Aluminum alloy machining is a cornerstone of modern manufacturing, offering unparalleled versatility, precision, and efficiency. From aerospace components to automotive parts, CNC-machined aluminum plays a critical role in industries that demand high-strength, lightweight materials and exceptional durability. This guide explores the process, benefits, applications, and future trends of aluminum alloy machining, with a focus on CNC-machined aluminum and custom-made on-demand services.

What is Aluminum Alloy Machining?

Aluminum alloy machining is the process of shaping aluminum into precise components using advanced manufacturing techniques. Aluminum alloys are favored for their unique properties, including:

- Lightweight yet strong: High strength-to-weight ratio makes them ideal for aerospace and automotive applications.

- Corrosion resistance: The Natural oxide layer provides excellent protection against environmental factors.

- Thermal and electrical conductivity: Suitable for heat sinks and electronic enclosures.

- Machinability: Easier to machine compared to other metals, reducing production time and costs.

Common aluminum alloys used in machining include 6061-T6, 7075-T6, and 5052, each offering distinct advantages for specific applications.

Custom-Made On-Demand Aluminum Parts

The rise of custom-made on-demand manufacturing has revolutionized the industry. Businesses can now order tailored aluminum parts without the need for large inventories. Benefits include:

- Flexibility: Designs can be modified to meet specific requirements.

- Cost efficiency: Pay only for what you need, reducing waste and storage costs.

- Rapid prototyping: Faster turnaround times for testing and production.

For example, a medical device manufacturer might use on-demand services to produce patient-specific implants, while an automotive company could prototype new engine components quickly and cost-effectively.

Material Selection for Aluminum Alloy Machining

Choosing the right aluminum alloy is crucial for achieving the desired performance and cost-efficiency.

Aluminum 6061

If you’re looking for a go-to aluminum alloy, 6061 is a top pick. It’s heat-treatable and keeps all the good stuff aluminum is known for. Strong, resistant to corrosion, and easy to work with when annealed, it can be shaped and fabricated using most standard methods.

Aluminum 6082

Aluminum 6082 is a solid choice when you need strength and corrosion resistance. It’s the toughest of the 6000 series alloys and is often called a structural alloy for a reason. Machinists love using it in plate form, and its impressive strength has helped it overtake Aluminum 6061 in many areas.

Aluminum 6063

Aluminum 6063 is what you’d call the go-to alloy for architectural work. It’s got good strength, finishes beautifully, and resists corrosion like a champ. You’ll often see it in building trims and other architectural details, thanks to its excellent performance in extrusion processes.

Aluminum 5052

5052 is the toughest of the non-heat-treatable alloys, with better fatigue strength than most other aluminum types. It handles salty, marine conditions like a pro and is super easy to work with, making it a top pick for many uses.

Aluminum 7075

Aluminum 7075 is a powerhouse alloy, known for its incredible strength and lightweight properties. It’s perfect for parts that need to handle a lot of stress, which is why it’s a favorite in the aviation world, where precision and complex designs are a must.

Aluminum 2024

Aluminum 2024 is a great option when you need something strong yet lightweight, with good fatigue resistance. However, it’s not weldable, machines okay, and doesn’t handle corrosion well, so anodizing isn’t an option.

Cost Optimization in Aluminum Alloy Machining

Cost is a critical factor in any manufacturing project. Here are some tips for optimizing costs in aluminum alloy machining:

- Design for manufacturability (DFM): Simplify designs to reduce machining time and material waste.

- Material selection: Choose the right alloy for your application to balance performance and cost.

- Volume discounts: Larger production runs often reduce per-unit costs.

- Automation: Automated CNC machining reduces labor costs and improves efficiency.

