What is injection molding?

Injection molding is a widely-used manufacturing technique that enables the production of high-volume parts and goods. It is a flexible and efficient technology that is commonly applied across various industries such as consumer goods, automotive, electronics, and packaging. The process involves injecting molten material, typically a thermoplastic polymer, into the mold cavity at high pressure. The final product’s shape and properties are intended to be reflected in the mold design. After the molten material is injected into the mold, it cools down and solidifies to form a mold cavity. Finally, the mold is opened and the cured part is removed.

Injection molding machine structure

Injection Molding Machine Components

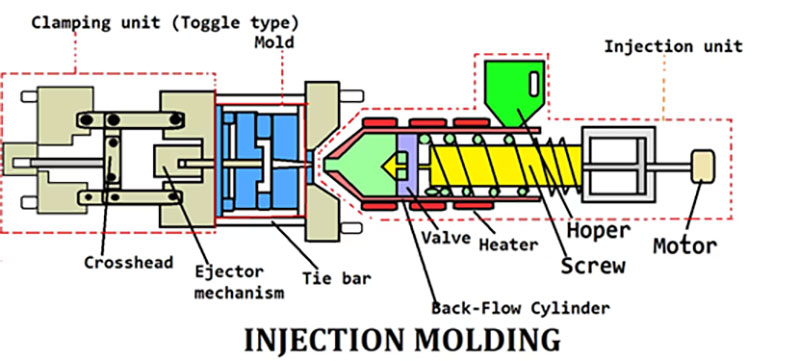

A machine used in the injection molding process to create plastic goods is called an injection molding machine. It is mainly made up of two primary components: the clamping unit and the injection unit.And here are some basic components of injection molding machine.

Clamping Unit, the clamping unit is responsible for holding the mold in place during the injection molding process. It consists of a stationary platen and a moving platen, which are mounted on the machine’s frame. The mold is clamped between these two platens.

Injection Unit: the injection unit is responsible for melting and injecting the molten plastic material into the mold cavity. It typically consists of a hopper, where the plastic pellets or granules are fed into the machine, a screw or plunger, which melts and injects the plastic material, and a nozzle that directs the material into the mold.

Heating and Cooling System: Injection molding machines have a heating system to melt the plastic material and a cooling system to solidify the molded part. The heating system usually involves electric heaters or oil heaters to heat the barrel and melt the plastic. The cooling system may include water channels or air vents to cool the mold and the molded part.

Control System: Modern injection molding machines are equipped with a control system that allows operators to set and monitor various parameters of the molding process. The control system typically includes a control panel with a display, buttons, and switches for adjusting settings such as temperature, pressure, injection speed, and cycle time.

Ejection System: After the plastic part has solidified inside the mold, it needs to be ejected from the mold cavity. The ejection system consists of ejector pins or plates that push the part out of the mold when the mold opens.

What Is the Difference Between 3D Printing and Injection Molding?

3D printing and injection molding are both technologies for producing plastic parts. 3D printing is an additive printing process that creates objects by building layers of material, while plastic injection molding uses a mold filled with molten material, which is cooled and hardened before production parts. Both injection molding and 3D printing can be used for prototyping, but there are some key differences between the two processes.The main difference: When refering to mass production of goods with little material waste, injection molding works well. Although 3D printing takes longer to set up, it is preferable for complicated designs and allows for rapid design modifications.

3D Printing

3D printing, or additive manufacturing, provides a quick turnaround time of 1-2 weeks, making it an ideal solution for rapid prototyping and designs that require frequent changes. Additionally, this process is capable of producing small plastic parts and intricate designs. It is not the most suitable option for large production runs of over 100 parts, as it can be expensive in terms of both time and money. However, it is a great choice for low-production runs.

However, 3D printing is a slow production method that can only produce a limited number of parts at a time. The size of the printing area restricts the production of larger items, as any part hanging over the edge of the print area risks instability. This means that while large-scale 3D printing is possible, it may not be the best application of the process. Additionally, 3D-printed parts have a rough surface finish due to the additive manufacturing process, regardless of the level of detail. If you require a smooth surface finish, post-finishing will be necessary.

Injection Molding

Injection molding involves long turnaround times to prepare for creating parts, taking up to 5-7 weeks even for simple parts. As such, it is not well-suited to frequent design changes. However, despite these long turnaround times, the process is perfect for producing parts in high volumes, running up to 1,000+ parts per run. Moreover, the mold tool is suitable for producing components of any complexity, regardless of their size. However, Injection molding is not ideal for producing intricate and delicate designs that can stand independently. Correcting any mistakes or changing the design can be challenging because of the prolonged setup times involved in injection molding. Besides, rectifying errors in the design can be expensive and time-consuming. Modifying the mold to fix issues or change designs requires a complete remake, which results in scrapping anything produced and incurring additional expenses.

In conclusion, both processes have their own advantages and disadvantages, so they should be treated as complementary instead of competing technologies. 3D printing is more suitable for producing small batches of complex parts that may require frequent design changes or customization. On the other hand, injection molding is more appropriate for mass production of less complex parts that have already completed the design stage successfully.

How does injection molding work?

Injection molding is the most popular manufacturing process for producing plastic parts. Injection molding is the most popular manufacturing process for producing plastic parts. Injection molding machines, using raw plastic and a variety of molds, can make many different parts, large or small, durable or disposable, for many industries and applications. So how does injection molding work?

