Sheet Metal Riveting

Our Custom Sheet Metal Riveting Service

Providing efficient and economical sheet metal riveting services to our customers at competitive prices. Our expertise ensures you get fast, strong sheet metal riveted parts that exceed your expectations. Get a sheet metal riveting quote online now with delivery times as fast as 1 day.

- 10+ Years of Sheet Metal Riveting

- ISO 9001 & ISO13485 Certified Factory

- Quote Within 24 Hours

- 100% Part Inspection

- State-of-the-art Equipment

- 99.5% On-Time Delivery

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

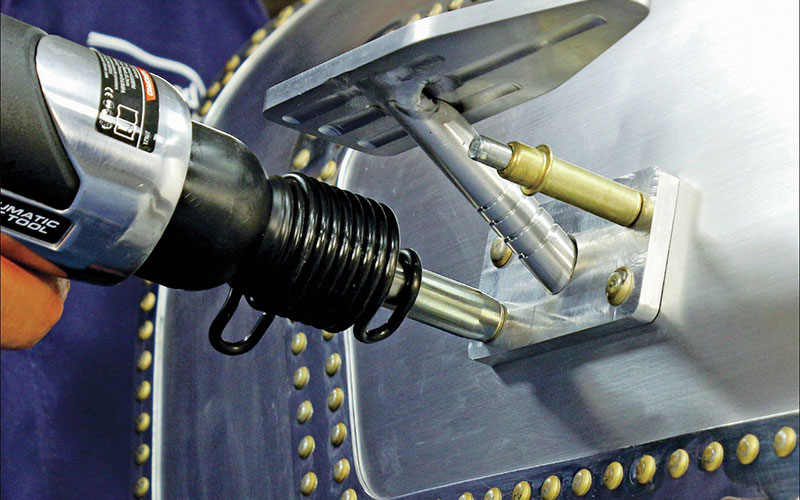

Our Powerful Sheet Metal Riveting Processes

Each sheet metal riveting process is selected based on the application and accessibility of the material. NOBLE customizes sheet metal riveting solutions at competitive prices. Our professional sheet metal riveting technology ensures efficient, precise, and consistent riveting, guaranteeing the excellent quality of each project.

Tubular riveting is a fastening process that uses hollow-shaft rivets to join materials, featuring ease of application, reliable strength, and suitability for high-speed, automated assembly.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

Solid riveting is a fastening process that uses solid metal rivets to create strong, permanent joints, offering durability, high shear strength, and reliability in heavy-duty applications.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

Blind riveting is a fastening method that allows joining materials from one side using a specialized rivet, offering convenience, adaptability to hard-to-reach areas, and secure, vibration-resistant joints.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Pop riveting is a fastening technique using a mandrel and hollow rivet to securely join materials, offering quick installation, versatility, and suitability for single-sided access applications.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

Self-piercing riveting is a fastening process that joins materials without pre-drilling by driving a rivet through layers, offering high strength, leak-proof joints, and suitability for dissimilar materials.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

Drive riveting is a fastening method where a rivet is driven into a pre-drilled hole and secured by hammering, offering ease of use, strong holding power, and suitability for various materials.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Flush riveting is a fastening technique where rivet heads are countersunk to sit flush with the material’s surface, offering a smooth finish, reduced aerodynamic drag, and enhanced structural integrity.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Blind riveting is a fastening process that uses rivets designed to be installed from one side of the workpiece, offering ease of use, adaptability for hard-to-reach areas, and strong, vibration-resistant joints.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Threaded riveting is a fastening method that incorporates a rivet with internal threads, allowing for the installation of screws or bolts, offering secure, reusable connections and high load-bearing capacity.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Sheet Metal Riveting Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.State-of-the-art Equipment

- 10+ Years of Sheet Metal Manufacturing

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose NOBLE for Custom Sheet Metal Riveting Service

NOBLE’s complete production line provides sheet metal riveting services covering all manufacturing processes required for new project development, including secondary finishing, custom packaging, and final product assembly. With advanced manufacturing skills and technical expertise, our engineers are committed to reducing cycle times by up to 50%.

Expertise and Experience

With years of experience, our skilled team provides high-quality sheet metal riveting solutions for projects of varying complexity, ensuring the reliability and strength of each joint.

Specialized Customization

We offer customized sheet metal riveting services, adapting to your specific material, size, and design needs for a perfect fit.

State-of-The-Art Equipment

Our global manufacturing network is equipped with the latest sheet metal equipment. We use the latest sheet metal riveting technology and automation technology to achieve efficient, precise, and consistent riveting even in large-scale production, ensuring the superior quality of each project.

