Introduction to Aluminum Alloys

Aluminum alloys are among the most widely used metals in modern manufacturing. These materials are popular because they are strong, lightweight, and can be used in many different ways. Engineers and designers choose aluminum alloys because they offer a good balance of performance, cost, and sustainability.

Aluminum alloys are made by mixing pure aluminum with other metals like copper, magnesium, and zinc. This creates materials that are stronger and more durable than pure aluminum while keeping the weight low. Because of these benefits, aluminum alloys are used in industries such as aerospace, automotive, construction, and electronics.

In recent years, new manufacturing methods and improved alloy formulas have made aluminum even more useful. Companies now use aluminum alloys to make lighter cars, stronger airplanes, and more efficient electronics. The ability to recycle aluminum without losing quality also makes it an environmentally friendly choice.

Common Types of Aluminum Alloys

5××× Series Aluminum Alloys

The 5××× series is one of the most commonly used aluminum alloys. The main element in this series is magnesium, which makes up between 3% and 5% of the material. Because of this, it is also called aluminum-magnesium alloy.

This type of aluminum has several important features:

- Low density– It is very lightweight.

- High tensile strength– It can handle heavy loads without breaking.

- Good elongation– It can bend without cracking.

- Strong durability– It lasts a long time even under stress.

- Easy to weld– It can be joined without weakening the material.

The 5××× series is made using a process called continuous casting and rolling. This method helps keep the material strong and consistent. In many countries, including China, this series is well-developed and widely used in construction, transportation, and marine applications.

6××× Series Aluminum Alloys

The 6××× series is another important group of aluminum alloys. The most common type in this series is 6061 aluminum, which contains magnesium and silicon.

6061 aluminum combines the best features of other alloys. It is strong, resistant to corrosion, and easy to work with. Some key benefits include:

- Good corrosion resistance– It does not rust easily.

- Excellent surface finish– It can be polished or coated for a better appearance.

- Easy to machine– It can be cut, drilled, and shaped without difficulty.

Because of these qualities, 6061 aluminum is used in many industries. It is often found in aircraft parts, automotive frames, and electronic housings.

Key Advantages of Aluminum Alloys

Lightweight and Strong

One of the biggest advantages of aluminum alloys is their strength-to-weight ratio. They are much lighter than steel but still very strong. This makes them perfect for industries where weight matters, such as aerospace and automotive.

For example, airplanes use aluminum alloys to reduce weight, which helps save fuel. Cars also use aluminum to improve fuel efficiency while keeping the structure strong.

Resists Corrosion

Aluminum alloys do not rust like iron or steel. When exposed to air, they form a thin oxide layer that protects the metal from further damage. This makes them ideal for outdoor and marine applications.

Ships, bridges, and building facades often use aluminum because it can withstand rain, saltwater, and pollution without corroding. This reduces maintenance costs and extends the life of structures.

Easy to Shape and Machine

Aluminum alloys can be easily molded into different shapes. They can be rolled into sheets, extruded into bars, or cast into complex parts. This flexibility allows manufacturers to create custom designs for various products.

Machining aluminum is also simple. It can be cut, drilled, and welded without the need for special tools. This saves time and money in production.

Good Heat and Electricity Conduction

Aluminum conducts heat and electricity well. Due to this, it is utilized in power lines, heat sinks, and various electronic devices.

For example, many computers utilize aluminum heat sinks to maintain processor temperature. Power companies use aluminum cables because they are lighter and cheaper than copper while still conducting electricity efficiently.

Fully Recyclable

Aluminum is one of the most recyclable metals. It can be melted down and reused without losing quality. Recycling aluminum uses much less energy than making new aluminum from raw materials.

This makes aluminum alloys a sustainable choice. Many industries now focus on recycling aluminum to reduce waste and lower environmental impact.

Industrial Applications of Aluminum Alloys

Aluminum alloys are essential in aerospace. They are used to make airplane bodies, wings, and engine parts. The lightweight nature of aluminum helps planes fly more efficiently while maintaining strength.