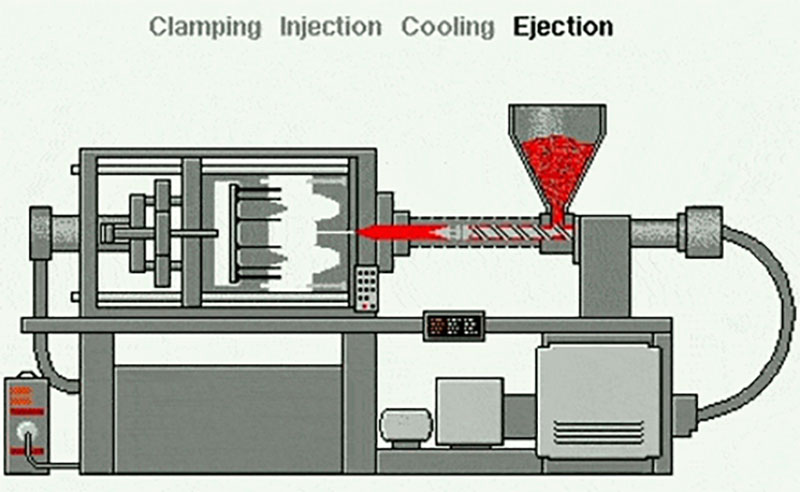

1: selecting the right thermoplastic and mold

The thermoplastic material selected for molding directly impacts the performance and properties of the part. Different materials offer varying characteristics, such as strength, flexibility, heat resistance, chemical resistance, and electrical properties. Choosing the appropriate material is important to ensure that the part meets the desired specifications and performs well. Material selection and mold design affect the molded parts’ quality, dimensions, surface finish, and structural integrity. Factors like material flow, shrinkage, warpage, and cooling determine the parts’ defects and need to be considered. Proper material and mold selection help produce high-quality parts consistently.

2: feeding and melting the thermoplastic

The injection process begins with the injection unit of the machine. Plastic pellets or pellets are added to the hopper and the material is fed into a heated barrel. The material is then melted inside the barrel, usually by the rotation of a screw or the movement of a plunger.

3: injecting the plastic into the mold

The molten plastic is then injected under high pressure into the mold cavity through a nozzle and runner system.

4: holding and cooling time

Once the mold cavity is filled with molten plastic, the cooling process begins. The mold contains channels or channels through which a cooling medium (such as water or oil) circulates. The cooling medium helps to quickly cool and solidify the plastic material into the shape of the mold cavity. During this period, the cooling time should be controlled according to the properties of the material.

5: ejection and finishing processes

Once the plastic has melted and cooled inside the mold, the mold clamping device of the machine opens up. The two halves of the mold separate, and the cured part is ejected out of the mold cavity using an ejection system, such as an ejector pin or plate.And then workers do the fininshing process,enhancing the final appearance, functionality, and overall quality of the molded parts.After that, the product could be pacakeaged and delivery to the customers.

Common types of injection molding

Plastic injection molding

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to produce plastic parts in large quantities. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, and then ejecting the finished part from the mold. Plastic injection molding is widely used in various industries due to its efficiency, versatility, and ability to produce complex and precise parts, such as automotive, electronics, consumer goods, medical devices, and etc.

How Does Plastic Injection Molding Work?

Plastic injection molding is an incredibly efficient and versatile manufacturing process. It involves creating a mold, melting and injecting the plastic material into it, allowing it to cool and solidify, and then ejecting the finished part from the mold. This process is automated and controlled, making it possible to produce complex parts with high precision and consistency. Plastic injection molding is a cost-effective method for producing plastic components in large quantities and is widely used across various industries.

Cost of Plastic Injection Molding

Injection molding’s primary cost driver is the mold, also known as tooling cost. The cost depends on the part design’s complexity, material type, and production volume. Despite high fixed start-up costs, injection molding has low variable costs, using inexpensive materials and progressive automation, resulting in fewer labor needs. As production volume increases, the cost per part decreases, making the process more efficient by distributing costs.

Which Plastic is Best for Injection Molding?

Selecting the appropriate material is essential for almost all stages of the injection molding procedure. Because of this, it’s frequently one of the most important decisions a manufacturer and their customer will have to make over the course of the manufacturing cycle. Several typical plastic injection molding materials may be utilized because of their various features and functions, even if there is occasionally secrecy surrounding the reasons for the selection of particular plastic material types and brands. Some important material features should be taken into account during the design and development phase when choosing the appropriate material for a project. Remember to consider possibilities for biodegradable materials as well.

Advantages of Plastic Injection Molding

High Efficiency

Plastic injection molding is a highly efficient process, allowing for the production of a large number of parts in a relatively short time. Once the mold is set up, the actual molding process is fast, and each cycle can produce multiple parts simultaneously.

Cost-Effective

When producing goods on a large scale, injection molding can be a financially advantageous manufacturing technique. High production volumes, little material waste, and automation are all made possible by it, all of which can lower labor costs. Moreover, choosing the most economical and appropriate plastic material for a given application might result in cost savings because of the versatility of the material.

Complex and Precise Part Design: Injection molding enables the production of complex and intricate part designs that may be difficult or impractical to achieve with other manufacturing processes. The molds used in injection molding can be highly detailed and replicate intricate features, allowing for precise and consistent part production.

Plastic Injection Molding Tolerances and Standards

Plastic injection molding tolerances and standards are crucial for achieving functional, high-quality parts that meet the required specifications. They ensure part compatibility, functionality, and fit, contribute to consistent quality, and enable cost-effective production. Proper consideration of tolerances throughout the design and manufacturing process is essential for successful plastic injection molding.

| Standards | Description |

| Maximum Part Size | 1200×1000×500 mm

47.2×39.4×19.7 in |

| Minimum Part Size | 1×1×1 mm

0.039×0.039×0.039 in |

| Part to Part Repeatability | ±0.1 mm

±0.0039 in |

| Mold Cavity Tolerances | ±0.05 mm

±0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Machines Available | Single cavity, multi-cavity, and family molds,

50 to 500 press tonnage |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts and basic assembly. |

| Inspection and Certification Options | 15 business days or less for most orders,

