What is Magnesium Alloy CNC Machining

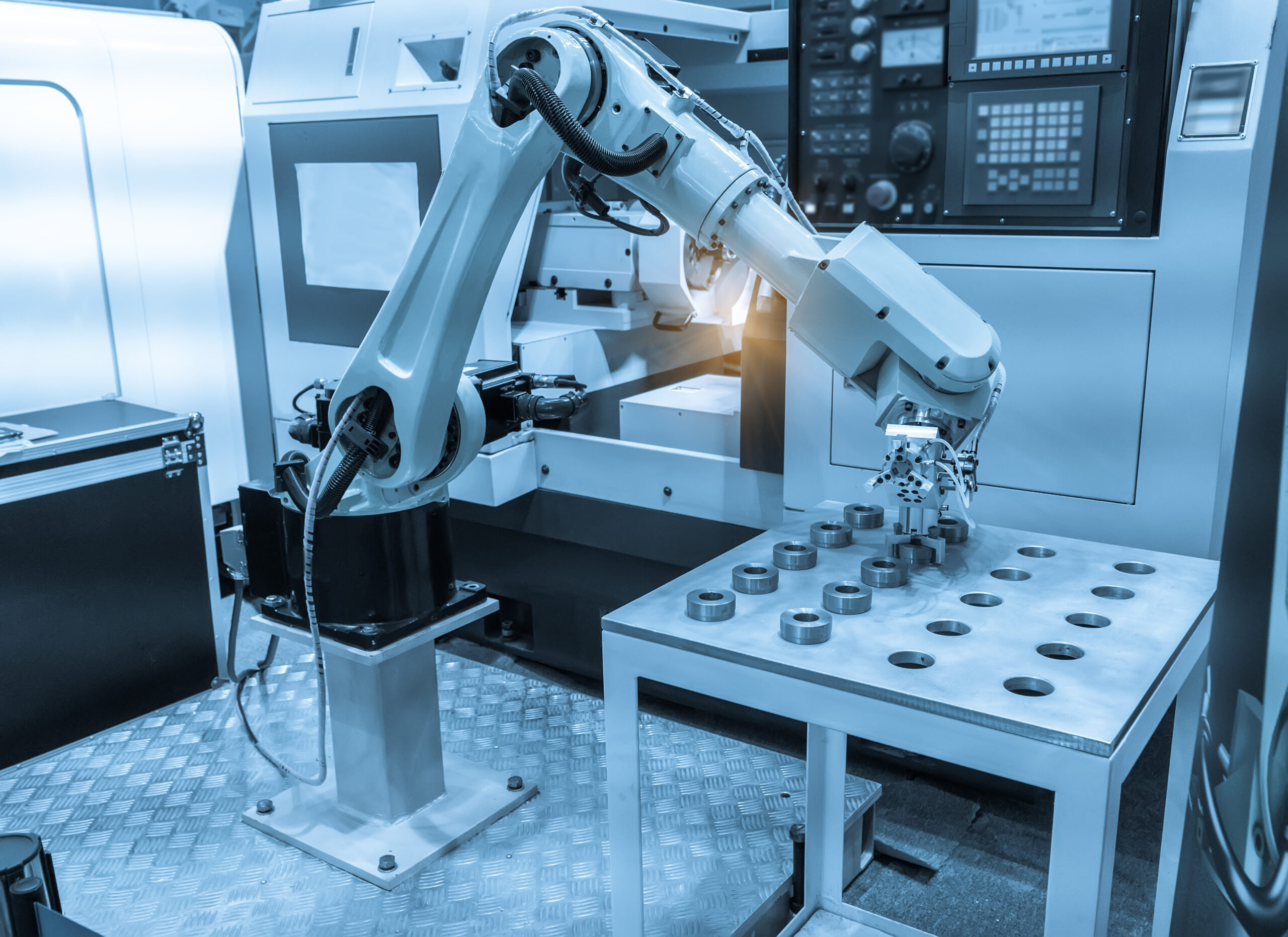

Magnesium Alloy CNC Machining refers to the process of using computer-controlled machine tools to cut, shape, and finish components made from magnesium-based alloys. This method allows for precise, repeatable, and efficient manufacturing of lightweight magnesium parts used in industries like aerospace, automotive, medical, and electronics.

Advantages of CNC machining magnesium alloys

Although CNC machining of magnesium alloys is very risky, as long as we follow safety guidelines, magnesium alloys are CNC machining materials. Most importantly, magnesium alloys are ideal materials for CNC machining due to their lightweight properties, excellent surface finish, and superior machining performance.

1. Lightweight Material:

Magnesium is the lightest structural metal used in machining, with a density about two-thirds that of aluminum. This makes it ideal for components where weight reduction is critical (e.g., aerospace, automotive).

2. Excellent Machinability:

Magnesium alloys have low cutting forces and good chip formation, making them easy and fast to machine. They cause less tool wear compared to harder metals like titanium or stainless steel.

High-speed machining is possible, reducing cycle times.

3. High Strength-to-Weight Ratio:

Despite being lightweight, magnesium alloys offer good mechanical strength, especially for non-load-bearing structural components.

4. Good Thermal and Electrical Conductivity:

This property makes magnesium suitable for electronic housings, heat sinks, and thermal management components.

5. Excellent Surface Finish:

CNC-machined magnesium components often require minimal post-processing due to the smooth surface finish produced during machining.

6. Recyclability:

Magnesium is highly recyclable, which makes it an environmentally friendly choice for sustainable manufacturing practices.

7. Vibration Damping:

Magnesium alloys have good damping capacity, which helps reduce noise and vibration in mechanical systems, improving performance and comfort in end-use applications (e.g., automotive dashboards, aerospace panels).

8. Compatibility with Coatings:

Magnesium surfaces are highly receptive to surface treatments (anodizing, painting, electroplating), which enhance corrosion resistance and aesthetic finish.

9. Shorter Cycle Times:

The combination of fast material removal rates and lower tool wear allows for shorter production times, leading to increased productivity in CNC operations.

Risks and Solutions in Magnesium Alloy Machining

🔥1. Fire and Explosion Hazard

Magnesium is highly flammable, especially in the form of fine chips, dust, or powder.

Dry machining, high spindle speeds, or poor chip removal can increase fire risk.

Magnesium fires burn at very high temperatures and cannot be extinguished with water—doing so may cause violent reactions.

