Why is CNC Machining Suitable for Robot Parts

CNC machining is suitable for robot parts mainly because of its high precision, high consistency, and excellent flexibility. Robot parts, such as joints, arms, and end effectors, have extremely high requirements for dimensional accuracy, geometric complexity, and material strength.CNC machining controls machine tools through digital instructions, achieving micron-level tolerances and ensuring precise assembly and smooth operation of parts. CNC machining can also handle a variety of engineering materials, such as aluminum alloys, titanium alloys, and special steels, meeting the dual demands of robots for lightweight and durability. Whether it is small-batch prototypes or large-scale production, CNC machining can maintain stable quality and quickly adapt to design iterations, which is crucial for the rapid evolution of robotics technology.

Materials for Parts of CNC Machining Robots

Aluminum Alloy

Aluminum alloy is one of the preferred structural components for robots. Its core advantage lies in its excellent lightweight properties, which can significantly reduce movement inertia and energy consumption. It is particularly suitable for high-speed articulated arms and mobile robots. Aluminum also has the characteristics of good specific strength, excellent thermal conductivity, and easy acquisition ofa high surface finish through CNC machining. Aluminum can undergo anodizing and other treatments to enhance its surface hardness and corrosion resistance, achieving a good balance between performance and processability.

Stainless Steel

Stainless steel is widely used in robot components in harsh environments due to its excellent corrosion resistance and high strength. Robots in the food or medical industry need to be repeatedly cleaned and disinfected, and their actuators and housings are often made of 304 or 316 stainless steel. For critical load-bearing or transmission components that require high strength and certain wear resistance, precipitation-hardening stainless steels like 17-4PH are an excellent choice. They can achieve higher mechanical properties through heat treatment.

Titanium Alloy

Titanium alloys have an extremely high strength-to-weight ratio and excellent fatigue resistance and corrosion resistance, making them ideal materials for manufacturing key components of high-demand robots in aerospace, special operations, and other fields.

Titanium materials can effectively enhance the load capacity and structural rigidity of robots while also withstanding the erosion of various harsh media. Although its material cost and machining difficulty are relatively high, for application scenarios with cutting-edge performance requirements, such an investment is necessary and worthwhile.

Engineering Plastics

Engineering plastics are suitable for manufacturing components that are relatively lightweight, self-lubricating, have special requirements for shock absorption and noise reduction, or electrical insulation.POM, due to its low coefficient of friction and high dimensional stability, is often used to manufacture wear-resistant parts such as gears and bearings. Nylon has good toughness and fatigue resistance.PEEK, as a high-performance plastic, can replace some metals in high-temperature and highly chemically corrosive environments and be used to manufacture special insulating parts or lightweight structural components.

Carbon and Alloy Steel

Steel materials are renowned for their high strength and excellent wear resistance, and their relatively low cost. Steel is often used to manufacture basic structural components, gears, rotating shafts, etc., in robots that are subject to heavy loads, high impacts, or require high surface hardness.F or instance, 45# steel that has undergone quenching and tempering treatment or 20CrMnTi gears with surface carburizing and quenching can ensure reliability and service life under long-term heavy-load operation, making them reliable choices for industrial robot bases.

The Types of Parts for CNC Machining Robots

Joint Housings

The various connecting rods, rotating bases, and joint shells of the robotic arm are the core components that constitute the robot’s skeleton. They need high rigidity to ensure the positioning accuracy of the robot, while being as lightweight as possible to increase the movement speed and reduce energy consumption.CNC machining can precisely mill these complex, x-large three-dimensional structures out of a single piece of metal, ensuring the perfect fit between each component and the uniformity of the assembly reference.

Reduction Drive

The reducer is the “muscle” of a robot’s joints, directly affecting its motion accuracy and smoothness. Its core components, such as flexible wheels, rigid wheels, gears, and housings, have extremely high precision requirements, usually reaching the micrometer level.CNC machining, especially high-precision 5-axis machining, can manufacture these parts with complex tooth profiles and precise inner cavities. The machining uses high-strength alloy steel or special materials to meet the requirements of extremely high wear resistance, fatigue strength, and long-term operational reliability.

