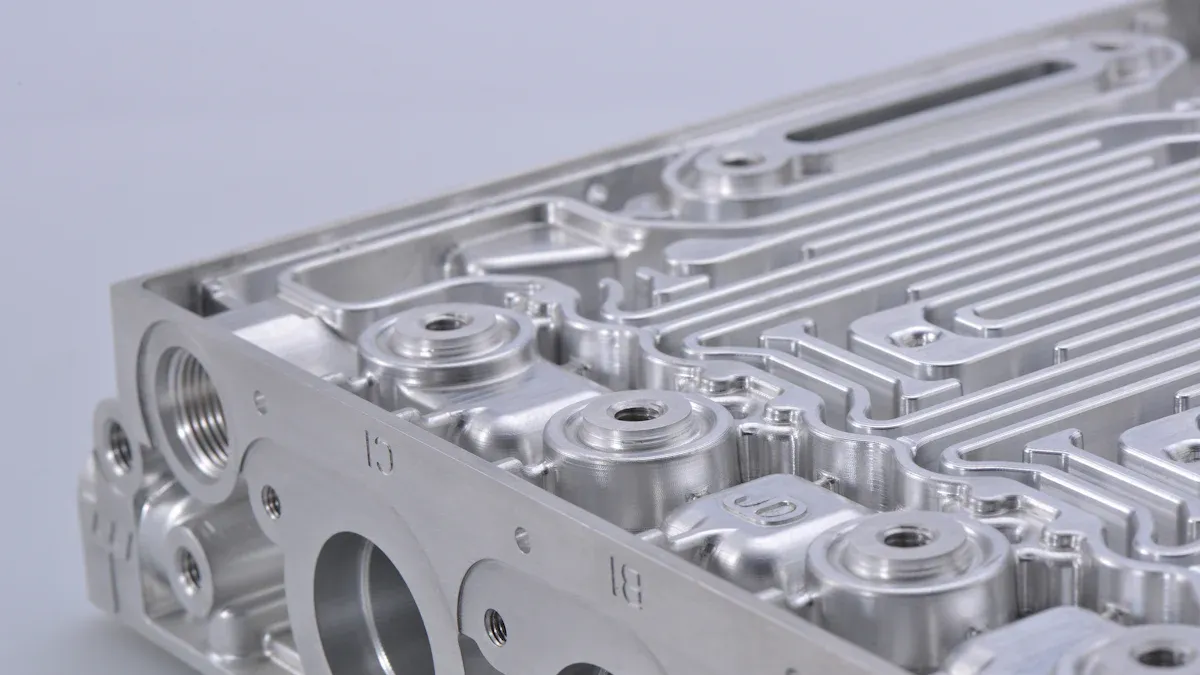

When you use aluminum CNC machining, you use four main steps. These are milling, turning, drilling, and tapping. Each step shapes aluminum in its own way. First, you make a CAD model. Next, you set up your machine. Last, you check the quality carefully. The table below shows these steps.

| Step | Description |

|---|---|

| 1 | Make a 2D or 3D model using CAD software. |

| 2 | Set the technical details, like size and limits. |

| 3 | Change the model to a CNC format for the machine. |

| 4 | Check the quality to match what the customer wants. |

People like aluminum machining because it is easy to work with and strong. The world market for cnc machining of aluminum was $89.2 billion in 2024. It keeps getting bigger. The 6000 series is the most used because it can do many things.

Key Takeaways

- Aluminum CNC machining has four main steps. These are CAD design, machine setup, machining, and quality control. Each step is important to make accurate parts.

- Picking the right aluminum grade is very important. Grades like 6061 and 7075 have different strengths. They also resist rust in different ways. Choose the grade that fits your project best.

- Using the right tools and cutting plans helps the process work better. Use sharp carbide tools for good results. Keep the spindle speed high for a smooth finish.

- After machining, you can use anodizing or coating. These steps make aluminum parts stronger and look better. Pick the best method for how you will use the part.

- Good team communication and planning can save money and time. Try to keep your design simple. This makes the machining process easier.

Where does aluminum come from?

Have you ever thought about where aluminum starts? Aluminum is not found by itself in nature. It is inside a rock called bauxite. People dig up bauxite from the ground. Then, factories clean it and make a white powder called alumina. Next, workers use electricity to change alumina into pure aluminum metal. This step is called electrolysis. Factories use this method in many places around the world.