Modern aircraft, such as Boeing and Airbus models, rely heavily on aluminum alloys. The material’s ability to resist fatigue and corrosion makes it perfect for long flights and harsh weather conditions.

Car manufacturers use aluminum to reduce vehicle weight. Lighter cars use less fuel and produce fewer emissions. Aluminum is found in engine blocks, wheels, and body panels.

Electric vehicles (EVs) especially benefit from aluminum alloys. Since batteries are heavy, using aluminum in the frame helps balance the weight and improve driving range.

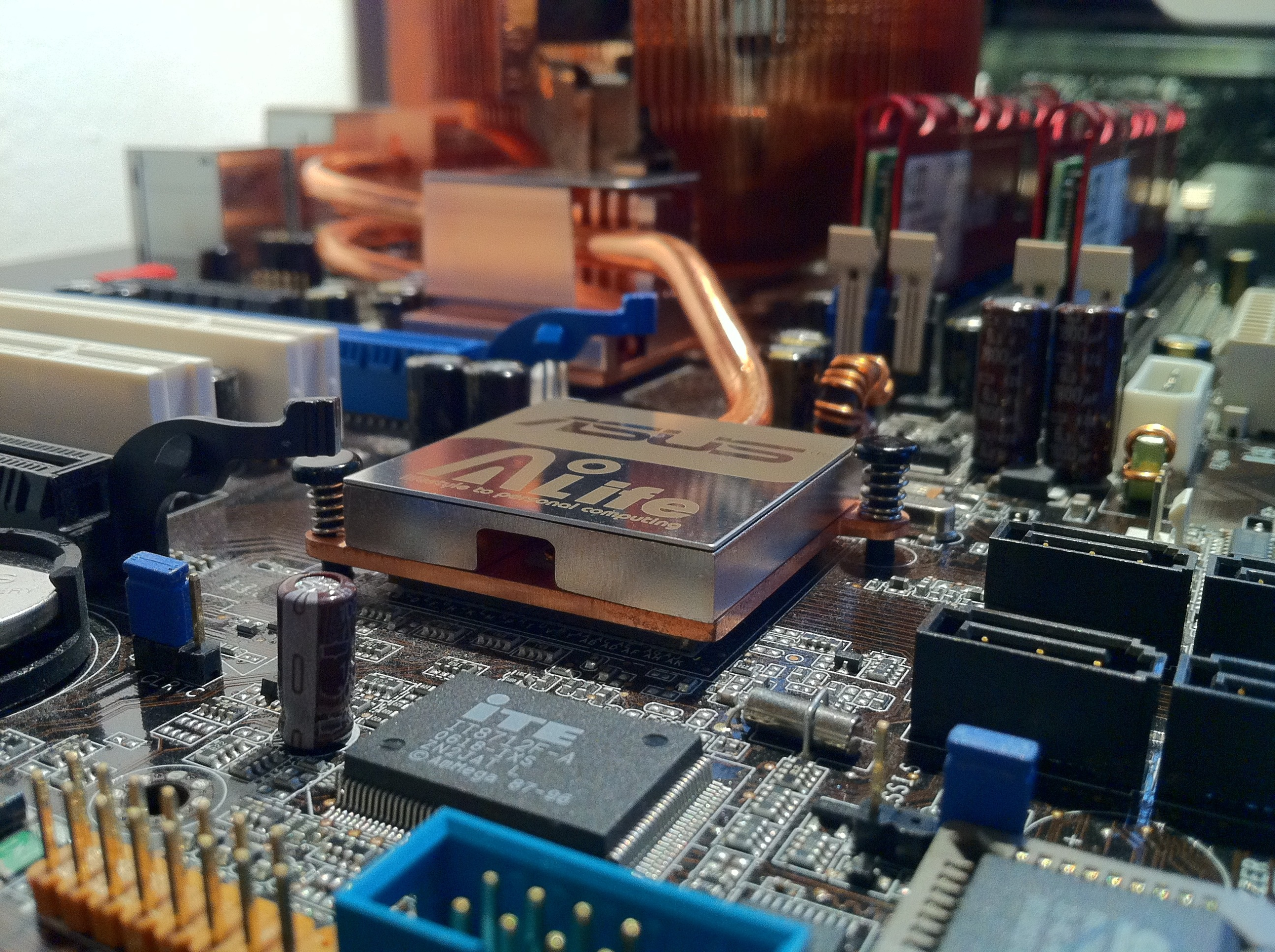

Electronics and Electrical Systems

Aluminum is widely used in electronics because it dissipates heat well. Smartphones, laptops, and LED lights often have aluminum casings to keep components cool.