End Effector

The end effector is the part of the robot that interacts directly with the environment, including grippers, suction cups, and quick-change devices that enable automatic tool switching. These components usually require a customized design to adapt to different working tasks.CNC machining can quickly and accurately manufacture these complex-structured parts with precise air channels or sensor installation positions, and ensure their reliability, which is the key to achieving flexible applications of robots.

Sensor Holder

The precise movement of robots relies on the feedback from various sensors. The mounting seats and brackets of these sensors require extremely high dimensional stability and positional accuracy to ensure the accuracy of sensor data.CNC machining can produce small and precise parts with compact structures and strict tolerances, providing a solid and deformation-free installation foundation for sensors.

Connector

Inside the robot, there are a large number of cables and air pipes that need to be neatly arranged and fixed, and reliable mechanical and electrical connections are also required between each module. CNC-machined connectors, cable clamps, electrical adapter boards, and other parts can provide highly integrated and precise solutions, ensuring neat internal wiring and stable connections. This is crucial for the reliability, maintainability,y and electromagnetic compatibility of robots.

Surface Treatment Required for Parts of CNC Machining Robots

Anodizing

Anodizing is mainly applicable to aluminum alloy parts, generating a dense layer of aluminum oxide ceramic film on the aluminum surface through electrochemical methods. This film can greatly enhance the surface hardness, wear resistance, and corrosion resistance of parts, and can be dyed in various colors such as black and blue, which is convenient for component identification and appearance beautification. The oxide film has good insulation properties and can serve as an excellent base layer for subsequent coatings. For robot structural components that require lightweight, corrosion-resistant materials and have appearance requirements, anodizing is the preferred process.

Electroplating

Electroplating is a process of depositing a layer of metal coating on the surface of parts. Common types include galvanizing, nickel plating, chromium plating, and electroless nickel plating, etc.

Galvanization can provide economical and effective rust protection. Nickel plating and chemical nickel plating can simultaneously provide excellent corrosion resistance, wear resistance, and a beautiful metallic luster, and are often used in sensor housings or exposed connecting parts. Hard chromium coating can significantly enhance the surface hardness and wear resistance of moving parts. Electroplating can flexibly endow the base material with new surface characteristics according to functional requirements.

Sand Blast and Brushing

Sandblasting utilizes high-speed sand flow to impact the surface of parts, creating a uniform and fine matte texture. It can also remove minor tool marks and enhance the adhesion of the coating. Brushing is a process that creates a straight texture on the metal surface through mechanical friction, combining aesthetics with the ability to resist fine scratches. The main purpose of these two processes is to improve the appearance, enhance the texture, and prepare a clean and appropriately rough surface for subsequent spraying or oxidation treatment.

Passivation

Passivation is a chemical treatment process for stainless steel parts. By using an acid solution to remove free iron ions on the surface and form a very thin but dense passivation film on the surface. This film can greatly enhance the inherent corrosion resistance of stainless steel, preventing it from pitting or rusting in damp or specific chemical environments. Passivation is an indispensable and cost-effective anti-corrosion treatment process for stainless steel robot components working in food, medical, or humid industrial environments.

Painting

Surface spraying includes powder coating and painting. Powder coating uses static electricity to adsorb epoxy or polyester powder onto the workpiece. After curing, it forms a thick, strong, impact-resistant, and corrosion-resistant coating. There are many color options available, making it suitable for the shells of outdoor or harsh working conditions of robots. Spray painting, on the other hand, offers a wider range of colors and gloss options and is often used for brand logos or visual alerts. Both can provide comprehensive physical isolation protection and can achieve special functions as required, such as anti-static or antibacterial coatings.

Tolerances for High-Performance Robot Parts

Ensuring Motion Accuracy

The core of high-performance robots lies in their ability to precisely perform repetitive tasks. Strict tolerance control, especially for key mating parts such as spherical plain bearing holes, transmission gears, and lead screw mounting seats, can minimize the cumulative error in the motion chain to the greatest extent.