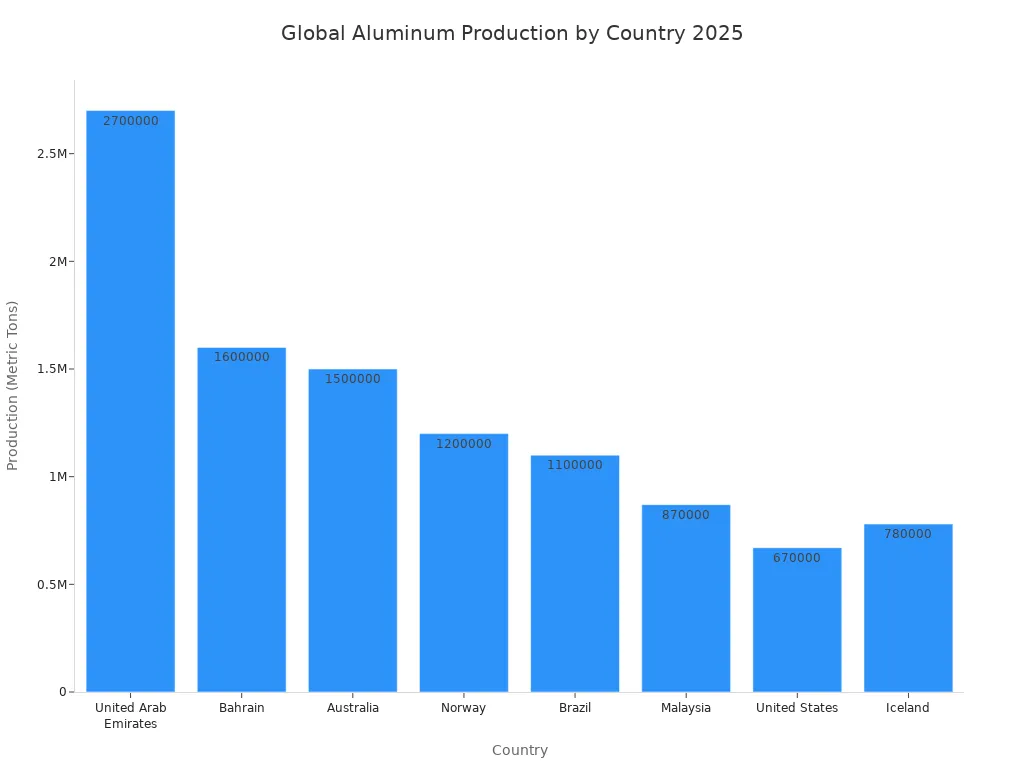

Many countries make aluminum. Some countries make more than others. The United Arab Emirates makes the most aluminum. Bahrain and Australia also make a lot. You can see how much each country makes in the table below:

| Country | Aluminum Production (Metric Tons) |

|---|---|

| United Arab Emirates | 2.7 million |

| Bahrain | 1.6 million |

| Australia | 1.5 million |

| Norway | 1.2 million |

| Brazil | 1.1 million |

| Malaysia | 870 thousand |

| United States | 670 thousand |

| Iceland | 780 thousand |

You can see that the United Arab Emirates makes the most aluminum. Bahrain and Australia are also important. These countries use new machines and have skilled workers. When you pick aluminum for your CNC machining, you use metal from all over the world.

Tip: When you choose aluminum, you help a big and well-run industry. This means you get good quality and can count on getting the parts you need.

Aluminum goes through many steps before you use it. Many people and machines help make it ready for your workshop.

What is Aluminum CNC machining?

Aluminum CNC machining helps you make parts very exact. Computer-controlled machines cut, drill, and mill aluminum blocks or sheets. You start with a digital design. The CNC machine reads the design and follows clear steps. It removes material from the aluminum piece. This way of making things is called subtractive manufacturing.

Here are the main ideas about aluminum CNC machining:

- Computer numerical control (CNC) tells the machine what to do.

- The machine takes away material from a solid aluminum piece.

- You can make shapes that are tricky and have small details.

- You need the right cutting fluids to keep things cool.

- After you finish, you can make the part look and work better with extra steps.

There are many CNC machines for aluminum. Each one is good for certain shapes and jobs. The table below shows the most common types:

| Type of CNC Machine | Description |

|---|---|

| CNC Milling Machines | These machines are good for very exact and detailed work. They take away material from a part that does not move. |

| CNC Lathe Machines | These machines are best for round parts. The part spins, and the machine cuts it to make it smooth. |

| CNC Router Machines | These machines cut and engrave aluminum sheets. They work fast and are good for patterns. |

| CNC Grinding Machines | These machines make surfaces smooth and shiny. This helps parts look and work better. |

| CNC Plasma Cutters | These machines cut thick aluminum sheets with hot plasma. You mostly use them for other metals. |

Tip: Always check your machine and cutting fluids. This stops problems like rough edges or tools wearing out.

People pick aluminum CNC machining because aluminum is easy to cut. It makes strong and light parts. Many industries use this process, like aerospace, cars, and electronics.

Why Aluminum for CNC Machining

Properties of Aluminum

It is important to know why aluminum is special for CNC machining. The table below lists the main reasons people pick aluminum for many jobs:

| Property | Description |

|---|---|

| Machinability | Aluminum is easy to cut and shape. You do not need much force. This saves money and helps you make parts more exact. |

| Strength-to-Weight Ratio | Aluminum is light but also strong. This makes it great for cars and planes. |

| Corrosion Resistance | Aluminum does not rust or scratch easily. You can make it even better with anodizing. |

| Low-Temperature Performance | Aluminum stays strong and bendy in cold places. Other metals can break, but aluminum does not. |

| Conductivity | Aluminum lets electricity flow well. This is good for electronic parts. The amount depends on the type of aluminum. |

| Recyclability | Aluminum can be recycled many times. It does not need much energy to recycle, so it is good for the earth. |

| Anodizing Potential | You can anodize aluminum. This makes it tougher and gives it color. |

Benefits of CNC Machining

There are many good things about using CNC machining for aluminum parts. The biggest reason is that it saves money. Aluminum costs less than other metals like stainless steel or titanium. You also do not have to change your tools as much because aluminum is soft. This means you spend less money on new tools. That is why people use aluminum cnc machining for both testing and making lots of parts.

Machinability

Aluminum is simple to cut, drill, and shape. It is soft and melts at a low temperature. This helps you make tricky parts that are very exact. You can finish your work faster and your tools last longer.