24/7 quotation response |

| Lead Time | 15 business days or less for most orders,

24/7 quotation response |

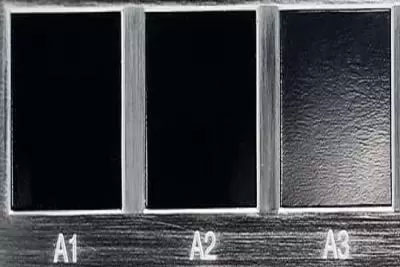

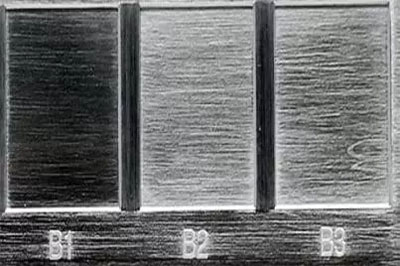

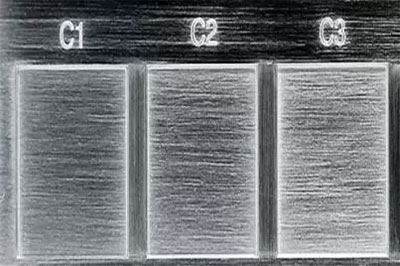

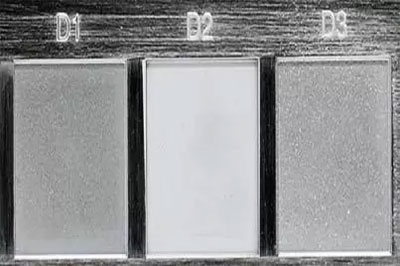

Surface Finishes of Plastic Injection Molding

The surface treatment of the mold is usually completed during the production process. After the injection molding is completed, we will carry out certain surface treatments on the finished product as per your requirements.

| Name | Description | |

|

Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. |

|

Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. |

|

Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. |

|

Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

What Equipment is used in the Plastic Injection Molding Process?

The plastic injection molding process involves the use of various equipment to produce plastic parts. The main equipment used in the process includes an injection molding machine, a mold, and auxiliary equipment.

The injection molding machine

The injection molding machine is the primary piece of equipment used in plastic injection molding. It consists of a hopper, an injection unit, a mold clamping unit, and controls. The machine melts the plastic material, injects it into the mold, and cools it to form the desired shape.

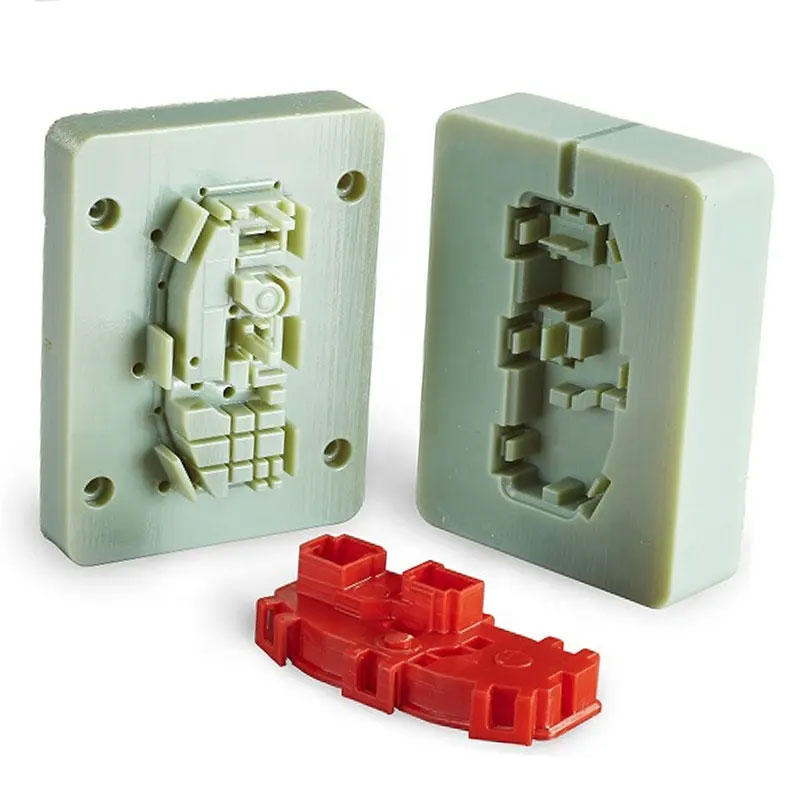

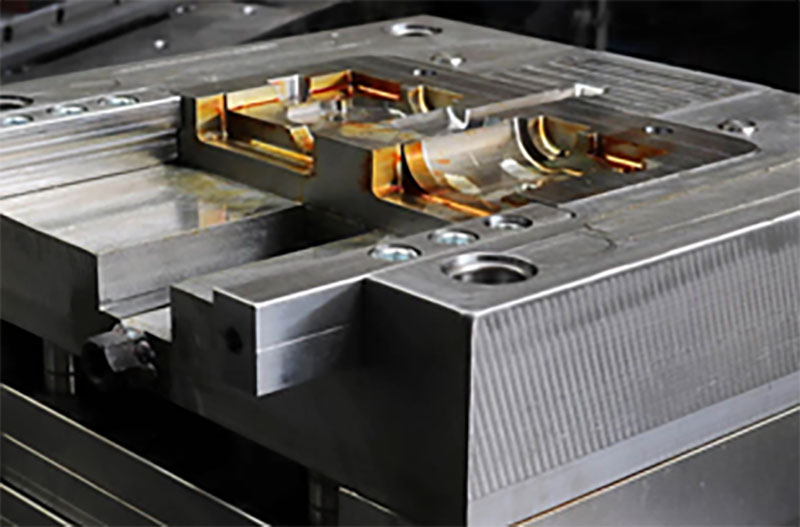

The mold

The mold is a precision tool that defines the shape and features of the plastic part to be produced. It is typically made of steel and consists of two halves: the cavity and the core. The mold is mounted on the injection molding machine and is designed to withstand high pressures and temperatures.

Additional equipment

Additional equipment may be used to support the injection molding process, such as material drying equipment, material handling systems, granulators for recycling scrap plastic, and robots or automation systems for part removal and handling.

It’s important to note that the specific equipment used in plastic injection molding can vary depending on the size and complexity of the parts being produced, as well as the requirements of the manufacturing process.

Is 3D Printing the Same as Plastic Injection Molding?

3D printing and plastic injection molding are not the same processes. While both techniques are used for manufacturing plastic parts, they employ different approaches and have distinct advantages and limitations. Both 3D printing and plastic injection molding are valuable manufacturing processes for plastic parts, but they have different strengths and applications. 3D printing is advantageous for prototyping, customization, and low-volume production, while plastic injection molding is ideal for large-scale manufacturing and achieving cost-effective production of consistent, high-quality parts.

