Industries

CNC Machining for Global Industries

NOBLE provides global industries with Ultra-Precision Machining Services. Our high-quality CNC machining services include 5-axis machining, CNC milling machining, and CNC turning. Our engineering team has vast experience in complex component production with tight tolerance, high precision, and extraordinary accuracy for various industries. We claim to take up all your challenge request, no matter how difficult to achieve. We also can conquer them with the same precision in our easiest machining job.

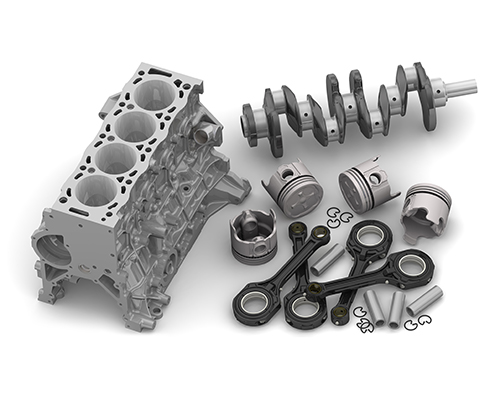

Rapid Prototyping for Automotive Industry

In the automotive industry, failure or breakdown of any component can lead to catastrophic consequences. Hence, it is crucial to thoroughly test and evaluate any new component or product to ensure its expected performance before it hits the market. Prototypes serve as an ideal solution for such testing operations. NOBLE employs rapid prototyping technology to produce high-performance physical prototypes that undergo rigorous validation and testing. NOBLE is committed to delivering top-notch quality products to our customers.

Rapid Prototyping and On-Demand Production for Aerospace Industry

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

Precision Machined Parts for the Medical Industry

NOBLE is a reliable manufacturer of medical critical components for surgical instruments and tools, and medical device prototyping. With over 10 years of CNC manufacturing experience, we are powered by our guarantee of the closest tolerances and precision on every machined part. Our skilled machinists can custom machine part designs to the highest standards for all aspects of the medical industry.

NOBLE is fully trusted by customers around the world, and most of them become firm partners after placing orders and receiving finished products that far exceed expectations. Precision medical components manufactured by NOBLE are easily found in trocar/cannula systems, CT and MRI scanner systems, biopsy cutters, respiratory, cardiopulmonary and cardiac equipment, and more.

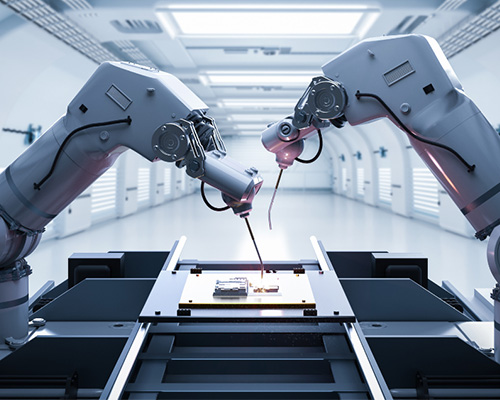

Our Custom Machining for Robot Industry

The robotics industry is being propelled forward by advanced production techniques. For robots to function with precision and durability, top-notch hardware and meticulous manufacturing are essential. NOBLE offers a personalized parts service to help you turn your ideas into tangible solutions. Our team specializes in creating custom robots that cater to your specific needs and overcome your unique challenges.

Rapid Prototyping and On-Demand Production for Automation Industry

As the automation industry continues to evolve and innovate, the need for rapid prototyping and on-demand production has become increasingly important. NOBLE rapid prototyping services allow you to quickly and easily create functional prototypes to test and refine your designs, allowing you to see and feel your design before moving into production. And on-demand services produce parts with a high level of accuracy and detail.

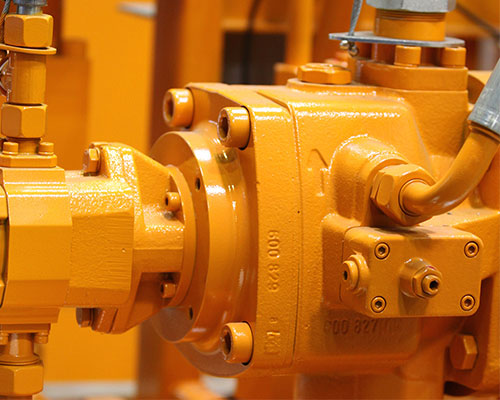

Rapid Prototyping and On-Demand Production for Industrial Equipment and Machinery Industry

Rapid prototyping and on-demand production have revolutionized the industrial equipment sector by accelerating product development, reducing costs, enabling customization, facilitating design optimization, mitigating risks, improving supply chain flexibility, and fostering innovation. Manufacturers that embrace these technologies can gain a competitive edge by delivering high-quality products faster and more efficiently.

Rapid Prototyping and On-Demand Manufacturing For Communication Equipment Parts Industry

Provides communications equipment manufacturers with customized rapid prototyping and on-demand manufacturing communications component processing solutions, performance optimization, design flexibility, integration and compatibility advantages, time and cost efficiencies, and intellectual property protection at competitive prices. These advantages contribute to the overall success and competitiveness of communications equipment manufacturers in meeting the changing needs of the industry and consumers.

Rapid Prototyping and On-Demand Production for Energy Industry

The new energy industry is expanding rapidly, and companies are always looking for new ways to enhance their operations and products. High-quality parts are a key element in this industry. Producing durable, high-quality parts that can withstand harsh environments and challenging operating conditions is critical to the new energy industry. We help you develop reliable energy products from prototype to production through best-in-class manufacturing processes and technical expertise at competitive prices.

Rapid Prototyping and On-Demand Production for Consumer Pruduct Industry

Rapid prototyping and on-demand production empower consumer product companies to innovate rapidly, respond to market demands efficiently, reduce costs, and create customized products. These practices contribute to increased competitiveness and customer satisfaction in the ever-evolving consumer products industry.