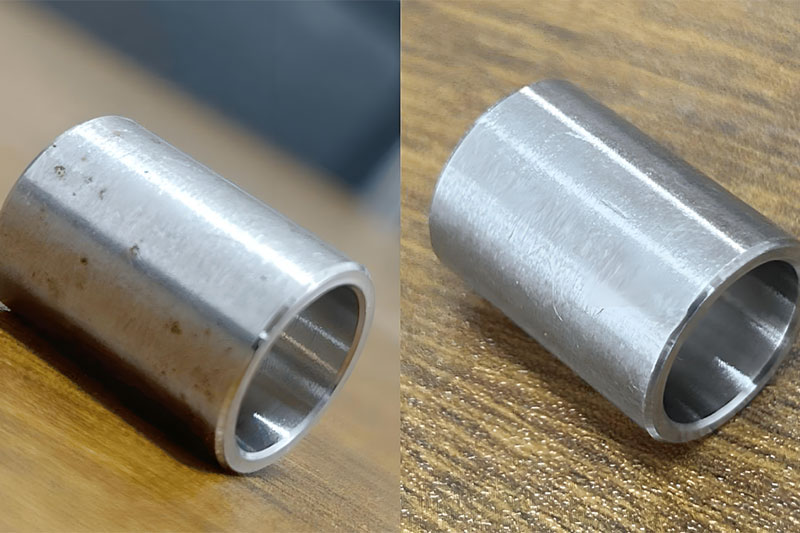

Parts Interchangeability

In mass production or modular design, all parts of the same model must have a high degree of interchangeability. Strict and consistent tolerances ensure that any bushing, connecting rod, or housing can be perfectly installed during assembly without manual selection or additional grinding.

This greatly simplifies the process of replacing spare parts in later maintenance, reduces the full life cycle maintenance cost of the robot, and is a prerequisite for achieving efficient industrial applications.

Optimizing Performance

The robot joints and arm bodies need to maintain minimal deformation under high loads. Applying strict flatness, parallelism, and positional tolerances to the key load-bearing surfaces, threaded hole positions, and the mating surfaces of each component can ensure that the parts achieve large-area uniform contact after fastening.

Extending Component Lifespan

The precision reducers, harmonic generators, or ball screws and other transmission components of robots are extremely sensitive to the installation environment. Specifying strict coaxiality, perpendicularity, and dimensional tolerances for their mounting seats and connecting components can prevent uneven internal stress, eccentric loading, or abnormal wear caused by installation deviations.

Dynamic Balance

Strict shape and position tolerances and symmetry requirements help control the centroid position of components during the design and manufacturing stages. This can reduce the centrifugal force and vibration generated during high-speed operation, prevent the robot from shaking due to its own inertial force, and is crucial for achieving smooth, stable, and precise movement at high speeds.

Comparing CNC Machining with Other Manufacturing Methods for Robotics

Design Complexity

CNC Machining

Skilled in manufacturing parts with regular geometric shapes, mainly featuring prismatic or rotary surfaces. For extremely complex internal cavities or lattice structures, CNC machining is difficult, costly, and even impossible to achieve.

Additive Manufacturing

Additive manufacturing has a revolutionary advantage in design freedom. It can easily achieve complex internal flow channels for integrated manufacturing and irregular-shaped parts that cannot be processed by traditional methods, providing a unique solution for robot lightweighting and functional integration.

Injection Molding

Injection molding can efficiently form complex shapes, but it is usually restricted by process limitations such as the demolding Angle and cannot achieve complex and closed internal structures. Its design freedom lies between that of numerical control machining and additive manufacturing.

Material Performance

CNC Machining

Directly using rolled or forged plates or bars, the material structure is uniform and dense, and the mechanical properties are usually the best. It is very suitable for the key moving parts of robots that bear high loads and high impacts.

Additive Manufacturing

The material melts and solidifies layer by layer, and its properties are anisotropic. It may also contain defects such as pores and incomplete fusion. Its strength and toughness are usually lower than those of forged and rolled parts of the same material, but after appropriate heat treatment, it can meet the requirements of most robot parts under non-extreme loads.