Plastic Injection Molding for Various Industries

Plastic injection molding is a versatile manufacturing process that finds applications in various industries. Here are some examples of industries that commonly utilize plastic injection molding:

Plastic Injection Molding in the Automotive Industry

Plastic injection molding is extensively used in the automotive industry for manufacturing a wide range of components, including interior and exterior trims, dashboards, door panels, bumpers, vents, and engine parts. The process allows for the precise production of complex shapes and lightweight parts, contributing to improved fuel efficiency.

Plastic Injection Molding in the Aerospace and Defense Industry

Plastic injection molding is widely used in the aerospace and defense industries for the manufacturing of sturdy and lightweight components. These include control panels, aircraft interior parts, protective equipment, connectors, and housings for electronic systems. This process enables the production of parts with intricate geometries, high durability, and resistance to harsh environmental conditions.

Plastic Injection Molding in the Medical Industry

Plastic injection molding plays a crucial role in the medical and healthcare industry, where precision, cleanliness, and biocompatibility are essential. It is used to manufacture medical devices, such as syringes, catheters, surgical instruments, implantable components, drug delivery systems, and lab equipment. The process ensures tight tolerances, sterile production, and compliance with regulatory standards.

Plastic Injection Molding in the Robotic Industry

Plastic injection molding provides the robotic industry with the capability to produce high-quality, customized, and cost-effective components. The process offers design flexibility, scalability, and the ability to manufacture complex geometries, meeting the specific requirements of robotic systems in terms of performance, durability, and functionality. Commonly in robot housings and enclosures, grippers and end effectors, sensor housings, internal components.

2. Metal Injection Molding

What Is MetalInjection Molding?

Metal Injection Molding (MIM) combines plastic injection molding with powdered metals to produce precise, intricate metal parts. It’s versatile but has higher tooling costs and longer lead times compared to plastic injection molding. Nonetheless, it’s valuable for producing high-performance, complex metal components.

Benefits ofMetal Injection Molding

Complex Design

MIM is a manufacturing process that can be used to produce metal parts in large quantities, even those with complex geometries and intricate details. This process is best suited for the production of small and precise parts in high volumes, with strict tolerances.MIM is capable of accurately producing internal and external threads, undercuts, teeth (such as gear teeth), slots, holes, fins, markings, and engravings without requiring additional machining or fabrication processes.

High Quality

MIM allows for a variety of shapes and produces parts with comparable strength and hardness to machined wrought alloys. MIM can fabricate multi-component parts as a single piece and provide an excellent surface finish.

Cost-Effective Price

MIM can be performed on a wide range of metals, which include:Stainless Steel Carbon Steel,Copper Alloys,Nickel Alloys,Tungsten Alloys,Titanium Alloys,Cobalt Alloys,Iron,Carbide,Cermet,etc. Metal Injection Molding (MIM) is a manufacturing process that is known for generating less waste and scrap in comparison to traditional machining processes. This is especially beneficial for expensive materials such as refractory materials, titanium alloys, superalloys, and specialty metals. Through MIM, up to 98% of the material can be converted into usable metal parts, making it an efficient process. Moreover, MIM is a cost-effective alternative to long-term machining, investment casting, and stamping.

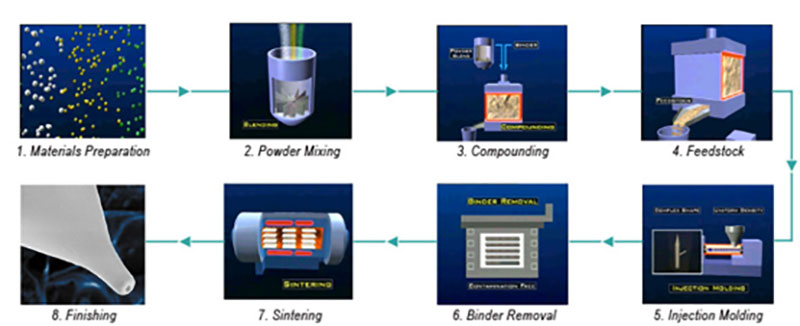

How Does Metal Injection Molding Work?

Metal Injection Molding (MIM) is a process that combines plastic injection molding with powdered metals to create complex metal parts. The process involves feedstock preparation, injection molding, cooling and solidification, ejection, debinding, sintering, and post-processing. MIM offers design flexibility, cost efficiency, and the ability to produce high-precision metal parts with excellent mechanical properties.

Surface Finishingof Metal Injection Molding

Surface finishing is a crucial step in the metal injection molding (MIM) process to improve the appearance, functionality, and performance of the final metal parts. Various surface finishing techniques are used in MIM:

CNC Machining

CNC machining like milling, turning, drilling, and grinding achieves precise dimensions, smooth surfaces, and specific features on MIM parts. It’s used for tight tolerances, critical geometries, and post-processing modifications.

Polishing

Polishing enhances the MIM part’s appearance by removing imperfections and creating a smooth, reflective surface using abrasive materials, buffing wheels, and polishing compounds.

Electroplating

Electroplating enhances MIM parts by depositing a thin layer of metal onto them. The process involves immersing the parts in an electrolyte solution containing metal ions and applying an electric current. Common metals used for electroplating include nickel, chrome, gold, and silver.

Heat Treatment

Heat treatment enhances the mechanical properties of MIM parts by subjecting them to controlled heating and cooling cycles, modifying their surface characteristics, appearance, hardness, strength, and dimensional stability.

Ceramic Injection Molding

What Is Ceramic Injection Molding?

Ceramic injection molding is a precise and advanced technology used to develop high-quality components in large quantities. Ceramic parts are more durable and resilient than plastic or steel parts, making them ideal for numerous applications. Ceramic injection molding (CIM) is a process used to create custom ceramic parts. It is similar to the injection mold process used for plastics. The process involves pre-heating a pelletized blend of Alumina powder and certain binders, which is then forced under high pressure into a custom-made mold to form parts according to the customer’s specific design. After the part is removed from the mold, it undergoes several additional processes, including sintering at high temperatures.