Strength-to-weight Ratio

You want parts that are strong but not heavy. Aluminum gives you both. That is why people who build cars and planes use it.

Corrosion Resistance

You do not want your parts to rust or get scratched. Aluminum fights off rust and scratches. You can make it even stronger by anodizing it.

Performance at Low Temperatures

Sometimes, you need parts that work in cold places. Aluminum stays strong and bendy when it is cold. Other metals can break, but aluminum does not.

Electrical Conductivity

Aluminum is good for electronic parts because it carries electricity well. How well it works depends on the kind of aluminum you use.

Recyclability

Using aluminum helps the planet. You can recycle it easily. It does not take much energy to recycle, so it is better for the environment.

Anodisation Potential

You can anodize aluminum to make it stronger and add color. Anodizing puts a shield on the part. This helps your parts last longer and look nice.

Tip: If you pick aluminum for CNC machining, you get a material that is easy to use, strong, and good for the earth.

Aluminum CNC Machining Process Overview

CAD Design and Preparation

You always begin with a clear design. You use CAD software to make a digital model of your aluminum part. This model shows the shape, size, and features before you cut anything. You can change the design if you need to. Planning well helps you avoid mistakes later. You save time and material when you get ready first.

Tip: Always check your CAD files for mistakes. Even small errors in the design can cause big problems during aluminum CNC machining.

Choose Aluminum Grade

You must pick the right aluminum grade for your project. Each grade has its own special features. Some grades fight rust better. Others are good for strong or light parts. The table below shows how common grades change the machining process and the final product:

| Aluminum Grade | Corrosion Resistance | Typical Applications |

|---|---|---|

| 6061 | Very Good | Structural components, automotive |

| 7075 | Good | Military, aerospace |

| 2024 | Moderate | Aircraft structures |

| 5052 | Excellent | Marine equipment |

| 3003 | Good | Cooking utensils |

You choose the grade based on where you will use the part and what you want it to do.

Machining Setup and Operation

You set up your CNC machine for the job. You hold the aluminum piece in place and pick the right tools. You check the speed and feed rates. You use coolant to keep the part cool and stop tool damage. You follow the steps to shape, drill, or mill the aluminum. Careful setup helps you get exact results.

Quality Control Steps

You end the process by checking the quality. You measure the aluminum parts to see if they match your design. You look for problems like scratches or wrong sizes. You use tools like calipers and gauges. You write down your results and fix any mistakes. Good quality control keeps your customers happy and your business strong.

Note: Every step in the machining process is important. You get better results when you pay close attention to details.

Key Design Considerations and Techniques

Maintain Adequate Wall Thickness

You need to keep walls thick enough to avoid problems during machining. Thin walls can bend or break. Thick walls help your part stay strong and keep its shape. If you use walls that are too thin, you risk tool chatter and poor surface finish. Most engineers recommend a minimum wall thickness of 1.0–1.5 mm for aluminum parts. This thickness gives you a good balance between strength and weight.

Tip: Always check your design for thin areas. Thin walls can cause trouble during cutting and may lead to part failure.

Avoid Sharp Internal Corners

Sharp corners inside your part make machining harder. Tools do not like sharp turns. You should add fillets, which have rounded corners, to your design. Fillets help tools move smoothly and reduce stress on the part. Rounded corners also lower the chance of tool breakage and improve the finish.

| Design Feature | Recommendation |

|---|---|

| Internal Corners | Use fillets with radius ≥ tool radius |

| External Corners | Sharp corners are possible, but fillets are better for strength |

Note: Fillets make your part easier to machine and last longer.

Limit Hole Depth

Deep holes can cause chips to build up and make it hard for tools to reach. You should keep the hole depth less than four times the diameter of the hole. This rule helps you avoid tool breakage and keeps the machining process smooth. Shallow holes are easier to clean and inspect.

- Keep hole depth ≤ 4 × hole diameter

- Use standard drill sizes for best results

Prefer Thread Milling over Tapping

Thread milling works better than tapping for aluminum parts. You get more control over the thread size and finish. Thread milling also lowers the risk of tool breakage, especially in thin walls or deep holes. You can fix mistakes more easily with thread milling.

Tip: Choose thread milling for small or deep threads. You will get better accuracy and longer tool life.

Apply Tolerances Rationally

You should set tolerances that match your part’s needs. Tight tolerances cost more and take longer to machine. Loose tolerances may not fit your application. Find a balance between cost and function. Use standard tolerances for non-critical features and tighter ones only where needed.

| Feature Type | Suggested Tolerance |

|---|---|

| Non-critical areas | ±0.1 mm |

| Critical fits | ±0.01 mm |

Note: Rational tolerances help you save money and get parts that work as planned.

Main Processes in CNC Machining of Aluminium

When you use cnc machining for aluminum, there are a few main steps. Each step changes the metal in its own way. You need to learn how these steps work to make strong and exact parts.