The material is also non-magnetic, which is important for devices like hard drives and medical equipment. Its smooth surface allows for sleek, modern designs in consumer electronics.

Construction and Architecture

Builders use aluminum for windows, doors, and roofing because it is strong and weather-resistant. Skyscrapers with aluminum facades stay lightweight while standing up to wind and rain.

Aluminum is also used in bridges and stadiums. Its durability ensures structures last for decades with little maintenance.

Medical Equipment

Aluminum alloys are safe for medical use because they do not react with the human body. Surgical tools, wheelchairs, and MRI machines often contain aluminum.

The metal’s ability to be sterilized makes it ideal for hospitals. Its lightweight properties also help in designing portable medical devices.

Future Developments in Aluminum Alloys

New Alloy Compositions

Researchers are developing stronger aluminum alloys by adding elements like titanium and zirconium. These new mixtures could work better in extreme conditions.

Some experimental alloys contain lithium, which makes them even lighter. Such materials could revolutionize aircraft and spacecraft design. Other studies focus on improving aluminum’s heat resistance for engine parts.

Better Manufacturing Techniques

New production methods make aluminum alloys easier to work with. Advanced casting and 3D printing allow more complex shapes.

Computer-controlled machining ensures higher precision. These improvements help reduce waste and lower costs. Factories can now produce aluminum parts faster than ever before.

Growth in Green Industries

More companies are focusing on aluminum recycling programs. Better collection systems ensure less metal goes to landfills.

Recycling plants are becoming more efficient at sorting and processing scrap aluminum. This supports sustainable manufacturing practices. Governments are also creating policies to encourage aluminum recycling worldwide.

About Us – Professional Aluminum Alloy Solutions Provider

We’ve been at the forefront of the aluminum alloy industry, shaping innovative solutions that drive progress. As a recognized leader in aluminum manufacturing, we offer superior quality products and tailor-made solutions to meet the unique demands of clients across the globe. Aluminum alloys are integral to modern industries, and we are committed to enhancing both the performance and quality of our offerings.

Why Partner with Us for Aluminum Alloys?

- Complete Product Range

We offer a comprehensive selection of aluminum alloys, spanning from the 1xxx to 7xxx series. Our portfolio includes everything from sheets, rods, and tubes to profiles, each designed to fulfill the diverse requirements of industries such as aerospace, automotive, electronics, and construction. - Expert Technical Team

Our team of engineers brings deep expertise in aluminum alloy processing. From initial material selection to the final stages of manufacturing, our technical staff is dedicated to providing you with end-to-end support and guidance. - Strict Quality Control

All products follow ISO9001 standards. We use advanced testing equipment to ensure every batch meets industry requirements. - Custom Solutions

We offer special alloy compositions and heat treatments. This helps customers get the best cost-performance solutions. - Fast Delivery

We have a complete supply chain and warehouse system. This ensures quick response and on-time delivery for all orders.

Key Industries We Serve

- Aerospace: High-strength lightweight aluminum materials

- Automotive: Aluminum sheets and structural parts for vehicles

- Electronics: Heat dissipation materials and precision parts

- Construction: Aluminum profiles and curtain wall materials

- Industrial Equipment: Special aluminum alloys with corrosion resistance

We look forward to collaborating with you and pushing the boundaries of aluminum alloy technology together!

Conclusion

In short, aluminum alloys have a wide range of applications, including aerospace, automobile manufacturing, electronics, construction, and medical equipment. With the development of new materials, technological progress, and the enhancement of circular economy awareness, aluminum alloys will continue to play a greater role in future development.