Quality Assurance

Our strict quality control ensures every riveted joint meets industry standards for durability and performance.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Advantages of Sheet Metal Riveting

In precision manufacturing, selecting the right fastening method is crucial to ensuring the strength, durability, and reliability of an assembly. Sheet metal riveting is one of the most versatile and robust methods for joining sheet metal components. The following points highlight the core benefits:

Types of Rivets for Metal Sheet Assembly

Rivets are widely used in sheet metal assembly for their simplicity, strength, and reliability. Depending on project requirements, different rivet types are selected for secure, long-lasting connections. This includes applications with thin metals, hollow parts, or smooth finishes.

Here are some commonly used rivet types for reference:

| Type of Rivet | Image | Description | Applications |

| Solid Rivets |  | Be durable and easy to install. Come in various materials, colors, and sizes. Achieve strong, permanent joints in sheet metals. | Used in assembling sheet metals. |

| Tubular Rivets |  | Be hollow and strong. Available in two types: Full Tubular and Semi-tubular. Full tubular rivets punch holes; semi-tubular rivets reduce force during assembly. | Suitable for aluminum and thin metals. Full tubular rivets for punching holes, semi-tubular for light applications like electronics, HVAC, and brakes. |

| Blind Rivets |  | Used when one side of a surface is inaccessible. Ideal for hollow parts. | Used when one side of the surface cannot be accessed (e.g., hollow parts) |

| Flush Rivets |  | Use countersunk holes and heads for a smooth, aesthetically pleasing finish. | Commonly used in aircraft to maintain smooth airflow. |

| Split Rivets |  | Have two legs at the bottom, folded back after installation | Used in applications like bicycle seats, leather, fabrics, and tin plates. |

| Self-Piercing Rivets |  | Require no drilling. Use a bevel drill to form a button-like element during assembly. | Used for assembly without pre-drilled holes. |

| Friction Lock Rivets |  | suitable for demanding applications. | Commonly used in light aircraft maintenance. |

Materials for Custom Sheet Metal Riveting

In sheet metal riveting, selecting the right material is crucial to ensure the durability and strength of the riveted joints. Here are some of the most commonly used materials for sheet metal riveting:

Aluminum

Lightweight and Corrosion-Resistant: Aluminum is widely used in aerospace, automotive, and electronics industries due to its light weight and resistance to corrosion. It’s ideal for applications where reducing weight is critical.

Stainless Steel

Corrosion-Resistant and Durable: Stainless steel is used in applications requiring high strength and corrosion resistance, such as in the food, chemical, and medical industries. Its durability makes it suitable for harsh environments.

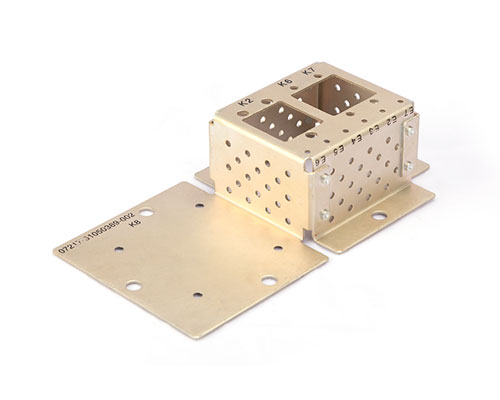

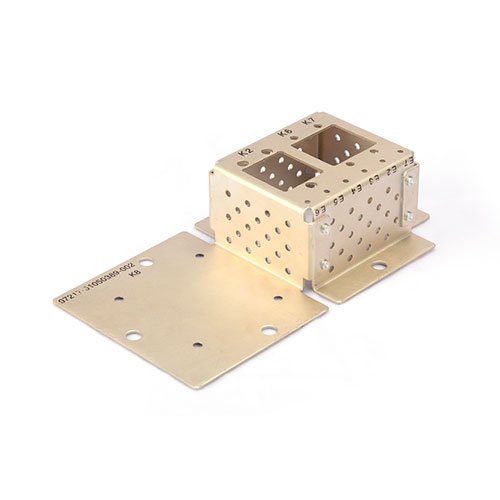

Brass

Corrosion-Resistant and Aesthetic Appeal: Brass offers good corrosion resistance and is often chosen for decorative applications or where a high-quality finish is needed. It is commonly used in the manufacturing of fittings, instruments, and small enclosures.

Titanium

Lightweight and High Strength: Titanium is used in specialized applications, particularly in aerospace and medical devices, due to its exceptional strength-to-weight ratio and corrosion resistance, though it’s more expensive.