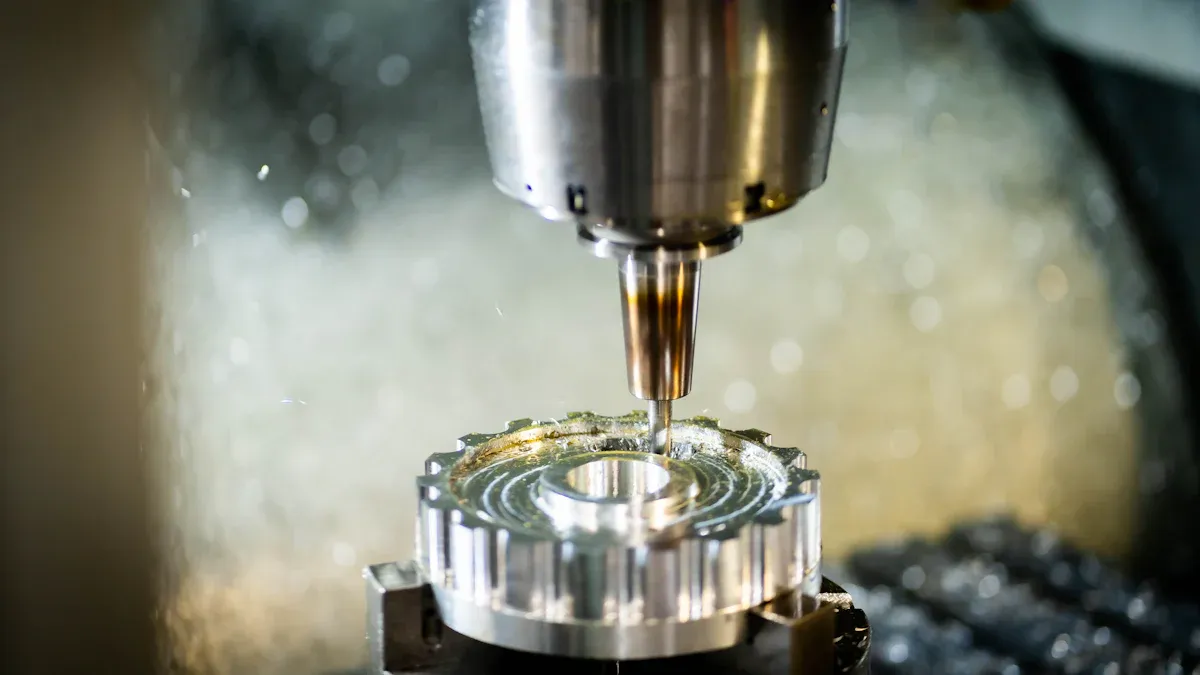

CNC Milling

CNC milling is a very common step in aluminum cnc machining. A spinning tool cuts pieces off a solid block of aluminum. The tool can move in many ways to make flat areas, slots, or tricky shapes. You can make simple or detailed parts with this step.

In 2025, cnc milling will be even better than before. New software and machines help you work faster and more accurately. The table below lists some new improvements:

| Advancement Type | Description |

|---|---|

| Software Advancement | New CAD and CAM tools help you design better and control the process more. |

| Automated Quote Generation | AI software gives you quick and correct prices for your jobs. |

| Multi-Axis Machining | You can now make tricky parts easier and for less money. |

| Environmental Consciousness | You use less energy and follow new rules to help the Earth. |

| Machine Learning and AI | AI helps keep your machines working well and checks quality. |

| Advanced Robotics and Automation | Robots do simple jobs, so you can focus on harder work. |

Tip: Try the newest software and machines. You will save time and get better results in cnc milling.

CNC Turning

CNC turning spins the aluminum part while a tool shapes it. You use this step to make round parts, like shafts or bushings. CNC turning is fast and makes smooth surfaces.

The table below shows how cnc turning, cnc drilling, and cnc tapping compare for speed and accuracy:

| Process | Efficiency Description | Precision Description |

|---|---|---|

| CNC Turning | Makes round parts quickly and well. | Gives tight fits and smooth surfaces. |

| CNC Drilling | Makes holes fast and keeps them the same size. | Holes are always the right size and in the right spot. |

| CNC Tapping | Makes threads quickly with few mistakes. | Threads are even and strong for holding things together. |

You can count on cnc turning for parts that fit right and look nice. You also save time because it works quickly.

CNC Drilling

CNC drilling makes holes in aluminum parts. A spinning drill bit cuts straight into the metal. This step is important for making holes the right size and in the right place.

You can drill many holes fast, and they all turn out the same. CNC drilling works for both small and large parts. You can also use special drill bits for different hole shapes.

Note: Always check your drill bits. Sharp bits make cleaner holes and better parts.

CNC Tapping

CNC tapping cuts threads inside holes. A tapping tool makes spiral lines so screws or bolts can fit tightly. This step is important for parts that need to be joined together.

CNC tapping is quick and makes strong, even threads. You can use it for many thread sizes and types. The machine controls the tool, so you make fewer mistakes.

Tip: Use thread milling for deep or tiny threads. You get more control and your tools last longer.

Advanced Techniques (5-Axis, High-Speed Machining)

You can use special steps like 5-axis machining and high-speed machining for tough jobs. These steps let you make tricky shapes and very exact parts. The tool can move in five ways, so you can reach hard spots.

Here are some good things about these special steps:

- You work fast and make very exact parts.

- You can make new molds for cars and planes.

- You can shape tricky and odd parts.

- You finish jobs faster and with fewer steps.

But there are some hard parts too:

- Machines and software cost more money.

- Taking care of these machines is harder.

- Parts made with 5-axis machining can cost more.

When you use these special steps, you must watch the temperature and use sharp tools. Aluminum can bend if it gets too hot or if you push too hard. You also need coolants to keep the surface smooth.

Note: Special steps help you meet strict rules in fields like airplanes and medical tools. You can make parts as exact as ±0.002 mm.

If you know these main steps, you can pick the best one for your aluminum cnc machining job. You get better parts, save time, and spend less money.

