in electric vehicles.