Corresponding solutions:

Use non-flammable cutting fluids (avoid water-based coolants unless specifically approved).

Keep a Class D fire extinguisher (metal fire type) nearby.

Design for efficient chip evacuation and minimize dust accumulation.

Use wet machining when appropriate, or maintain proper ventilation and chip collection systems.

Ever use water to put out a magnesium fire? When a magnesium fire occurs during magnesium processing, it is not recommended to use water to put out the fire. This is not ideal because using water will only make the fire more severe.

🛠️2. Tool Wear and Damage

While magnesium is easy to cut, improper tool selection or excessive feed/speed can cause buildup or galling, leading to premature tool wear or surface damage.

Corresponding solutions:

Use sharp carbide or coated tools.

Optimize cutting parameters (low feed and moderate speed) for clean cuts.

🌬️3. Dust Generation and Respiratory Risk

Machining can create fine airborne particles that pose respiratory risks and increase fire danger.

Corresponding solutions:

Use proper ventilation and dust extraction systems.

Equip operators with appropriate respiratory PPE in poorly ventilated environments.

🌧️4. Corrosion Susceptibility

Magnesium alloys are more prone to corrosion than aluminum or stainless steel, especially in moist or salty environments.

Corresponding solutions:

Apply protective coatings, anodizing, or passivation after machining.

Minimize exposure to moisture during storage and handling.

⚖️5. Dimensional Instability

Magnesium has a high coefficient of thermal expansion, meaning it can distort with heat buildup during machining.

Corresponding solutions:

Use coolants or controlled cutting strategies to minimize heat.

Allow for post-machining aging or stress relief processes if precision is critical.

🧩6. Limited Alloy Selection

Not all magnesium alloys are suitable for every application; some have limited mechanical strength or poor corrosion resistance.

Corresponding solutions:

Select the right alloy based on application (e.g., AZ31, AZ91, AM60 for general use).

Not all magnesium alloys are suitable for every application; some have limited mechanical strength or poor corrosion resistance.

Corresponding solutions:

Select the right alloy based on application (e.g., AZ31, AZ91, AM60 for general use).

⏱️7. Short Tool Life in Inappropriate Conditions:

If incorrect machining parameters are used, magnesium may cause vibration or chatter, reducing tool life and affecting finish quality.

Corresponding solutions:

It is best to use carbide tools because they maintain hardness even at high temperatures, extending service life and reducing the possibility of sparks causing ignition.

✅Summary of Risk Solutions for Magnesium Alloy Machining

| Risks | Solution Strategies |

| Fire hazard | Use Class D extinguishers, chip control, and non-water coolants |

| Dust & explosion | Use extraction systems, PPE, and proper housekeeping |

| Corrosion | Apply coatings and store properly |

| Tool wear | Use sharp tools, correct feeds/speeds |

| Dimensional instability | Manage heat, use coolants |

| Respiratory exposure | PPE + good ventilation |

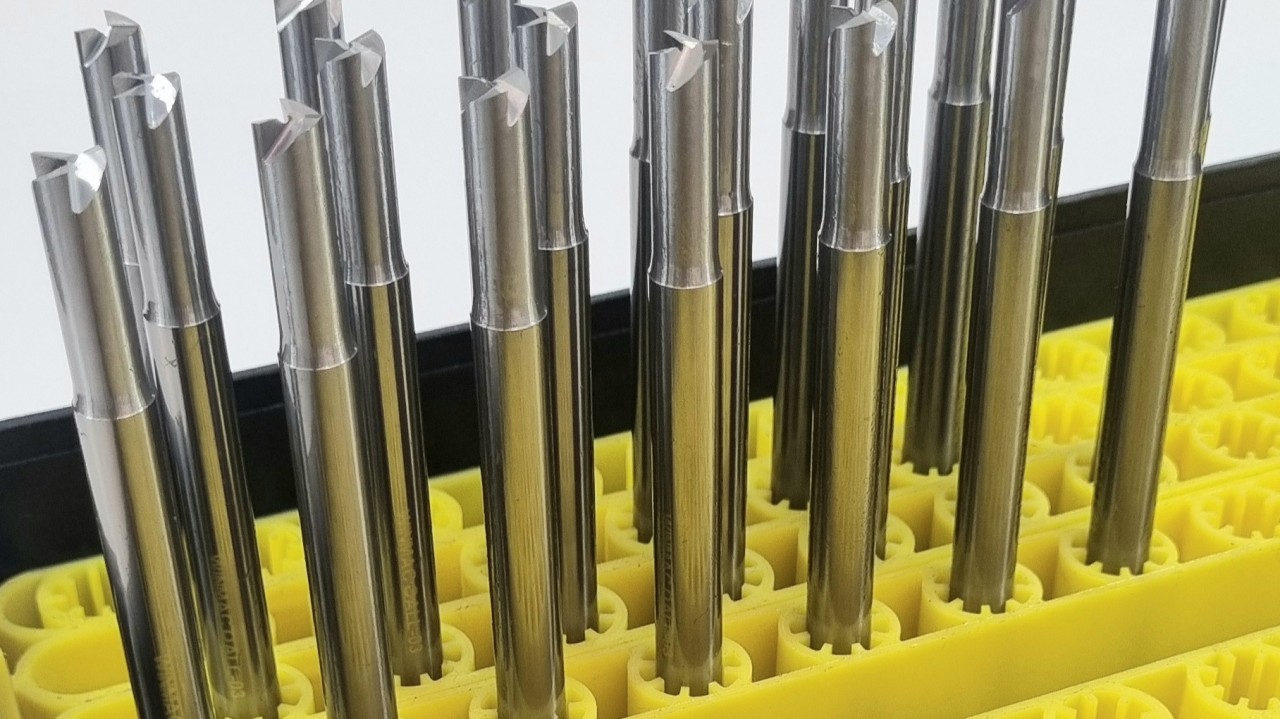

Selection of tools for machining magnesium alloys

Selecting the right tools for machining magnesium alloys is critical to achieve high-quality results, maintain safety, and maximize efficiency. Magnesium is relatively soft and easy to machine, but tool selection must still account for its unique characteristics, especially its flammability and tendency to gall or form built-up edges under poor conditions.