How Does Ceramic Injection Molding Work?

The Ceramic Injection Molding (CIM) process involves combining solids through injection molding and sintering techniques to produce complex shapes using hard materials that are too difficult, expensive, or impossible to produce using conventional methods. The CIM process involves several steps:

1. Injection Molding Tool

The injection molding tool is designed and built with CAD/CAM technology to ensure that the ceramic part is manufactured exactly according to the CAD drawings.

2. Raw Material Preparation

The ceramic powder is selected based on the customer’s requirements, including the grain size, shape, and distribution. Special binders and additives are mixed with the powder under monitored conditions to ensure the resulting mixture is ready for injection molding. Recording the properties of the resulting raw material precisely as part of quality control and batch tracing.

3. Injection Molding

Purpose-built injection molding machines fill molds with raw material in a fully automated process that ensures uniform consistency. Statistical process control (SPC) collects process data.

4.Controlling

Cutting costs and raising quality, innovative monitoring techniques allow real-time monitoring of opaque materials’ interior properties during molding.

5.Thermal Treatment

The binder is removed from the preform through evaporation and an exothermic reaction, leaving a small fraction behind. Parts are sintered in an oxidizing/reducing atmosphere or vacuum. Injection Molded parts can undergo hot isostatic pressing (HIP) to increase density and strength.

6. Post-Processing

Post processing methods can achieve higher surface quality and precision than sintering while maintaining exceptional tolerances at economical prices.

7. Final Inspection

During the design phase, NOBLE collaborates with customers to establish control and evaluation criteria. State-of-the-art measuring technology is utilized to ensure that the manufactured parts meet technical specifications.

Benefits of Ceramic injection molding

Ceramic injection molding, like any other manufacturing process, has its own set of pros and cons. One of the major advantages of this process is its ability to produce intricate geometries with high precision and accuracy. This makes it an ideal choice for applications that require tight tolerances. Moreover, ceramic parts manufactured through injection molding are often more robust and durable than those produced through other methods.

Ceramic Injection MoldingMaterials

Usually, a mixture of ceramic powder and a binder material is utilized in ceramic injection molding. The ceramic powder is held together and given the necessary strength to be moulded by the binder substance. Wax, thermoplastic polymers, and thermosetting polymers are examples of common binder materials. The particular needs of the item being made, such as the required strength, flexibility, and temperature resistance, determine the binder material selection. Debinding is the process of removing the binder material from the ceramic portion after it has been moulded, leaving only the pure ceramic part.

Ceramic Injection Molding Surface Finishing

Different surface finishes can be applied to custom ceramic injection molding parts to enhance both their practical performance and aesthetic appearance.

| Surface Finishes | Pictures | Process Description | Advantages |

| PVD (Physical Vapor Deposition) |  |

PVD stands for Physical Vapor Deposition. It is a process that involves the deposition of a thin film of material onto a substrate using physical means such as evaporation or sputtering in a vacuum environment. | PVD produces thin films with a high degree of uniformity in thickness and composition, making it useful for applications that require precise coatings. |

| Plating |  |

Electroplating is a process of depositing a thin layer of metal onto a conductive surface by means of an electrochemical reaction. | Electroplating produces a highly durable and wear-resistant coating that can protect the substrate from corrosion and other forms of damage. |

| Powder Coating |  |

Powder coating is a type of coating that is applied as a free-flowing dry powder and then sprayed onto a surface. The powder is cured by heating it to a temperature that causes it to melt and then bond to the surface. | Powder coatings are highly durable and resistant to scratches, chipping, and fading. They can withstand exposure to harsh weather conditions, chemicals, and UV radiation, making them ideal for outdoor applications. |

| Brushing |  |

Brushing is a surface finishing process that involves using a brush or abrasive material to create a pattern of fine lines or scratches on a metal surface. | Brushed finishes are highly durable and can withstand exposure to harsh environments, making them a popular choice for applications such as industrial equipment and architectural elements. |

| Chemical Etching |  |

Chemical etching, also known as chemical milling or photochemical machining, is a surface finishing process that involves using chemicals to selectively remove material from a metal surface. | Chemical etching allows for extremely precise patterns and shapes to be etched onto a metal surface, with tolerances as low as a few microns. This level of precision makes it ideal for producing complex parts or components with intricate designs. |

| Laser Marking |  |

The laser beam causes a reaction in the surface of the material, resulting in a permanent mark that can be customized to meet specific design requirements. | Laser marks are highly durable and resistant to wear, fading, and other types of damage. This makes laser marking ideal for applications that require long-lasting marks, such as branding, identification, and traceability. |

| Polishing |  |

Polishing is the process of smoothing and refining a surface by using an abrasive material to remove small amounts of material. | The purpose of polishing is to create a smooth and reflective surface, enhance the appearance of the surface, and improve its resistance to wear and corrosion. |

What Is Overmolding?

Over-molding is a widely used process in manufacturing industries. It involves injection molding or urethane casting to make high-quality prototypes. This technique helps mold two or more layers of material together, which is beneficial for plastic and rubber over-molding. It is particularly useful for rapidly manufacturing prototypes of industrial machine parts and creating custom parts by overlaying plastic or rubber with other materials such as metals.

How does Overmolding Work?

Overmolding is the process of joining two or more materials to create a single machine part or component. The first component is the substrate, which is the base material, and the second component is the overmold, which is the secondary material that is molded over the substrate. There can be multiple over molds depending on the desired end product.

Materials of Overmolding

These are common molded plastics offered by our injection molding services. After knowing the basics of materials such as common grades, brands, advantages, and disadvantages, choose the appropriate injection molding material according to your application requirements.

Tooling Materal:

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

| Tool Steel: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

| Stainless Steel: | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

| Aluminum: | 6061, 5052, 7075 |

Plastic Materials:

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

| UV | absorbers | Colorants |

| Flame | retardants | Glass fibers |

| Plasticizers |

Advantages of Overmolding

Overmolded components offer reliable product performance by tightly connecting and protecting themselves from moisture and dust. By combining the excellent properties of multiple materials into one, over-molded components ensure better performance.