Post-Processing in Aluminum CNC Machining

When you finish making aluminum parts, you want them to work well and look nice. Post-processing steps help make the surface smoother and the part stronger. You can pick from different methods. Each method has its own good points.

Anodizing

Anodizing is a common way to treat aluminum. You use electricity to make a hard layer on the part’s surface. This layer helps the part last longer and makes it tougher. Anodizing makes the surface harder, so it does not scratch or wear out easily. It also helps the part fight rust and damage from bad weather. You can choose many colors or keep the metal look. Many companies use anodizing for strong and good-looking parts in planes and electronics.

Tip: Anodized aluminum can be very hard, almost like sapphire. Your part will look nice and handle tough jobs.

Sandblasting

Sandblasting makes the surface of your aluminum part clean and smooth. Tiny grains hit the part and take away rough spots and old marks. This step gives the part a dull finish and gets it ready for paint or coating. Sandblasting also helps paint and coatings stick better. Use sandblasting when you want the part to look even and clean.

Coating

You can put a coating on your aluminum part to protect it and make it look better. Powder coating is used a lot. It gives a strong finish with bright colors that do not chip or scratch easily. You can also use paint or add a thin metal layer with electroplating. Coatings help your part last longer and look more professional.

| Coating Type | Main Benefit |

|---|---|

| Powder Coating | Strong, colorful finish |

| Electroplating | Thin metal layer |

| Painting | Looks nice and protects |

Heat Treatment

Heat treatment changes how the inside of your aluminum part works. You heat and cool the part specially. This step makes the part stronger and less likely to break. Use heat treatment when you need the part to be tougher or stronger. Parts for cars and planes often need this step.

Note: Always pick the post-processing step that fits how you will use the part. The right choice helps your part work better and last longer.

Popular Aluminum Alloys for CNC Machining

When you choose aluminum alloys for CNC machining, you unlock a wide range of options. Each aluminum alloy brings unique strengths to your project. You need to know which one fits your needs best. Here is a table that shows the most popular aluminum alloys and their key properties:

| Alloy/Grade | Machinability Rating (%) | Key Properties |

|---|---|---|

| 6061 | 90–100 | Excellent machinability; low tool wear; good corrosion resistance; weldable. |

| 7075 | N/A | High yield strength (503 MPa); excellent strength-to-weight ratio; used in aerospace applications. |

| 5052 | N/A | Outstanding corrosion protection; good machinability; suitable for marine applications. |

| 2024 | N/A | Exceptional strength and fatigue properties; used in aerospace applications. |

6061 Alloy

You will find 6061 aluminum alloy in many industries. It offers great machinability and weldability. You can use it for automotive parts, window frames, and fuel lines. This alloy resists corrosion and keeps tool wear low. You get reliable results when you use 6061 for most aluminum parts.

Is 5052 or 6061 aluminum cheaper?

You often compare 5052 and 6061 when you look for cost savings. 6061 is usually more cost-effective. It is easy to find and simple to produce. 5052 costs more because it offers better corrosion resistance. If you want to save money and need general strength, pick 6061. If you need extra protection from corrosion, 5052 is a better choice.

7075 Alloy

7075 stands out among aluminum alloys for its high strength. You see it in aircraft components and structural parts. This aluminum alloy has a yield strength of 503 MPa. It also has a high strength-to-weight ratio. You should use 7075 when you need strong and lightweight aluminum parts.

Is 7075 Aluminum Stronger Than Steel?

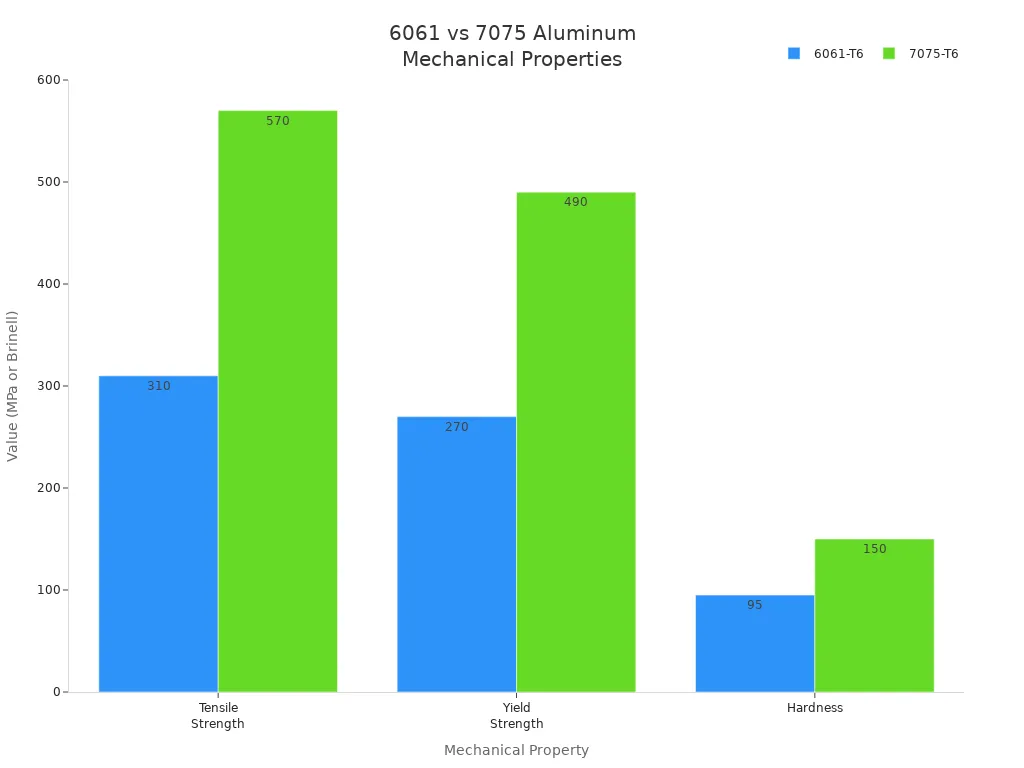

7075 aluminum alloy comes close to some steels in strength. It has a tensile strength of 570 MPa and a yield strength of 490 MPa. Look at this chart to see how 7075 compares to 6061:

You get high performance from 7075, but most steels still have higher strength. You should use 7075 when you want the best strength among aluminum alloys.

2024 Alloy

2024 is another strong choice for demanding jobs. You find it in commercial and military aircraft. This alloy gives you excellent fatigue resistance. You can trust 2024 for parts that face repeated stress.

Is 7075 aluminum stronger than steel?

7075 aluminum alloy is one of the strongest aluminum alloys. It can match some mild steels in strength. However, most steels still have higher strength and hardness. You should use 7075 when you want the highest strength in aluminum parts.

Which is better, 6061 or 7075 aluminum?

You should pick 6061 if you want easy machining, good weldability, and lower cost. Choose 7075 if you need maximum strength and can accept higher costs. Here is a quick comparison:

| Property | 6061-T6 | 7075-T6 |

|---|---|---|

| Tensile Strength (MPa) | 310 | 570 |

| Yield Strength (MPa) | 270 | 490 |

| Hardness (Brinell) | 95 | 150 |

Other Common Alloys

You may also use other aluminum alloys like 5052 and 3003. 5052 works well for marine hardware and chemical processing. 3003 is good for cooking utensils and general sheet metal work. Each alloy gives you different benefits for your aluminum parts.

Steel VS Aluminum CNC Machining

You might wonder how aluminum alloys compare to steel. Aluminum parts weigh less and resist corrosion better. Steel gives you higher strength and hardness. You should use aluminum alloys when you want light, corrosion-resistant, and easy-to-machine parts. Pick steel when you need maximum strength and wear resistance.

Tip: Always match the alloy to your project’s needs. The right choice helps you get the best performance from your CNC machining.

Best Tools & Cutting Strategies for Aluminum

When you machine aluminum, you want to use the right tools and methods. This helps you get smooth parts, save time, and keep your tools in good shape. Aluminum is soft and melts at a low temperature, so you must control the heat and chips carefully.

- Pick solid carbide end mills with 2 or 3 flutes. These tools let chips escape easily and keep the tool cool.

- Choose tools with a high rake angle (10°–20°). This design shears the metal instead of pushing it, which gives you a cleaner cut.

- Use sharp cutting edges. Dull tools make rough surfaces and heat up fast.

- Look for a high helix angle (35° or more). This pulls chips out quickly and stops them from clogging the tool.

- Try tools with polished or non-stick coatings. These reduce friction and stop aluminum from sticking to the tool.

Cutting Strategies for Success:

- Set spindle speeds high—start at 10,000 RPM or more if your machine allows.

- Adjust feed rates based on tool size and how thick your aluminum is.

- Take shallow passes. This keeps chips small and helps your tool last longer.

- Use coolants like minimum quantity lubrication (MQL) or flood cooling. Coolant keeps the part and tool from overheating.

- Clear chips often. Chips left in the cut can cause scratches and tool wear.

- Avoid aggressive cuts. Gentle cuts give you better control and surface finish.

- Make sure your workpiece is held tight. Good workholding stops vibration and keeps your part accurate.

Tip: Carbide tools work best for high speeds and keep their edge longer than high-speed steel (HSS) tools.

| Tool Feature | Why It Matters |

|---|---|

| 2–3 Flutes | Better chip removal |

| High Rake Angle | Cleaner, easier cuts |

| Sharp Edge | Smooth surface, less heat |

| High Helix | Fast chip evacuation |

| Polished Coating | Less friction, less sticking |

You can get the best results by matching your tool and strategy to your part. Watch your machine, listen for changes, and check your parts often. This way, you make strong, smooth, and accurate aluminum parts every time.

Optimizing CNC Machining Process

Design for Manufacturability

You can make your aluminum cnc machining project easier if you design simple parts. Work with your team to take out features that are not needed. Use hole sizes that are common. Try not to make deep pockets in your part. Keep the wall thickness the same all around. Simple designs help you finish faster and make fewer mistakes.

Cost-Saving Tips

You can save money when you machine parts by doing these things:

- Pick the best aluminum alloy for your part. Make sure it has the right strength, fights rust, and is easy to cut.

- Use CAM software to plan how the tool will move. This helps you use less machine time.

- Choose machines that fit your part size. This saves energy and setup time.

- Buy good cutting tools. Good tools last longer and keep your parts correct.

- Change tools less often. Fewer changes mean you waste less time.

- Use strong workholding devices. This keeps your part still and stops scrap.

- Check your parts while you work. Early checks help you find problems before they get worse.

- Order more parts at once if you can. Bigger orders make each part cost less.

Tip: Always look at your process to find ways to save time and cut waste.

Quality Assurance

You need to check your parts at every step. Use calipers and gauges to measure important features. Check your parts while you work to find mistakes early. Write down what you find and fix problems right away. Good quality checks keep your customers happy and your business strong.