1. Tool Material:

| Tool Material | Suitability | Notes |

| Carbide (Cemented Carbide) | ✅ Excellent | Best choice for high-speed machining, excellent wear resistance |

| High-Speed Steel (HSS) | ✅ Good (for low-speed work) | More affordable but wears faster |

| Coated Carbide (TiAlN, TiN, DLC) | ✅ Excellent | Reduces friction and wear, improves heat resistance |

| Polycrystalline Diamond (PCD) | ✅ Excellent (for finishing) | Ideal for high-precision or abrasive operations |

Note: Magnesium’s low hardness allows a broad range of tooling, but sharpness and edge integrity are crucial to prevent chip welding and smearing.

2. Tool Geometry

- Sharp Cutting Edges: Prevents material smearing and reduces heat.

- Large Rake Angles (Positive Rake): Enhances chip formation and reduces cutting forces.

- High Helix Angles: Improves chip evacuation in drilling and milling.

- Large Relief Angles: Helps minimize tool rubbing and friction.

- Polished Tool Surfaces: Reduces chip adhesion and improves surface finish.

3. Tool Geometry

- CNC Turning: Carbide inserts with positive rake, sharp edges

- CNC Milling: Solid carbide end mills, high-helix design

- CNC Drilling: Split-point HSS or carbide drills, peck drilling strategy recommended

- CNC Tapping: Spiral-point taps, preferably HSS with good chip evacuation design

- CNC Boring: Sharp carbide boring bars with high clearance angles

4. Cutting Fluids / Lubrication

-

-

-

Dry Machining is common for magnesium due to its low cutting resistance

-

Use an air blast or inert gas to remove chips and cool tools

-

If lubrication is necessary, use non-water-based, fire-resistant fluids (e.g., mineral oil-based or ester-based coolants)

-

-

5. Tool Wear Monitoring:

Magnesium causes relatively low tool wear, but built-up edges can still form.

Watch for surface roughness or increased cutting temperatures—these may signal dulling or improper chip removal.

6. Magnesium machining compared with other materials:

| Metal | Turning Rough | Turning Finish | Milling 100 mm miller 1 mm cut | Drilling (5-10 mm drill) m/min | |

| Magnesium | Up to 1200 | 1800-2400 | 200-500 | 150-500 | |

| Cast Iron | 30-90 | 60-120 | 15-20 | 10-40 | |

| Aluminum | 75-750 | 120-1200 | 200-300 | 60-400 | |

| Steel | 40-200 | 60-300 | 20-25 | 15-30 |

Magnesium alloy is the lightest metal structure material, specific gravity is only 1.8, respectively, aluminum 2/3 and iron 1/4, but the strength is as high as 133, no less than aluminum, with strong anti-shock, anti-electromagnetic, thermal conductivity, electrical conductivity, and other excellent performance, and can be fully recycled without pollution.

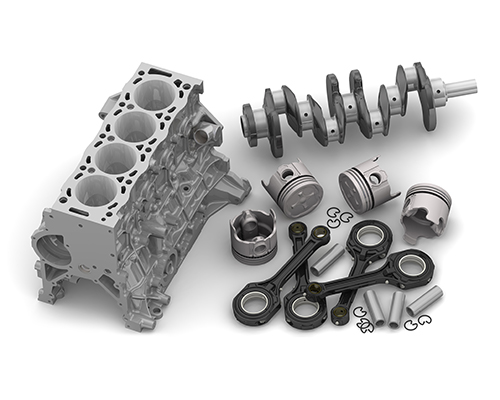

Magnesium alloy, as the lightest metal material, coupled with its high specific strength degree, good vibration dissipation, and the ability to withstand impact loads better than aluminum alloy, to aerospace brings huge weight reduction benefits and significant improvement in the combat performance of aircraft to aerospace. Commonly used in aircraft landing gear, hatch, reinforcement, engine parts, propeller, direct structure, etc.

Electronic products and transportation, and other areas that require lightweight materials also play a significant role. Magnesium alloy material 3C electronic product quality is lighter, glossy, and good coloring, and can meet people’s personalized aesthetics of the product; at the same time, recyclability also meets the requirements of today’s society on environmental protection. At present, in addition to the production of notebook computers, Walkman, and digital cameras using a magnesium alloy, most of the three major products in military computers, communications equipment such as cell phones, televisions, plasma displays, hard disk drives, advanced audio-visual equipment and equipment, audio-visual equipment, LED and another lighting has also been well used.

The good biocompatibility and degradability of magnesium alloy make it a hot spot to be studied in the medical field, attracting the attention of more and more researchers at home and abroad. Magnesium is one of the common trace elements in the human body, which is involved in almost all metabolic processes in the human body. Its good mechanical properties, very close to the elastic modulus of human bone, can reduce the adverse reaction caused by the mismatch of elastic modulus between the implant and human bone, thus promoting the healing of bone tissue. It is biodegradable and avoids the pain and mental stress of secondary surgical removal of the magnesium alloy.

Putting all these properties together creates an environmentally friendly material that is lighter, stronger, and more widely used than aluminum.

Where does magnesium & magnesium alloy come from?

Magnesium is one of the ten most widely distributed elements in nature (magnesium is the eighth most abundant element in the Earth’s crust, accounting for about 2% of the mass, and is also the ninth most abundant element in the universe).

The current method of magnesium smelting has two main processes: an electrolytic method and the silicon heat method.

1. With ferrosilicon on the thermal reduction of magnesium oxide produced from carbonate ore by calcination, this method is called the thermal reduction method (also known as the Lijiang method). The Lijiang method is a more typical method of producing magnesium metal. The method requires raw materials such as dolomite ore, fluorite, silica ore, coke, and waste iron. In the production process, the dolomite ore will be calcined in the rotary kiln to produce albite, then it will be crushed, then the fluorite will be crushed, and the mixture of both will be put into the mixing ball, and the silica ore, coke, and scrap iron will be put into the electric arc furnace for reaction and then crushed to produce ferrosilicon powder, which will be put into the ball making machine with the mixture in the mixer, and then put into the reduction furnace and add the pellet containing ferrosilicon and fluorite. After the reduction reaction, magnesium crystals will be produced and then melted and purified to produce magnesium metal. The production time of this method is about 10 hours. Its process is divided into almost three stages, including the preheating period, the low vacuum heating period, and the high vacuum heating period.