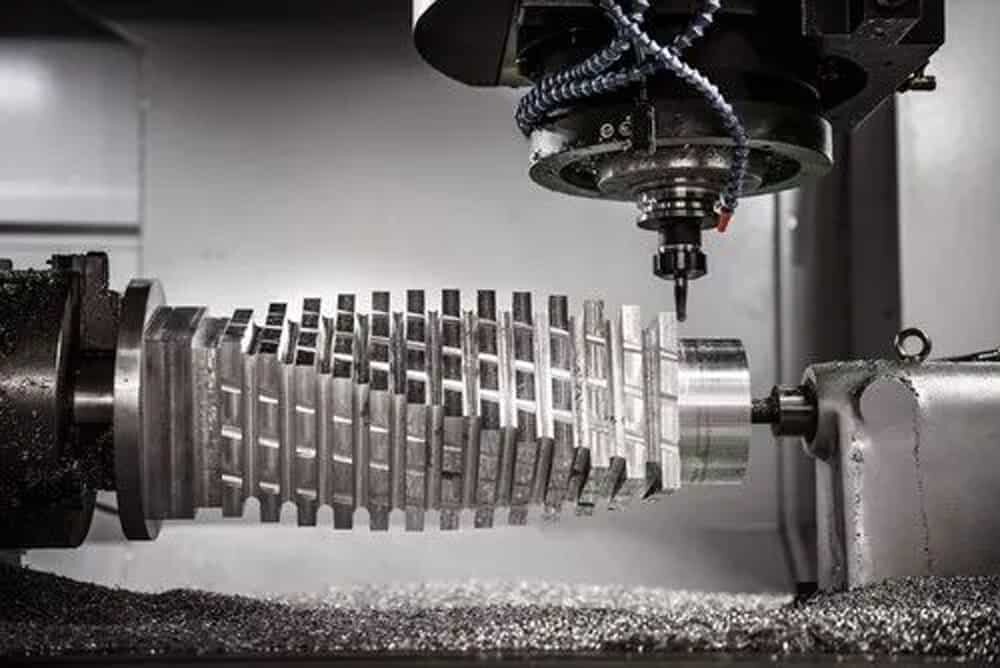

CNC Machined Aluminum: Precision and Efficiency

CNC (Computer Numerical Control) machining is the gold standard for aluminum alloy machining. It involves using computer-controlled machines to remove material from a solid block of aluminum, creating complex geometries with high accuracy. Key benefits of CNC-machined aluminum include:

- High precision: Tolerances as tight as ±0.125mm ensure consistent quality.

- Complex geometries: 3-axis and 5-axis milling machines enable intricate designs.

- Scalability: Suitable for both prototyping and mass production.

Industries such as aerospace, automotive, and electronics rely heavily on CNC-machined aluminum for components like engine parts, structural frames, and heat sinks.

Quality Control in Aluminum Alloy Machining

Quality control is essential to ensure that machined parts meet design specifications and industry standards. Common inspection methods include:

- CMM (Coordinate Measuring Machines): For dimensional accuracy.

- Surface roughness testing: To ensure smooth finishes.

- Visual and mechanical inspections: To identify defects or inconsistencies.

Certifications like ISO 9001 and ISO 13485 are indicators of a provider’s commitment to quality.

Custom-Made On-Demand Aluminum Parts

The rise of custom-made on-demand manufacturing has revolutionized the industry. Businesses can now order tailored aluminum parts without the need for large inventories. Benefits include:

- Flexibility: Designs can be modified to meet specific requirements.

- Cost efficiency: Pay only for what you need, reducing waste and storage costs.

- Rapid prototyping: Faster turnaround times for testing and production.

Applications of Aluminum Alloy Machining

Aluminum alloy machining is a versatile and indispensable process that serves a wide range of industries. Below, we explore how CNC-machined aluminum and custom-made on-demand services are transforming key sectors.

1. Aerospace Industry

The aerospace industry demands materials that are both lightweight and durable to ensure fuel efficiency and safety. Aluminum alloys, particularly 7075-T6 and 2024, are widely used in this sector due to their high strength-to-weight ratio and fatigue resistance.

Wing Ribs and Spars: These structural components require precise machining to ensure aerodynamic efficiency and structural integrity.

Engine Mounts: Aluminum’s lightweight properties reduce the overall weight of the aircraft, improving fuel efficiency.

Landing Gear Parts: High-strength aluminum alloys withstand the immense stress during takeoff and landing.

Companies like Boeing and Airbus rely heavily on Aluminum Alloy Machining services to produce these critical components with the precision and reliability that CNC machining offers.

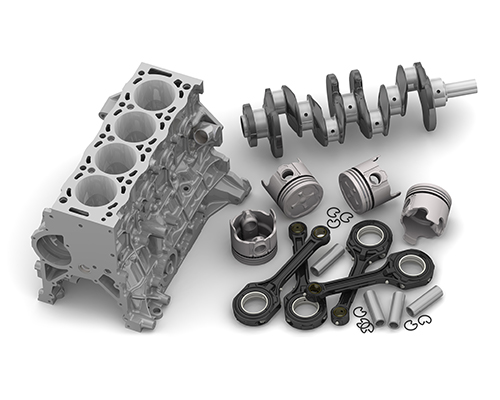

2. Automotive Industry

In the automotive sector, aluminum alloys are used to reduce vehicle weight, enhance fuel efficiency, and improve performance. The rise of electric vehicles (EVs) has further increased the demand for CNC-machined aluminum parts.