Additionally, over-molding helps to reduce overall manufacturing costs by combining multiple parts into one, eliminating the need for assembly and saving time and labor costs.

Moreover, over-molding enhances design and aesthetics by adding one material to another. It allows for various design optimizations and surface machining improvements.

Applications of Overmolding

Overmolding in Medical Instrument

Overmolding is critical to satisfying precision and safety,withstanding sophistication and storage in medical devices.Overmolding combines plastics and metal into one product.The common usage in surgical instruments, like syringes,dilators,soft-touch and more.

Overmolding in Hardware tools

Overmolding Improved the grip of hardware tools, making them safer and more ergonomic. Excellent examples are screwdrivers, pliers, wrenches, blades, and more.

Overmolding in Car Trims

The overmolding’s aesthetic advantages are fully reflected in the application of car trims.Such as the door edge, side body, fender, bumper, wheel, and others. These not only reduce the weight of the car but also facilitates the customization of multiple colors in cars.

Overmolding in Household items

Overmolding could improve grip, cleanliness, chemical resistance, and more in products. Overmolded products also improve the consumers’ quality of life. They are easy to use, clean, and prolong the shelf life. Like kitchen utensils, multi-port chargers, toothbrushes, and the like.

Insert Injection Molding Process

What is Insert Molding Process?

Injecting plastic materials around another part to create a new one is called insert molding. As is customary, the inserted component may be made of metal or plastic. The insert is inserted into the mold beforehand in the insert molding process, and the machinist then uses a thermoplastic resin to inject plastic into the cavity. Parts are ready to be packaged and shipped to clients once they have cooled.

How Does Insert Injection Molding Work?

Insert molding is a process that is very similar to conventional injection molding. In this process, molten raw materials or plastic are melted and injected into a mold, using the same materials that are used in conventional plastic molding. The main difference between conventional injection molding and insert molding is that in the latter, inserts are added to the mold during the molding process.

Materialsof Insert Injection Molding

Thermoplastics

Reusable and chemically resistant, these materials are eco-friendly and ideal for achieving variance and sheen in insert molding. Types of thermoplastics include

wPolystyrene

Polystyrene is a lightweight, thermoplastic material that is transparent and has low melting point. Its high resistance to acids and bases makes it suitable for a wide range of applications, including medical devices and consumer goods.

wPolyethylene

This variant of the thermoplastic polymer is usually lightweight and has high toughness asides from its resistance to the chemical. It has dielectric and impermeability properties. Common polyethylene thermoplastic materials include LDPE, HDPE, and MDPE..

wNylon

This tough thermoplastic polymer is resistant to chemicals and abrasions. Its high melting point makes it a great replacement for metal in many applications. It’s widely used in heavy-duty manufacturing and extraction products.

Thermosets

Thermosets are non-recyclable plastic polymers, making them less eco-friendly and cost-effective than thermoplastics. Manufacturers tend to avoid using them. Examples of thermosets include:

wEpoxy

This is a variant of thermosets that hardens/solidifies permanently after processing without a melting point. Consequently, it makes them very suitable for challenging uses. They have excellent adhesion and high resistance to chemicals and heat.

wPhenolic

Phenolic is a thermosetting material with high resistance to chemicals and electricity. It can withstand heat and possesses exceptional hardness and dimensional stability. Phenolic resins are suitable for making electrical equipment, circuit boards, and more.

Advantages of Insert Molding Process

Insert molding is a process that combines various materials, such as metal and plastics, to produce a single component. The resulting product has enhanced mechanical properties and improved durability. There are several advantages to using insert molding:

No assembly

No assembly is required: Since the materials are combined during the molding process, there is no need for additional assembly steps. This speeds up the production process and reduces labor costs.

Increased efficiency:

The absence of assembly also contributes to increased production efficiency.

Improved durability

The plastic injected around the parts in insert molding enhances the strength of engineering plastics, making them more resistant to wear and tear. The strength and conductivity of metallic materials are also utilized, resulting in final parts with improved properties.

Reduced weight

The combination of plastic and metal in the final component results in a lower weight compared to corroding metal parts.

Applications of Insert Injection Molding

Insert Injection Molding in Medical Devices

Biocompatible plastics are widely used in insert molding to produce medical devices.

Insert Injection Molding in Aerospace and Automotive

Insert molding parts’s durability is suitable for handheld devices, like truck shifter Levers, dials, and knobs, etc.

Insert Injection Molding in Hardware tools

Overmolding Improved the grip of hardware tools, making them safer and more ergonomic. Excellent examples are screwdrivers, pliers, wrenches, blades, and more.

Insert Injection Molding in Consumer Products

Insert molding is a good way for consumer products to design and develop new products for its functional and aesthetic benefits.

Injection Molding Tooling

What is Insert Injection MoldingTooling?

Injection mold tooling is the process of designing and manufacturing molds used in injection molding. The mold consists of two halves, the core and the cavity, which fit together precisely. Molten plastic is injected into the cavity, where it cools and solidifies to form the final product.

How Does Injection Molding Tooling Work?

Injection molding tooling is a crucial part of the injection molding process. It is responsible for shaping and producing plastic parts. The tooling process begins with design and engineering, where a 3D CAD model of the mold is created. During this stage, factors such as part geometry, material flow, cooling channels, and mold construction are taken into account.The injection molding tooling process involves designing and engineering a mold, manufacturing its components, assembling and finishing the mold, and conducting testing and validation. The mold base provides structural support, while the core and cavity shape the part. Cooling channels regulate temperature, and the injection and ejection systems facilitate material injection and part removal. Expertise and maintenance are crucial for successful tooling, which ultimately influences the quality and efficiency of the injection molding process.

Materialsof Injectio Molding Tooling

The choice of mold material largely determines its life and the quality of the injection molded part. NOBLE provides a diverse selection of material grades that cater to various stages of your product development. Our team also offers expert guidance on mold material selection to ensure optimal dimensional accuracy and aesthetic quality.