2. From the spinel, brine, or seawater will contain magnesium chloride solution by dehydration or baking magnesium chloride melt, followed by electrolysis; this method is called electrolysis method; electrolysis method of magnesium refining principle is the electrolysis of molten anhydrous magnesium chloride at high temperature so that it decomposes into magnesium metal and chlorine gas. The electrolysis method is a very promising method of magnesium refining because of its advanced production process and low energy consumption. At present, more than eighty percent of magnesium metal in developed countries is produced by the electrolysis method. Magnesium alloys are formed by adding other elements to the refined magnesium metal. The most common magnesium alloys are plates, billets, rods, tubes, sheets, bars, and wires. They are then cut into different shapes and sizes and shipped to another company or manufacturer, who processes them into various products.

What kinds of magnesium alloy can be divided into?

As we all know, magnesium alloy is based on magnesium metal; through the addition of some other elements and the formation of the alloy, magnesium alloy added alloy elements are mainly AL, Zn, Mn, Si, x, Cu, Li, and part of the rare earth group elements and so on. Magnesium alloy can be classified according to the alloy composition but also according to the magnesium alloy processing methods and performance used to classify. Magnesium alloys can be divided into the following three.

1. According to the classification of magnesium alloy composition.

According to the chemical composition, based on the five main alloy elements Mn, Al, Zn, Zr, and rare piles of Earth, they can be divided into Mg-Mn, Mg-AL-Mn, Mg-Al-Zn-Mn, Mg-Zr, Mg-Zn-Zr, Mg-Re-Zr, Mg-Ag-Re-Zr, Mg-Y-Re-Zr.

2. According to the processing method of magnesium alloy classification.

Magnesium alloy, according to processing methods, can be simply divided into three categories: casting magnesium alloy, deformation magnesium alloy, and hot dip plating magnesium alloy. Among them, casting and deformation are commonly used in two categories. These two types of alloys have great differences in composition and metallurgical organization performance, casting magnesium alloy is mainly used for die-casting transportation equipment, machinery, electrical and electronic products, and other spare parts, die-casting magnesium alloy workpiece with high casting efficiency, excellent surface quality, fine and uniform grain, can produce thin wall thickness and complex shape of the workpiece. Transformation magnesium alloy is mainly used for forging and extrusion. High strength performance and plasticity are very good.

3. According to the performance and use of magnesium alloy classification.

It can be divided into creep-resistant magnesium alloy, magnesium alloy mold, wear-resistant magnesium alloy, anti-corrosion magnesium alloy, and structural magnesium alloy.

What types of magnesium alloys are used in CNC machining?

According to the molding process classification, magnesium alloy can be divided into cast magnesium alloy and deformed magnesium alloy; in composition and organizational properties, there are great differences.

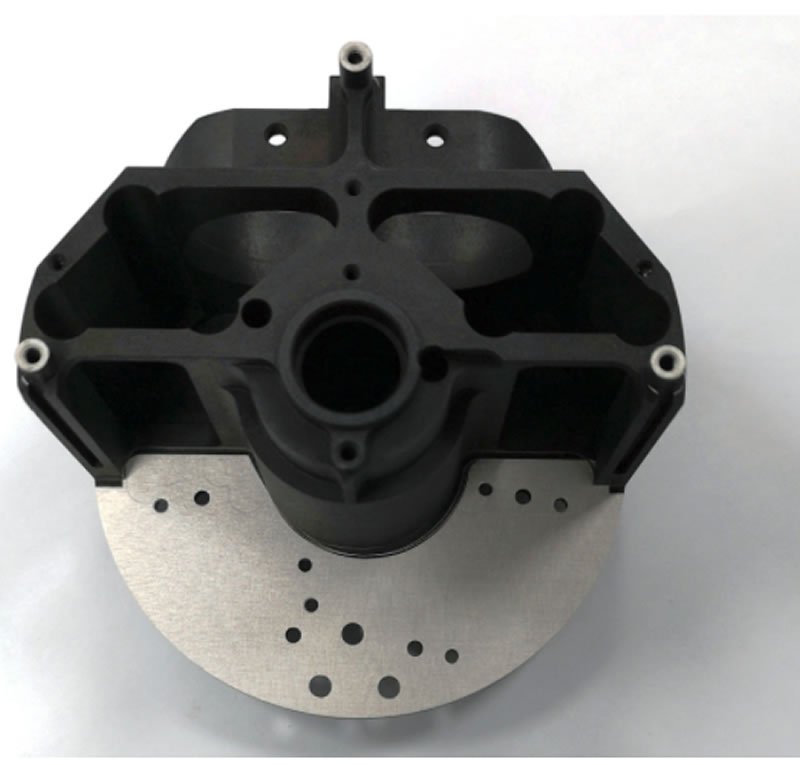

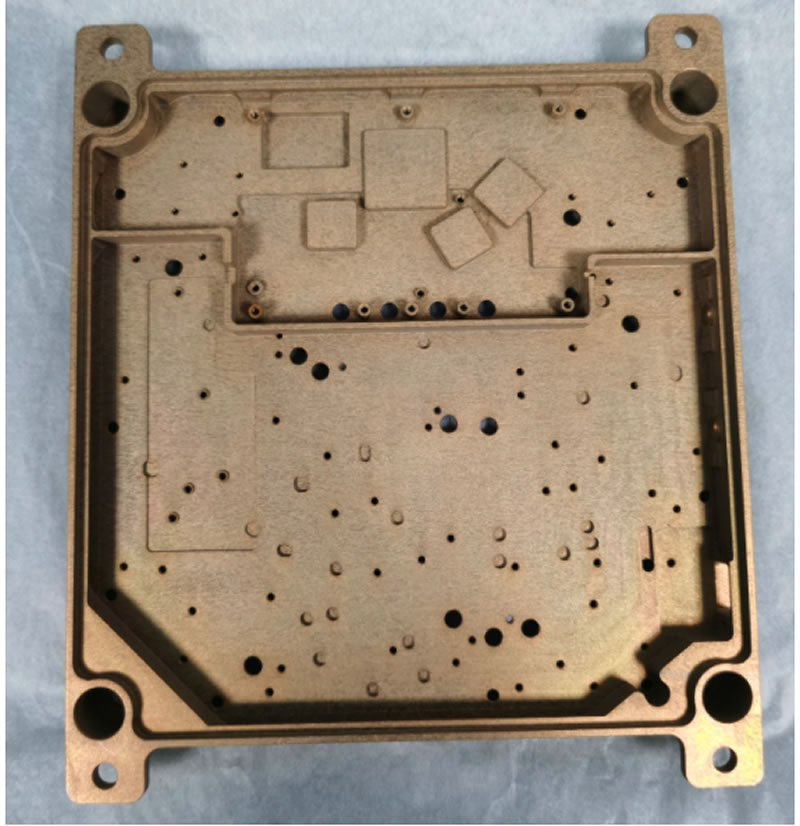

1. Casting magnesium alloy CNC machining.

Casting magnesium alloy is based on magnesium to join the alloying elements to form a magnesium alloy suitable for the production of parts by the casting method, The most commonly used magnesium alloy is casting magnesium alloy. The casting method of magnesium alloy mainly includes sand casting, metal casting, extrusion casting, and fusion casting. Casting magnesium alloy is mainly used in automotive parts, machine parts, shell covers, electrical components, etc. Casting magnesium alloy more with the die-casting process production, its main process characteristics for high production efficiency, high precision, good quality castings, etc.