Various Post-processing Options

You can pick from many steps to make your parts better. Anodizing makes the surface harder and adds color. Sandblasting makes the part smooth. Powder coating protects the part and gives bright colors. Heat treatment makes the part stronger. Pick the step that fits how you will use the part.

| Alloy Type | Key Characteristics | Suitability for CNC Machining |

|---|---|---|

| 1100 | High conductivity, fights rust | Needs care, can cost more |

| 2024 | Very strong, fights rust well | Easy to machine, costs more |

| 5052 | Easy to bend, fights rust a bit | Good for sheet metal |

| 6061 | Cheap, easy to machine | Great for testing and making many parts |

| 7075 | Very strong, used in planes | Can break if not careful |

You get better results when you pick the right alloy and use new steps like 5-axis machining. Always try to make your process better and learn about new tools and ways to work.

Challenges in Aluminum CNC Machining

When you work with aluminum cnc machining, you face some unique challenges. You need to understand these problems to get the best results from your processes.

- Tolerance and Dimensional Accuracy: You must keep tight tolerances, especially for aerospace and electronics parts. Aluminum can warp or vibrate during cutting. These issues make it hard to keep every part the same size.

- Tool Wear and Cutting Parameters: High-speed cutting wears out tools quickly. If you use the wrong tool or do not add enough lubricant, your tools will not last. You need to pick the right tool and keep it cool to avoid problems.

- Surface Finish Requirements: Some jobs need a smooth or shiny surface. You may need extra steps after machining to make the part look and work better.

- Material Properties: Aluminum is soft. Chips can stick to your tools and cause gummy buildup. The metal can also melt and stick to the tool if it gets too hot. You must watch your cutting speed and keep the tool sharp.

- Thermal Expansion and Residual Stress: Aluminum changes size when it gets hot. This can make your part bend or twist. Sometimes, stress inside the metal causes it to move after you finish machining.

Tip: You can solve many of these problems by choosing high-quality alloys, using advanced CNC machines, and working with skilled manufacturers.

You need to check your equipment and understand how each process affects the metal. When you plan and use the right methods, you can make strong, accurate parts every time.

Common Industry Applications of Aluminum CNC Machining

Aluminum CNC machining helps you make parts that are strong and light. Many industries use these parts. Each industry picks aluminum because it is strong, not heavy, and does not rust.

| Industry | Common Applications |

|---|---|

| Aerospace | Brackets, fuel system parts, and strong pieces |

| Automotive | Engine parts, transmission cases, and car bodies |

| Medical Devices | Exact housings, mounting brackets |

Aerospace

You see CNC-machined aluminum parts in many airplane parts. They are used for brackets, fuel system parts, and strong pieces that hold weight. Aluminum is strong but not heavy, so planes can fly better. It also does not rust, so parts last longer in bad weather.

medical

In hospitals, you need parts that are exact and clean. Aluminum CNC machining makes housings and mounting brackets for medical devices. These parts are easy to wash and do not rust. Doctors trust these parts for their tools and machines.

Automotive

Car makers use cnc machined aluminum parts for engines, transmission cases, and car bodies. Aluminum keeps cars light, so they use less gas. It is strong, so the parts last a long time. Aluminum also carries electricity well for battery cables and connectors.

Robotics

Robots need parts that are strong and not heavy. Aluminum CNC machining makes robot arms, joints, and frames. These parts move fast and do not break easily. You can shape them into special forms for different robots.

Electronics

Electronics companies use aluminum for cases, heat sinks, and connectors. Aluminum lets electricity flow well, so devices work right. You can recycle aluminum, which is good for the earth. You find these parts in computers, phones, and power tools.

Construction

Builders use aluminum CNC machining for window frames, brackets, and support pieces. Aluminum does not rust, even in rain or sun. This helps buildings last longer. You can shape aluminum to look nice and stay strong.

Consumer goods

You see aluminum parts in bikes, kitchen tools, and sports gear. These things need to be light and strong. Aluminum CNC machining makes smooth and good-looking items that last a long time.

Tip: If you pick aluminum CNC machining, you get parts that are light, strong, and good for many uses. You also help the earth because you can recycle aluminum again and again.

How to Optimize Your Aluminum CNC Machining Project

You want your aluminum CNC machining project to go well and finish fast. Work together as a team. Use online chats and video calls to stay in touch. Talking often helps you stop mistakes and keeps things moving.

Think about how long it takes to set up your machine. Skilled workers can get machines ready faster. You save time if you plan each step and use the right tools. Pick the best aluminum grade for your part. The right choice makes cutting easier and saves time.

Look at your part’s design. Simple shapes and normal features help you finish jobs quickly. If your part has lots of tiny details, it will take longer and need special tools. Try to keep your design simple.

Check when you can use the CNC machines. Make sure the machines are free when you need them. Sometimes, machines are busy or broken. Plan your work so you do not have to wait.

Here are some good ways to manage your project:

- Talk clearly with your team.

- Train workers to set up machines faster.

- Pick the best aluminum alloy for your job.

- Make simple part designs to finish faster.

- Book machine time early so you do not get delayed.

Tip: If you plan well, you can spend up to 40% less money and finish 30% faster. You also get better parts.

| Optimization Area | Benefit |

|---|---|

| Communication | Fewer mistakes |

| Setup Time | Finish projects faster |

| Material Choice | Work more efficiently |

| Design Simplicity | Easier and cheaper to make |

| Machine Scheduling | Get parts on time |

If you follow these steps, you will get better results. Your aluminum CNC machining project will be quicker, cost less, and work better.