Surface Finishes for Sheet Metal Cutting

Outstanding surface finishing choices can enhance the surfaces of your bending components and final products. In order to improve the product’s aesthetic appeal and other qualities, a variety of surface finishing could be offered for you from NOBLE.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

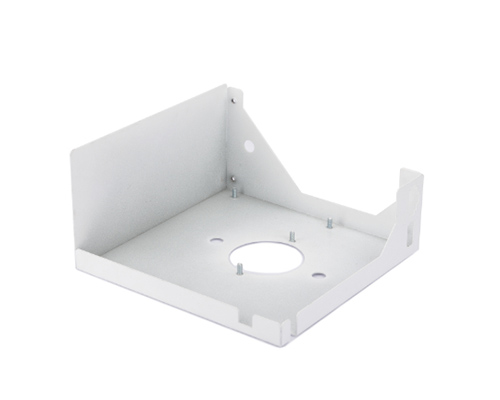

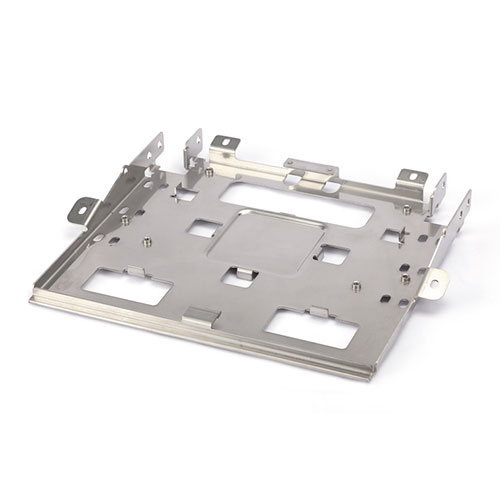

Custom Sheet Metal Riveting Parts Display

Check out our over a decade of custom sheet metal riveting parts, including precision machined prototypes and parts from our valued customers.

See What Our Customers Say About Us

NOBLE has been providing sheet metal riveting services for over ten years and has served many overseas customers. Customers’ feedback is more meaningful than the company’s statement—see the objective evaluations from our customers.

Emily Martinez

Procurement Manager

NOBLE has been a trusted partner for years. Whether it’s a small batch or large-scale production, they consistently deliver on time and with impeccable quality. Their ability to execute complex riveting requirements without delay has made them an invaluable part of our supply chain.

Mark Roberts

Operations Director

From the initial consultation to the final product, the customer service at NOBLE has been outstanding. They listen to our needs and are always responsive to any concerns or requests. The team’s professionalism and commitment to excellence make them our go-to for custom sheet metal riveting.

Linda Thompson

Senior Project Manager

NOBLE’s expertise in custom sheet metal riveting has been a game-changer for our industrial projects. Their ability to adapt and provide tailored solutions, whether it’s for prototypes or large production runs, has consistently exceeded our expectations.

Tom Harrison

CEO

We’ve been working with NOBLE for multiple years, and they continue to deliver high-quality riveting solutions at competitive prices. Their process is efficient, and their team is always able to meet our demanding requirements. We highly recommend their services to anyone in need of sheet metal riveting.

Applications of Sheet Metal Riveting

As one of China’s leading precision machining suppliers, NOBLE provides rapid prototyping and precision machining services with over 10 years of experience. We have exported millions of riveted sheet metal parts worldwide, helping OEM customers turn ideas into products and achieve exceptional results.

Aerospace Parts

Sheet metal riveting is essential in aerospace for assembling parts like fuselages and wings. It ensures structural strength without heat damage, making it ideal for high-performance components in aircraft and jet engines.

Automotive Parts

Sheet metal riveting is widely used in automotive production to secure body panels, frames, and interior components. It offers strong, lightweight connections that enhance vehicle safety, performance, and efficiency.