2. Deformed magnesium alloy CNC machining.

Although the current amount of cast magnesium alloy is greater than that of magnesium alloy, the deformation of magnesium alloy can reduce organizational defects, obtain higher strength, better ductility, and diverse mechanical properties, and can meet the application needs of various engineering structural parts. The main deformation methods of magnesium alloys are extrusion, rolling, and forging. Deformed magnesium alloys are the most widely used material in the CNC machining of magnesium alloys. This is due to their superior mechanical properties and structural integrity compared to cast alloys. They are easier to machine, have a better surface finish, and have less wear on the edges of cutting tools.

3. Magnesium alloy processing types :AZ31: Good machining performance, general purpose.

AZ91: High strength, corrosion resistance.

AM60: Excellent energy absorption performance, used for automotive parts.

What are the common CNC machining processes for magnesium alloy?

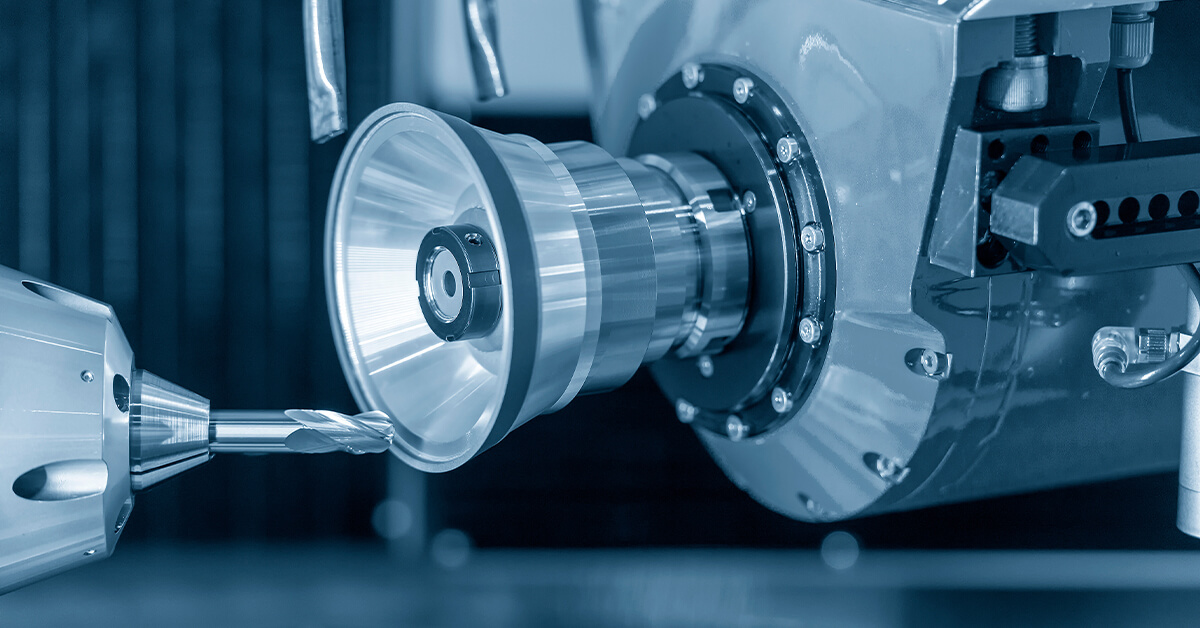

1. CNC milling machine magnesium alloy CNC machining:

CNC milling machine is the most common and versatile method for machining magnesium alloy parts. The machine uses a rotary cutting tool to cut material efficiently and precisely from a stationary block of material.

CNC milling machines can be used to machine flat surfaces, internal and external contours, holes, threads, etc., of parts. The flat contours of the part are machined by two-axis linkage, and the spatial surfaces of the part are machined by two-and-a-half, three-axis, or multi-axis linkage. From the distribution characteristics of the machine tool movement, a CNC milling machine can also be used as a CNC drilling machine or CNC boring machine, complete milling, boring, drilling, reaming, reaming, tapping threads, and other processes.

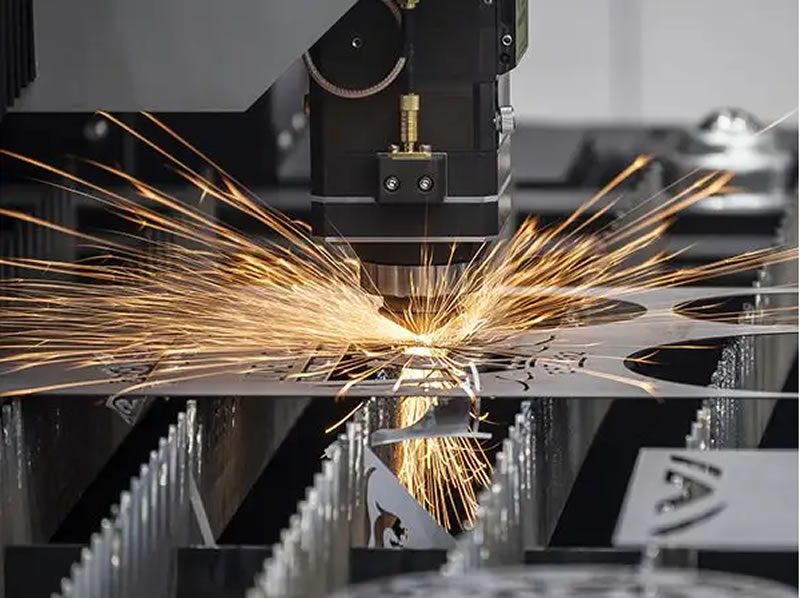

2. Laser cutting magnesium alloy CNC machining:

CNC laser cutting machine uses laser beam irradiation to the surface of the metal plate, when the energy is released, to melt the metal plate

melt and then blown away by the gas to dissolve the slag. The plate is placed flat on the cutting table, and the computer controls the path of the high-power laser beam. Laser cutting machines consume less energy and are more accurate than plasma cutting machines, making them more suitable for cutting thin sheets. Only the most powerful and expensive laser cutting machine can cut thick or dense material.