Engine Blocks and Cylinder Heads: Aluminum’s thermal conductivity helps dissipate heat, improving engine performance.

Transmission Cases: Lightweight yet strong, aluminum transmission cases contribute to overall weight reduction.

EV Battery Housings: Aluminum’s corrosion resistance and durability make it ideal for protecting sensitive battery components.

Suspension Components: CNC-machined aluminum parts provide the strength needed to handle road stress while reducing vehicle weight.

Automakers like Tesla and Toyota utilize custom-made made on-demand aluminum parts to streamline production and meet evolving design requirements.

3. Electronics Industry

The electronics industry benefits from aluminum’s excellent thermal and electrical conductivity, making it a preferred material for heat management and enclosures.

Heat Sinks: CNC-machined aluminum heat sinks dissipate heat from CPUs, GPUs, and other electronic components, ensuring optimal performance.

Enclosures and Housings: Aluminum enclosures protect sensitive electronics while providing electromagnetic shielding.

Connectors and Frames: Precision-machined aluminum parts ensure reliable connections and structural support in devices like smartphones and laptops.

Companies like Apple and Samsung use Aluminum Alloy Machining services to produce high-quality components that meet stringent performance standards.

4. Medical Industry

In the medical field, aluminum alloys are valued for their biocompatibility, precision, and lightweight properties. CNC machining enables the production of complex, patient-specific components.

Surgical Instruments: Aluminum’s lightweight nature reduces fatigue for surgeons during lengthy procedures.

Imaging Equipment Parts: Precision-machined aluminum components are used in MRI machines, CT scanners, and X-ray devices.

Prosthetics and Implants: Custom-made on-demand aluminum parts ensure a perfect fit for patients, improving comfort and functionality.

Medical device manufacturers rely on CNC-machined aluminum to meet the high standards of accuracy and reliability required in healthcare.

5. Consumer Goods

Aluminum alloys are also widely used in the production of consumer goods, where aesthetics, durability, and lightweight properties are essential.

Luxury Products: High-end watches, eyewear, and jewelry often feature precision-machined aluminum components.

Sports Equipment: Bicycle frames, golf clubs, and camping gear benefit from aluminum’s strength and lightweight properties.

Home Appliances: Aluminum parts are used in products like blenders, coffee makers, and vacuum cleaners for their durability and sleek appearance.

Brands like Dyson and GoPro leverage Aluminum Alloy Machining services to create innovative, high-quality products that stand out in the market.

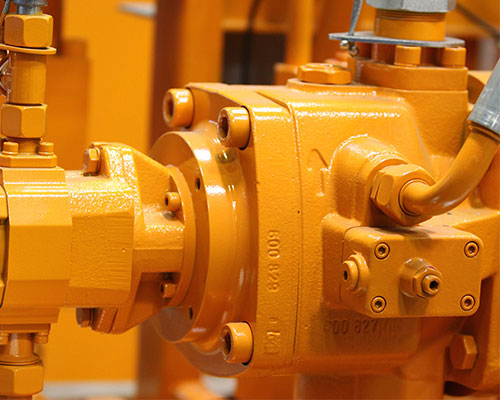

6. Industrial Machinery

In industrial settings, aluminum alloys are used to manufacture components that require high precision and durability.

Robotic Arms: CNC-machined aluminum parts provide the strength and precision needed for automated systems.

Pneumatic and Hydraulic Systems: Aluminum components are used in valves, cylinders, and fittings due to their corrosion resistance and lightweight properties.

Tooling and Fixtures: Custom-made on-demand aluminum fixtures ensure accurate and efficient production processes.

Industries ranging from manufacturing to logistics rely on CNC-machined aluminum to enhance the performance and longevity of their machinery.

7. Renewable Energy

The renewable energy sector is increasingly adopting aluminum alloys for their lightweight and corrosion-resistant properties.

Solar Panel Frames: Aluminum frames provide structural support while resisting environmental degradation.

Conclusion

Aluminum alloy machining is a vital process in today’s manufacturing landscape, offering unmatched precision, versatility, and efficiency. Whether you need CNC-machined aluminum parts or custom-made on-demand services, partnering with NOBLE ensures high-quality results tailored to your needs. Explore the possibilities of aluminum alloy machining and unlock new opportunities for your business.

Ready to start your next project? Contact NOBLE today for a free consultation or quote!