Tool Steel

Before starting the injection molding process in small or large batches, a CNC machined tool with high tolerances is necessary. Tool steel is the most commonly used material in such cases.

| Types: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

Stainless Steel

Steel and stainless steel are the primary materials used to create injection molds, but their manufacturing costs are quite high. As a result, these molds are generally reserved for large-scale productions.

| Types: | 420, NAK80, S136, 316L, 316, 301, 303, 3 |

Aluminum

Aluminum molds are a cost-effective alternative to traditional steel and carbon steel injection molds. They not only cost less but also provide faster cycles and quicker turnaround times, which is especially useful for testing markets.

| Types: | 6061, 5052, 7075 |

Advantages of Injection Molding Tooling

Molds are widely used in the production process to improve material stability, reduce losses, and ensure product quality. Many industries have benefited from the versatility of molds, and injection molds offer several advantages. Below are some of the benefits of using injection molds.

Cost-effective

When selecting a mold for use in different industries, it is essential to make an informed choice. The cost of injection molding processing molds can be managed effectively by carefully selecting the mold production material. Plastic is the raw material used in injection mold production, which supports the production process of many products. The use of injection molds can also minimize material waste, leading to a steady reduction in production costs.

High Quality

Injection molding processing molds are widely used because of their high quality. The process is simple and does not involve any complicated operation, which ensures that there is no internal stress and guarantees the quality and sturdiness of the product during use. The production structure of the product is more stable, ensuring its safety of use.

Flexibility

Injection molding processing molds are versatile in their overall structure design, making them suitable for various industries with differing structural needs. A single set of molds can be used to alter both the material type and product color.

Environmentally friendly

Sustainability has always been a concern for society, so when a product is developed, environmental protection is considered. Injection molding is not only efficient but also environmentally friendly, as the parts used for testing or discarded can be recycled.

Applications of Injection Molding Tooling

Injection Molding Tooling in the Automotive Industry

Plastic injection molded parts have a flexible design, high durability, and long life, and their use in parts is very frequent in the automotive industry. Such as mirror housings, cup holders, bumpers, but also the entire dashboard.

Injection Molding Tooling in the Medical Industry

Plastic parts manufactured for the medical and pharmaceutical fields must follow more stringent guidelines. To meet these standards, manufacturers must use FDA or medical-grade resins and manufacture their parts according to ISO certification. Medical parts require a variety of chemical properties, such as high tensile strength and high-temperature resistance. Commonly used injection molded parts include testing kits, surgical preparation products, dental X-ray components, and many more.

Injection Molding Tooling in the Aerospace Industry

Our precision manufacturing services offer exceptional durability and accuracy, meeting the sophisticated requirements of various phases within the aerospace industry.

Injection Molding Tooling in the Robotic Industry

We offer top-notch services for prototyping and manufacturing robot parts at an industrial level, supporting the ongoing development of the robotics industry.

Liquid silicone rubber molding

What is Liquid silicone rubber molding?

Using liquid silicone as the raw material, liquid silicone is injected into the mold using an injection molding machine, and after additional steps involving heating and cooling, the finished product is created. In comparison to solid silicone, the liquid silicone is odorless, safe, and ecologically friendly. It is often referred to as liquid silicone rubber. Liquid silicone injection molding is a straightforward process; it does not require the manual steps of solid silicone processing, such as dosing, refining, cutting, and laying out, which call for manual product handling or even a completely automated production line without human involvement.

How does Liquid silicone rubber molding work?

LSR parts are manually removed from the mold, so ejector pins are not built in. The mold is made using CNC machining for high-temperature durability. It is then hand-polished to meet customer requirements, and six surface finishes are available. The mold is loaded into an advanced LSR-specific injection molding press that is precisely calibrated to ensure consistent parts. LSR is a thermosetting polymer, so once molded, it cannot be melted again. Parts are boxed and shipped immediately after production.

![]()

Materialsof Liquid silicone rubber molding

wStandard Silicone (30, 40, 50, 60, and 70 durometers)

wMedical-Grade Silicone

wOptical-Grade Silicone

wFluorosilicone (fuel and oil resistant)

Advantages of Liquid silicone rubber molding

High Precision

LSR’s flow characteristics make it perfect for molding intricate, smaller, and tighter tolerance parts compared to other materials.

More Availabile

The unique molecular structure of LSR makes it highly versatile for various applications. Unlike other materials, LSR does not produce any by-products. And due to its strong bonding between silicon and oxygen atoms, it cannot be recycled or broken down easily like other thermoplastics. This strength also allows LSR to withstand high temperatures without degrading. Its purity and chemical inertness, along with its ability to endure sterilization, make it an excellent option for medical devices, food applications, and baby care products.

More Efficient

Compared to plastics, LSR molding cycle time is much shorter, often measured in seconds instead of minutes. This makes LSR a more suitable option for fulfilling large orders in a timely manner.

Ecologically Friendly

During the LSR manufacturing process, the material is contained within a closed system, ensuring that the operator does not come into contact with it and is not exposed to the environment. This effectively prevents any environmental contamination.

Applications of Liquid silicone rubber molding

Liquid silicone rubber is a versatile material used in various industries. In the automotive industry, it’s used for engine parts, windshield wiper blades, and air conditioning ventilation mats. In the medical industry, it’s used for biotechnology components, catheters, and respiratory masks. In aerospace, it’s used for cockpit and landing module seals, high-altitude photography module seals, and oxygen masks. In the consumer products industry, it’s used for kitchen utensils, shower heads, electronic devices, and bottle dispensers.

Materials for Injection Molding

Tooling Materal:

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

| Tool Steel: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

| Stainless Steel: | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

| Aluminum: | 6061, 5052, 7075 |

Plastic Materials:

Plastic injection molding servicecomes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

| UV | absorbers | Colorants |

| Flame | retardants | Glass fibers |

| Plasticizers |

Surface Finishes of Injection Molding

Injection molding includesinjection mold tooling,plastic injection molding, and more. The surface treatment of the mold is usually completed during the production process. After the injection molding is completed, we will carry out certain surface treatments on the finished product as per your requirement.

| Pic | Name | Description |

| Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | |

| Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | |

| Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. | |

| Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

Advantages of Injection Molding

Injection molding is widely considered the best option for mass-producing plastic parts. It is a popular choice among manufacturing companies worldwide due to its ability to produce precision parts. Engineers at NOBLE have identified six key advantages of using injection molding technology:

Efficiency

The mold injection process is highly efficient, allowing large orders to be produced quickly.