3. Water-cutting magnesium alloy CNC machining:

CNC water cutting machine, also known as a waterjet, uses high-pressure water jets forced through a narrow nozzle to cut the material. Under the control of the computer, it can carve the workpiece at will, and is affected by the material texture being small. Water cutting is a cold cutting process of cutting metal to adds abrasives to cut metal, with no chemical reaction, no thermal deformation, and no impact on the physical and chemical properties of the cut material.

What is the Difference Between Aluminium Alloy & Magnesium Alloy?

1. Magnesium and aluminum alloy tensile strength are different.

The same volume of magnesium alloy material made of frame strength is not as strong as aluminum alloy. From a weight point of view, from the weight point of view and aluminum alloy and magnesium alloy are comparable, and aluminum alloy tensile strength is greater.

2. Magnesium alloy and aluminum alloy specific gravity densities are different.

In general, the same volume conditions magnesium alloy as aluminum alloy; this is the advantage of magnesium alloy. This is the advantage of magnesium alloy processing auto parts: it can reduce the weight of the body, can travel faster, and save energy.

3. Magnesium and aluminum alloy metal oxidation is different.

From the periodic table of elements, we can conclude that magnesium alloy is more susceptible to oxidation and corrosion than aluminum alloy, so aluminum alloy is more widely used than magnesium alloy and is more resistant to corrosion.

4. Magnesium alloy and aluminum alloy CNC machining costs are different.

Because magnesium alloy is an active metal, the manufacturing equipment and environment have high requirements, resulting in the processing of magnesium alloy cost being relatively high, but magnesium alloy processing out of the bicycle frame is far less cost-effective than aluminum alloy processing out of the frame.

5. Magnesium alloy and aluminum alloy processing fatigue strength is different.

In general, the same volume of magnesium alloy processing into frame durability performance as aluminum alloy processing into frame performance is poor, and this is also magnesium alloy as processing material fatal shortcomings, so aluminum alloy processing than magnesium alloy processing applications are more extensive.

What are the common magnesium alloy machining surfaces’ post-treatment?

Due to the characteristics of low density and high strength of magnesium alloy, it can withstand impact load capacity better than aluminum alloy and other advantages known as green metal materials, widely used in the field of automotive parts processing. But magnesium alloy’s high-temperature performance and corrosion resistance are poor and need to undergo certain surface modifications or layer treatment to improve its performance of magnesium alloy. The surface treatment of magnesium alloy mainly has the following methods.

1. Magnesium alloy pretreatment.

Remove the magnesium alloy surface attached to the oil, rust, and other foreign matter, to obtain the role of environmental isolation of the underlying layer; the common treatment methods are mechanical cleaning and chemical cleaning.

2. Magnesium alloy electroplating/chemical plating.

Protection of the magnesium alloy substrate improves the electrical conductivity of the magnesium alloy, wear resistance, corrosion resistance, and oxidation resistance.

3. Magnesium alloy conversion film treatment.

We carry out magnesium alloy conversion film processing to make the magnesium alloy surface form a stable, insoluble compound film layer; the following is the magnesium alloy conversion film processing method:

3.1. magnesium alloy chemical transformation: simple operation, low cost, but the formation of protective film quality is brittle and porous, not as magnesium alloy’s long-term corrosion protection film.

3.2. Magnesium alloy anodic & micro-arc oxidation: anodic oxidation using electrolysis to form an oxide film on the surface of magnesium alloy; micro-arc oxidation breakthrough anodic oxidation technology, both with the performance of anodic oxide film, but also have a ceramic coating layer of the point, but the technology is not mature enough, to be further research.

3.3. Magnesium alloy E coating: Through this method, the surface of magnesium alloy can get good corrosion resistance.

4. Magnesium alloy coating.

4.1. Magnesium alloy thermal spraying: through the flame, laser, arc, plasma, and other heat sources, the spraying material will be heated and melted, with a certain speed jet guiding the magnesium alloy surface to form a protective layer.

4.2. magnesium alloy organic coating, powder coating: the organic layer is thin, easy to fall off; powder coating on some hidden areas is not easy to obtain.

4.3. Magnesium alloy vapor deposition: improve the corrosion resistance of magnesium alloy

5. Magnesium alloy surface modification.

Magnesium alloy surface modification is divided into magnesium alloy expansion, infiltration, and magnesium alloy ion injection.

6. Magnesium alloy high-energy beam machining.

The use of laser, plasma, etc. on the surface of magnesium alloy for rapid heating treatment, to get quenching, rapid solidification, or fusion of the surface layer.

How to choose the cutting fluid used in the process of magnesium alloy machining?

1. The role of cutting fluid in the magnesium alloy machining process:

Cutting fluid in the magnesium alloy cutting process, grinding process plays a cooling, lubricating role, and workpiece, while cleaning the magnesium alloy machining process generated chips, grinding chips, and sludge, etc., to play the role of rust prevention.

2. The classification of magnesium alloy cutting fluid.

We can go first according to the type of magnesium alloy cutting fluid, divided into oil-based cutting fluid and water-based cutting fluid.

2.1 magnesium alloy oil-based cutting fluid: also known as cutting oil, lubrication, good antirust performance, but cooling, cleaning performance are poor, for magnesium alloy cutting is easy to lead to chip sticking tool, and even burning bo in accordance, so at present rarely used. 2.2. Magnesium alloy water-based cutting fluid: divided into the emulsion, semi-synthetic, and fully synthetic types.

2.2.1 Magnesium alloy emulsion: good lubricity, low price, but poor antibacterial properties. In the process of magnesium alloy processing, its cooling performance check can not effectively reduce the temperature; easy precipitation leads to sticky tools and produces bacteria with odor. Cleaning performance is poor, and it is easy to scratch the surface of the workpiece.