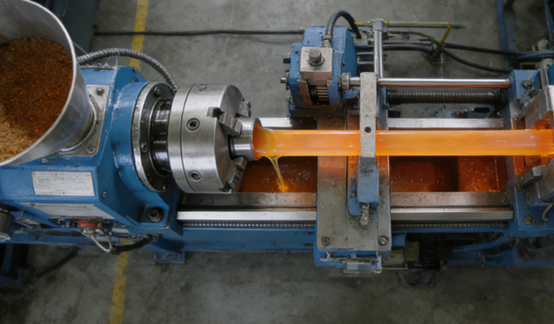

Manufacturing Precision

CNC Machining

CNC machining is recognized as the benchmark in terms of precision and surface finish. Through precision machine tools and exquisite craftsmanship, micron-level dimensional tolerances and excellent surface roughness can be achieved, making it the only choice for manufacturing all high-precision mating parts such as robot joints and reducer mounting surfaces.

Additive Manufacturing

The forming accuracy is limited, and there are obvious step patterns on the surface. Usually, subsequent CNC processing is required to meet the fit accuracy requirements. Its advantage lies in the forming ability rather than the final precision.

Injection Molding

The forming accuracy is relatively low, the surface quality is poor, and the important mating surfaces must rely on subsequent CNC machining for fine machining.

Cost-Effectiveness

CNC Machining

It has excellent flexibility, does not require special molds, and has relatively low production costs for single pieces or small batches. It is an ideal choice for prototype trials and medium and small batch production. However, when it comes to mass production, the cost per piece does not decrease significantly, and its economic viability is insufficient.

Additive Manufacturing

There is almost no mold cost, and the single-piece manufacturing cost has little to do with the batch size. It is very suitable for the production of single-piece and small-batch complex parts. However, the cost of materials and equipment depreciation is high, making mass production uneconomical.

Die Casting

It has a significant scale effect. The investment in molds is huge, but once amortized, the cost per piece for mass production is extremely low. Therefore, such processes only have economic advantages when a large production volume is reached.

Production Cycle

CNC Machining

The path from the drawing to obtaining the parts is the shortest and fastest. For regular parts, they can be produced quickly after programming and clamping, which is particularly suitable for R&D iterations and emergency spare parts supply.

Additive Manufacturing

Without complex tooling, digital files can directly drive equipment production. For complex parts, the manufacturing cycle is shorter than that of CNC machining. But the post-processing might be time-consuming.

Injection Molding

The initial mold design and manufacturing cycle is very long, but once the mold is completed, the production cycle of a single part is very short. Therefore, its overall response speed is slow, and it is not suitable for the stage when the product has not yet been finalized or is undergoing rapid changes.

Why Choose NOBLE for CNC-Machined Robot Parts?

NOBLE provides fast and reliable robot parts manufacturing services, promotes the research and development and launch of innovative products in the robot industry, selects advanced technologies and materials to manufacture robot prototypes or parts, and ensures that your products enter the market as soon as possible.

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, with huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

- Advanced Equipment & Cost-Effective Price

- Tight Tolerance of 0.001 mm

- 10+ years of Robot Parts Machining

- ISO 9001 & ISO13485 Certified Factory

- Free&Professional DFM Report

- 24/7 Engineering Support

FAQ

Why are CNC-machined parts preferred for industrial robots?

CNC-machined parts are preferred for industrial robots primarily due to their exceptional precision, consistency, and material strength. Robots require components with extremely tight tolerances for smooth assembly and accurate movement. CNC machining reliably produces parts with micron-level accuracy from high-performance materials like aluminum, titanium, and steel.

What materials are commonly used for CNC robot parts?

The most common materials include Aluminum Alloys, Stainless Steel, Titanium Alloys, and Engineering Plastics like PEEK. Material selection depends on the part’s function, required strength, weight, and operational environment.

Can CNC machining produce complex robot parts?

Yes, modern multi-axis CNC machining can produce highly complex geometries essential for robots, such as intricate housings, sensor mounts, and components with internal channels.

How does CNC machining compare to 3D printing for robot parts?

CNC machining is superior for parts requiring the highest dimensional accuracy, excellent surface finish, and optimal material integrity from solid blocks of metal or plastic. 3D printing excels at creating extremely complex, lightweight designs that are impossible to mill.

What surface finishes are available for CNC-machined robot parts?

Common surface finishes include Anodizing, Passivation, Plating, and Powder Coating. The choice of surface finish for parts depends on the material, the required function, and the working conditions of the robot.