Advantages of Choosing NOBLE for Aluminum CNC Machining Services

When you need an aluminum machining service, you want someone who gets what you need. NOBLE gives you more than just finished parts. You get help from experts, quick delivery, and great results every time.

Here are some reasons to pick NOBLE for your next aluminum machining job:

- Expert Engineering Team

You work with engineers who really know aluminum. They help you choose the right alloy and design for your project. Their advice helps you save both time and money. - Advanced CNC Technology

NOBLE uses new CNC machines. These machines cut, drill, and shape aluminum very exactly. Your parts match your drawings and fit tight rules. - Strict Quality Control

Every part gets checked carefully. NOBLE uses tools like calipers and CMMs to measure each piece. You can trust your parts will work the way you want. - Fast Turnaround Times

You want your parts fast. NOBLE plans each job to finish quickly. You get updates at every step, so you always know how your order is going. - Flexible Order Sizes

You can order just one part or many. NOBLE can handle small or big jobs. This helps you test ideas or make lots of parts for production.

| Advantage | What You Get |

|---|---|

| Expert Team | Smart design and material choices |

| Modern Machines | High accuracy and smooth finishes |

| Quality Checks | Reliable, consistent parts |

| Fast Delivery | Short lead times, clear updates |

| Flexible Orders | Prototypes or mass production |

Tip: If you pick NOBLE, you get an aluminum machining service that helps you from start to finish. You save time, make fewer mistakes, and get the best value for your project.

FAQs of Aluminum CNC Machining

Can CNC machines cut aluminum?

Yes, you can cut aluminum with CNC machines. Aluminum is soft and easy to shape. You get smooth edges and accurate parts if you use the right tools and speeds.

Can you CNC 6061 aluminum?

You can machine 6061 aluminum easily. It is one of the most popular grades for CNC work. You get good strength and a nice finish.

What materials cannot be CNC machined?

Some materials are too soft, brittle, or flexible for CNC machining. For example, rubber, foam, and some plastics do not work well. You should also avoid glass and ceramics unless you use special machines.

How to cut aluminum on CNC?

You need sharp carbide tools, high spindle speeds, and coolant. Hold the aluminum tight. Remove chips often. Use 2-3 flute end mills for best results.

Which aluminum is stronger, 5052 or 6061?

6061 aluminum is stronger than 5052. You should pick 6061 if you need more strength.

How expensive is CNC aluminum?

CNC aluminum costs depend on the alloy, part size, and order quantity. 6061 is usually the cheapest. Complex shapes and small orders cost more.

Is there a difference between 6061 and 6061-T6?

Yes. 6061-T6 means the aluminum has been heat-treated. You get higher strength and better hardness with T6.

Is it better to cut aluminum fast or slow?

You should cut aluminum at high speeds with light cuts. This keeps the tool cool and gives a smooth finish.

What is the hardest metal to machine?

Titanium and hardened steel are the hardest to machine. They wear out tools quickly.

How strong is CNC aluminum?

CNC aluminum parts can be very strong. 7075 aluminum is almost as strong as some steels.

What is the best method for cutting aluminum?

Use CNC milling with sharp carbide tools and coolant. This gives you the best finish and accuracy.

Is 7075 aluminum heavier than 6061?

No. 7075 and 6061 have almost the same weight. 7075 is just stronger.

Can 6061 aluminum be machined?

Yes, you can machine 6061 aluminum easily. It is a top choice for many projects.

Can you machine 5052 aluminum?

You can machine 5052 aluminum, but it is softer than 6061. It is better for bending and forming.

What is the cheapest metal to CNC?

Mild steel and 6061 aluminum are usually the cheapest metals to CNC.

Is aircraft aluminum stronger than steel?

Aircraft aluminum, like 7075, is strong, but most steels are still stronger.

Why is 6061 aluminum so popular?

6061 is easy to machine, weld, and finish. It is strong and not expensive.

What are the disadvantages of 6061 aluminum?

6061 does not have the highest strength. It is not as good for very tough jobs as 7075.

What is the cheapest grade of aluminum?

1100 aluminum is the cheapest grade. It is soft and used for simple parts.

You have learned how the main processes shape aluminum cnc machining. These processes help you make strong and exact parts in 2025. You should focus on each step, from design to post-processing. Pick the right alloy for your needs. Try new tools and methods to improve your results. Stay updated with the latest industry trends for better projects.

What is the best aluminum grade for CNC machining?

You should use 6061 aluminum for most CNC projects. It is easy to machine, strong, and resists corrosion. Many industries trust this grade for both prototypes and production parts.

How do you prevent tool wear when machining aluminum?

You should use sharp carbide tools and high spindle speeds. Always apply coolant to keep the tool cool. Remove chips often. This keeps your tools sharp and your parts smooth.

Can you recycle aluminum chips from CNC machining?

Yes, you can recycle aluminum chips. Collect them in a clean bin. Take them to a recycling center. Recycling saves energy and helps the environment.

Why does aluminum sometimes stick to cutting tools?

Aluminum melts at a low temperature. If the tool gets too hot, aluminum can stick. Use coolant and sharp tools. This keeps the temperature down and prevents sticking.

What is the main advantage of CNC machining aluminum over steel?

You get lighter parts with aluminum. Aluminum also resists rust and is easier to machine. You save time and money on tools and energy.