2.2.2 Magnesium alloy semi-synthetic cutting fluid: between emulsified and fully synthetic, its performance is similar to an emulsion; cooling and cleaning performance is poor, the cutting process, magnesium alloy and water reaction produce a large number of magnesium ions, resulting in cutting fluid destabilization, processing performance decline, and other adverse phenomena.

2.2.3 Magnesium alloy fully synthetic cutting fluid: no base oil and emulsifier, good cooling performance, can quickly reduce the temperature of the cutting area, reduce tool wear, high content of surface active ingredients, good cleaning performance, good stability performance.

3. The choice of cutting fluid in the magnesium alloy machining process.

Given the above characteristics of magnesium alloy cutting fluid, the magnesium alloy machining process, according to need, should choose a fully synthetic cutting fluid. Of course, the choice of magnesium alloy cutting fluid is certainly important; choosing a strong magnesium alloy machining factory is also very important; having the strength of a magnesium alloy CNC machining factory not only improves the quality of your magnesium alloy machining, but there is also a one-stop CNC machining after-sales service.

What are the precautions needed in the process of CNC machining of magnesium alloy?

1. Keep magnesium alloy cutting tools sharp.

In the process of cutting the tool to keep it sharp and grinding a larger back angle and clearance angle, do not allow the use of blunt, sticky chips or broken tools; do not allow the tool to stop in the middle of the workpiece.

2. Larger feed. In general, try to use larger feeds for magnesium alloy CNC machining, avoid using tiny feeds to produce a larger thickness of chips, and use a small cutting volume to use mineral oil coolant to reduce the cooling. If magnesium alloy parts have a steel core lining, be careful with the tool touching to produce sparks.

3. Magnesium alloy machining cutting fluid selection.

In production, also pay attention to the choice of cutting fluid; do not choose a flammable liquid. Most parts of the machine tool have lubricants, and other flammable liquids exist; pay attention to safety issues to prevent magnesium alloy from burning. Once the magnesium chip fires, when fighting, you can not use water; a carbon dioxide extinguishing agent, which will produce a chemical reaction, releasing a large amount of heat energy, will intensify the fire. Should use the dry powder fire extinguisher to extinguish the fire can effectively extinguish the fire.

4. Magnesium alloy CNC machining production environment finishing.

Keep the environment neat and clean. Smoking, living, and welding in the machining work area are strictly prohibited, and the working area should be stored in sufficient quantities of fire extinguishing equipment.

🏭Applications of Magnesium Alloy CNC Machining

✈️ Aerospace industry:

Magnesium alloys are highly regarded for their lightweight and high strength, which helps reduce aircraft weight and improve fuel efficiency.

Structural brackets: Mounting points for internal and external components.

Housings: Avionics housings, gearboxes, and actuator covers.

Interior components: Seat frames, panels, and control housings.

Vibration-absorbing components: Components used to reduce vibration and noise.

🚗 Automotive industry:

Used to improve performance, reduce emissions, and improve fuel economy.

Steering columns: Strong and lightweight components that are critical to vehicle control.

Gearboxes: Reduce drivetrain weight while maintaining durability.

Wheels: Lighter than aluminum, improving acceleration and efficiency.

Dashboard frames and brackets: Structural support for instruments and infotainment systems.

Crush-absorbing structures: Energy absorption of magnesium can be used in safety areas.

💻 Electronics industry:

Magnesium alloys’ electromagnetic interference (EMI) shielding properties, thermal conductivity, and lightweight make them ideal for modern electronic devices.

Lightweight housings: for laptops, smartphones, tablets, and cameras.

Heat sinks: efficient heat dissipation in compact electronics.

Shielding: protection against electromagnetic interference (EMI).

Connector housings: durable conductive structures for ports and plugs.

🏥 Medical device industry :

Certain magnesium alloys are biocompatible and biodegradable, suitable for external surgical instruments and internal implants.

Orthopedic instruments: handles, guides, and surgical instruments.

Implants (research and testing): biodegradable screws, pins, and plates that dissolve in the body over time, reducing the need for secondary surgeries.

Imaging safety components: magnesium alloys are MRI-compatible and can be used in nonferrous surgical instruments.

🔩 Robotics and drones industry:

Lightweight frames and housings for improved performance and efficiency.

Industrial machinery: custom brackets, mounts, or covers, reducing weight helps improve automation speed and efficiency.

Why choose NOBLE for magnesium alloy machining?

1. China CNC machining custom manufacturer profile.

Ltd. is a Sino-British joint venture awarded the qualification of “National High-tech Enterprise” by the government; the company has two major directions of intelligent manufacturing business and product business. The intelligent manufacturing business of Noplato specializes in providing customers with high-precision parts CNC machining (aluminum machining, magnesium machining, etc.), including new The main industries are robot parts CNC machining, automotive parts CNC machining, commercial aerospace parts CNC machining, medical parts CNC machining, automation parts CNC machining and other high-tech fields, assisting customers in optimizing design, choose the right process, reduce costs and achieve rapid mass production.

2. China parts custom CNC machining factory honors and certificates.

Founded in 2012, Noplato China Parts CNC machining supplier, started from the production of innovative products of hand-plate model processing and small and medium-lot CNC processing production. After years of efforts and development, Noplato has gradually transformed from a precision parts CNC machining manufacturing enterprise with a perfect industry chain supporting service capability to a service enterprise that provides comprehensive support to customers’ entire CNC machining projects. Our company has been transformed from a precision parts and components manufacturer with complete industry chain supporting services to a service company providing comprehensive support to customers’ entire CNC machining projects. It has accumulated rich experience and fruitful results in many innovative fields such as intelligent health care equipment parts machining, medical equipment parts machining, automotive transportation parts machining, robot parts machining, commercial aerospace, and automation equipment.

Since 2015, the company has provided project support services and reached stable cooperation for many domestic and foreign customers, such as the new American robotics company and intelligent medical company, the British intelligent car research and development team, the leading domestic robotics companies, Huawei and other well-known domestic enterprises, Tsinghua University and Xiangya Hospital and other universities and research institutions.