Consumer Products

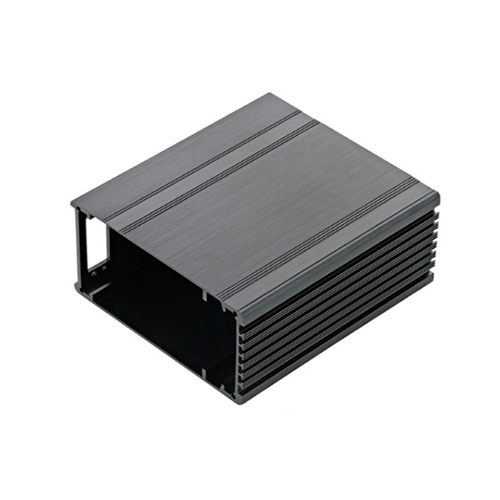

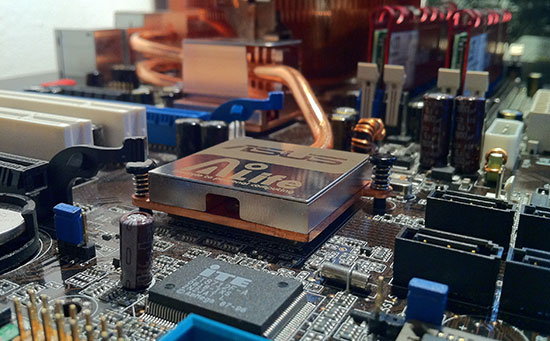

Sheet metal riveting assembles enclosures and holds circuit boards in electrical devices, providing secure, heat-free fastening while protecting sensitive components, ensuring both durability and functionality.

Industrial Equipment

Sheet metal riveting is used to assemble heavy machinery and industrial structures, providing strong, reliable connections that withstand mechanical stresses and ensure smooth operations.

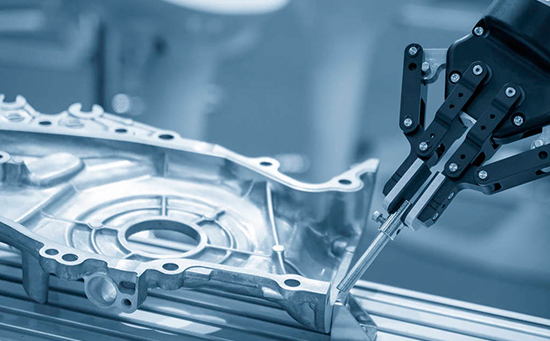

Robotic Parts

Sheet metal riveting is used in assembling robot frames, arms, and structural components. It provides secure, heat-free joints and ensures reliable performance without damaging sensitive motor and gear enclosures.

Medical Devices

Sheet metal riveting is essential in assembling surgical instruments, medical equipment enclosures, and implants. It ensures strong, durable joints, maintaining the functionality and safety of devices in critical medical applications.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

FAQs on Sheet Metal Riveting

Sheet metal riveting is ideal for heat-sensitive materials, flexibility, and disassembly, especially with lightweight or thin materials. Welding is better for strong, permanent joints, especially in load-bearing applications. Consider strength, material type, and heat tolerance when deciding.

Environmental factors like corrosion, temperature fluctuations, and vibrations can weaken riveted joints. Using the right materials, coatings, and rivet types helps prevent damage. This ensures durability and reliability in harsh conditions, allowing joints to last longer and stay strong.

Automated sheet metal riveting systems increase speed, accuracy, and consistency in large-scale production. They reduce labor costs, improve safety, and offer flexibility with rivet sizes. This boosts efficiency while ensuring high-quality, reliable results in high-volume production.

When riveting sheet metal, consider material compatibility, choosing the right rivet type and size, hole preparation, tooling, and environmental factors like temperature and moisture. Sequencing steps correctly ensures smooth assembly and strong, durable joints.

Material selection affects riveted joints’ performance and lifespan. Strong, corrosion-resistant materials like stainless steel or aluminum improve durability. Matching rivet and base materials maximizes strength, while considering thermal expansion and environmental conditions ensures longer-lasting joints.

At NOBLE, we meet complex customer needs through close communication and a streamlined process. We ensure real-time synchronization across design, prototyping, and production. With a flexible, fully equipped production line, we ensure precision and quality in every project, regardless of complexity.

Sheet metal riveting is a process that joins two or more sheet metal pieces by inserting a rivet through aligned holes and deforming its ends to create a strong, permanent bond. Sheet metal riveting is widely used in industries where high-strength, permanent joints are needed but welding is impractical.By combining our expertise with a customer-centric approach, NOBLE ensures every joint is strong, precise, and durable. Our commitment to quality, speed, and cost-efficiency makes us your ideal partner.

Sheet metal riveting is generally not expensive, especially for high-volume or standard applications. However, costs can vary based on the materials, equipment, and labor involved.

The dimensions of sheet metal rivets typically include the diameter and length of the rivet shank and the size and shape of the rivet head, which vary depending on the application and material thickness.

To rivet metal plates, align them, drill matching holes, insert a rivet through them, and use a rivet gun or hammer to secure the rivet by deforming its tail end.