Superior detail

Injection molding is one of the most affordable ways to manufacture large quantities of parts, especially for bigger production runs. Although designing and creating the mold can take time, the process then becomes very affordable and efficient.

High accuracy

Injection molding technology ensures high accuracy in the production of parts.

Affordability

Fast and efficient production ensures a low cost per part, while high production volumes produce further economies of scale. Aluminum, a cost-effective and readily available material, can be used for injection mold tools to control costs.

Various material options

Injection molding allows for the use of various materials, including those with fillers that can improve tensile strength.

High-volume productio

Injection molding with steel molds can facilitate the production of parts in the millions.

Ready-to-go finish

With the proper treatment, injection-molded parts come out of the mold with a smooth finish that requires no further refinement.

What are the Disadvantages of Injection Molding?

Injection molding has several drawbacks that need to be considered. Firstly, it requires a significant upfront investment due to the high cost of custom molds, which can make it challenging for small businesses. Secondly, the process has lengthy lead times, which can be a drawback when quick production is needed. Thirdly, injection molding has limited design flexibility, especially for complex parts, and may require additional mold features. Fourthly, material options are limited primarily to thermoplastics, and specialized materials can be costly. Fifthly, injection molding is most cost-effective for high-volume production, making it less suitable for low-volume runs. Lastly, the process generates waste and has environmental considerations. It is important to carefully evaluate these disadvantages against the specific requirements of a project to determine the most appropriate manufacturing method.

How NOBLE uses injection molding to save material?

Injection molding can be optimized to save material by implementing certain strategies and practices. Here are some ways to use injection molding to save material:

- Design optimization: Careful part design can help reduce material waste. Consider designing parts with uniform wall thickness and minimal features that require excess material. Avoid unnecessary thick sections or excessive fillets that can increase material usage. Utilize features like ribs or gussets to add strength without adding excessive material.

- Mold filling analysis: Conducting mold filling analysis using simulation software can help optimize mold design and process parameters. This analysis allows for identifying potential issues such as inadequate filling or excessive pressure, enabling adjustments to optimize material flow and reduce material waste.

- Gating and runner design: Proper gating and runner design are crucial for material efficiency. Use appropriate gate locations and sizes to ensure efficient material flow while minimizing gate vestige. Optimize runner layouts to reduce the volume of material trapped in runners, minimizing waste.

- Regrind usage: Implementing a regrind system allows for the recycling and reuse of plastic waste generated during the injection molding process. Regrind can be mixed with virgin material in controlled proportions, reducing the overall material consumption.

- Process optimization: Fine-tuning the injection molding process parameters can help achieve optimal material usage. Adjusting parameters such as injection speed, pressure, and temperature can help minimize material waste and improve part quality.

- Proper maintenance: Regular maintenance of molds and equipment is essential to ensure consistent and efficient operation. Properly maintained molds help avoid issues such as excessive flash or part defects that can result in material waste.

- Material selection: Choosing the most appropriate material for the application can also contribute to material savings. Opt for materials with high strength-to-weight ratios or those specifically designed for lightweight applications.

By implementing these strategies, injection molding can be utilized to save material, reduce waste, and improve overall sustainability in the manufacturing process. It is important to consider these factors during the design phase and continuously monitor and optimize the injection molding process for maximum material efficiency.

Injection Molding Applications

Injection molding is a widely used manufacturing process for producing plastic parts and products. It involves injecting molten plastic material into a mold cavity and allowing it to cool and solidify, resulting in the desired shape. Injection molding offers several advantages, including high production efficiency, repeatability, and the ability to create complex geometries.

There are numerous applications for injection molding across various industries. Some common examples include:

Injection Molding in the Automotive industry:

Injection molding is extensively used in the automotive sector for manufacturing components such as interior panels, dashboard parts, door handles, bumpers, and various other plastic parts.

Injection Molding in the Aerospace industry

Injection molding is utilized in aerospace applications for producing lightweight and durable components such as interior trim, brackets, knobs, and housings.

Injection Molding in the Medical and healthcare

Injection molding plays a crucial role in producing medical devices and equipment like syringes, vials, IV components, surgical instruments, and disposable items.

Injection Molding in the Consumer goods

Many consumer products are produced using injection molding, including electronic housings, appliance components, packaging containers, toys, and kitchenware.

Injection Molding in the Electronics industry

Plastic enclosures for electronic devices, connectors, switches, and other electronic components are often manufactured using injection molding.

Injection Molding in the Industrial equipment

Various industrial components like gears, handles, housings, and machine parts are produced through injection.

Why Choose Us For Custom Injection Molding Services

NOBLE is a Sino-British joint venture awarded by the government as a”National High-tech Enterprise”.We are a comprehensive entity enterprise with the ability of independent R&D, production, and sales.

More than 10 years of professional CNC machining and rapid prototyping experience. We provide project supporting services including precision parts machining and manufacturing. We can help customers optimize designs, choose appropriate processes, reduce costs, and achieve rapid mass production. Our project supporting services focus on medical, automotive, robotics and other fields and provide customers with project supporting services including parts machining and manufacturing.

Our injection molding service could benefit you:

Increased Productivity

A component can be produced an unlimited number of times using the same mold. The material can be changed to achieve the same geometry with unique properties and usefulness.

Consistency and High Quality

Owing certified factories, conducting in-process inspections and dimensional verification after production, guarantee the custom molded parts are consistent in quality regardless of the complex shape with high precision.

Comparatively Cheaper Productions

Productions can be made at a low cost with injection molding. Given that the entire process is automated, very little human intervention is necessary. Thus, companies and entrepreneurs can improve their startups and enterprises by utilizing our affordable services.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your overmolded parts as fast as possible.