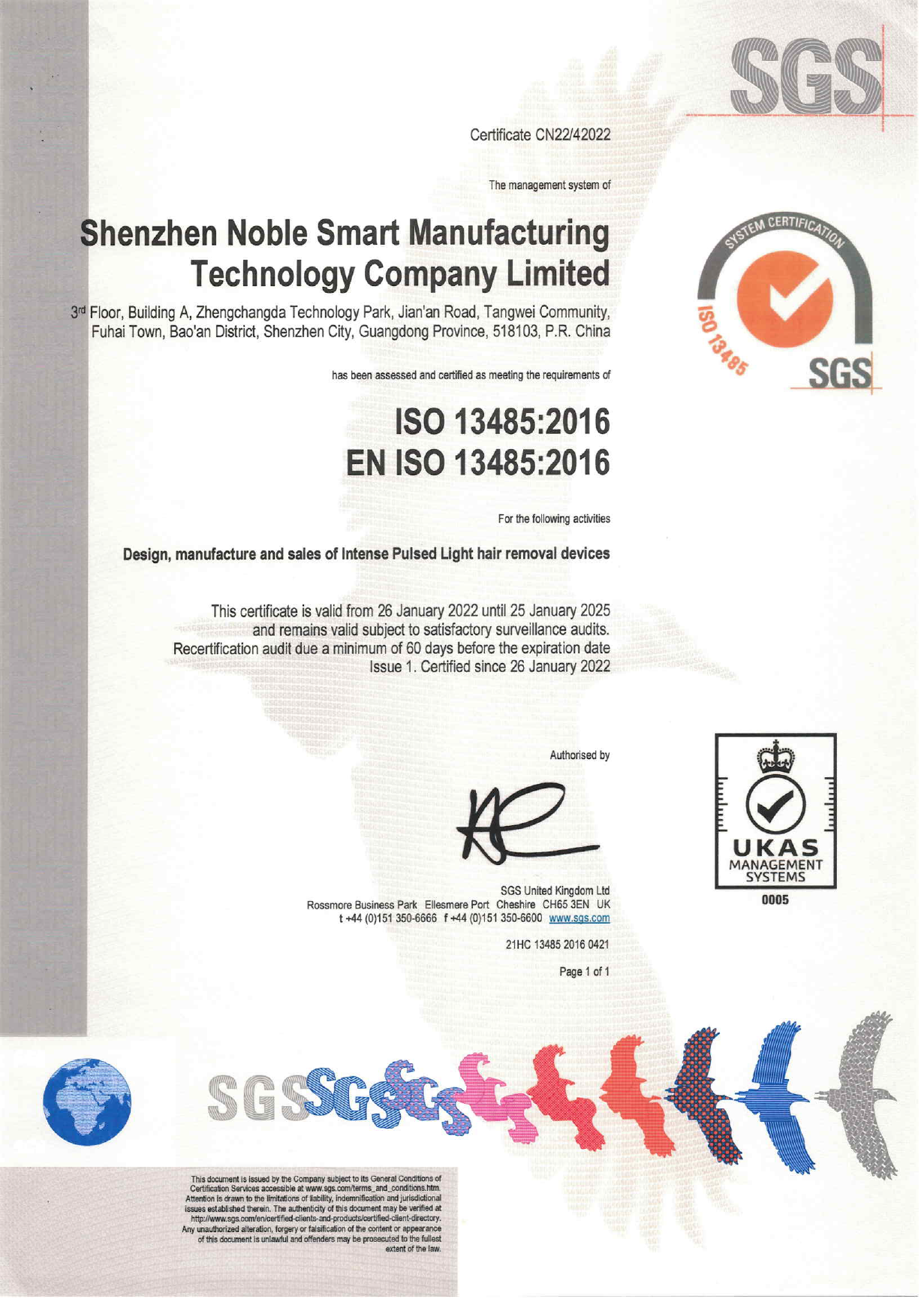

The company has standardized management and has obtained ISO9001-2015 and ISO13485-2016 certifications, and will soon obtain a Class II medical device manufacturing license.

3. China spare parts custom CNC machining factory advantage.

| Noble CNC Service | Include |

| Main service | 1. Structure design optimization;

2, CNC Machining: to make medium & low volume metal parts 3, Rapid Prototyping: CNC, 3D printing(SLA, SLS); Also, we can provide the following services to meet your demand; Rapid Tooling, die-casting, Extrusion molding, Silicone mold vacuum casting, etc. |

| Drawings | 3D: step/stp, igs, prt, sld, etc.

2D:.dwg . pdf. cdr. AI, other picture formats. |

| 3D Software | Pro-e (Creo)

UG Solid works Catia Rhinoceros 3dmax |

| 2D Software | AutoCAD

Photoshop CorelDraw Adobe Illustrator |

| Plastic Material | ABS, acrylic/PMMA, PP(Polypropylene),PC(Polycarbonate),PU(Polyurethane),POM(Delran,Acetyl),PVC, PE(Polyethylene), PA(Nylon, Polyamide) PEEK(Polyetheretherketone), Chemical Wood, etc; |

| Metal Material | aluminum, aluminum-magnesium alloy, aluminum-zinc alloy, copper, brass, bronze, stainless steel, SUS303, SUS304, 45 steel, iron, Galvanized steel sheet, sheet metal, SPCC, etc. |

| Manufacture process | 1. CNC Machining Center: Milling, drilling, turning, threading, tapping, boring, facing, spotting, counter boring.

2. CNC Milling: High precision milling, numerical control carving and milling, CNC engraving and milling. 3. Sheet Metal Bending: Bending- High precision seamless bending, sheet metal bending. 4. CNC Punching: Punching/stamping- High precision Sheet Metal Fabrication. 5. Sheet Metal Welding: GMAW, MIG, Laser welding. 6. Sheet Metal Laser cutting: High precision cutting. 7. Molding/Tooling: Rapid Tooling, die-casting, Extrusion molding, Silicone mold vacuum casting, etc. 8. 3D printing Services: SLA, SLS, FDM. |

4. NOBLE spare parts custom China CNC machining factory can support CNC machining services.

From a high precision parts CNC machining manufacturing company with a perfect industry chain supporting service capability, Nobu gradually transformed into a service-oriented company that supports the entire CNC machining projects for customers.

Parts CNC machining manufacturing: focus on aluminum parts machining, stainless steel parts CNC machining, magnesium alloy parts CNC machining, brass& copper parts CNC machining, plastic parts CNC machining, metal parts CNC machining.

Project support services: We have rich experience in the CNC machining industry of new energy automobile parts and components, Medical Equipment Parts machining, Service Robot Parts Machining, drone parts and components processing industry, automatic instrumentation equipment parts and components machining, intelligent personal care parts and components machining industry, etc.